The dairy industry is transforming significantly as consumer preferences, technological advancements, and sustainability goals drive innovation. From the growing demand for plant-based alternatives to the integration of smart farming technologies, recent dairy industry trends are reshaping how dairy products are produced, processed, and marketed.

Staying informed about these shifts is crucial for dairy farm owners, processors, and manufacturers to maintain a competitive edge. In 2025, dairy industry trends and technologies will continue to evolve, presenting new opportunities and challenges.

The rise of functional dairy products, the emphasis on sustainable practices, and the application of data-driven decision-making are key factors influencing the sector. Understanding these milk trends can help businesses adapt to consumer demands while optimizing operations.

In this blog, we will explore the top five trends in the dairy industry for 2025. Whether you’re a dairy farmer seeking efficient production methods or a manufacturer exploring product innovation, these dairy farming industry trends will offer valuable guidance for surviving in the dynamic industry ahead.

Let’s dive into the key developments shaping the future of dairy.

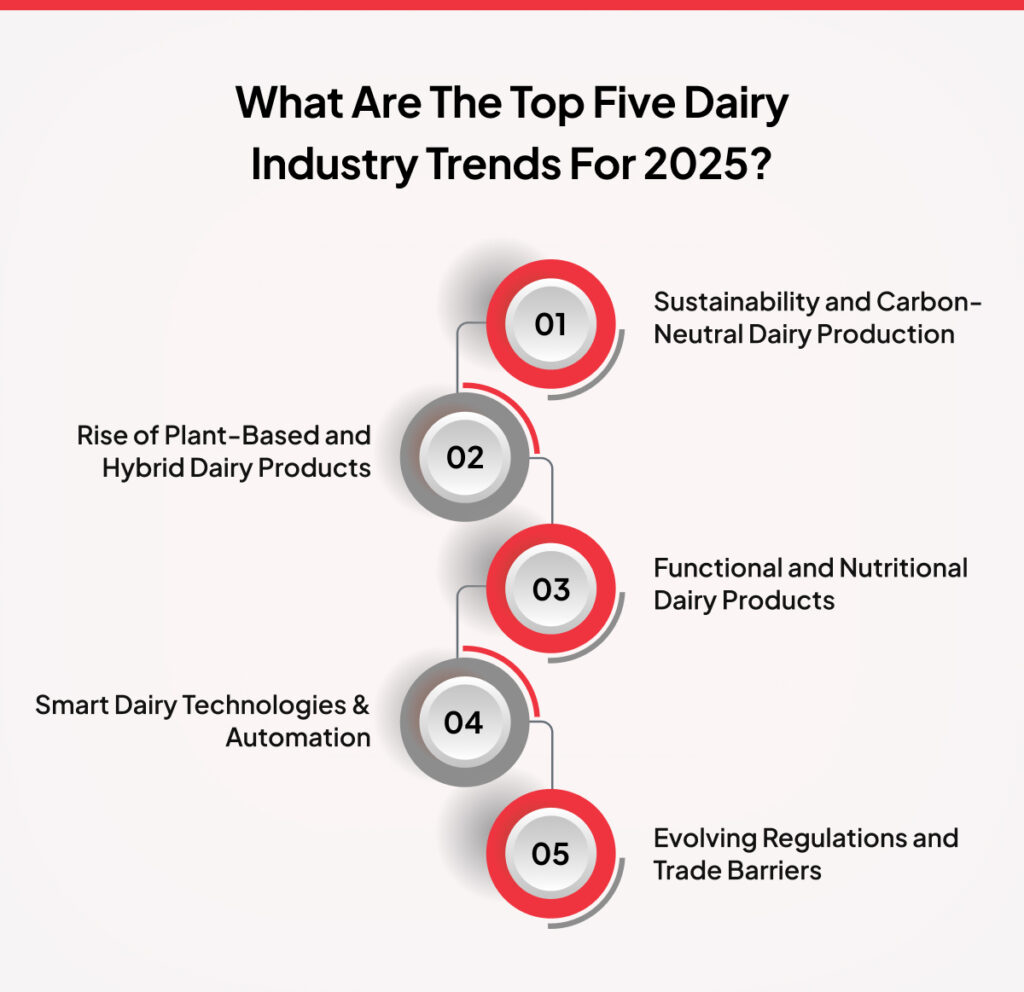

What Are the Top Five Dairy Industry Trends for 2025?

The dairy industry is evolving rapidly, driven by changing consumer preferences, technological advancements, and regulatory shifts. To stay competitive, dairy businesses must adapt to these emerging dairy industry trends. From sustainability initiatives to digital transformation, these dairy industry trends are set to reshape the sector in 2025. Let’s explore the top five dairy industry trends you should know.

