Rising costs aren’t a surprise anymore. For food manufacturers, the question is no longer if prices will rise, but how quickly they’ll impact production, procurement, and profitability. What’s changing now is the scale and the stakes.

When Tyson Foods reports a $258 million loss in its beef segment and Kraft Heinz rolls out a $3 billion plan to modernize its U.S. plants, it’s clear that food manufacturers are facing a cost crisis. The pressures aren’t isolated; inflation, labor shortages, and tariff-driven supply chain disruptions are hitting simultaneously. Rising food costs aren’t just squeezing margins anymore; they’re forcing the industry to rethink profitability, resilience, and long-term strategy.

And it’s not just the industry giants. Across the U.S., mid-sized food businesses feel the ripple effects, from soaring ground beef prices to sudden import costs and packaging delays. We hear it daily from our partners: “We need better visibility. We can’t afford to guess anymore.”

In this blog, we’ll explain why rising food costs are outpacing growth, where the blind spots are, and how smarter ERP strategies can help you turn insight into savings before the next crisis hits.

Why Food Manufacturing Costs Keep Going Up

If you’re running a food manufacturing business today, chances are your cost sheets look different every month, and not in a good way. You place an order for packaging, and the price has changed. Your protein supplier adjusts rates mid-quarter. The freight invoice comes in, and there’s a new line item you’ve never seen before. It’s not just rising food costs. It’s unpredictability layered on top of unpredictability.

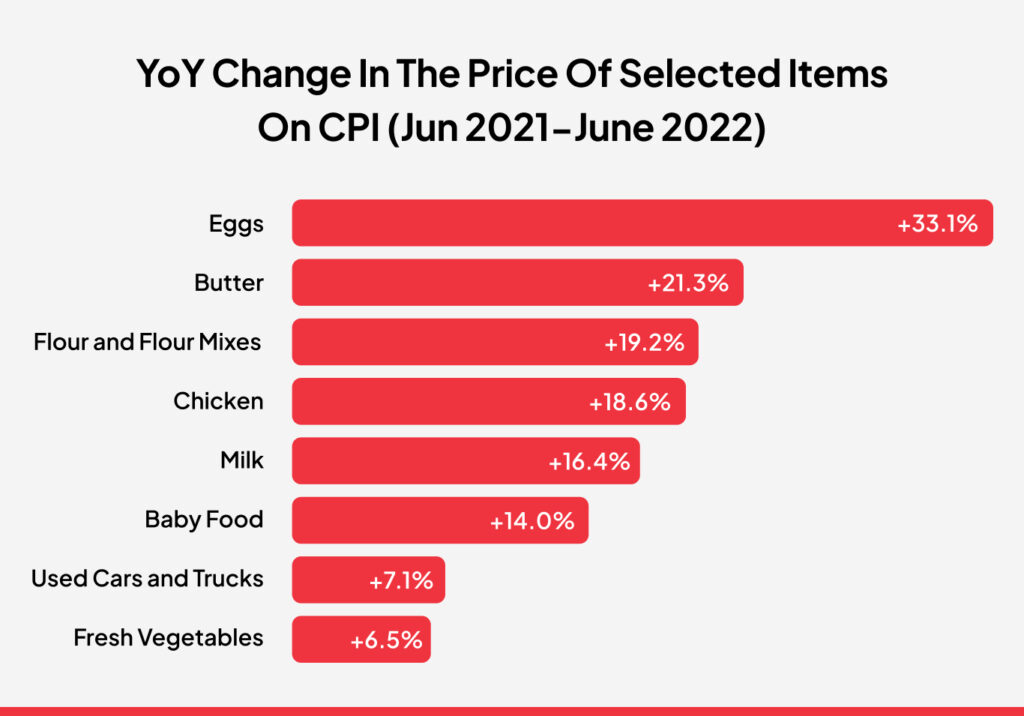

What’s driving it? A lot, and most of it’s outside your control. Commodities are volatile. Take beef, for example, U.S. cattle herds are at record lows, pushing prices through the roof. Ingredients like sugar, flour, and oil aren’t far behind, especially when extreme weather hits growing regions. And if you rely on imports like spices, canned goods, and specialty ingredients, the recent tariffs have likely added another layer of cost to your bottom line.

