Food safety and quality are non-negotiable in the food and beverage industry. With stringent regulations and growing consumer awareness, certifications have become essential for food manufacturers, processors, and quality assurance professionals.

Food and beverage certifications play crucial roles in every stage of the supply chain, from ensuring compliance with government regulations to reinforcing brand credibility. A 2024 survey by the International Food Information Council (IFIC) revealed that 79% of consumers consider whether a food product is processed when purchasing, indicating a significant concern for food quality and safety.

Regulatory bodies and industry organizations have developed various food and beverage certifications to maintain industry standards. These include global benchmarks like HACCP and ISO 22000 and sector-specific programs tailored for dairy, meat, and organic products.

For instance, in the meat industry, SQF (Safe Quality Food) and BRCGS certifications ensure compliance with international safety standards, while the dairy sector often requires adherence to standards like FSSC 22000. Companies that invest in these food and beverage industry certifications meet legal requirements and gain a competitive edge by fostering trust among consumers and business partners.

This guide will explore a comprehensive list of food and beverage certifications, their significance, and how they vary across different sectors. Whether navigating HACCP, VACCP, and TACCP distinctions or determining the best certification for your industry, this resource will help you make informed decisions that align with regulatory and market demands.

Understanding Food and Beverage Certifications

Food and beverage certifications are crucial for maintaining industry safety, quality, and compliance. These certifications help businesses meet regulatory requirements, prevent food safety risks, and build consumer trust whether it’s a broad certification like HACCP or an industry-specific one like USDA Organic for organic food producers, understanding which certifications apply to your business is essential for long-term success.

What Are Food and Beverage Certifications?

Food and beverage certifications are official endorsements that verify a company’s compliance with industry regulations, safety protocol audits, and quality standards. These certifications prove that food manufacturers, processors, and quality assurance teams adhere to strict guidelines to minimize risks such as contamination, mislabeling, and fraud.

Regulatory bodies and independent organizations issue these certifications to ensure food safety and consumer protection. Some certifications, like HACCP (Hazard Analysis and Critical Control Points), apply broadly across the industry. In contrast, others are industry-specific—for example, the USDA Organic Certification for organic food producers or the BRCGS (Brand Reputation Compliance Global Standards) for packaged food companies.

According to the Food Marketing Institute (FMI), food recalls cost companies an average of $10 million per incident. Thus, obtaining the right food and beverage industry certifications isn’t just about compliance but preventing financial and reputational damage.

Benefits of Obtaining Food and Beverage Certifications

Beyond compliance, food and beverage certifications provide a competitive edge by opening doors to new markets, improving operational efficiency, and strengthening brand reputation. Companies that invest in the proper certifications avoid costly recalls and legal issues and enhance product credibility, ensuring consumer confidence and business growth.

1. Compliance with Legal Standards

Governments worldwide have strict food safety laws that businesses must follow to operate legally. Certifications like HACCP, SQF, and ISO 22000 help companies meet regulatory requirements set by the FDA (U.S. Food and Drug Administration) and USDA (U.S. Department of Agriculture). Failing to comply can lead to hefty fines, shutdowns, or product recalls.

2. Access to New Markets

Many retailers, suppliers, and export markets require suppliers to have specific certifications before doing business. For example, GFSI (Global Food Safety Initiative)-recognized certifications like FSSC 22000 are often mandatory for international trade. Obtaining the right food and beverage certifications is essential for securing contracts if you aim to supply significant grocery chains like Walmart or Costco.

3. Enhanced Operational Efficiency

Certified companies follow standardized procedures that reduce waste, improve production consistency, and streamline supply chain management. Implementing HACCP-based risk assessment methods helps food processors prevent contamination at critical points, reducing costly product recalls and downtime. Studies show that businesses with proper food safety systems experience up to a 30% reduction in operational inefficiencies.

