Meat processing is the backbone of the modern food supply chain. It transforms raw livestock into safe, consumable, and market-ready products that stock our shelves and fuel global consumption. From the burger patties in fast food joints to packaged sausages in grocery stores, processed meat touches nearly every aspect of the modern diet.

The demand for processed meat continues to grow and fast. According to recent market data, the processed meat market was valued at USD 318.2 billion in 2024 and is projected to reach USD 429.1 billion by 2029, rising at a compound annual growth rate (CAGR) of 5%. This surge underscores not just consumer appetite but the need for efficient, scalable, and hygienic meat processing systems.

In this blog, we’ll break down what meat processing really means, explore the step-by-step operations inside modern meat factories, and examine how technology is simplifying the industry from slaughter to shipment. Whether you’re new to the field or looking to optimize your operations, this blog will help you understand how meat processing facilities work and why they matter.

What Is Meat Processing?

At its core, meat processing refers to the entire set of techniques used to convert raw animal meat into consumable products that meet safety, quality, and consumer standards. It is a structured sequence of steps that ensures meat is handled in a hygienic, efficient, and scalable manner from the moment of slaughter to its final packaged form. While the process may vary depending on species and product type, the underlying goal remains the same: to produce safe, shelf-stable, and market-ready meat.

If you’ve ever purchased a pack of sausages, ground beef, deli cuts, or marinated chicken breasts, you’ve encountered the result of meat processing. It is not limited to just cutting meat into smaller pieces. It includes curing, grinding, seasoning, packaging, and in some cases, cooking or smoking. The scope of what meat processing is, goes far beyond the factory floor. It is part of a global industry that bridges the gap between livestock production and consumer demand.

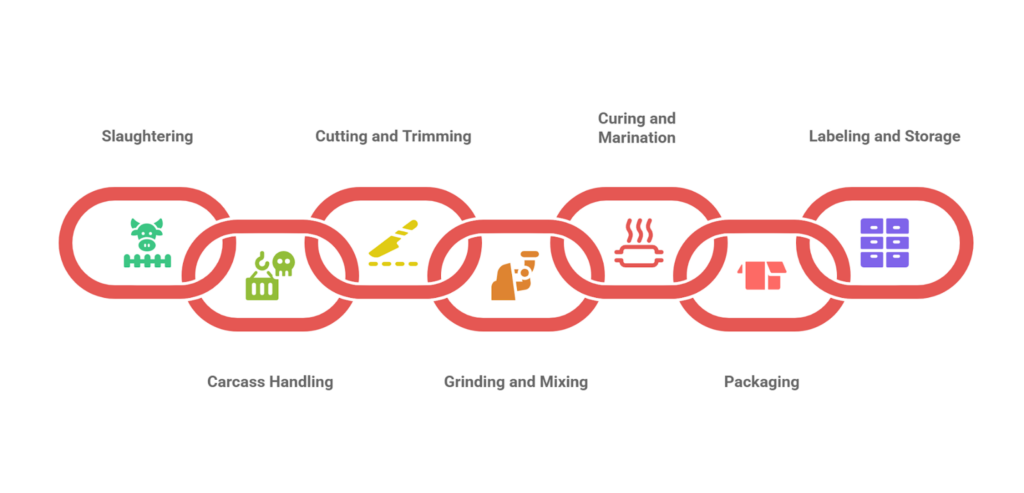

The Typical Steps in Meat Processing

Slaughtering

Humane and regulated slaughter of livestock, ensuring minimal stress and adherence to food safety protocols for meat processing plants.

Carcass Handling

Removal of internal organs, inspection, washing, and chilling to reduce microbial risk

Cutting and Trimming

Breaking down carcasses into primal cuts and removing bones or excess fat

Grinding and Mixing

Especially for products like burgers and sausages, where meat is ground and blended with seasonings or additives

Curing and Marination

Adding salts, nitrates, or spices to enhance flavor, texture for preservation

Packaging

Vacuum sealing, modified atmosphere packaging (MAP), or skin packaging to extend shelf life

Labeling and Storage

Compliance with food safety regulations, traceability tagging, temperature-controlled units for meat preservation and storage.

These steps form the backbone of modern meat supply chains and are critical for maintaining quality across all distribution points, from supermarkets to restaurants. Understanding what meat processing is helps us see the hidden infrastructure that ensures the meat we consume is not only flavorful and fresh, but also safe and compliant with health standards.

