In food manufacturing, every batch matters. From raw ingredients to final products, the pressure to maintain consistency and quality is constant. But without the right processes in place, things can easily go wrong. Batch management is important not only for maintaining product integrity but also for smooth operations.

Whether you produce baked goods, dairy, ready-to-eat meals, or any other consumable product, every batch you create represents a defined moment in your operation. The ability to clearly define and manage that moment can determine how well your company responds to recalls, audits, or even subtle shifts in consumer demand. But managing this all becomes harder as production scales.

Without a system designed to capture batch-level details accurately and in real-time, slight deviations can go unnoticed until they become costly problems.

In this blog, we’ll discuss the role of batch management in food production and explore how an ERP system helps purpose-built for manufacturers like you can give you control over every batch you produce.

What Is Batch Management?

In food manufacturing, batch management is the practice of producing goods in groups, known as batches. Each batch consists of a specific quantity of product made in one production run, using the same ingredients and processes. Unlike continuous production, which flows without interruption, batch production allows for tighter control over each unit produced, ensuring consistency and quality.

For food manufacturers, managing batches is essential for tracking ingredients, monitoring production processes, and maintaining product standards. It’s not just about labeling products; it’s about keeping a detailed record of each batch, including any deviations from the standard process. This level of detail helps manufacturers identify issues quickly and address them before they become problems.

Key Elements For Effective Batch Management

When it comes to food manufacturing, managing batches goes beyond just keeping things organized.

Here are the key aspects you need to consider:

1. Ingredient Traceability

Every ingredient needs to be tracked precisely. The batch management process allows you to trace each raw material’s origin, batch number, and movement through production, ensuring food traceability in case of contamination or regulatory audits.

2. Real-Time Process Monitoring

It is vital to monitor your production parameters in real time. This means continuously monitoring temperature, humidity, and processing time to ensure consistent output and identify deviations instantly.

3. Detailed Batch Record Keeping

A digital record of each batch provides transparency and accuracy. It includes raw materials, production steps, equipment, and quality control checks.

4. Yield Monitoring

Yield monitoring measures the actual output against expected production quantities. This data helps identify inefficiencies or deviations in the process, such as ingredient waste or machine downtime, that could affect the cost and quality of the batch.

5. Lot Code Assignment and Labeling

It assigns unique identifiers to each batch for traceability throughout the supply chain. Lot codes track production date, expiry, and origin, making the batch inventory management system and product recalls more accurate.

6. Shelf Life and Expiry Tracking

Shelf life isn’t just about monitoring expiry dates; it’s about knowing exactly when the product loses quality. Shelf-life tracking ensures that you account for environmental variables like temperature control and humidity, preventing spoilage before it happens.

Why Batch Management Matters More Than Ever in Food Manufacturing

Managing batches effectively allows you to isolate ingredient-level issues, reduce waste tied to overuse or miscalculation, and enforce consistency across every run.

Take allergen management, for example. If you’re producing both allergen-free and standard variants, you can’t afford even a minor slip. The batch management process helps ensure that changeovers are logged, cleaning protocols are verified, and ingredient usage is traceable to the source.

From a production perspective, batch-level oversight helps teams detect inefficiencies early. Let’s say one batch shows lower yield or higher waste than usual. With detailed batch records and real-time monitoring, you can investigate specific process steps, identify the issue, and correct it before it recurs, saving time and raw materials.

As your operation scales, batch management becomes even more important. With more SKUs, inputs, and regulatory complexity, you need the ability to drill down into any batch and know precisely what happened.