Trend #1: Sustainability and Carbon-Neutral Dairy Production

Sustainability is no longer a buzzword in the dairy sector but a business investment. Consumers increasingly prioritize eco-friendly products, so dairy producers focus on carbon-neutral practices to reduce their environmental impact. According to the International Dairy Federation (IDF), the industry is committed to achieving net-zero emissions by 2050, with many producers already making significant progress.

Achieving sustainability goals requires precise data management and real-time monitoring. This is where a robust Dairy ERP software like Folio3’s solution becomes invaluable. With integrated tracking and reporting features, Dairy ERP helps farm owners and processors monitor resource consumption, detect inefficiencies, and reduce waste.

Dairy industry sustainability trends include using renewable energy sources, improving manure management through anaerobic digesters, and adopting regenerative agricultural practices. These methods reduce carbon emissions, enhance soil health, and promote biodiversity. Many companies also implement water recycling systems and optimize feed efficiency to minimize resource consumption.

Fortunately, Dairy ERP offers automated carbon footprint calculations, enabling businesses to measure progress toward carbon-neutrality. Additionally, predictive analytics provide actionable insights for optimizing operations, reducing emissions, and enhancing overall productivity.

Furthermore, partnerships with carbon credit programs enable dairy businesses to generate additional revenue while contributing to global climate goals. Transparency is another key factor, with consumers demanding traceability in the supply chain to maintain sustainable practices.

Folio3 Dairy ERP ensures processors’ and manufacturers’ sustainability compliance across the supply chain. From tracking dairy industry trends to managing production processes, it supports transparent reporting and regulatory adherence. Its traceability features offer consumers verifiable proof of eco-friendly practices, building brand credibility.

Trend #2: Rise of Plant-Based and Hybrid Dairy Products

Consumer demand for healthier, sustainable alternatives is driving the rise of plant-based and hybrid dairy products. While traditional dairy remains a staple, many consumers opt for alternatives made from oats, almonds, soy, and other plant-based ingredients. The global plant-based food market is expected to reach $95.52 billion by 2029, growing at a CAGR of 12.4% from 2022 to 2029.

Hybrid dairy products, which combine traditional milk with plant-based ingredients, are also gaining traction. These products offer dairy’s familiar taste and texture while reducing the environmental footprint. Dairy processors are leveraging innovation to create hybrid cheese, yogurts, and ice creams that appeal to conventional dairy consumers and plant-based enthusiasts.

Health-conscious consumers are a significant driver behind these dairy industry trends, seeking lower-fat, lactose-free, and cholesterol-free options. Additionally, sustainability-conscious buyers are increasingly aware of the lower carbon emissions associated with plant-based alternatives.

Trend #3: Functional and Nutritional Dairy Products

As consumers increasingly focus on health and wellness, the demand for functional and nutritional dairy products surges. Dairy processors are introducing fortified milk, probiotic yogurts, and protein-enriched drinks that cater to specific dietary needs. Products infused with vitamins, minerals, and immune-boosting ingredients are particularly popular. According to market research, the functional dairy sector is expected to grow at a CAGR of 8.5% through 2025, reflecting a significant shift in consumer preferences.

Functional dairy products are often positioned as solutions for gut health, weight management, and improved immunity. Additionally, personalized nutrition is gaining momentum, with dairy manufacturers using data-driven insights to create customized products that meet individual dietary and health goals.

How Dairy Manufacturers Can Use Data-Driven Insights for Personalized Nutrition?

Manufacturers must leverage data analytics for deeper consumer insights to succeed in the functional dairy. Here’s how ERP solutions can support this approach:

- Consumer Trend Analysis: Dairy ERP aggregates and analyzes data from multiple sources to identify dairy industry trends and evolving consumer preferences. This allows manufacturers to align product development with market demands.

- Nutritional Profiling: Through integrated data systems, manufacturers can create detailed nutritional profiles for various demographics, offering specialized dairy products such as lactose-free, high-protein, or calcium-enriched milk.

- Supply Chain Optimization: Real-time data tracking helps manage ingredient sourcing for fortified products, ensuring safety and quality standards compliance.

- Product Innovation: By using predictive analytics, dairy businesses can anticipate which functional ingredients resonate most with consumers, leading to more targeted product development.

- Customer Feedback Integration: Implementing structured feedback surveys provides businesses with continuous and precise insights to refine product formulations, packaging, and marketing strategies.

Trend #4: Smart Dairy Technologies & Automation

Smart technologies and automation transform the dairy industry, enabling farmers and processors to optimize operations, reduce waste, and ensure consistent product quality. These innovations, from automated milking systems and robotic feeding to predictive analytics and real-time monitoring, drive efficiency across the dairy supply chain.