Processed meat products are incredibly diverse and can be grouped into a few common categories:

- Fresh-Cut Products: Pre-portioned steaks, fillets, or poultry cuts

- Ground and Minced Meats: Beef, pork, or poultry ground for retail or bulk sale

- Cured and Smoked Meats: Bacon, hams, salami, and jerky products

- Ready-to-Cook Items: Pre-seasoned or marinated meats, burger patties, meatballs, or skewers

- Fully Cooked and Sliced Deli Meats: Used in sandwiches and cold platters

Meat processing adds value to raw meat, extends its shelf life, improves food safety, and offers a wider range of products to meet different culinary needs. It is both an industrial operation and a public health responsibility, making it one of the most important systems in the global food economy.

Types of Meat Processing

Meat processing is not a one-size-fits-all operation. It covers a range of methods tailored to different products, food safety standards, and consumer preferences. Each type of meat processing plays a unique role in shaping how meat is prepared, preserved, and packaged.

Primary Meat Processing

Primary meat processing begins with the slaughter of livestock. This is where raw animals are converted into carcasses for further handling. It includes stunning, bleeding, skinning or dehairing, evisceration, and chilling. This step is critical for ensuring meat is safe for human consumption. Hygiene, temperatures, and animal welfare are strictly monitored. It forms the base of all industrial meat processing operations.

Secondary Meat Processing

In secondary processing, carcasses are broken down into usable cuts and forms. This includes cutting, deboning, grinding, mincing, and slicing. Secondary processing turns whole carcasses into retail-ready portions like steaks, chops, or ground meat. For many factories, this is the phase where efficiency and yield make a direct impact on profitability. It also sets the stage for packaging and food distribution.

Value-Added Meat Processing

This stage includes transforming raw or minimally processed meat into products with added flavor, texture, or shelf life. Curing, marinating, smoking, and cooking are all part of this phase. Sausages, hot dogs, bacon, deli meats, and pre-seasoned cuts fall under this category. Value-added meat processing increases product variety, market appeal, and margins.

Each type of meat processing serves a different purpose in the supply chain. Primary processing ensures food safety and carcass quality. Secondary processing turns raw meat into familiar cuts. Value-added processing delivers convenience and consumer-ready options. Together, these categories drive the output of every meat processing factory and allow producers to meet diverse market demands.

Inside a Meat Processing Plant

A modern meat processing plant is a highly organized environment where hygiene, speed, and precision are non-negotiable. These facilities are designed to turn raw livestock into finished products while maintaining strict safety and quality standards. Each section of a plant is built for efficiency and separation of tasks to minimize cross-contamination.

Key Operational Zones

A typical meat processing plant is divided into zones, each serving a specific part of the workflow. The main sections include:

- Receiving Area

This is where live animals arrive. Livestock are handled carefully to reduce stress, which directly impacts meat quality.

- Slaughtering and Evisceration

Once animals are inspected and approved, slaughter takes place under regulated, humane procedures. Carcasses are then cleaned and chilled.

- Cutting and Deboning Room

This is where carcasses are broken down into primal and retail cuts. Skilled butchers or automated machines handle this process depending on the scale of the operation.

- Processing and Packaging Area

Products are seasoned, cured, or cooked here depending on requirements. After processing, meat is vacuum-sealed or packaged for distribution.

- Storage and Dispatch

Finished goods are stored in chilled or frozen environments before being loaded for delivery.

Each zone is separated and often color-coded to prevent cross contamination. Workers follow specific hygiene protocols when moving between zones.

