Meat production puts significant pressure on the environment due to several interconnected factors. It’s a leading contributor to greenhouse gas emissions, particularly methane from livestock and nitrous oxide from manure and fertilizers. These gases are far more potent than carbon dioxide. To raise animals and grow their feed, large areas of land are cleared, often through deforestation. This not only releases stored carbon into the atmosphere but also destroys natural habitats, leading to biodiversity loss. The process also consumes vast amounts of water and contributes to soil degradation and pollution, especially from waste runoff and chemical use.

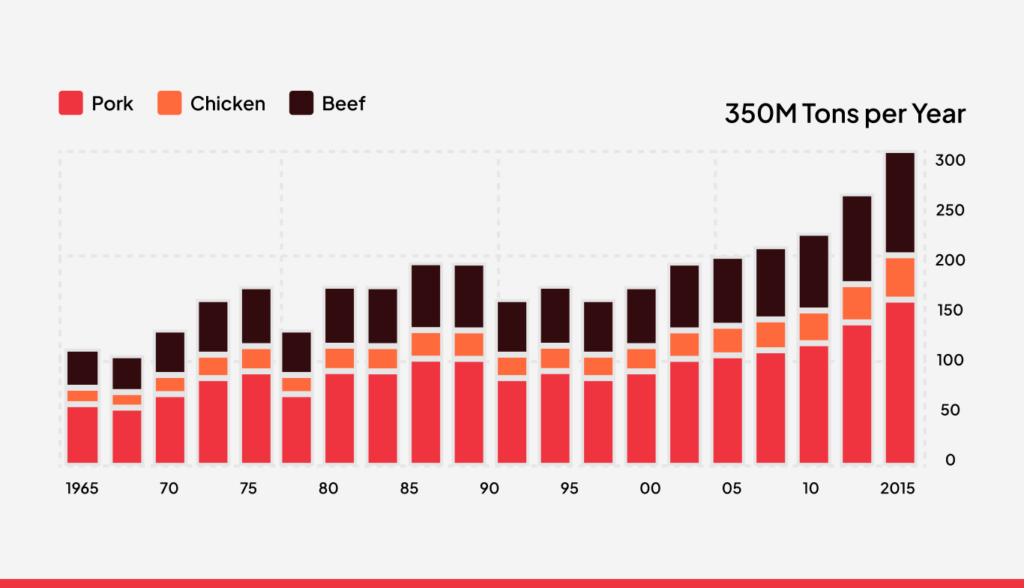

As the world continues to demand more meat to feed growing populations, the pressure on our planet intensifies. According to research by the UN Environment Programme (UNEP), the global meat consumption is projected to increase up to 14% by 2030. That puts the environmental impact of meat production under more scrutiny than ever. From methane emissions and water waste to deforestation and energy consumption, the industry leaves a heavy carbon footprint at every stage.

Notably, livestock supply chains account for 14.5% of all human-induced greenhouse gas emissions. While natural processes contribute to these figures, operational inefficiencies often exacerbate the problem. In this blog, you’ll learn about the core environmental impact of meat production.

Environmental Impact of Meat Production

Before we dive into the impact, let’s take a step back and look at just how much meat the world is actually producing.

The Global Footprint

The meat industry carries a disproportionate share of environmental burden. For instance, livestock farming alone generates about 7.1 gigatons of CO₂ equivalent emissions annually, that’s roughly 14.5% of all human-induced emissions, per the Food and Agriculture Organization of UN.

Methane, a far more potent greenhouse gas than CO₂, comes primarily from cattle digestion (enteric fermentation) and manure handling. Water consumption is another major concern. The Water Footprint Network explains that producing 200 grams of meat uses water equivalent to 47 eight-minute showers. Additionally, meat production drives deforestation, especially in regions like the Amazon, where vast areas are cleared for cattle grazing or soy feed production. The ripple effects include biodiversity loss and soil erosion.

So is the cost of a steak more than just money? When you add up emissions, water usage, and forest loss, the answer is undeniably yes.