4. Competitive Advantage

Consumers are more aware than ever of food safety and ethical sourcing. Certifications like Non-GMO Project Verified and Fair Trade influence purchasing decisions, helping brands differentiate themselves. According to a Nielsen study, 73% of global consumers are willing to pay more for products with verified safety and sustainability claims. Companies can build trust and increase market share by securing the right food and beverage certifications.

Most Important Food Safety Certifications & Qualifications

Food safety is a top priority for manufacturers and processors as regulatory bodies enforce strict guidelines to prevent contamination and ensure public health. The right food and beverage certifications help businesses comply with these regulations and strengthen consumer trust and market credibility. Below is a list of critical food and beverage certifications in food safety management.

1. ISO 22000: Food Safety Management Systems

ISO 22000 is a globally recognized food safety management system (FSMS) that ensures food safety hazards are controlled at every stage of the supply chain. It integrates HACCP (Hazard Analysis and Critical Control Points) principles with internationally accepted food safety standards, making it applicable to businesses of all sizes.

With food safety concerns rising, more companies are adopting ISO 22000. Studies indicate that 61% of food recalls occur due to poor supplier management (Food Safety Magazine). The certification helps businesses mitigate risks, improve traceability, and enhance operational efficiency.

Key Requirements and Implementation Steps

To achieve ISO 22000 certification, food businesses must:

- Develop a food safety policy aligned with industry regulations.

- Conduct hazard identification and risk assessment across the supply chain.

- Establishing prerequisite programs (PRPs) to manage contamination risks.

- Implement an effective food traceability system for recalls and audits.

- Undergo regular audits and reviews to maintain compliance.

2. HACCP (Hazard Analysis Critical Control Point)

HACCP is one of the most fundamental food and beverage certifications. It focuses on preventing hazards rather than reacting to them. The system is mandatory in many industries, including meat, seafood, dairy, and processed foods, and it ensures that biological, chemical, and physical hazards are controlled at critical points.

A study by the CDC found that foodborne pathogens cause 48 million illnesses annually in the U.S.. HACCP helps businesses reduce contamination risks and prevent costly recalls, making it an essential certification for compliance.

HACCP is closely linked to VACCP and TACCP, which focus on food fraud and defense, respectively. These additional frameworks ensure comprehensive protection against intentional and unintentional contamination.

Steps to Develop and Implement an HACCP Plan

- Conduct a hazard analysis to identify potential food safety risks.

- Determine critical control points (CCPs) where hazards must be controlled.

- Establish critical limits for each CCP to prevent unsafe conditions.

- Implement monitoring procedures to ensure compliance.

- Develop corrective actions to address deviations.

- Set up verification processes to maintain system effectiveness.

- Maintain detailed documentation for audits and regulatory reviews.

3. GFSI (Global Food Safety Initiative) Recognized Certifications

The Global Food Safety Initiative (GFSI) is an industry-driven initiative that benchmarks food safety certification programs to ensure global standards are met. GFSI-recognized schemes are often required by large retailers, suppliers, and international markets, making them a key factor in business expansion and supply chain approvals.

Overview of Recognized Schemes

1. BRCGS (Brand Reputation Compliance Global Standards)

- Primarily used in retail and packaged food sectors.

- Focuses on product safety, quality, and operational efficiency.

- GFSI is recognized and widely accepted by supermarkets and global retailers.

2. SQF (Safe Quality Food)

- Popular in North America, covering all food supply chain sectors.

- Ensures farm-to-fork food safety and quality assurance.

- Often required by Walmart, Costco, and other major retailers.

3. FSSC 22000 (Food Safety System Certification)

- Built upon ISO 22000 principles with additional GFSI requirements.

- Highly preferred by large-scale food manufacturers.

- Provides a structured approach to risk management and compliance.

4. NSF International Certification

NSF International is a trusted third-party certification body that ensures food manufacturers, suppliers, and retailers meet safety and quality standards. Their certifications validate ingredient safety, processing methods, and facility compliance with industry regulations.

Certified companies experience higher customer confidence, improved product safety, and increased regulatory compliance, making it vital for food and beverage industry certifications.

Why Does it Matter?