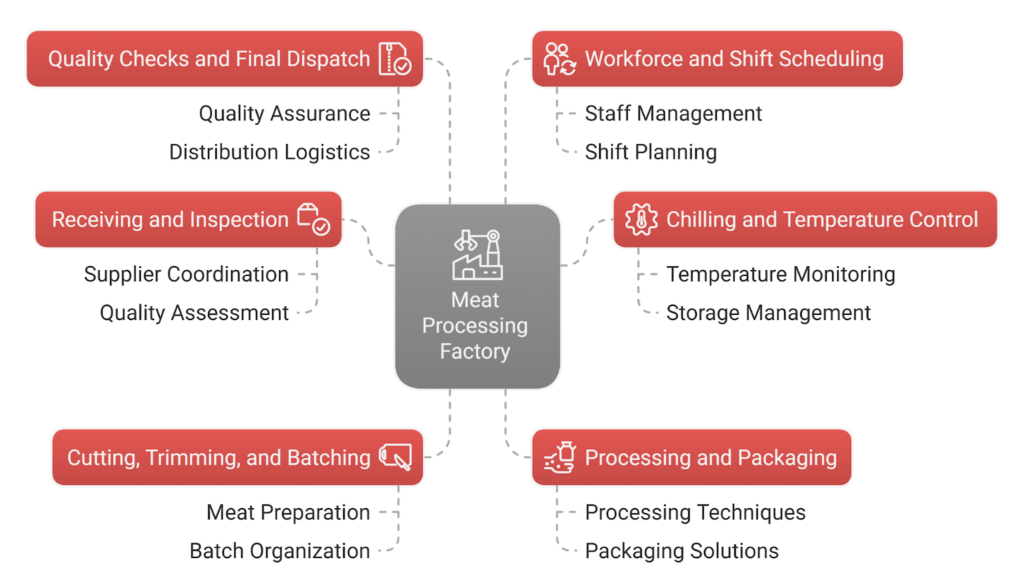

How a Meat Processing Factory Operates Daily

Running a meat processing factory is a continuous, time-sensitive operation that requires precision at every step. Each day follows a tightly managed schedule, balancing productivity, safety, and quality. The process begins early and unfolds in carefully orchestrated stages to ensure the delivery of high-quality meat products.

Receiving and Inspection of Raw Material

Every day begins with the arrival of raw meat or live animals, depending on the factory’s setup. In facilities that handle slaughter, animals are inspected by veterinary staff to ensure they meet safety and health standards. For factories that process pre-slaughtered meat, incoming shipments are checked for temperature, packaging integrity, and documentation. Any deviation can result in immediate rejection.

Chilling and Temperature Control

Time is critical once raw meat enters the factory. It must be transferred quickly into chilled storage rooms to prevent bacterial growth. Industrial chillers reduce the internal temperature of carcasses or meat cuts to safe levels. These chilled environments are monitored closely using digital thermometers and sensors, ensuring no breaks occur in the cold chain.

Cutting, Trimming, and Batching

Once the meat is cooled, it moves to the processing floor. Skilled workers or automated machines trim fat, separate cuts, and portion meat according to orders. Batching is a key part of this stage. Meat is grouped by product type, weight, or destination to enable batch management with ease. For example, a batch may consist of ground beef for burger patties or pork loin for curing.

Precision is crucial here. Even small errors in portioning can affect profitability, quality, or customer satisfaction. Digital scales and portioning systems help standardize this step.

Processing and Packaging

Depending on the product line, meat may go through marination, curing, grinding, or cooking. These stages are conducted in temperature-controlled zones using stainless steel equipment for hygiene. Once processed, products are packed in vacuum-sealed or modified-atmosphere meat packaging techniques to extend shelf life. Labeling is also done at this stage. Labels include critical information like batch numbers, expiration dates, and traceability codes. Automated labelers ensure speed and accuracy across thousands of units per day.

Quality Checks and Final Dispatch

Before products leave the facility, they pass through a series of inspections. Quality assurance teams check for color, texture, weight, and label accuracy. Random microbiological sampling is also done to ensure safety compliance. Once cleared, the packaged meat is moved to dispatch coolers. Logistics teams then organize orders for shipping based on destination and storage requirements. Trucks are pre-cooled, and inventory data is updated to reflect stock movement.

Workforce and Shift Scheduling

Meat processing factories usually run in shifts to keep up with demand. Staff are assigned based on production needs, regulatory limits, and rest requirements. Schedulers coordinate cleaning shifts, maintenance windows, and peak production hours to avoid downtime. In larger factories, digital scheduling systems help automate these tasks to prevent human error.

This daily rhythm keeps a meat processing factory running efficiently while ensuring the end product meets safety and quality expectations. Let me know when you’re ready to continue with the next section: Challenges Faced by Industrial Meat Processing Facilities.

Challenges Faced by In Daily Operations

Running an industrial meat processing facility comes with a unique set of operational, regulatory, and environmental challenges. While automation and modern tools have streamlined many parts of the process, there are still persistent obstacles that plants must manage daily to remain competitive and compliant.

Ensuring Food Safety and Hygiene

Hygiene is the most critical aspect of any meat processing operation. Contamination risks exist at every stage, from handling raw meat to packaging finished products. Facilities must follow strict sanitary protocols such as regular equipment sanitization, use of personal protective equipment, and routine microbial testing. Even a minor lapse can lead to widespread recalls or public health incidents.

Temperature and Spoilage Control

Maintaining cold chain integrity is non-negotiable in meat processing. A few degrees above the recommended holding temperature can trigger bacterial growth, spoilage, and huge financial loss. However, constant refrigeration across multiple zones and transport stages adds to operational costs and infrastructure strain. Many facilities now rely on digital sensors and real-time alerts to reduce the risk of breakdowns, but system failures or human oversight can still lead to serious disruptions.