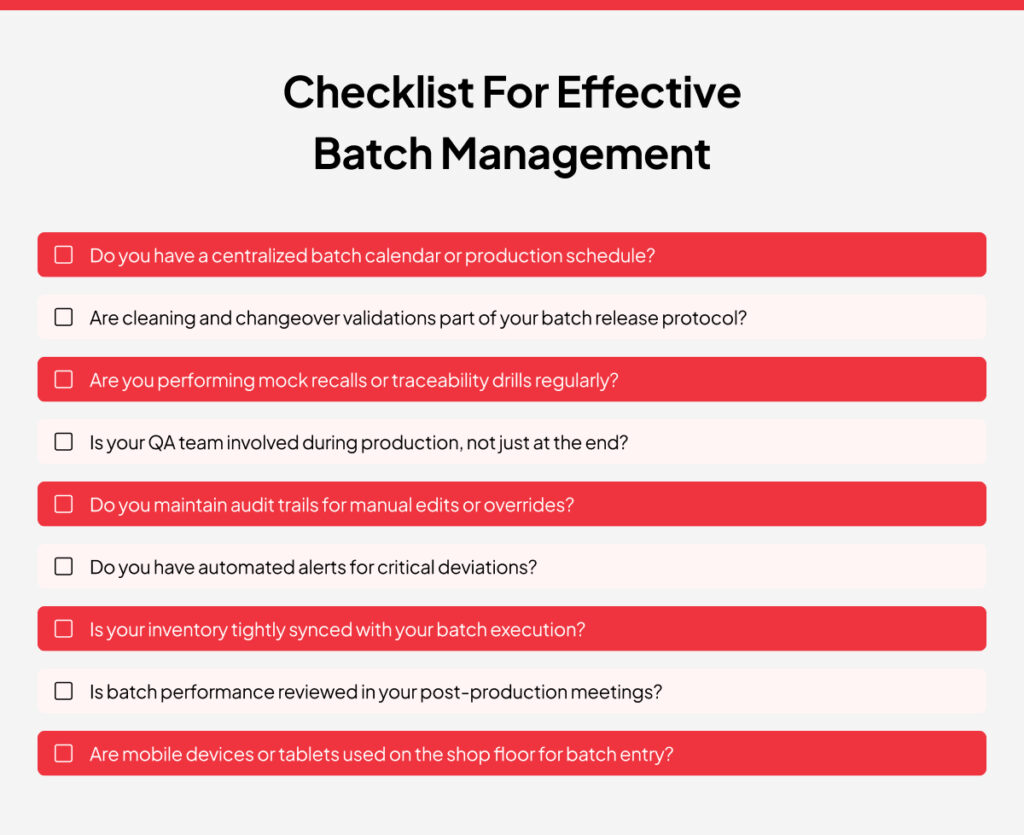

You might be tracking batches, but is your process airtight, audit-ready, and scalable?

Use this checklist to evaluate how operationally mature your batch management really is:

Issues in Batch Management Without a Digital System

Even with experienced teams, batch management can quickly become a bottleneck if the right tools and discipline aren’t in place. Here are the most common challenges food manufacturers face specifically with the batch management process:

1. Recipe & Batch Version Control

Batch production management relies heavily on following exact formulations. But in many food facilities, recipe management updates aren’t communicated in real time, and worse, operators work off outdated printouts. Without centralized version control, even small inconsistencies in formulations can lead to quality variations.

Why it matters: Even slight deviations in seasoning or allergen content, sometimes less than 1%, can lead to flavor inconsistencies or contamination, one of the leading causes of food recalls globally.

2. Inconsistent Batch Documentation

Many manufacturers still rely on manual logs or non-standardized forms for ingredient usage, in-process checks, or corrective actions. This results in incomplete batch histories that can’t be trusted during food safety inspections.

Risk: Missing or illegible batch logs break your food traceability chain and undermine audit readiness.

3. Unplanned Deviations & Lack of Corrective Logging

A batch might run longer in the retort, or a filling line may pause mid-run. The problem isn’t just the deviation; many teams skip documenting it due to shift pressure or lack of integrated tools.

Impact: Undocumented deviations can disqualify an entire batch under food safety compliance, including HACCP or BRCGS protocols.

4. Manual CIP & Changeover Validation

Allergen lines (e.g., switching from milk-based to milk-free granola) require validated cleanouts. Yet many teams still rely on verbal sign-offs or paper logs.

Risk: One missed CIP step can trigger undeclared allergen contamination and immediate product withdrawal.

5. Yield Variance Without Root Cause Analysis

Your bread line might consistently show 3% dough overuse, or your bottling line loses volume due to foaming, but no one’s connecting the dots.

Consequence: Margin erosion becomes invisible without linking yield variance to batch data.

What Role Does Food ERP Play In Managing Batch Production

Food ERP isn’t just a digital system; it is designed to control the flow, quality, and compliance of every batch you produce. A purpose-built food ERP, like the one offered by Folio3 FoodTech, helps integrate every step of the batch lifecycle, raw material intake, production execution, quality checks, and outbound logistics into a single platform.

Here are the core food ERP features that support this:

- Batch Production Scheduling and Sequencing

Food ERP systems enable you to plan production batches based on real-time inventory, equipment capacity, and labor availability. They also automate batch sizing based on current demand or forecasted orders.

