In the food industry, particularly in sectors like meat, seafood, and dairy, accurately measuring and managing product weight is crucial. Unlike packaged goods with fixed weights, many food products vary in weight, making them challenging to price, track, and manage. This concept is known as catch weight, which describes the actual weight of naturally fluctuating products.

Understanding what catch weight is in food and effectively managing it can significantly impact a company’s profitability and operational efficiency. From inventory management to invoicing, businesses handling catch-weight items face the constant challenge of maintaining accuracy and consistency.

PwC highlights that traditional and manual methods of managing catch weight are labor-intensive, error-prone, and costly. It emphasizes the importance of efficient catch-weight management to improve operational performance and reduce financial losses. Moreover, with increasing regulatory demands and the need for transparent pricing, mastering catch weight management is no longer optional—it’s essential.

In this blog, we’ll explore the meaning of catch weight, why it matters in the food industry, and practical strategies for managing it effectively. Whether you’re a food processor, distributor, or retailer, gaining control over your variable-weight products can organize operations and improve profitability.

Let’s dive deeper into what catchweight means and how your business can tackle its challenges head-on.

What is Catch Weight?

Catchweight refers to products sold by weight that may vary from package to package due to natural variations, processing methods, or storage conditions. Unlike fixed-weight products, catchweight items require precise measurement during sales to ensure accurate pricing and inventory management. Understanding the meaning of catchweight is essential for businesses dealing with variable-weight products, as even minor discrepancies can lead to significant financial losses.

Catch Weight Definition

In the simplest terms, catch weight is the actual weight of a product at the time of sale rather than a predetermined or standard weight. This concept is particularly relevant in the food industry, where product weight can fluctuate due to moisture loss, trimming, or packaging.

Common Examples of Catch Weight in the Food Industry

Catch-weight products are prevalent in many food sectors, particularly fresh and perishable. Some common examples include:

- Seafood: Due to natural differences, products like fish, shrimp, and lobster often vary in size and weight.

- Meat: Steaks, chops, and roasts are typically sold by catch weight, reflecting their actual size and density.

- Fresh Produce: Large fruits and vegetables, such as melons and pumpkins, can differ significantly in weight.

- Cheese: Blocks or wedges of artisanal cheese are frequently sold by weight, with slight variations from batch to batch.

- Nuts: Products like peanuts or cashews may be measured using catch weight, mainly when sold in bulk.

- Poultry: Whole chickens or turkeys are sold based on weight, as sizes naturally vary.

The Importance of Catch Weight in Food Manufacturing

Managing catch-weight items accurately ensures fair pricing, improves inventory control, reduces waste, and enhances customer satisfaction. By understanding the importance of catching weight in the food industry and applying effective management practices, companies can improve operational efficiency, comply with food safety regulations, and maintain customer satisfaction.

Accurate Pricing

Accurate catch-weight management ensures fair pricing for both businesses and customers. Since products like meat and seafood are often priced per pound or kilogram, even a small error in weight can lead to significant financial discrepancies. For example, overestimating the weight may result in overcharging, causing customer dissatisfaction. Conversely, underestimating the weight can reduce profit margins. Implementing advanced weighing systems and integrating them with ERP solutions like Food ERP can help mitigate these issues and maintain pricing transparency.

Inventory Management

Another critical benefit of proper catch-weight management is effective food inventory management. By capturing the actual weight of products, businesses can maintain accurate inventory records, track stock levels, and predict demand more efficiently. Companies using catch-weight data can reduce spoilage, avoid stockouts, and optimize storage space. According to Grazecart, accurate inventory management using catch-weight data can cut food waste by up to 20%.

Regulatory Compliance

Compliance with food industry regulations is essential for maintaining consumer trust and avoiding legal complications. Regulatory bodies like the FDA and USDA often require transparent labeling, including the product’s net weight. Mislabeling due to poor catch weight management can lead to fines, food product recalls, or damage to brand reputation. Implementing digital traceability and automated weighing systems helps companies adhere to these regulations and ensure accurate product labeling.

Customer Satisfaction

Transparency in pricing and labeling directly impacts customer satisfaction. Consumers expect to pay a fair price based on the actual weight of products. Food businesses can build trust and retain loyal customers by recording and communicating the correct weight. Solutions offered by Folio3 FoodTech facilitate real-time weight tracking and provide accurate invoicing, improving customer experiences.

