Connect your entire supply chain, from ingredient sourcing to packaging, with an all-in-one beverage ERP. Use data-driven insights to maintain quality & consistency across every ready-to-drink product.

Unexpected disruptions, such as ingredient shortages or seasonal fluctuations, can delay bottling workflows. A complete beverage ERP software can help keep your operations running smoothly.

Sourcing ingredients like flavor extracts, preservatives, or sweeteners that are adulterated can compromise product quality and lead to safety concerns.

Variations in raw materials, such as fruit concentrates, can result in flavor inconsistencies across batches and dampen consumer trust.

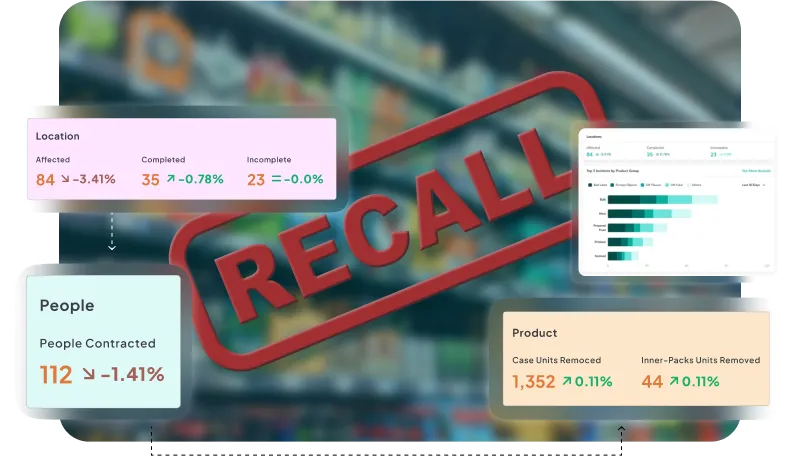

Incomplete information about allergens, ingredient sourcing, and nutritional content can lead to mislabeling, which can risk food recalls and legal consequences.

The inability to source fresh produce, such as seasonal fruits, during off-seasons can lead to inconsistent flavor profiles in ready-to-drink beverages.

A slight delay in delivery schedules of finished beverages or bottled drinks can lead to product spoilage, expiration of shelf life, and increased wastage.