- NSF-certified facilities meet FDA, USDA, and international food safety laws.

- Helps businesses secure retail and export opportunities.

- Provides customized auditing and risk management solutions.

Certification Process and Benefits

- Companies apply and undergo a gap assessment.

- On-site audits evaluate hygiene, hazard control, and compliance.

- Businesses receive recommendations for corrective actions.

- Upon successful completion, NSF certification is granted.

Industry-Specific Certifications in the Food & Beverage Industry

For food manufacturers and processors, ensuring compliance with food and beverage certifications goes beyond general food safety standards. Industry-specific certifications help businesses meet specialized consumer demands, such as organic, gluten-free, and non-GMO products.

These certifications improve market access, brand credibility, and consumer trust, making them essential in today’s competitive food industry. Below is a list of food and beverage certifications focusing on niche market segments.

1. Organic Certification

Standards For Organic Food Production

Organic certification is essential for food businesses that produce or sell organic products, ensuring compliance with strict agricultural and processing standards. Certified organic foods must be:

- Grown without synthetic pesticides, herbicides, or fertilizers.

- Free from genetically modified organisms (GMOs).

- Processed without artificial preservatives, colors, or additives.

Certification Process and Regulatory Bodies

The certification process for organic products involves detailed inspections, record-keeping, and compliance with national standards. Key steps include:

- Application Submission – Businesses apply to an accredited certifying body.

- Inspection & Compliance Review – On-site inspections ensure compliance with organic farming and processing regulations.

- Approval & Certification – The business receives an organic certification label if all criteria are met.

- Annual Renewals – Ongoing compliance checks and audits are required.

Key Organic Certification Bodies Include:

- USDA Organic (United States)

- EU Organic (European Union)

- Canada Organic Regime (Canada)

Why Does It Matter?

Organic certification increases export opportunities, strengthens brand trust, and helps businesses meet the growing consumer preference for clean-label foods.

2. Gluten-Free Certification

Importance for Consumer Health

Gluten-free certification is crucial for businesses catering to individuals with celiac disease, gluten intolerance, or dietary preferences. Studies show that 1 in 133 Americans (or about 1% of the population) has celiac disease, while many others opt for gluten-free diets for health reasons.

The global gluten-free food market was valued at $6.7 billion in 2022 and is expected to grow significantly due to increased awareness of gluten-related disorders and clean eating trends.

Certification Standards and Processes

To obtain a gluten-free certification, food manufacturers must ensure the following:

- Strict ingredient sourcing and facility controls to prevent gluten contamination.

- Per FDA and Codex Alimentarius standards, products contain less than 20 parts per million (ppm) of gluten.

- Regular testing and audits confirm compliance.

Leading Gluten-Free Certification Organizations:

- Gluten-Free Certification Organization (GFCO) – Recognized worldwide for its strict gluten-free verification process.

- Celiac Support Association (CSA) Certificate: This certification requires products to contain less than 5 ppm of gluten and offers even stricter compliance.

Why Does It Matter?

Certified gluten-free products help businesses tap into the rising demand for allergen-free foods, build consumer confidence, and expand into specialized retail markets.

3. Non-GMO Project Verification

Understanding GMOs and Market Demand for Non-GMO Products

Non-GMO certification ensures food products are free from genetically modified organisms (GMOs), meeting the growing demand for natural and transparent food labeling. According to studies, 64 countries worldwide require labeling of genetically modified foods, encompassing nations like those in the European Union, Japan, Australia, Brazil, Russia, and China. Many countries, including the European Union, Japan, and Australia, have strict GMO-labeling laws, making certification essential for global exports.

Verification Process and Labeling

The Non-GMO Project Verification is one of the most recognized certifications for non-GMO products. The process includes:

- Ingredient Review – All raw materials must be sourced from non-GMO crops.

- Testing & Documentation – Independent testing ensures products do not contain genetically modified ingredients.

- Facility Inspections – Production facilities must implement segregation and food traceability protocols.

- Verification & Labeling – Products receive the Non-GMO Project Verified seal once approved.