Labor Shortages and Workforce Training

Meat processing is labor-intensive, especially in tasks like cutting, inspection, cleaning, and packaging. The industry frequently faces shortages of trained staff due to the physically demanding nature of the job. High employee turnover adds pressure on HR and operations teams to continuously recruit, train, and manage workers. Inexperienced staff can lead to inefficiencies and safety hazards on the line.

Supply Chain Disruptions

Global supply chains for meat are sensitive to delays caused by transportation issues, feed shortages, or livestock availability. Even a small delay in receiving raw material can disrupt the factory’s entire production schedule. For export-focused factories, changing international regulations and certification requirements create further complications. These disruptions affect delivery timelines, cost structures, and customer trust.

Waste Management and Environmental Compliance

Meat processing generates significant waste like blood, bones, fat, and packaging materials. Managing this waste in a sustainable and compliant manner is a growing challenge as the impact of meat production on the environment is an alert globally. Facilities must adhere to local environmental guidelines for waste disposal, wastewater treatment, and emissions control. Many plants are investing in circular systems to reuse or convert waste, but the costs of compliance remain high.

These challenges reflect the complexity of industrial meat processing operations. Each issue requires not just manpower and vigilance but also smart systems to mitigate risk and maintain productivity. We’ll now look at how technology is helping solve many of these problems inside modern plants.

How Folio3 FoodTech Helps Solve These Challenges in Meat Processing

Industrial meat processing facilities face a range of complex challenges, including strict hygiene requirements, precise temperature control, labor constraints, and supply chain vulnerabilities. According to insights shared by our meat industry consultants, these operational issues are best addressed through a unified, digital approach. By centralizing data, automating key processes, and improving real-time visibility, such systems help processors manage operations more efficiently and stay compliant with evolving industry standards.

Here are few features from the Folio3 FoodTech’s meat processing solution that enable smoother operations:

- Meat Traceability: Track each batch from origin to final product, ensuring transparency and faster response in case of recalls or audits by enabling food traceability.

- Predictive Maintenance and Scheduling: Prevent costly downtime by anticipating equipment failures and scheduling timely maintenance.

- Labor and Resource Optimization: Assign staff more efficiently based on skill, shift patterns, and production needs, improving overall plant productivity.

- Automated Quality Control: Enforce consistent quality checks across batches without manual intervention, reducing human error and compliance risks.

- Real-Time Inventory Tracking: Know exactly what you have, where it is, and when it expires with live inventory dashboards.

- Integrated Production Analytics: Gain insights into yields, process efficiency, and bottlenecks to make smarter operational decisions.

- Optimized Logistics and Routing: Plan the fastest and most efficient delivery paths, lowering transport costs and reducing spoilage risk within the cold chain logistics.

Conclusion

Meat processing is a structured system that ensures safe, high-quality products reach consumers efficiently. From primary butchering to advanced packaging, every stage in modern meat processing plants requires careful coordination, hygiene, and consistency.

As the industry grows, the role of technology becomes increasingly critical. Digital tools help streamline operations, improve traceability, and support regulatory compliance. Platforms like Folio3 FoodTech’s Meat ERP enable processors to overcome operational challenges with greater control and efficiency.

FAQs

What Are The Examples Of Meat Processing?

Examples of meat processing include activities that transform raw meat into products that are ready for sale or consumption. This includes cutting, trimming, grinding, marinating, curing, smoking, and packaging. Common processed meat products are sausages, bacon, ham, deli meats, meat patties, and jerky.

Is A Meat Processing Plant A Slaughterhouse?

Not always. A meat processing plant may include slaughtering as part of its operation, but many focus solely on further processing after slaughter, such as deboning, portioning, or packaging. Slaughterhouses are typically facilities where animals are killed for meat, while processing plants may handle the next stages in the supply chain.

What’s The Difference Between A Butcher And A Meat Processor?

A butcher usually works on a smaller scale, preparing fresh cuts of meat for direct sale to consumers, often in retail settings. A meat processor, on the other hand, works in industrial settings and may be involved in larger-scale operations like producing packaged meats, ground products, or cured items for wholesale or distribution.

What Are The Four Types Of Meat Processing?

The four types of meat processing are typically categorized as:

1- Primary Processing: Slaughtering and carcass handling

2- Secondary Processing: Cutting, deboning, and mincing

3- Value-Added Processing: Marination, curing, smoking, or making ready-to-eat products

4- Packaging and Preservation: Vacuum sealing, freezing, or applying modified atmosphere packaging to extend shelf life