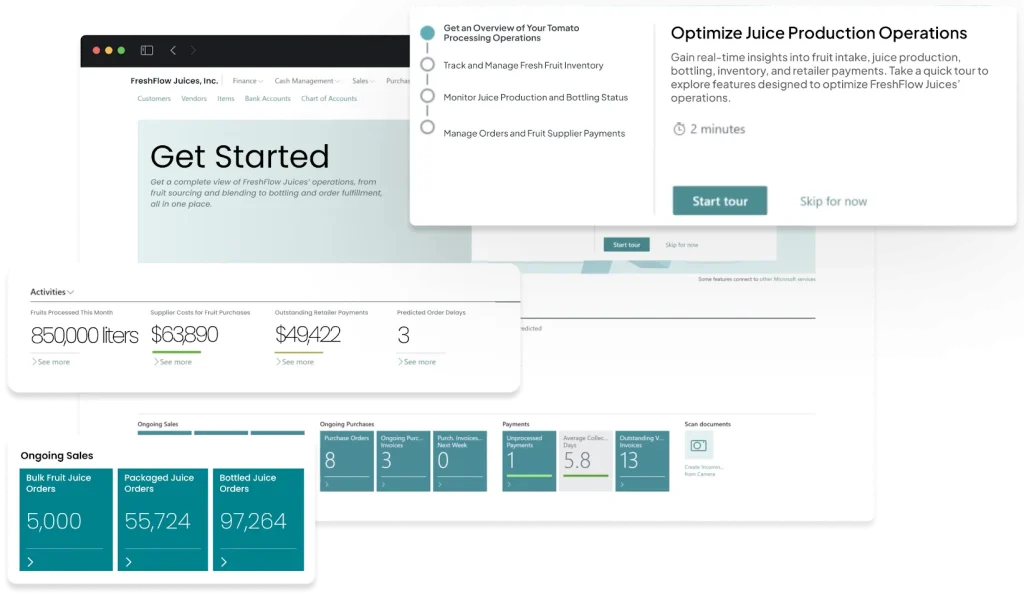

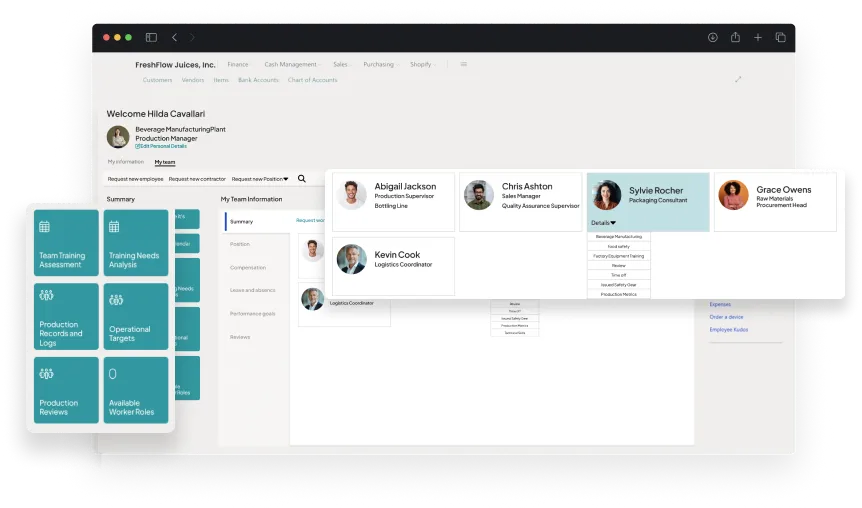

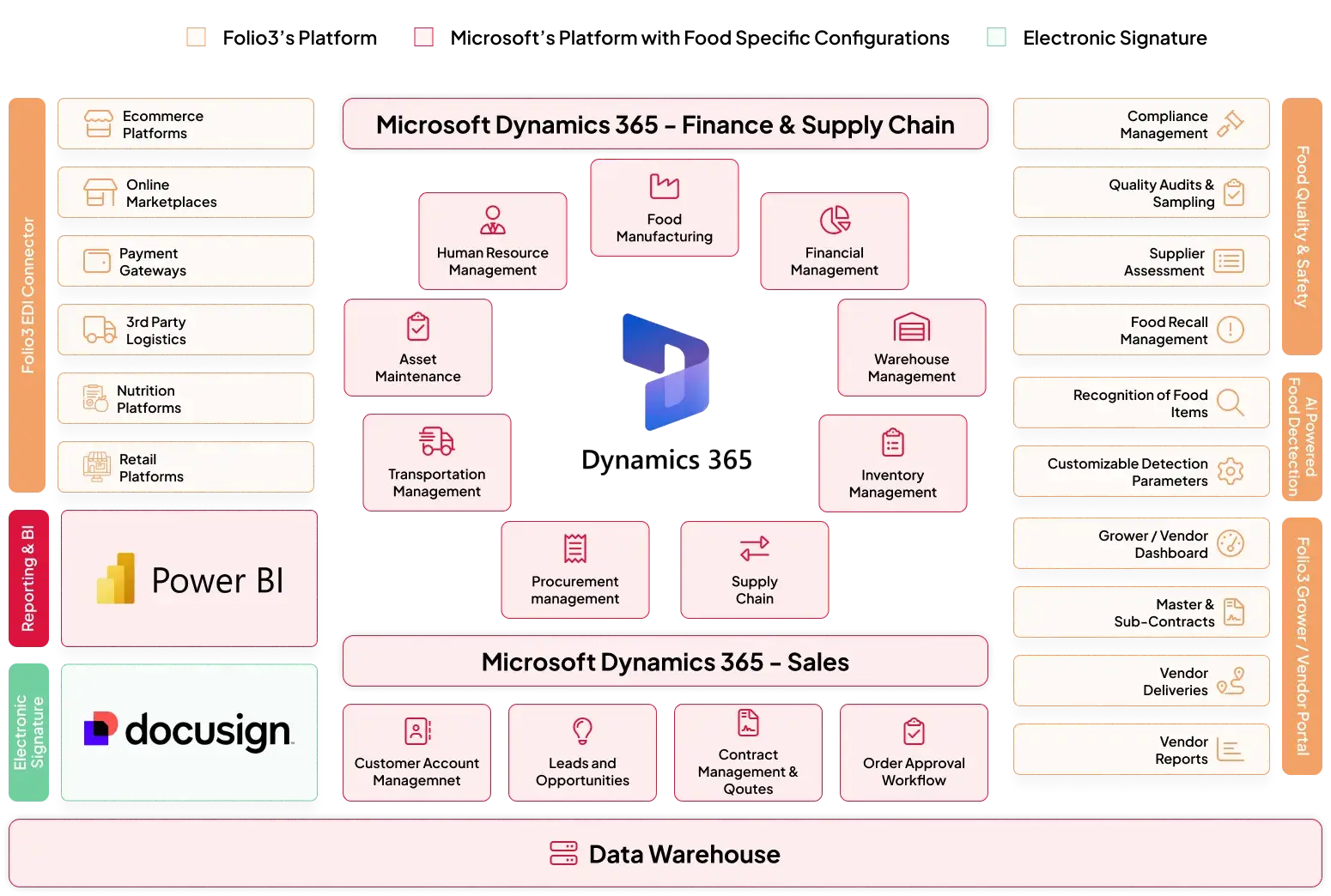

Oversee every production phase, whether it is sourcing raw ingredients or tracking shelf-ready drinks with beverage ERP software built to optimize your business operations.

Whether you're formulating juices, bottling sodas, managing a coffee shop, or overseeing distribution, our ERP system is designed to manage your unique processes efficiently.