The global dairy processing equipment market is projected to grow from $10.7 billion in 2023 to $14.4 billion by 2028, at a CAGR of 6.2%. Smart sensors and IoT devices provide real-time data on milk quality, herd health, and equipment performance.

Additionally, AI-powered analytics offer predictive insights to detect irregularities, prevent downtime and improve herd management. For dairy processors, production, packaging, and distribution automation ensures faster processing times, reduced labor costs, and minimized errors.

How Dairy ERP Supports Smart Dairy Operations

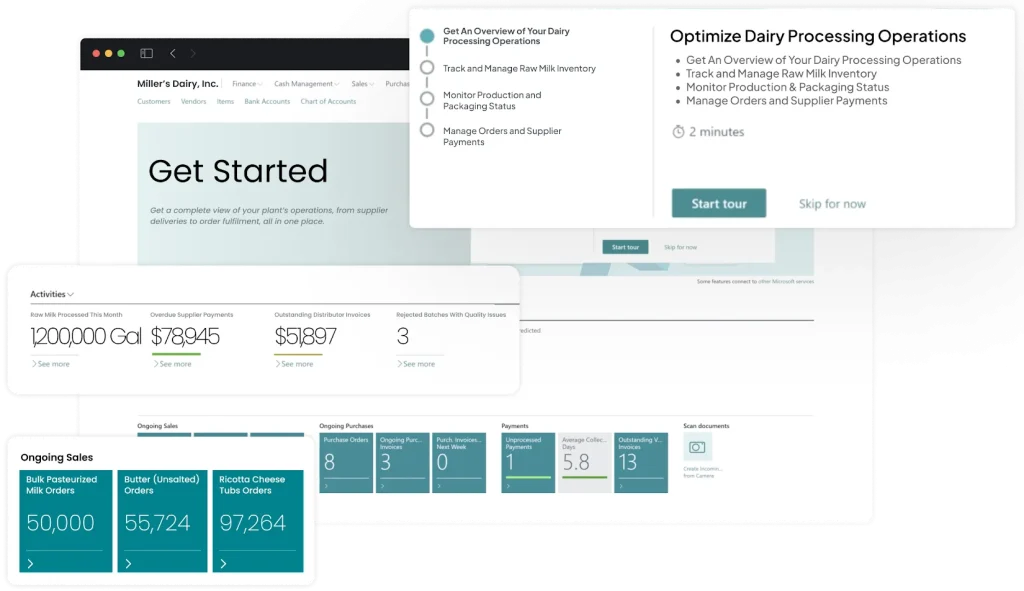

Dairy ERP systems offer comprehensive solutions to integrate and manage smart dairy technologies. They provide actionable insights that enhance decision-making by consolidating data from sensors, automated machinery, and supply chain operations.

With a Dairy ERP solution, dairy farm owners and processors can harness the full potential of innovative technologies. By using automation and data-driven insights, they can enhance operational efficiency, reduce waste, and stay competitive in the evolving dairy landscape.

- Real-Time Tracking: Monitor milk quality, temperature, and supply chain logistics in real-time, ensuring compliance with safety standards and reducing spoilage.

- Herd Health Monitoring: Track individual animal data, detect early signs of disease, and optimize feeding strategies using AI-powered insights. This helps ensure healthier herds and higher milk yields.

- Automation Management: Oversee automated milking, feeding, and cleaning processes to reduce manual intervention and improve productivity.

- Efficiency Optimization: Streamline production and packaging operations using real-time analytics to minimize downtime and optimize resource utilization.

- Predictive Maintenance: Anticipate equipment failures with predictive analytics, reducing costly downtime and maintenance expenses.

Trend #5: Evolving Regulations and Trade Barriers

The dairy industry faces heightened regulatory pressure, particularly regarding sustainability and environmentally friendly practices. Governments and regulatory bodies are implementing stricter carbon emissions, water usage, and packaging waste guidelines.

As a result, dairy manufacturers are shifting towards sustainable packaging solutions like biodegradable materials and reusable containers to comply with regulations and meet consumer expectations. Recent dairy industry trends and packaging innovations also explore plant-based and compostable materials.

How Can Dairy ERP Help?

Navigating these regulatory challenges requires a robust system for tracking compliance, optimizing processes, and minimizing environmental impact. Folio3’s Food ERP solution offers comprehensive tools for:

- Compliance Management: Monitor adherence to regional and international regulations with automated reporting and audit trails.

- Sustainability Tracking: Track carbon emissions, water usage, and energy consumption to identify areas for improvement.

- Supplier Management: Ensure raw materials meet sustainability standards by evaluating and monitoring supplier practices.

- Packaging Optimization: Streamline product packaging development with data insights to reduce waste and implement eco-friendly alternatives.

- Real-Time Data Insights: Access dashboards and reports for instant visibility into regulatory compliance status and operational sustainability.