Challenges in Managing Catch Weight

Effectively managing catch weight in the food industry comes with its own set of challenges. From inconsistent product sizes to the risk of human error, businesses must navigate these obstacles to ensure accurate pricing, compliance, and inventory management.

Acknowledging and addressing these food industry challenges can help businesses organize operations and reduce losses. Implementing the right technologies and best practices will ensure greater accuracy in pricing, improved compliance, and enhanced customer satisfaction.

Variability in Product Size and Weight

One of the most significant challenges is natural product size and weight variability. Unlike packaged goods with fixed weights, catch-weight items such as meat, seafood, and produce can differ significantly in weight. This makes it difficult to predict exact weights and maintain uniformity in pricing and inventory management. Managing this variability is crucial for avoiding pricing discrepancies and ensuring fair trade practices.

Manual Recording Errors

Many food businesses still record product weights manually. While this may work for small operations, human error is inevitable, leading to inaccurate data entry and mislabeling. Automation can significantly reduce these errors, providing more reliable weight records and smoother operations.

Complex Inventory Tracking

Tracking inventory becomes particularly challenging when products have fluctuating weights. Traditional inventory systems often struggle to account for variable-weight items, leading to discrepancies between actual stock and recorded data. Implementing specialized ERP systems with catch weight management capabilities can help food manufacturers maintain accurate inventory records and optimize their supply chains.

Effective Strategies for Managing Catch Weight

Businesses can adopt a series of best practices and technologies to overcome the challenges associated with catch weight in food manufacturing.

Invest in Accurate Weighing Equipment

Accurate weighing tools are the backbone of effective catch weight management. High-quality scales and automated weighing systems provide precise measurements, minimizing discrepancies. Using regularly calibrated equipment to ensure reliable results and compliance with industry standards.

Implement Automated Software Systems

Automated ERP and inventory management systems, like those from Folio3, are invaluable for tracking catch-weight items in real-time. These systems can integrate with weighing equipment, automatically recording product weights and reducing manual errors. Real-time data also supports better decision-making and operational efficiency.

Employee Training

Training staff on proper weighing and recording procedures is crucial. Employees should understand how to handle variable-weight products, use weighing equipment correctly, and follow best practices for accurate data entry. Moreover, regular training ensures compliance and consistency across operations.

Proper Packaging and Labeling

Accurate and transparent labeling is essential when dealing with catch-weight items. Clear labels with correct weight information help build customer trust and meet regulatory requirements. Automated labeling systems can further enhance accuracy and efficiency.

Monitor Storage and Shipping Conditions

Environmental factors such as temperature and humidity can impact product weight, especially for fresh or frozen foods. Maintaining controlled storage and shipping conditions minimizes weight loss or gain due to moisture loss or ice buildup. Monitoring these factors closely to preserve product quality and accurate catch weight records.

Role of ERP Solutions in Catch Weight Management

Managing catch weight in the food industry can be complex, but Enterprise Resource Planning (ERP) solutions offer a practical and effective way to address these challenges. Food ERP systems ensure accurate and transparent operations, from streamlining inventory tracking to automating weight recording.

Integration of Catch Weight Functionality

ERP systems with catch weight functionality can manage products using inventory and catch weight units. This dual-tracking capability ensures businesses can maintain precise records of variable-weight products. By integrating catch weight data directly into inventory management systems, food companies can prevent discrepancies, minimize losses, and optimize pricing accuracy.

For example, ERP solutions enable real-time monitoring of products like meat, seafood, and cheese, where actual weight can fluctuate. This integrated approach ensures accurate sales orders, invoicing, and reporting.

Automation of Weight Recording

Automated weight recording using ERP systems reduces the reliance on manual data entry, which often leads to errors. Advanced systems directly capture and log real-time weight data from scales and other measurement devices into the ERP platform.

This automation streamlines workflows and ensures the correct weight is applied to pricing, reducing human error and saving valuable time. Companies using automated ERP systems experience a 30% improvement in data accuracy, enhancing overall operational efficiency.

Enhanced Traceability

Food Traceability is essential for maintaining food safety and regulatory compliance. ERP systems improve end-to-end traceability by tracking catch weight data from procurement to distribution. This capability enables businesses to monitor product movement, ensure compliance with labeling standards, and swiftly respond to recalls or quality issues.

ERP systems, which maintain detailed records of product weight and source information, help food manufacturers comply with industry regulations and meet consumer demands for transparency.

How Can Folio3 Foodtech Help Catch Weight Management?

