Artificial Intelligence (AI) is transforming the food industry, enhancing safety and efficiency across various sectors. According to studies, in 2023, the global AI in the food and beverages market was valued at $8.45 billion and is projected to grow at a compound annual growth rate of 39.1% from 2024 to 2030.

In food manufacturing, AI tools analyze vast amounts of data to optimize and improve the production process, enhance quality control, and ensure food safety. For example, an AI-powered inspection system can detect contaminants and defects in real time to help reduce the risk of recalls.

One of the successful examples of AI in the food industry is Wendy’s. With the help of AI, Wendy has cut drive-thru wait times by 22 seconds, improving customer service. The benefits of AI in the food industry are substantial. Predictive analytics optimize inventory management, reducing food waste, while AI-driven allergen detection enhances consumer safety, ensuring compliance with strict food safety regulations.

Since the role of AI in the food industry is expanding, 41% of food retailers and 69% of suppliers currently use AI for tasks such as assortment planning and customer data. As AI technology in the food industry continues to evolve, it offers promising solutions for a safer and more efficient future.

Keep reading this blog to learn more about AI in the food industry.

Understanding AI in the Food Industry

Artificial Intelligence (AI) is the simulation of human intelligence processes by machines, especially computer systems. AI is crucial in automating processes, analyzing vast amounts of data, and improving operational efficiency in the food industry. AI technologies such as machine learning, computer vision, and predictive analytics are revolutionizing food production, safety, and supply chain management.

The global AI market for food processing is growing rapidly. It is expected to be worth approximately USD 22.3 billion by 2032, up from USD 11.1 billion in 2023. This represents a compound annual growth rate (CAGR) of 8.3% from 2023 to 2032. This growth demonstrates the increasing reliance on AI to enhance productivity and safety in food-related operations.

AI has already transformed the food industry, especially food processing. Machine learning, computer vision, and data analytics help improve quality control, predict maintenance needs, and optimize production workflows.

For example, machine learning algorithms can analyze large volumes of data to identify patterns, leading to automated sorting and enhanced product quality. Additionally, AI-powered computer vision systems can detect defects, food contaminants, and spoilage in real time, ensuring only safe, high-quality food reaches consumers.

AI’s growing presence in food processing is just one example of how the food industry uses advanced technologies to address challenges and improve safety, quality, and efficiency across the supply chain. As businesses adopt AI solutions, the industry will become even more automated, reliable, and responsive to consumer needs.

AI Applications in the Food Industry

AI transforms traditional processes in the food industry, making them smarter, safer, and more efficient. AI technology is revolutionizing businesses ‘ operations, from ensuring food safety to optimizing supply chains. Below, we explore some key areas where AI is making a significant impact, highlighting its benefits in food industry operations.

1. Food Safety and Quality Control

AI technology is significantly improving safety standards in the food industry. For instance, advanced AI-powered image recognition tools detect contaminants in food products during production, ensuring that items reaching consumers meet strict safety regulations. Research shows that AI-enabled food safety solutions can reduce contamination risks by up to 30% in processing plants. AI Image Detector systems are one such innovation, using machine learning and computer vision to scan food products for anomalies such as foreign objects, discoloration, or irregular shapes. These tools can process thousands of images per minute and flag defective products in real time—far exceeding the capabilities of manual inspections.

2. Predictive Maintenance of Equipment

AI used in food industry machinery helps monitor equipment performance and predict potential failures before they occur. This minimizes downtime and ensures seamless production. A 2023 study from MarketsandMarkets revealed that AI-powered maintenance systems can improve operational efficiency by over 20%.

3. Personalized Customer Experiences in Food Service

AI in food service industry applications is revolutionizing customer interactions. For example, AI-driven chatbots and automated restaurant ordering systems speed up service while tailoring menu suggestions based on customer preferences. Gen AI in food industry solutions, like language-based AI models, helps understand and cater to diverse consumer needs, enhancing satisfaction.