Then there’s labor. Even if you’re offering competitive pay, it’s hard to find experienced people. And when you do, training and turnover eat away at time and efficiency. For many food manufacturers, managing staff has become just as hard as managing food inventory.

So why are food manufacturing costs going up? Because everything from rising food costs to staffing to shipping is more uncertain, more expensive, and less forgiving than it used to be. And that means the way we’ve always done things doesn’t work anymore.

The Real Impact of Rising Food Costs on Business Margins

Margins in food manufacturing were already tight. Now, with rising food costs touching every corner of operations, they’re being stretched to the breaking point. For most food businesses, the impact isn’t just about higher invoices; it’s about decisions you’re forced to make every week.

Recent data indicates that the average gross profit margin for the food processing industry is approximately 25.91%. However, these margins are under significant pressure with the current surge in ingredient prices.

With uncertainties like these, you’re constantly reformulating recipes because your original ingredients are too expensive to justify. You’re running fewer promotions because you can’t discount what’s already cutting into profit.

Finance teams are recalculating margins daily. Production leads are walking a line between efficiency and compromise. And if you’re selling through retailers, the pressure is even more intense, because price increases don’t always pass through cleanly.

Let’s break down how rising food costs can affect how different areas in your business operate:

| Operational Area | Typical Scenario | Post-Cost Surge Reality |

| Ingredient Margins | 22–25% on core SKUs | Down to 14–17% due to raw material volatility |

| Recipe Formulation | Optimized for taste and shelf life | Reformulated based on cost and availability |

| Promotion Strategy | Quarterly discounts to improve sales volume | Paused or cut back as margins can’t absorb the hit |

| Production Planning | Based on forecasted demand | Based on ingredient supply and price swings |

| Per-Unit Profitability | Steady within a 3–5% fluctuation range | Fluctuating 8–12% due to unstable inputs |

| Retail Price Negotiation | Negotiated annually or quarterly | Constant back-and-forth due to rising base costs |

| Procurement Flexibility | Long-term contracts with preferred suppliers | Frequent spot-buying based on cost and availability |

| Finance Forecasting | Monthly/quarterly visibility into margin outlook | Weekly re-forecasting to account for cost changes |

5 Ways Food Manufacturers Are Using ERP to Stay Resilient Against Rising Food Costs

Rising food costs have made one thing clear and that is food manufacturers need more than quick fixes. What’s working now isn’t slashing budgets, it’s building systems that help you adapt faster, plan smarter, and make decisions based on facts, not guesses. That’s precisely what ERP does.

Modern food ERP platforms aren’t just about digitizing your operations. They’re about helping you understand what’s happening across your food supply chain, production floor, inventory, and margins in real time. When costs shift suddenly, whether it’s a spike in protein prices or a shortage in packaging, ERP gives you the visibility to respond confidently instead of reacting under pressure.

The following are the five specific ways food manufacturers use ERP to create resilience, not just in their finances but also in how they plan, produce, and grow under pressure.

1. Switching to Real-Time Ingredient Cost Tracking

When ingredient prices fluctuate week to week, or even day to day, relying on monthly spreadsheets just doesn’t cut it. With modern F&B ERP solutions for rising costs, food manufacturers can track ingredient costs in real time, directly tied to purchase orders, supplier quotes, and landed costs. This means that if the price of canola oil jumps overnight, procurement sees it immediately, and finance can run margin impact scenarios before production even begins.

Imagine you’re producing salad dressings, and your key oil goes up 15%. By using a sauces ERP, you can get alerts instantly, not after you’ve already fulfilled low-margin orders. You can pivot: source differently, reformulate, or even pause certain SKUs.