Why Does It Matter?

Non-GMO certification helps businesses meet consumer demand for natural, minimally processed foods, comply with international regulations, and gain access to retailers requiring non-GMO verification.

Regional and National Certifications in the Food & Beverage Industry

Food manufacturers and processors operating in domestic and international markets must comply with regional and national food and beverage certifications to ensure product safety, quality, and regulatory compliance. Complying with these certifications ensures businesses avoid legal penalties, gain consumer trust, and maintain market access. In the United States, two key regulatory bodies oversee food safety:

- United States Department of Agriculture (USDA): Primarily responsible for meat, poultry, dairy, and organic products.

- Food and Drug Administration (FDA): Regulates most other food and beverage products, including processed foods, seafood, and dietary supplements.

USDA (United States Department of Agriculture) Certifications

The USDA regulates agricultural products, livestock, and organic foods to ensure they meet national safety and quality standards. The department’s Food Safety and Inspection Service (FSIS) inspects all meat, poultry, and egg products sold in the U.S. to prevent contamination risks, mislabeling, and fraud.

Key USDA Certifications

1. USDA Organic Certification

- Ensures that products are grown and processed without synthetic fertilizers, pesticides, genetically modified organisms (GMOs), or artificial additives.

- Overseen by the National Organic Program (NOP).

- Products with the USDA Organic seal must be at least 95% organic.

- The global organic food market is expected to reach $564.22 billion by 2030, showing the growing demand for organic certification.

2. USDA Process Verified Program (PVP)

- Allows companies to verify specific marketing claims such as “grass-fed,” “raised without antibiotics,” or “non-GMO.”

- Helps manufacturers build consumer confidence by providing third-party verified product claims.

3. USDA Meat and Poultry Inspection Stamp

- Indicates that meat and poultry products have passed federal inspection and meet sanitation, processing, and safety requirements.

- Facilities producing these products must undergo continuous USDA FSIS inspections.

FDA (Food and Drug Administration) Regulations

The FDA regulates 80% of the U.S. food supply, covering packaged foods, beverages, dietary supplements, and food additives. Unlike the USDA, which focuses on meat and dairy, the FDA is responsible for processed foods, seafood, bottled water, and infant formulas.

One of the most significant food safety laws under the FDA is the Food Safety Modernization Act (FSMA), which introduced preventive measures rather than relying solely on reactive inspections.

Compliance Requirements for Food Manufacturers

Food Facility Registration

- All food manufacturing, processing, and storage facilities must be registered with the FDA.

- Failure to register can result in severe legal penalties, food recalls, and market restrictions.

Hazard Analysis and Critical Control Points (HACCP) Compliance

- Required for seafood, juice, and certain high-risk food products.

- Helps identify potential biological, chemical, and physical hazards in food production.

- Manufacturers must have a written HACCP plan and follow preventive controls to mitigate risks.

Food Labeling and Nutritional Compliance

- All packaged foods must comply with FDA labeling laws, including ingredient lists and allergen information, accurate nutrition facts, and clear product identity and claims.

Good Manufacturing Practices (GMPs)

- Ensures food is processed, handled, and stored under sanitary conditions to prevent contamination.

- Includes employee hygiene, equipment cleanliness, and food safety monitoring.

Foreign Supplier Verification Program (FSVP)

- It requires food manufacturers to import products into the U.S. to verify that foreign suppliers meet the same food safety standards as domestic producers.

- Aimed at preventing unsafe food imports from entering the market.

Implementing and Maintaining Food and Beverage Certifications

Obtaining food and beverage certifications is not a one-time task—it requires a systematic approach, ongoing monitoring, and compliance with regulatory standards. Whether a business is seeking USDA Organic, FDA compliance, HACCP, or third-party certifications like SQF or BRC, the process involves several key steps to achieve certification and a commitment to long-term compliance.

Steps to Achieve Certification

1. Initial Assessment and Gap Analysis

Before applying for a certification, businesses must assess their current operations and identify gaps between existing practices and certification requirements. Conduct an internal audit to evaluate:

- Food safety protocols.