4. Supply Chain Optimization

The use of AI in food industry supply chains ensures real-time monitoring of inventory and delivery schedules. AI algorithms analyze patterns to optimize routes, reducing transportation costs and food wastage. A 2024 report by Forbes Insights highlighted that implementing AI in food logistics reduced delivery delays by 15% across global food retailers.

5. Sustainability and Waste Reduction

One key benefit of AI in food industry practices is its ability to address sustainability challenges. AI systems accurately track and forecast food demand, helping businesses reduce overproduction and minimize waste. For example, in recent pilot projects, IBM’s AI solutions for food manufacturers helped cut waste by nearly 40%.

AI for Optimizing Risk Assessment

AI is critical in the food industry for identifying and mitigating risks throughout the supply chain. By leveraging predictive analytics and real-time monitoring, businesses can ensure compliance with safety regulations, minimize contamination risks, and maintain high-quality standards.

By combining predictive analytics with real-time monitoring, AI is revolutionizing risk assessment in the food industry. AI’s role in food industry safety extends beyond prevention to include actionable insights that ensure consumer trust and regulatory compliance.

These advancements showcase how AI technology continues to elevate food safety standards, fostering a safer future for the industry. Here’s a detailed look at how AI technology is transforming risk assessment:

Predictive Analytics

One of the key benefits of AI in food industry operations is its ability to analyze vast amounts of data to predict potential risks before they occur. By proactively identifying risks, predictive analytics allows food businesses to take preventive measures, ensuring safer products for consumers. For example:

- Identifying Contamination Risks: AI systems use historical data and advanced algorithms to pinpoint patterns associated with food contamination. AI can highlight potential areas of concern by analyzing trends such as temperature fluctuations during transport or hygiene protocols during processing. According to a report by MarketsandMarkets, predictive analytics in the food safety market is expected to grow by over 25% annually, helping businesses reduce foodborne illness outbreaks.

- Supplier Risk Management: AI technology in food industry supply chains assesses supplier histories, including past recalls or quality issues. This enables companies to make informed decisions about which suppliers to trust, reducing the likelihood of compromised ingredients entering the production line.

Real-Time Monitoring

AI in food industry systems enables continuous monitoring of food safety parameters and provides instant alerts when something goes wrong.

- Monitoring Critical Control Points: AI-powered sensors monitor critical points in food production, such as cooking temperatures, storage conditions, and packaging. For instance, AI in food service industry kitchens tracks refrigeration systems to ensure ingredients are stored within safe temperature ranges, reducing spoilage. A 2024 Food Safety Magazine study found that real-time AI monitoring reduces contamination risks by 30-40% compared to manual checks.

- Tracking Supply Chain Conditions: AI technology tracks real-time data on food transport conditions, such as humidity and temperature. Companies using gen AI in food industry logistics solutions can generate instant reports and optimize routes to ensure products remain fresh upon delivery.

AI for Making Informed Decisions

AI is a game-changer in the food industry when it comes to decision-making. Using advanced tools for data integration and quality control, businesses can rely on actionable insights to enhance efficiency, improve product quality, and maintain compliance with safety regulations.

AI technology empowers food businesses to make timely and precise decisions by integrating data from diverse sources and enhancing quality control processes. Its benefits in food industry practices streamline operations and build consumer trust by delivering safe, high-quality products.

Let’s dive into how AI helps organizations make smarter decisions:

Data Integration

The role of AI in food industry operations extends to gathering, analyzing, and integrating data from various sources to present a clear and actionable picture.

- Centralized Data Analysis: AI technology in food industry systems consolidates data from different departments, such as production, supply chain, and customer feedback. This holistic view helps companies identify trends, such as seasonal demands or recurring quality issues, enabling them to make more informed business decisions.

- Predictive Insights for Demand Planning: AI in food industry operations helps businesses predict future demand by analyzing past sales trends and real-time consumer behavior.

Quality Control

Maintaining product quality is one of AI’s most important benefits in the food industry. AI tools ensure that every item meets the highest safety and quality standards.

