Automate hazard analysis, CCP identification, and create your audit-ready HACCP plan in minutes—no paperwork required. Simplify food safety compliance with innovative, user-friendly HACCP management software built for your unique processes.

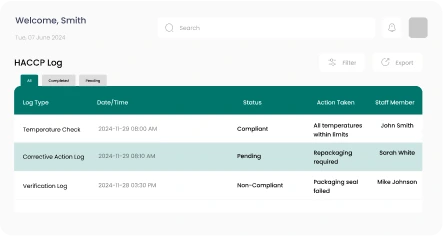

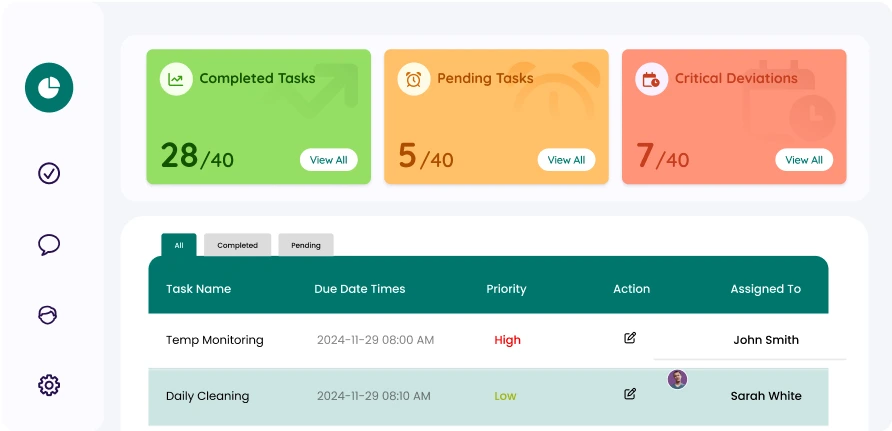

Simplify the complexities of HACCP implementation, from critical control point tracking to managing corrective actions, all while maintaining audit readiness.

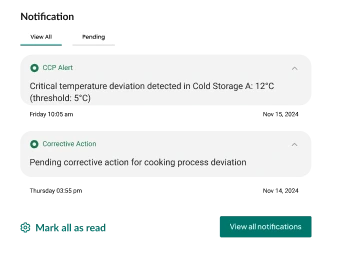

Struggling to spot hazards quickly can delay critical interventions, increasing the risk of quality issues and unsafe products reaching consumers.

Inflexible HACCP plans can create bottlenecks, leading to inefficiencies and difficulty adjusting to changing production lines or new food safety requirements.

Managing compliance across multiple sites can be time-consuming, leading to inconsistent practices and added pressure on staff to monitor procedures manually.

Decentralized records make tracking and updating information challenging, increasing the risk of errors, missed updates, and confusion when reviewing safety protocols.