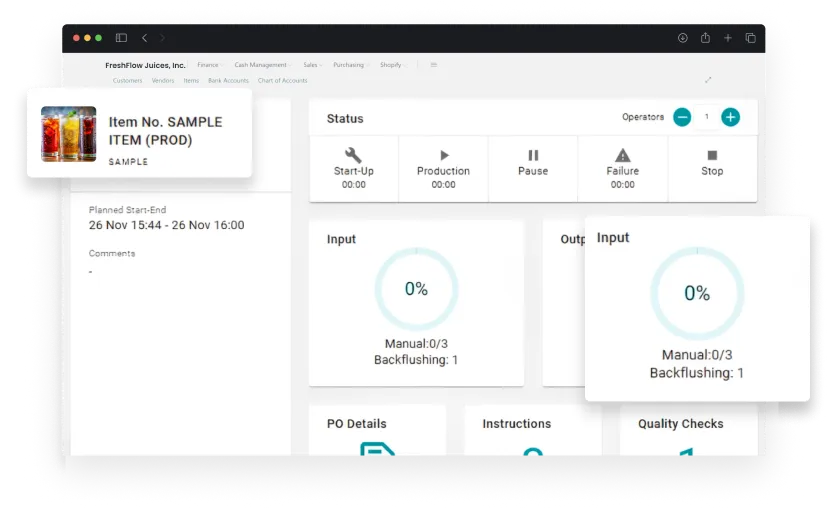

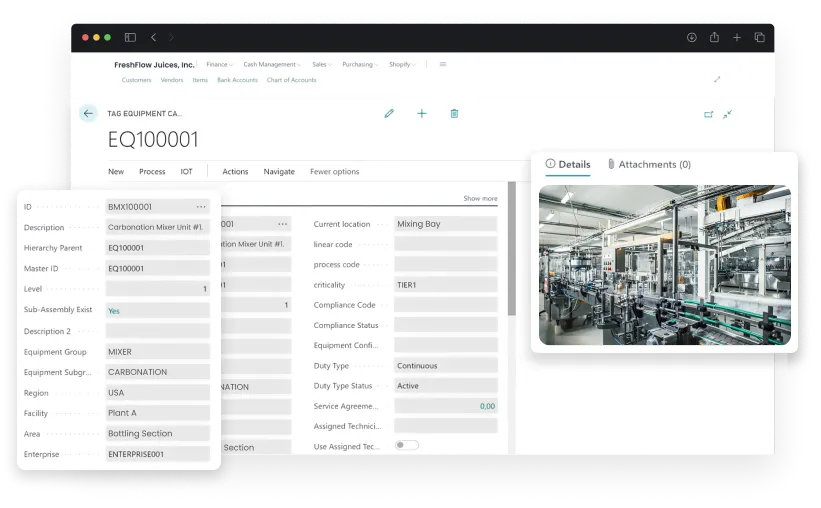

Ensure ingredient traceability, batch consistency, and timely production scheduling with ERP. Manage formulation changes, monitor carbonation levels, and control production costs to deliver high-quality beverages (soft drinks, coffee, tea, juices, etc) at scale.

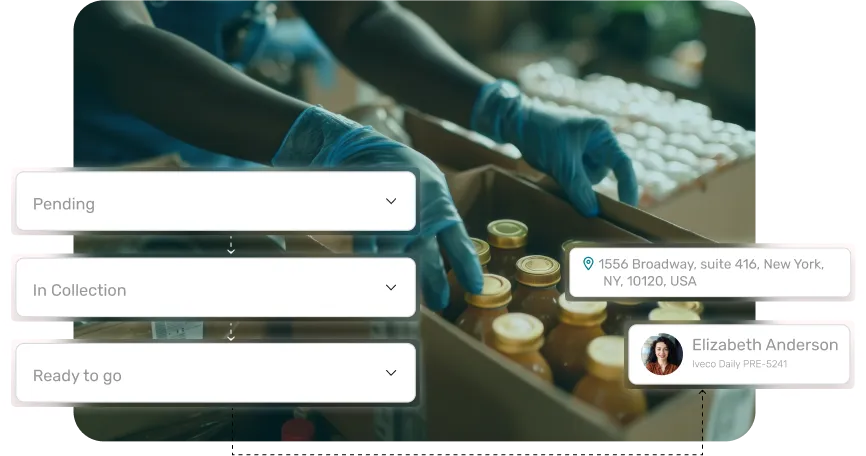

Use ERP to optimize production planning for packaging materials, manage inventory levels for bottles, cans, and labels, and track orders in real time. With ERP, companies can monitor supply chain efficiency, reduce overstocking, and ensure compliance with environmental regulations.

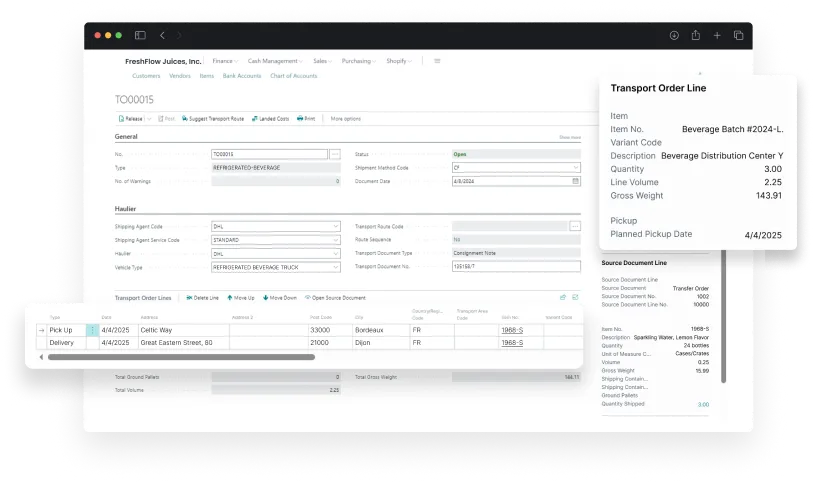

Manage diverse product types (carbonated, refrigerated, shelf-stable) across varying temperature conditions and optimize delivery routes for beverages. Use ERP to track inventory across multiple temperature zones, automate order processing for quick restocking, and maintain labeling compliance.