This level of visibility is what allows cost control to become proactive, not reactive.

Pro Tip: Don’t wait for monthly reports to spot margin slippage. Set real-time cost alerts in your ERP so Food purchasing and production teams can respond the moment input prices shift.

2. Optimizing Recipe Formulations Based on Cost Trends

Ingredient prices rarely stay still, but your recipe costs don’t have to spiral because of it. A robust food ERP lets R&D and production teams monitor cost trends over time and make informed tweaks to formulations without compromising quality, shelf life, or food safety compliance.

Let’s say you’re making energy bars, and the cost of honey has spiked. With food ERP, you can simulate cost-based substitutions, maybe shifting to a blend of syrups, while seeing the impact on nutrition, allergen profiles, and unit economics in real time. No spreadsheets, no guesswork, and no unpleasant surprises at the end of the month.

This isn’t just a reformulation, it’s controlled innovation in response to rising food costs

3. Running What-If Costing Simulations Before You Commit

When ingredient markets shift daily, food manufacturers can’t afford to base production on outdated cost assumptions. ERP systems with advanced costing engines allow you to simulate multiple production scenarios before a single PO is issued.

You can model rising food costs implications based on fluctuating ingredient prices, supplier changes, freight variations, or packaging upgrades, all within a controlled digital environment. These simulations consider real-time inventory values, supplier price lists, and BOM-level data to generate accurate per-unit and batch-level cost projections.

Instead of reacting in post-production, you make informed, cost-aware decisions before the line starts. This approach reduces financial risk and optimizes production strategy without manual guesswork or disconnected spreadsheets.

4. Forecasting and Demand Planning with Updated Cost Inputs

Planning production without factoring in updated cost data is like setting sail without checking the weather. With ERP-powered demand planning, manufacturers can dynamically align forecasts not just with sales history, but with real-time changes in ingredient costs, tariffs, and supplier conditions.

Recently, for example, new U.S. import tariffs on goods from Mexico and China have driven up costs for packaging materials and processed ingredients. ERP for food manufacturers allows them to feed those changes directly into planning workflows. That means you can prioritize runs that protect margins, hold off on temporarily unprofitable SKUs, or reroute demand to facilities with lower cost exposure.

This kind of responsiveness turns demand planning into a margin-preserving strategy, not just a volume-based forecast.

5. Dynamic Supplier Benchmarking and Cost-Based Purchasing Decisions

When supplier pricing, lead times, and freight terms are shifting constantly, food manufacturers can’t afford to operate on autopilot. With a modern ERP for procurement, teams gain live access to supplier performance data, not just who’s cheapest today, but who consistently delivers value: best lead times, lowest landed cost, and highest reliability.

This dynamic benchmarking helps you make smarter, faster decisions, especially when ingredient markets are volatile.

Del Monte Foods is a prime example. By implementing an advanced ERP with real-time collaboration features, they reduced inventory by 27% and still hit 99% service levels. Why? Because they had the visibility to shift sourcing strategies as needed, without compromising service.

Pro Tip: The cheapest supplier isn’t always the most cost-effective. Benchmark on reliability, lead time, and total cost, not just price.

How Folio3 FoodTech ERP Brings Real-Time Cost Visibility

At Folio3 FoodTech, we’ve worked alongside food manufacturers long enough to know this: most of the time, rising food costs don’t catch you off guard because you’re not working hard; they catch you off guard because you’re not seeing the whole picture.

Our Food ERP isn’t just a platform for digitizing operations. It’s a system built from the ground up for the complexities of food manufacturing, from volatile ingredient costs and batch-level costing to shelf life tracking, compliance, and supplier performance. What sets it apart is how it connects your financials, production, procurement, inventory, and quality processes into a single source of real-time truth.