- Facility sanitation and hygiene.

- Documentation practices.

- Compliance with regulatory and industry standards.

2. Documentation and Process Development

Certifications require comprehensive documentation that outlines standard operating procedures (SOPs), food safety plans, and compliance records. Businesses must develop:

- HACCP plans to identify biological, chemical, and physical food hazards.

- Good Manufacturing Practices (GMP) documentation covering hygiene, sanitation, and pest control.

- Food traceability records to track ingredients and suppliers.

3. Training and Implementation

Once documentation is in place, businesses must train employees on certification requirements, food safety protocols, and compliance standards. Key training areas include:

- Food handling and hygiene for plant workers.

- Audit readiness training for quality assurance teams.

- Emergency response protocols for contamination incidents.

4. Audit and Certification

After preparation, a certification body conducts an official audit to verify compliance. If compliance is met, the business receives certification approval. Corrective actions must be implemented before certification is granted if non-conformities are found. Audit process:

- On-site inspection of facilities.

- Review of documentation and safety protocols.

- Employee interviews to assess understanding of food safety requirements.

Maintaining Compliance

Achieving certification is just the beginning—businesses must maintain compliance through continuous monitoring, periodic audits, and staff training.

1. Continuous Improvement and Monitoring

Certified businesses must implement ongoing monitoring to consistently meet food safety standards. Best practices for continuous compliance:

- Implement real-time data tracking systems for temperature control and sanitation.

- Use food safety software to streamline compliance documentation.

- Conduct supplier verification audits to ensure ingredient safety.

2. Regular Audits and Updates

Regulations evolve frequently, requiring businesses to stay updated on changing certification requirements. Ongoing audit strategies:

- Annual internal audits to identify compliance gaps.

- Third-party inspections to validate safety protocols.

- Facility upgrades to meet updated food safety standards.

3. Employee Training and Awareness

Food safety compliance depends on well-trained employees who understand certification standards and protocols. Training strategies:

- Monthly refresher courses on food handling and hygiene.

- Certification-specific training for new compliance updates.

- Mock audits to prepare employees for real inspections.

Challenges and Considerations

Achieving food and beverage certifications presents unique challenges, from resource allocation to process modifications and employee adaptation. Businesses must strategically navigate these obstacles to ensure compliance and long-term success. Understanding these challenges and adopting best practices can make the certification process more efficient and sustainable.

Common Challenges in Certification

- Resource Allocation

Food and beverage certifications require financial investment, time, and skilled personnel. Small and mid-sized businesses often struggle to allocate resources for certification fees, training programs, and infrastructure improvements.

- Process Modifications

Meeting certification standards may require changes in production, storage, and supply chain processes. Implementing Hazard Analysis and Critical Control Points (HACCP) or ISO 22000 can be complex, requiring businesses to redesign workflows to comply with compliance requirements.

- Employee Resistance

Certification processes often introduce new protocols and documentation requirements, which can be met with resistance from employees. Proper training and change management strategies are essential to ensure smooth adoption.

Tips for Successful Certification

- Management Commitment

Leadership support is crucial for securing resources, setting priorities, and fostering a culture of compliance. To ensure long-term success, management must actively participate in certification initiatives.

- Engaging Qualified Consultants

Hiring experienced consultants can streamline the certification process. Industry experts help businesses navigate regulatory requirements, conduct gap analyses, and implement necessary changes efficiently.

- Leveraging Technology for Compliance

Digital solutions, such as automated compliance tracking, real-time monitoring, and cloud-based documentation, help businesses maintain certification standards. Platforms like the one by Folio3 simplify compliance management and ensure ongoing compliance with regulations.