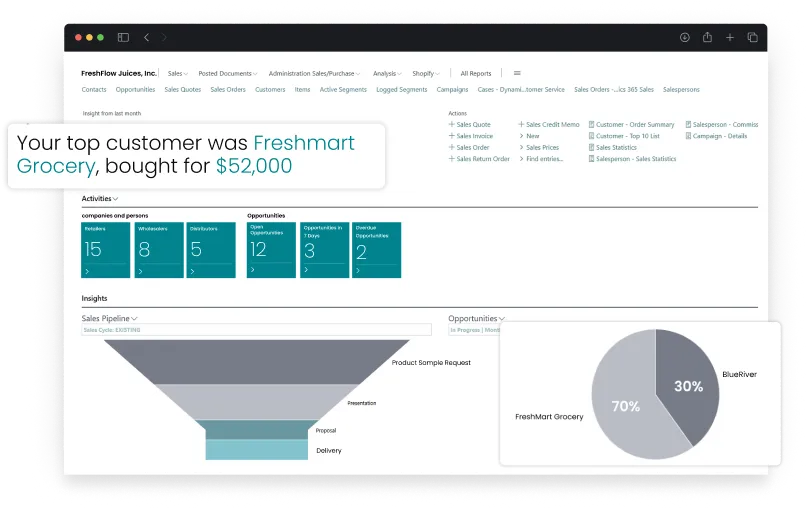

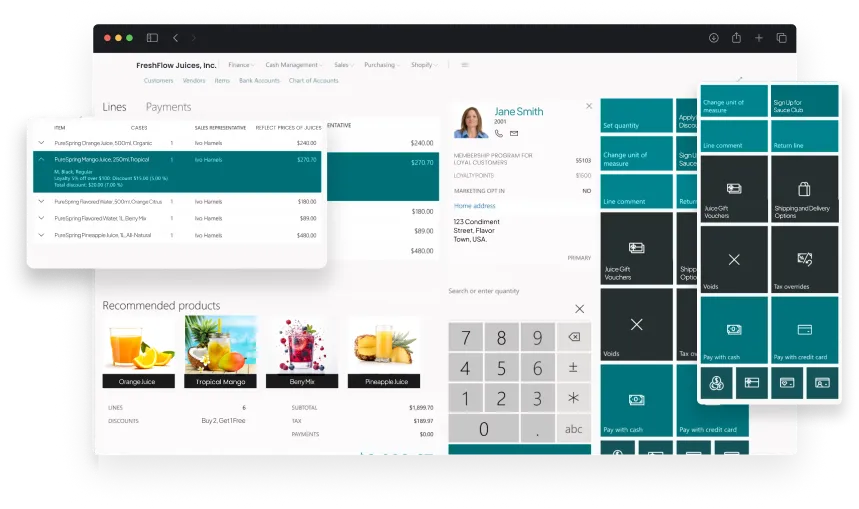

Integrate POS, track inventory, and manage customer preferences seamlessly. ERP ensures popular beverages are always in stock, reduces waste from excess inventory, and helps manage ordering processes for better customer service, whether you're running a coffee shop, juice bar, or online store.

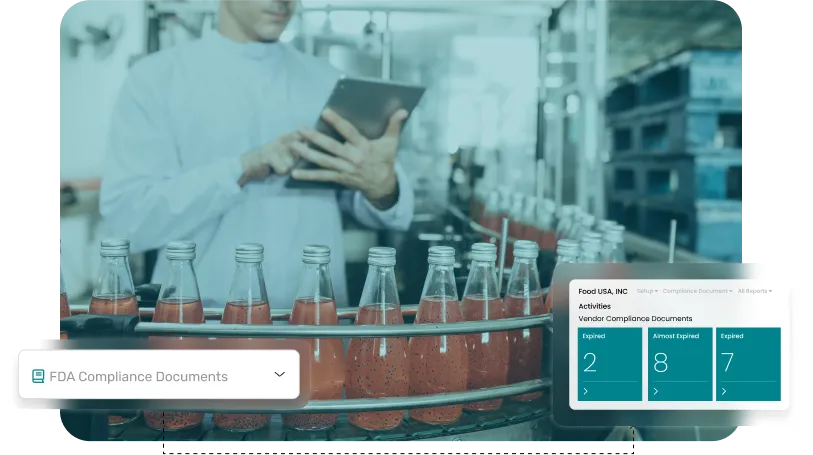

Follow the highest food safety practices in compliance with FDA standards across your beverage manufacturing operations.