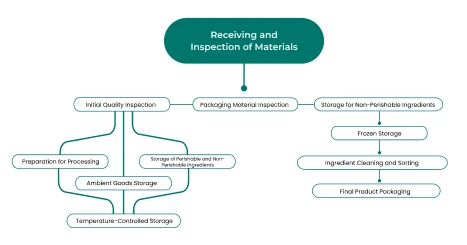

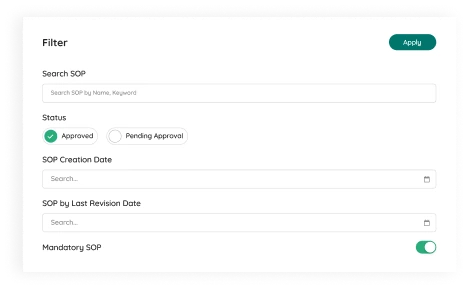

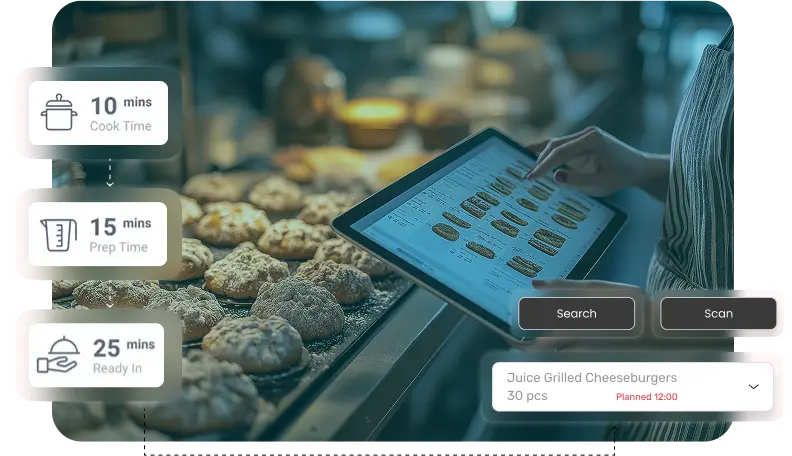

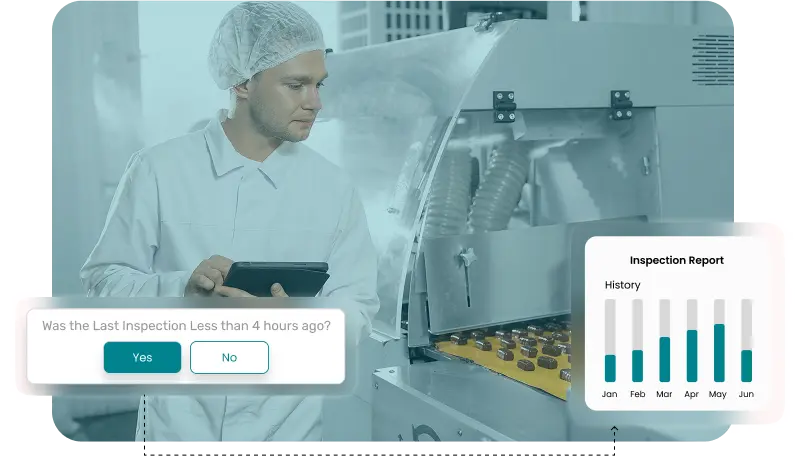

Easily create, monitor, and update your food safety plans with intuitive tools designed to simplify hazard analysis, process flow design, and compliance tracking.

Get full visibility and meet the standards and protocols of your HACCP plan effortlessly with HACCP Plan Software. Keep your food safety processes compliant from day one.

See how food businesses boost efficiency with solutions that simplify daily tasks!

Gain complete control over food safety by automating compliance, maintaining traceability, and managing risks across your entire supply chain.

Centralize compliance tracking with automated record-keeping, real-time alerts, and regulatory reporting for HACCP, FSMA, GFSI, and other food safety standards.

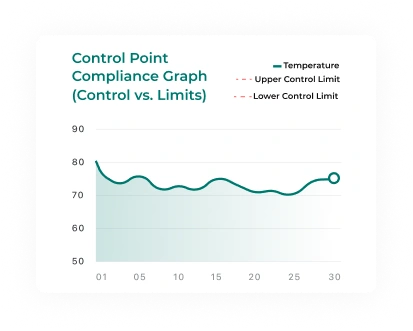

Enforce strict quality parameters with in-line inspections, automated deviation alerts, and real-time monitoring to prevent contamination and product defects.

Verify supplier credentials, monitor ingredient safety, and enforce quality requirements with digital supplier scorecards, audit logs, and compliance workflows.

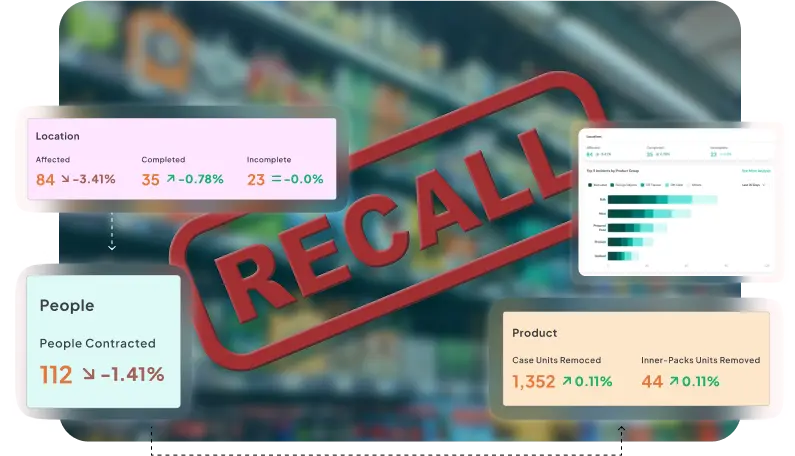

Rapidly identify contaminated batches, initiate recalls, and communicate with stakeholders using real-time traceability and automated recall execution tools.

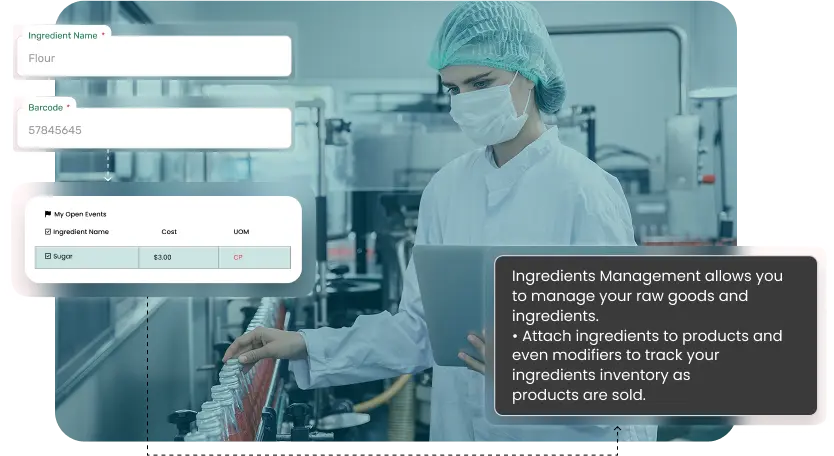

Manage ingredient specifications, allergen declarations, and formulation compliance with integrated tracking for nutritional and regulatory requirements.