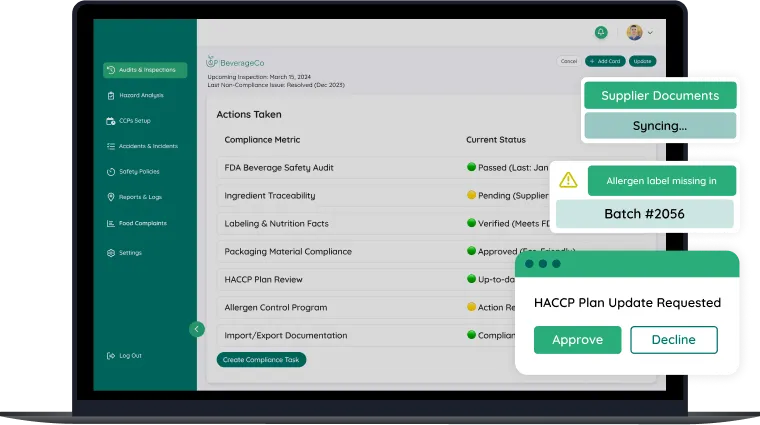

How Folio3 FoodTech Helps Manage Certification Compliance Digitally?

Achieving and maintaining food and beverage certifications requires meticulous documentation, regular audits, and strict adherence to food safety regulations. Managing these processes manually can be overwhelming and prone to errors. This is where Folio3 FoodTech provides a game-changing solution, helping food manufacturers streamline compliance management and efficiently prepare for audits.

Why Choose Folio3 FoodTech and How We Can Help?

While we don’t certify food businesses, we offer advanced digital tools that empower companies to meet certification requirements efficiently. Our compliance management and HACCP software simplify record-keeping, automate compliance tracking, and help businesses stay audit-ready.

Tools We Provide to Support Certification

Compliance Management Software

- Digitizes compliance processes, reducing paperwork and manual errors

- Automates tracking of food safety standards like HACCP, SQF, and ISO 22000

- Provides real-time alerts to ensure timely corrective actions

HACCP Software

- Helps implement Hazard Analysis and Critical Control Points (HACCP) plans

- Facilitates risk assessment and monitoring of critical control points

- Generates automated reports for audits and regulatory inspections

Comprehensive Support from Assessment to Certification

From initial assessment to certification preparation, Folio3’s digital solutions assist businesses in identifying compliance gaps, implementing corrective measures, and ensuring seamless adherence to industry standards.

Continuous Support for Maintaining Compliance

Even after achieving food and beverage industry certifications, businesses must maintain compliance through regular monitoring and updates. Folio3 FoodTech food safety solutions provide real-time monitoring, automated reports, and digital checklists to help food manufacturers stay compliant and avoid costly violations.

With Folio3 FoodTech, food manufacturers can focus on delivering safe, high-quality products while we handle the compliance complexities.

Conclusion

Food and beverage certifications are more than regulatory requirements—they are essential for ensuring product safety, building consumer trust, and gaining a competitive advantage. With regulators and consumers scrutinizing businesses more closely, businesses must adopt certifications like HACCP, ISO 22000, and USDA Organic to meet industry standards and market expectations.

Once you clearly understand the significance of these certifications and select the right ones for your sector, you can enhance your brand’s credibility, smoothen compliance processes, and ensure long-term success in the food and beverage industry. Certification is an investment in quality, safety, and consumer confidence—key pillars for any thriving food business!

FAQs

What Is The ISO Standard For The Food and Beverage Industry?

ISO 22000 is the key international standard for food safety management, ensuring safe production and handling of food and beverages.

Which Certification Is Best For The Food Industry?

The best certification depends on the sector, but HACCP, ISO 22000, and SQF are widely recognized for ensuring food safety and quality.

What Is The Highest Level Of HACCP?

HACCP doesn’t have levels, but it is often implemented alongside advanced certifications like ISO 22000 or GFSI-recognized standards.

How Many Categories Of Food and Beverage Are There?

The food and beverage industry has multiple categories, including dairy, meat, seafood, bakery, beverages, and processed foods.

What Are Food and Beverage Standards?

Food and beverage standards are regulations and guidelines, like HACCP and ISO 22000, that ensure food safety, quality, and compliance with legal requirements.