The Food and agriculture organization reports that the meat industry generates more greenhouse gases than all cars, trucks, planes, and ships combined. Their study, Livestock’s Long Shadow, states that meat production makes up around 18% of global greenhouse gas emissions. That makes it one of the biggest contributors to climate change.

How Does Meat Production Affect the Environment?

Before we break it down, let’s look at the chain reactions meat production sets off from emissions to ecosystem damage.

Gas Emissions

Ruminant animals like cows and sheep produce methane during digestion. This process is called enteric fermentation. Methane is a greenhouse gas that traps heat much more effectively than carbon dioxide. That’s just on the farm. Once animals are processed, fossil fuels enter the equation. Fuel is burned during slaughter, refrigeration, fresh meat packaging, and transport. Together, these activities push the meat industry challenges and environmental footprint to alarming levels.

Land Degradation

Livestock farming requires a lot of land. Overgrazing strips soil of essential nutrients. That makes the land less productive over time. In severe cases, it leads to desertification.

To grow enough feed, farmers often rely on large-scale monoculture crops like corn or soy. These crops use chemical fertilizers and pesticides. That leads to soil degradation, erosion, and lower biodiversity. Healthy land becomes harder to maintain. Regenerative practices exist but are not widely adopted.

Water Pollution

Animal waste is a major source of water contamination. When manure isn’t properly managed, it runs off into lakes, rivers, and streams. This runoff contains nitrates and phosphates. These chemicals cause algae blooms, which deplete oxygen in water.

The result? “Dead zones.” These are aquatic areas where most life cannot survive. Fish and other species either die or move away. Water treatment becomes more expensive for nearby communities. In some places, drinking water becomes unsafe due to nitrate contamination.

Why Are These Issues Hard to Fix?

Before we talk about them, we need to know that most of these issues sound like natural processes. But let’s discover the ones that we can get in control with to take steps towards sustainability.

Disconnected Supply Chains

Meat production involves many players. Farmers, transporters, processors, and distributors often work independently. Each step is isolated. There’s little to no real-time communication.

This fragmentation creates major blind spots. Data doesn’t move smoothly from one stage to the next. As a result, problems go unnoticed until it’s too late. You can’t fix what you can’t track. And without full visibility, sustainability efforts fall short.

Resource Waste and Inefficiencies

Wasted resources are common. Overstocking animals leads to higher methane emissions and feed waste. Spoiled feed adds to that burden.

At processing facilities, energy use often goes unchecked. Equipment runs longer than needed. Heating, cooling, and lighting are rarely optimized. These inefficiencies add up fast. They raise costs and increase the carbon footprint.

Poor Waste Management

Organic waste is a major byproduct of meat processing. Without proper systems, most of it goes to landfills. That creates more methane.

Some plants lack tracking systems. They don’t monitor how much waste is produced or where it ends up. Others miss alerts when thresholds are crossed. This makes compliance difficult. And it puts both the environment and brand reputation at risk.

Regulatory Pressure and Inconsistent Compliance

Regulations are tightening worldwide. From carbon reporting to animal welfare, food producers are under the spotlight.

But smaller meat businesses often fall behind. Many still use manual logs or outdated tools. Keeping up with food safety audits, certifications, and sustainability reporting is overwhelming. Without automation, it’s easy to miss deadlines or fail inspections.

That leads us to the next section.

Using ERP to Green the Meat Supply Chain

ERP softwares are not just about accounting or inventory anymore. An ERP developed for the food ecosystem becomes the centralized command center that enables sustainability.

Let’s break that down:

Precision Resource Management

ERP for food manufacturing helps monitor and optimize resource inputs like feed, water, energy based on real-time need, reducing waste at every stage. You avoid overfeeding, control irrigation, and track electricity use in processing units.

End-to-End Supply Chain Visibility

From livestock rearing to cold chain logistics, the supply chain management software connects all the dots. You gain full meat traceability of emissions, energy use, and inventory spoilage.