Use case: The dairy ERP system can auto-schedule smaller yogurt batches in off-peak hours for a dairy plant and align CIP between flavor variants.

- Lot Traceability & Bi-Directional Tracking

ERP systems capture upstream and downstream lot traceability data, linking raw material lots to finished goods and vice versa. It allows immediate traceback in the event of recalls and simplifies compliance with FSMA, BRCGS, or SQF requirements.

Use case: A candy manufacturing plant identifies an issue with a batch of cocoa butter used in multiple chocolate bars. With bi-directional lot tracking, the confectionery ERP quickly traces every finished product that used the affected lot.

- In-Process Quality Control (IPQC) Integration

Food ERPs embed QC checkpoints throughout the batch lifecycle, including raw material inspection, in-process testing, and finished product validation. Deviations automatically trigger alerts or hold actions.

Use case: A snacks ERP system blocks batch release if cooking temperatures fall outside critical control limits (CCLs).

- Real-Time Inventory Synchronization

The ERP adjusts inventory levels in real time as ingredients are issued or consumed per batch. It also supports the warehouse’s FEFO (First-Expiry-First-Out) and allergen segregation logic.

Use case: Sauces and dressing ERP prevents the use of expired tomato paste or stabilizers by automatically blocking batches if ingredients nearing expiry are picked.

- Recall Readiness and One-Click Traceability Reports

With centralized data, ERPs allow for the immediate generation of forward and backward trace reports, showing exactly which batches, shipments, and customers were affected.

Use case: A meat processor isolates a contaminated batch within minutes and notifies only the relevant distributors, minimizing financial and reputational damage.

How Folio3 FoodTech ERP Gives You Complete Control Over Every Batch

Batch management in food production leaves little room for error. Folio3 FoodTech ERP is designed specifically for food manufacturers and gives you real-time control over every batch you produce.

It starts with a structured recipe. You define your batch sizes, formulations, and ingredient specs once, and the system takes care of scaling, raw material allocation, and version control. No more chasing down updated SOPs or guessing whether the right formula is in use. Operators on the floor always follow the most recent instructions, with no room for guesswork.

As the batch moves through production, the ERP captures everything, including start times, mixing durations, QC checkpoints, and even unplanned deviations. Each batch is tagged with a unique lot code and automatically linked to both raw materials and finished goods, so traceability isn’t just possible, it’s instant.

The Food Manufacturing ERP module ties directly into inventory, quality, and compliance. Whether it’s allergen changeovers, FEFO inventory pulls, or CIP validation, the system ensures that each step is followed and logged. And if something goes wrong, you can trace it back to the source in minutes, not hours.

Fix the Gaps in Your Operations

with an ERP That Speaks Food

We help food businesses move from generic or patchworked systems to a fully

integrated ERP, purpose-built for the industry, and designed for you.

Talk to an ERP Specialist

Conclusion

In the current food manufacturing landscape, batch management is more than a back-end function. As production lines diversify and regulatory frameworks like FSMA, BRCGS, and SQF demand greater traceability, the margin for error shrinks. Folio3 FoodTech ERP gives manufacturers real-time visibility and control across every batch, from formulation and production to quality checks and traceability. It turns complicated processes into optimized workflows with features like allergen management, automated CIP validation, and bi-directional lot tracking.

FAQ

What Is The Meaning Of Batch Management?

Batch management produces and tracks items in defined groups, or batches, to ensure consistency, traceability, and compliance across food manufacturing operations.

What Is Batch Status Management?

Batch status management is the ability to assign and control the status of each batch throughout its lifecycle, such as “Released,” “On Hold,” “Quarantined,” or “Rejected.” It helps food manufacturers enforce quality checks, block non-compliant products from moving forward, and ensure only approved batches are released for packing or distribution.

How Does Batch Tracking Inventory Management Help Improve Food Production Efficiency?

It connects ingredients to each batch, enabling real-time FEFO-based inventory use, faster traceability, and accurate usage data. This helps reduce waste, avoid recalls, and keep production aligned with safety and shelf-life standards.

What Is Batch Management Software For Food, and Why Do Manufacturers Need It?

Batch management software helps food manufacturers digitally manage production lots, improve traceability, comply with food safety regulations, and minimize risks associated with quality issues or product recalls.