By efficiently managing catch-weight items, Folio3 FoodTech can help food manufacturers achieve greater accuracy, compliance, and customer satisfaction. Visit the website to learn how Folio3 can streamline your catch-weight management processes and explore its innovative Food ERP solutions.

Customized ERP Solutions

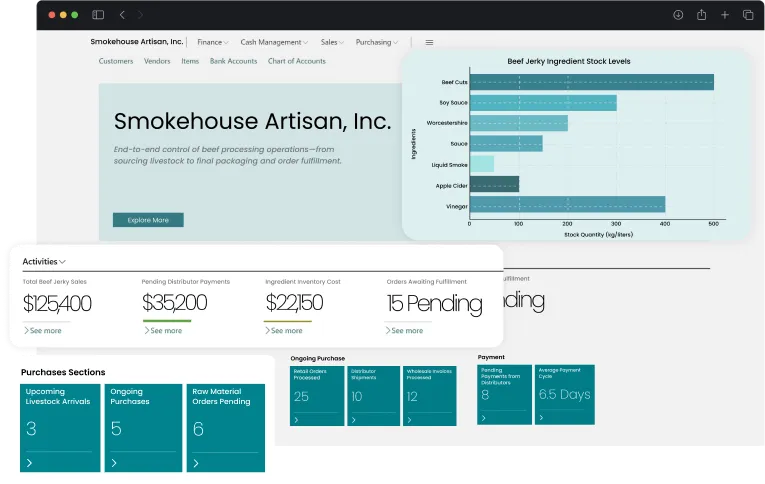

Folio3 FoodTech offers tailored ERP solutions designed for the food industry, integrating robust catch weight management functionalities. These solutions ensure easy tracking and management of variable-weight products by capturing accurate weight data at every stage of the supply chain. With customizable dashboards and automated reports, businesses gain actionable insights to optimize operations and reduce losses.

Real-Time Data Tracking

One of the standout features of Folio3 FoodTech is its real-time data tracking capability. By automating weight recording and integrating it directly into the ERP system, companies can monitor inventory levels, manage production schedules, and generate precise billing and invoicing. This ensures transparency, reduces manual errors and enhances decision-making for catch-weight food management.

Comprehensive Training and Support

Implementing a new ERP system can be challenging, but Folio3 FoodTech ensures a smooth transition with comprehensive training programs and dedicated support. From initial setup to ongoing maintenance, their experts provide hands-on training to staff, ensuring they are well-versed in using the system effectively. Additionally, their support team offers real-time assistance, minimizing downtime and ensuring continuous operations.

Fix the Gaps in Your Operations

with an ERP That Speaks Food

We help food businesses move from generic or patchworked systems to a fully

integrated ERP, purpose-built for the industry, and designed for you.

Talk to our Food ERP Specialist

Conclusion

Managing to catch weight effectively is crucial for food businesses to ensure accurate pricing, inventory tracking, and regulatory compliance. With ERP solutions with catch-weight management features, companies can reduce errors, enhance traceability, and optimize operations.

Folio3 FoodTech offers tailored ERP solutions to address these challenges. These solutions include real-time tracking, automated weight recording, and dedicated support. Partner with Folio3 FoodTech to streamline your catch weight management and drive operational efficiency.

FAQs

What Is Catch Weight in the Food Industry?

Catch weight in the food industry refers to products sold based on their weight, which can vary from package to package.

What Is Catch Weight?

Catchweight is the actual weight of variable-weight products like meat, seafood, and produce used for pricing and inventory management.

What Is the Catch-Weight Rule?

The catchweight rule requires products to be labeled and priced based on their weight at the sale.

How Is Catch Weight Calculated?

Catchweight is calculated using precise weighing equipment, with the actual weight recorded and used for pricing.

What Is the Difference Between Catch Weight and Standard Weight?

Catchweight varies for each product, while standard weight uses a fixed, consistent measurement for pricing and inventory.

How Much Is the Catch Weight?

Catchweight depends on the actual size and weight of the product at the time of sale or packaging.

What Is the Catch Weight Price?

Catchweight price is determined by multiplying the actual weight of a product by its per-unit price.

What Is the Difference Between Weighted and FIFO?

Weighted pricing averages product costs, while FIFO (First In, First Out) values inventory based on the oldest stock first.

What Is the Catch Weight of Inventory?

Catchweight inventory is tracked using actual product weights, ensuring accurate stock management and sales records.

What Is the Difference Between Catch Weight and Random Weight?

Catchweight refers to variable-weight products sold by actual weight, while random weight is often applied to unstandardized packaged items.