Want to know which route burns more fuel? Or which facility has high carbon output? An ERP tells you it all.

Automated Waste Management and Reporting

Smart ERP platforms help log waste generation, auto-flag thresholds, and integrate with composting or recycling workflows. Built-in reporting tools generate sustainability and compliance reports at the click of a button.

Compliance Management

Navigating evolving regulations becomes far easier with a dedicated compliance management software that centralizes certifications, documentation, and audit readiness.

Whether it’s carbon disclosure requirements or food safety certifications, an ERP ensures you stay audit-ready. It standardizes documentation, sets up alerts for non-compliance, and helps meet regional and global environmental standards.

Does it Make Meat Production Eco-friendly?

Lowers Carbon Footprint

An ERP helps track emissions across the supply chain. You can monitor transport, processing, and energy use in real time. It alerts you when fuel or electricity consumption spikes. That way, you can act fast and reduce waste. Over time, you build a clear picture of your carbon output. You can set reduction goals and track progress. This isn’t just about saving the planet. It’s about staying ahead of regulations and proving your sustainability efforts with real data.

Reduces Food Waste

With better forecasting and real-time quality checks, ERP helps cut spoilage. Cold chain monitoring tracks temperature shifts instantly. If something goes wrong in transit, you know right away. Features like FEFO and expiry alerts make sure older stock moves out first. You avoid overstocking, understocking, and costly recalls. This improves profit margins and product quality. Less waste, more efficiency. That’s good for business and the environment.

Better Brand Perception

Consumers care about sustainability. They want proof, not promises. ERP systems make that easy. You can show where your meat came from, how it was processed, and how much energy it used. QR codes on packaging let customers track the journey. This builds trust. It also opens doors to retailers who demand transparency from suppliers. Being green improves your image and puts you ahead of the competition.

Cost Savings

ERP helps you spot where money is being wasted. It tracks feed use, water, energy, and labor. Forecasting tools let you produce only what’s needed. You save on raw materials and avoid overproduction. Smarter routes mean less fuel used. Automated scheduling saves hours in manual work. These small wins add up. You cut costs while running a leaner, greener operation.

How Folio3 FoodTech Is Helping Meat Production Go Green

At Folio3 FoodTech, we’ve built a specialized ERP for the meat industry that actively supports meat production by minimizing the environmental footprint while boosting operational efficiency.

Here’s how our key features contribute to greener practices:

- Shelf-Life-Based picking (FEFO) and batch expiry notifications prevent unnecessary spoilage.

- Dynamic production scheduling and demand forecasting with historical data minimize overproduction.

- Real-Time inventory monitoring and automated replenishment optimize resource use.

- Integrated weighing scale, order allocation by weight range, and catch weight management functionality support precise, waste-free packing.

- Yield analysis, dynamic label printing, and weight-based costing ensure output efficiency.

- Byproduct tracking, revenue tracking, and waste disposal logs promote circular practices and transparency.

- Production waste threshold alerts and real-time waste analytics enable proactive waste control.

- Carbon footprint monitoring gives visibility into environmental impact at every stage.

- Temperature monitoring during transit, delivery scheduling, optimized route planning, and real-time Shipment tracking reduce fuel consumption and ensure cold chain integrity.

- Automated proof of delivery, dynamic carrier selection, and end-to-end lot tracking add logistical control.

- Compliance-ready reports, recall management, supply chain visibility, and consumer-facing QR codes build trust and accountability.

Bring Order to Your Food Business with Food ERP

Connect your production, inventory, and sales,

and finally get the control you’ve been missing.

Talk to an ERP Specialist

Case Study – How Hanor Farms Enhanced Operational Speed and Output for Sustainability

Hanor Farms farm workers relied on paper and struggled with communication. Tasks were often missed. Managers rotated frequently, making task handovers chaotic. Language barriers made things worse. Most workers spoke Spanish, but instructions were only in English.