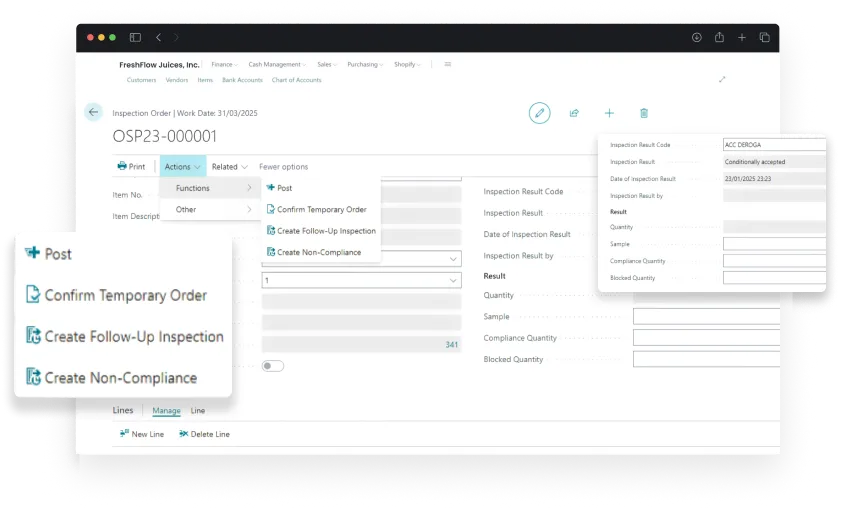

Implement lot tracking for full traceability, adhering to regulatory requirements for labeling, allergen information, and environmental safety.

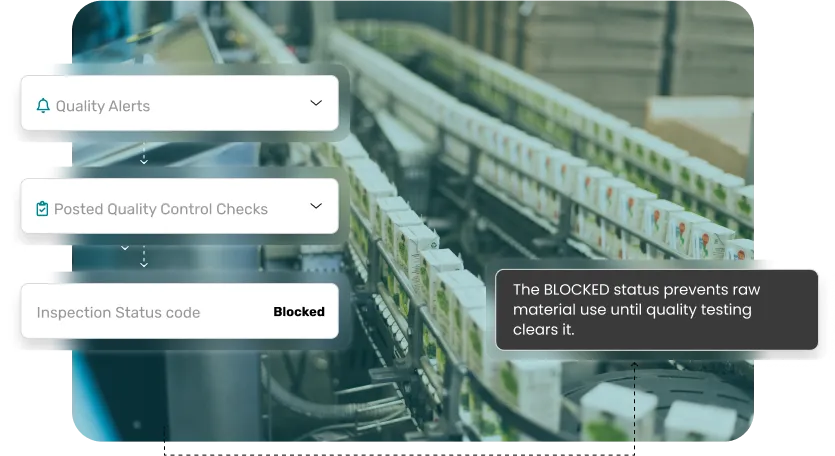

Maintain quality control from ingredient inspection (e.g., Brix levels in syrups) to production processes like pasteurization and carbonation.