Fuel Your Dairy Growth with a

Scalable ERP Solution

Ready to expand your dairy business? Our purpose-built ERP adapts to your

evolving needs, providing the foundation for sustainable growth.

See How Dairy ERP Scales

How Can Folio3 FoodTech Dairy ERP Help Businesses Adapt to These Dairy Industry Trends?

As the dairy industry evolves, businesses must stay agile to navigate emerging dairy industry trends and remain competitive. From sustainability initiatives to technological advancements, keeping up with these changes is essential.

Folio3 FoodTech Dairy ERP offers comprehensive solutions that empower dairy farm owners, processors, and manufacturers to organize operations, enhance product innovation, and ensure compliance. By using real-time data insights, automated workflows, and seamless integrations, businesses can adapt effectively to industry shifts and drive sustainable growth.

Here’s how Folio3 Dairy ERP can help you stay ahead of these dairy industry trends:

1. Sustainability and Carbon-Neutral Dairy Production

Folio3 FoodTech Dairy ERP supports sustainability initiatives with features like:

- Carbon Emission Tracking: Monitor carbon footprints across the supply chain and generate actionable sustainability reports.

- Waste Management: Optimize waste reduction and ensure responsible disposal practices.

- Sustainability Reporting: Produce detailed reports to meet regulatory compliance and sustainability goals.

2. Supporting Plant-Based and Hybrid Product Innovation

Stay competitive in the evolving market with Folio3 Dairy ERP’s product innovation capabilities:

- Recipe Management: Streamline ingredient sourcing and optimize plant-based or hybrid dairy product recipe formulation.

- Quality Control Management: Ensure product consistency through automated quality checks.

- Product Lifecycle Management (PLM): Accelerate product development and reduce time-to-market.

3. Personalized Functional and Nutritional Products

Respond to growing consumer demand for personalized nutrition with:

- Consumer Data Analytics: Leverage insights from customer preferences and market trends to tailor product offerings.

- Nutritional Labeling Management: Automatically generate accurate product labels that comply with regulatory standards.

- Flexible Formulation Management: Adjust formulations to cater to specific dietary needs and preferences.

4. Smart Dairy Technologies and Automation

Enhance operational efficiency through automation and real-time data monitoring with ERP features such as:

- IoT Integration: Connect with sensors and smart devices to monitor milk yield, herd health, and equipment performance in real-time.

- Production Management: Automate production scheduling, inventory management, and resource allocation.

- Predictive Maintenance: Reduce downtime by detecting equipment issues before they lead to failures.

5. Regulatory Compliance and Trade Management

Ensure seamless compliance and manage cross-border operations with:

- Compliance Management: Automate regulatory reporting and maintain accurate records to meet food safety and quality standards.

- Lot Traceability: Track food products from farm to consumer to ensure quality and safety.

- Global Trade Management: Streamline trade processes with integrated documentation and compliance management for international markets.

Conclusion

The dairy industry will undergo significant transformation in 2025, driven by sustainability initiatives, the rise of plant-based and hybrid products, demand for functional dairy options, the adoption of innovative technology, and evolving regulations. Staying ahead of these dairy industry trends is essential for dairy farm owners, processors, and manufacturers seeking to remain competitive.

Folio3 FoodTech Dairy ERP offers the tools and insights to understand these changes. With robust data analytics, automation capabilities, and real-time monitoring, your business can enhance operational efficiency, drive innovation, and meet sustainability goals.

Stay proactive, stay on top of the evolving dairy industry, and let Folio3 FoodTech Dairy ERP guide your business toward a sustainable and profitable future!

Fuel Your Dairy Growth with a Scalable ERP Solution

Ready to expand your dairy business? Our purpose-built ERP adapts to your

evolving needs, providing the foundation for sustainable growth.

See How Dairy ERP Scales

FAQs

What Is The Future Of The Dairy Industry?

Sustainability efforts, smart technologies, and the rise of plant-based alternatives are shaping the dairy industry’s future, driving innovation and growth in dairy industry trends.

What Is The Trend In Dairy Consumption?

Recent dairy industry trends show increasing demand for functional dairy products, hybrid milk alternatives, and personalized nutrition options to meet evolving consumer preferences.

What Is The Global Dairy Market Trend?

Global dairy industry trends indicate significant growth in plant-based dairy, sustainable packaging, and automated dairy farming technologies, enhancing production efficiency.

How To Increase Milk Sales?

To boost milk sales, dairy businesses can adopt data-driven insights using Dairy ERP systems, streamline operations, introduce innovative milk products, and track market dairy industry trends in dairy consumption.

Is There A Milk Shortage In 2025?

While no global milk shortage is confirmed for 2025, dairy farming industry trends suggest regional challenges may arise due to climate change and supply chain disruptions.