Our solution changed that. We automated task management. Managers could now create task templates and schedule them in advance. Assignments became consistent, even when supervisors changed.

We also added multilingual support. Tasks could be created in English but viewed in Spanish. This helped every worker understand what needed to be done. Communication improved immediately.

The system worked across mobile, tablet, and desktop. It even worked offline. That meant teams in the field stayed productive, no matter where they were.

Reviewing task history became easy. Managers had visibility into what was done, when, and by whom. No more chasing paper trails or second-guessing work status.

The results?

Task completion rates went up. Missed assignments dropped significantly. Workers were more confident and clear about their roles.

Supervisors reported smoother rotations. Incoming managers picked up where the last left off. No manual updates needed.

Quality control improved. Scheduled inspections were completed on time. Compliance violations decreased.

Even productivity saw a boost. The teams finished tasks faster, with fewer errors. Offline access helped field teams stay on track in remote areas. Most importantly, the company gained a system that scaled. As operations expanded, the digital workflow kept up. No extra paperwork. No added confusion.

Hanor Farms now runs leaner, smarter, and greener. Their story proves a key point. Digital tools don’t just streamline operations. They make sustainability possible.

Conclusion

As global demand continues to rise, the future of meat production hinges on more sustainable, data-driven practices. The environmental impact of meat production from methane emissions and water waste to land degradation can no longer be ignored. But technology, especially ERP solutions built for the food industry, is proving to be a game-changer. By enhancing transparency, reducing resource waste, and automating compliance, businesses can tackle the tough question: how does meat production affect the environment and what can be done to change that. At Folio3 FoodTech, we believe sustainability and profitability can go hand in hand. The meat industry’s impact on the environment is real, but with the right systems in place, it’s also reversible.

FAQs

How Does Meat Production Affect The Environment?

Meat production contributes heavily to greenhouse gas emissions, deforestation, water usage, and pollution. Livestock farming also leads to biodiversity loss and soil degradation through overgrazing and feed crop cultivation.

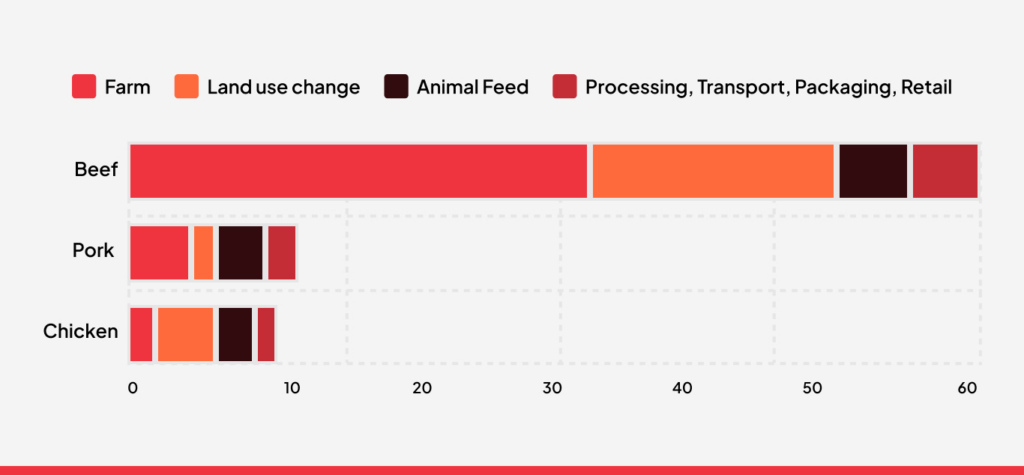

Which Meat Has The Biggest Environmental Impact?

Beef has the highest environmental footprint due to methane emissions from cattle digestion, land use for grazing, and deforestation for soy feed. It uses more water and energy than any other type of meat.

What Is The Biggest Problem In The Meat Industry?

The biggest issue is the environmental inefficiencies like high emissions, water waste, and poor waste management. Disconnected supply chains and lack of automation worsen the impact and make sustainability harder to achieve.