Maintain formulation accuracy, control recipe revisions, and validate ingredient substitutions while ensuring regulatory compliance and labeling accuracy.

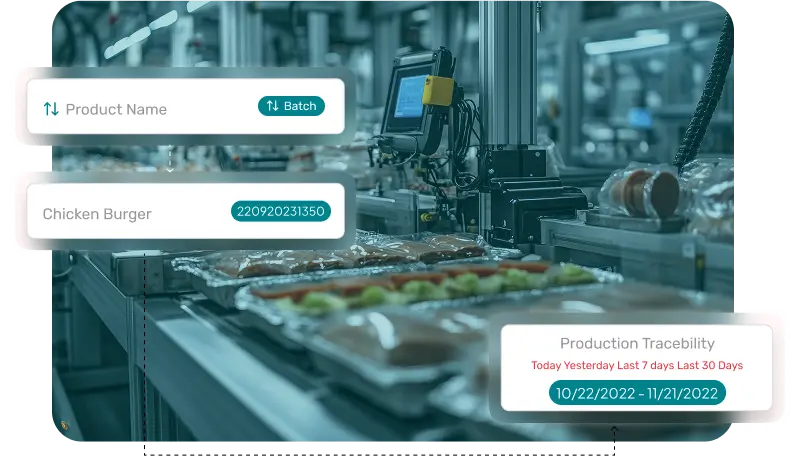

Achieve full visibility from raw material sourcing to finished product distribution with real-time tracking, batch history logs, and automated traceability reports.

Digitally manage audit records, supplier certifications, safety inspections, and compliance documentation with real-time access and automated reporting.

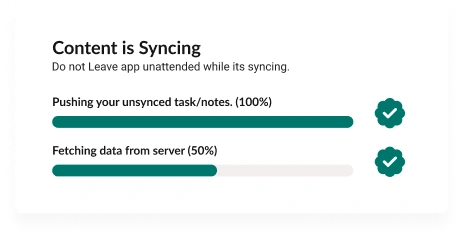

Integrate HACCP software with production systems to eliminate data silos, monitor food safety, and respond to issues in real-time.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

A HACCP system is a structured approach to identifying and managing food safety risks in food production processes. It involves analyzing potential biological, chemical, or physical hazards, determining Critical Control Points (CCPs) where risks can be controlled, and establishing preventive measures. By doing this, food companies ensure the products they manufacture are safe to consume.

HACCP certification is not universally mandatory, but it is essential for businesses involved in the production, processing, or handling of food, especially if they want to export or meet regulatory standards in certain markets. Many countries and regions, including the European Union, the United States, and Canada, require HACCP compliance for certain food sectors, such as meat, seafood, and dairy production.

Yes, many HACCP compliance software solutions include features for managing audit trails, tracking deviations, and generating reports necessary for certification and compliance audits.

Key features of HACCP software include:

HACCP plan software provides efficiency, accuracy, and real-time compliance monitoring. It reduces manual tasks, enhances traceability, and ensures that food safety practices are adhered to consistently across multiple facilities.

Folio3 FoodTech offers comprehensive HACCP food safety software with features such as hazard analysis, SOP automation, and compliance with HACCP standards. This robust food safety software streamlines processes for food manufacturers.

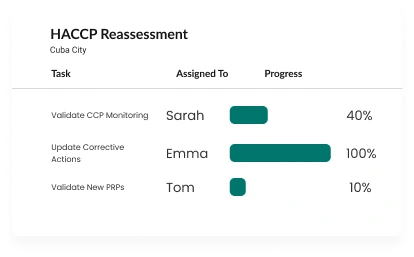

The 7 HACCP systems are key principles that guide hazard analysis and critical control point strategies. These include identifying hazards, establishing critical limits, monitoring procedures, corrective actions, verification, and record-keeping. Modern HACCP food safety software helps automate and simplify these processes.

To determine if your HACCP plan is working effectively, regularly monitor critical control points (CCPs) and evaluate if they remain within established limits. Usee internal audits, verify process compliance through tests (e.g., temperature checks, pH levels), and review corrective actions for incidents. Consistent documentation of these activities can provide transparency and accountability.

HACCP plans should be reviewed at least annually to make sure your facility is aligned with current regulations and operational practices. Regular reviews are essential when changes in processes, equipment, or ingredients occur, or after a food safety incident. Additionally, reviewing the plan after audits or external assessments will help identify areas of improvement.