That means no more waiting until the end of the month to understand if your margins held up; you’ll see it in the moment. Ingredient prices go up? You’ll know exactly how that impacts per-unit cost and whether a price adjustment, recipe change, or batch delay makes more sense.

What makes Folio3 FoodTech different isn’t just our technology; we build with food in mind. We understand that you’re not just moving data from spreadsheets to software, you’re managing real products, with real shelf lives, and real cost volatility.

Fix the Gaps in Your Operations

with an ERP That Speaks Food

We help food businesses move from generic or patchworked systems to a fully

integrated ERP, purpose-built for the industry, and designed for you.

Talk to an ERP Specialist

Features In Folio3 FoodTech ERP That Help You Control Rising Food Costs

Folio3 FoodTech ERP is purpose-built to give food manufacturers the visibility and control they need to avoid cost pressures. Here are the features designed specifically to help you manage rising food costs and protect profit margins:

- Real-Time Ingredient and Batch Cost Tracking: Instantly see how price fluctuations affect your per-unit and per-batch profitability.

- What-If Costing Scenarios: Simulate production runs under different input cost conditions to plan proactively.

- Dynamic Recipe & BOM Management: Adjust formulations based on real-time rising food costs trends without disrupting production or compliance.

- Supplier Benchmarking and Procurement Analytics: Compare supplier performance and total landed cost to make informed sourcing decisions.

- Yield and Waste Tracking: Monitor losses and inefficiencies to tighten control on shrinkage and maximize output.

- Integrated Demand Forecasting with Cost Inputs: Align production planning with demand and evolving cost dynamics.

- Automated Alerts for Margin Thresholds: Get notified when cost changes push SKUs below profit targets before they impact your bottom line.

- End-to-End Inventory Cost Visibility: Track actual vs. standard costs across raw materials, WIP, and finished goods in real time.

What Every CFO Should Know Before Approving a Food ERP

ERP isn’t just an operations tool it’s a financial decision with long-term margin impact. If you’re leading cost control and ROI planning at your food manufacturing business, this CFO’s Guide to Implementing a Food and Beverage ERP breaks down what matters: cost structures, implementation phases, and how to align ERP with real business goals.

See How CFOs Are Leading ERP Success in Food Manufacturing

Conclusion

If you’re running a food manufacturing business right now, you don’t need another reminder for rising food costs; you’re living it daily. Ingredients fluctuate, supplier terms change overnight, and freight isn’t what it used to be. And somewhere in between, you’re trying to protect margins, meet demand, and keep operations moving.

What this environment really demands is clarity. Not more data, but better data. Not more systems, but smarter ones. That’s where a food-focused ERP makes all the difference.

It’s not about automating for its own sake. It’s about having a clear view of your costs, your risks, and your next move, all in one place, in real time.

FAQs

Are Food Prices In The US Going Up?

Yes, and not marginally. In 2025, U.S. food prices continue to climb due to global supply constraints, climate-related crop issues, labor shortages, and new tariffs. For manufacturers, rising food costs translate to unpredictable ingredient costs and tighter production margins.

Why Are Food Manufacturing Costs Rising So Rapidly In 2025?

Costs are rising due to rising ingredient prices, increased labor wages, higher freight charges, and new import tariffs. These changes affect every part of the supply chain, making it harder for manufacturers to plan, budget, and protect margins.

How Fast Can A Food ERP System Show ROI When Tackling Rising Costs?

When implemented with cost tracking in focus, a specialized ERP for food and beverage can deliver ROI in 3–6 months. Early gains often come from real-time margin insights, reduced inventory loss, better supplier decisions, and fewer surprises in production costing.

How Does Demand Forecasting In ERP Improve Cost Resilience?

It allows manufacturers to plan smarter, not just based on sales, but on current cost realities. FoodTech ERP for profitability ties together real-time input costs, supplier trends, and sales forecasts to help prioritize high-margin products and avoid costly overproduction.