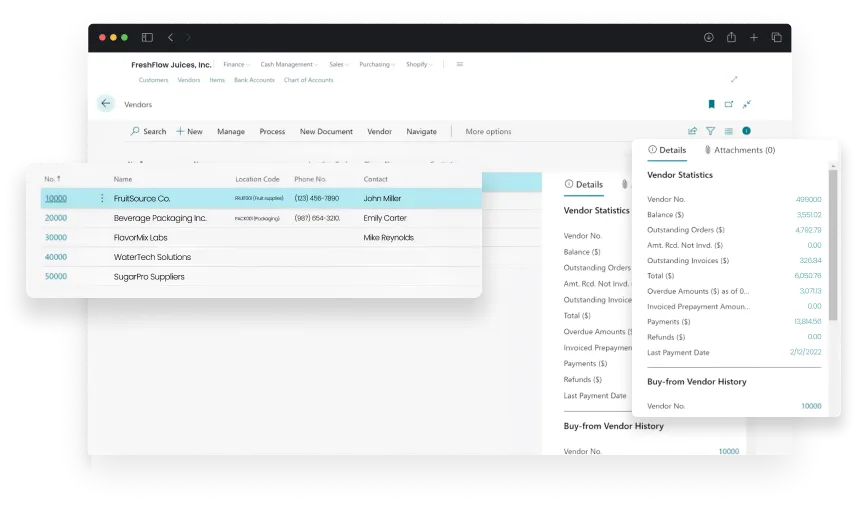

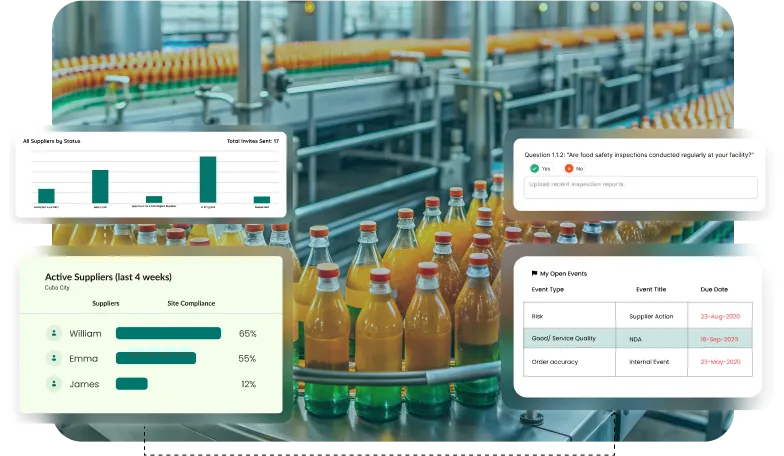

Simplify supplier collaboration by managing contracts, verifying raw material quality like flavor extracts and preservatives, and ensuring timely delivery of critical ingredients.

Identify and trace affected batches using lot and batch tracking to manage product recalls and ensure compliance with FDA recall protocols.

Don’t waste time switching between apps to track how your flavor batch is progressing, where your syrup stock is, or the orders placed for your best-selling drinks. Get all this data integrated within the beverage ERP system.

Our ERP implementation ensures seamless transition with minimal downtime and is designed to optimize your beverage business operations in a short period.

We understand your beverage manufacturing requirements to customize the ERP solution.

We develop a project plan focusing on industry-specific milestones and risk management.

We customize the ERP for your beverage production needs, from recipe formulation to supply chain management.

We rigorously test the system to ensure beverage quality management standards are met across all stages.

We seamlessly integrate ERP with your existing beverage manufacturing systems to ensure smooth operations.

We ensure secure and accurate migration of historical data critical to beverage manufacturing processes.

We guide you through the ERP launch to ensure a smooth transition without production disruptions.

We provide comprehensive training and ongoing support to ensure successful ERP adoption for your team.

Keep milk, cheese, and yogurt fresh with better inventory control, compliance tracking, and production planning.

Perfect every batch with smart recipe management, real-time tracking, and seamless regulatory compliance.

Never break the cold chain—optimize storage, logistics, and expiration tracking for frozen products.

Balance art and precision with automated recipe scaling, ingredient traceability, and shelf-life monitoring

Manage sugar processing, allergen control, and batch consistency for chocolates, candies, and sweets.

Handle large-scale snack production with real-time inventory, ingredient sourcing, and quality control.

Track every cut from slaughterhouse to store while ensuring food safety and compliance.

Control formulations, batch consistency, and allergens while optimizing production efficiency.

Watch how ADM Agriculture improved its processes and achieved grow using NetSuite SuiteSuccess.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

The best beverage ERP software is one that caters to the unique challenges of the beverage industry, including recipe management, batch traceability, and regulatory compliance with standards like the FDA and FSMA. It should optimize inventory management, handle expiration dates and cold storage, and manage supply chain operations. A good ERP also supports scalability and grows with your business, whether you’re producing beverages or managing a large-scale distribution network.

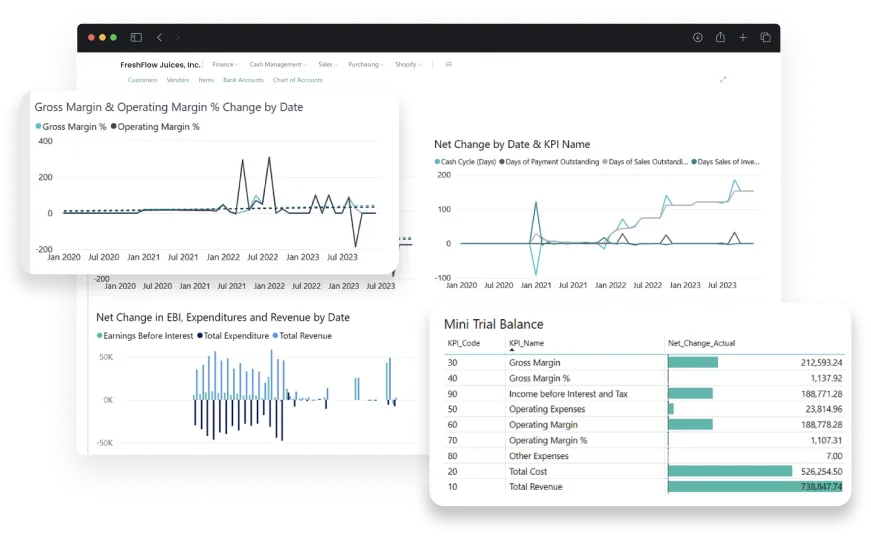

ERP enhances operational efficiency by offering custom tools to address industry-specific challenges. For instance, precise monitoring features in production processes like carbonation and blending manage consistency across batches. Real-time analytics help predict demand and align inventory with sales trends. Automated compliance tracking ensures all products meet regulatory standards, reducing the risk of penalties or recalls.

During ERP implementation beverage, companies should focus on aligning the system with their specific operational needs. Consider features like batch management, lot traceability, and compliance tracking to ensure adherence to industry regulations. Evaluate the system's ability to handle diverse formulations, monitor quality during production processes, and manage seasonal demand fluctuations. Integration with tools such as POS, supply chain software, or warehouse systems is crucial for a seamless transition.

Our ERP for beverage manufacturers is designed to scale seamlessly as your business grows. It adapts to increased production volumes, new product lines, and expanded distribution channels with flexible modules. As your needs evolve, the system can easily integrate with the latest technologies, manage more extensive data sets, and support multiple locations.

A cost-effective ERP implementation involves choosing a modular system to avoid unnecessary features. Opt for a cloud-based ERP to reduce upfront infrastructure costs and simplify scalability. Prioritize phased implementation, starting with critical processes like production and inventory, to minimize disruptions and spread costs over time. Invest in thorough staff training and use industry-specific templates to manage configuration and reduce customization expenses.

Yes, our ERP is designed to manage manufacturing and distribution processes smoothly. From production planning, batch tracking, and quality control in manufacturing to inventory management, order fulfillment, and logistics in distribution, our ERP offers end-to-end visibility and control. This ensures smoother workflows, better demand forecasting, and timely deliveries.

Custom ERP solutions for beverage companies like the one Folio3 provides can benefit by optimizing batch tracking for quality assurance, enabling real-time monitoring of production processes like filtration and pasteurization, and managing multi-location inventory precisely. ERP enhances shelf-life management, tracks nutrient and additive usage, and ensures accurate labeling for compliance. It also integrates seamlessly with equipment for bottling, canning, and labeling.

Beverage manufacturers face challenges like fluctuating ingredient availability, complicated production schedules, maintaining consistency across batches, and following strict industry regulations. These hurdles can lead to inefficiencies, inventory discrepancies, and compliance risks. Our ERP for beverage manufacturing addresses these pain points by providing real-time data integration, efficient recipe management, and automated compliance tracking.

ERP for beverage industry maintains quality control by integrating real-time monitoring and automating compliance processes like labeling and allergen management. These systems offer visibility across the entire production cycle, making it easier to manage product consistency and identify potential deviations. By facilitating full traceability, automated reporting for audits, and compliance with regulations like FDA, FSMA, and GFSI, an ERP provides a strong framework to ensure product safety and maintain industry-specific standards.