- Real-Time Defect Detection: AI used in food industry production lines, such as image recognition systems, can instantly identify defects in food items. These systems detect irregular shapes, foreign objects, or improper packaging, ensuring only the best products reach consumers.

- Ensuring Consistency: Gen AI in food industry applications allows businesses to compare production outputs against predefined standards, ensuring uniformity across batches. For instance, AI tools in the food service industry kitchens can monitor cooking times and ingredient proportions to ensure consistent dish taste and texture.

AI for Enhancing Food Safety

Ensuring food safety is a critical priority in the food industry, and AI is emerging as a powerful tool to address safety challenges. From detecting contamination to enhancing traceability and regulatory compliance, AI technology in food industry practices provides innovative solutions that protect businesses and consumers.

With AI for contamination detection, traceability, and regulatory compliance, food businesses can deliver safer products while maintaining operational efficiency. The benefits of AI in food industry safety measures highlight its pivotal role in shaping a future where food safety standards are consistently met and exceeded. Here’s how:

Contamination Detection

One of the most significant benefits of AI in food industry operations is its ability to detect contamination early, minimizing health risks and costly food recalls.

- AI-Powered Sensors: AI systems use advanced sensors to identify contamination at different stages of the production process. For instance, AI used in food industry quality control can detect pathogens, such as E. coli or Salmonella, using rapid diagnostic tools.

- Monitoring for Foreign Objects: AI in the food service industry kitchens and processing facilities utilizes image recognition to identify foreign objects in food products, such as plastic, glass, or metal, ensuring that only safe products reach consumers.

Traceability

The role of AI in food industry traceability is transformative. It provides end-to-end visibility across the supply chain and enables swift action in case of safety breaches.

- Enhanced Tracking Systems: AI technology in food industry supply chains uses blockchain and IoT devices to track food products from farm to fork. If a safety issue arises, businesses can trace the affected product’s origin within minutes, significantly reducing the time needed to recall unsafe items. Just as decentralized exchange software enables secure and transparent tracking in digital assets, this technology ensures accountability and efficiency in the food sector.

- Building Consumer Trust: AI in food industry systems ensures transparency by providing consumers with detailed product information, such as sourcing and safety certifications, through QR codes and digital labels. This builds trust and confidence in food brands.

Regulatory Compliance

Compliance with food safety regulations is a critical requirement for businesses, and AI simplifies this process by automating compliance checks and documentation.

- Automated Audits: AI in food industry processes can automatically monitor production practices against regulatory standards, identifying non-compliance in real-time. This ensures businesses stay ahead of safety requirements without relying solely on manual inspections.

- Streamlining Documentation: Gen AI in food industry management simplifies compliance reporting by organizing and analyzing data from various sources. For example, AI systems generate detailed reports on production logs, hygiene protocols, and supply chain records, ensuring businesses are always prepared for inspections.

AI for Optimizing Supply Chain

An efficient supply chain is essential in the food industry to ensure products are delivered on time, maintain freshness, and reduce costs. AI in food industry operations has revolutionized supply chain management, enabling businesses to accurately forecast demand, optimize logistics, and improve inventory management. Let’s explore these aspects in detail:

Demand Forecasting

AI technology in food industry systems excels in predicting consumer demand, helping businesses balance inventory levels, and reducing food waste.

- Accurate Predictions: AI analyzes historical sales data, market trends, and external factors like weather or seasonal events to provide precise demand forecasts. For example, AI used in food industry supply chains can anticipate spikes in ice cream sales during summer or predict the demand for seasonal produce like pumpkins in October. According to a report by McKinsey, AI-enabled demand forecasting reduces forecasting errors by up to 30%, resulting in significant cost savings.

- Minimized Waste: One key benefit of AI in food industry supply chains is its ability to align production with actual demand. By avoiding overproduction, businesses can significantly reduce food waste while improving sustainability, a priority in today’s industry.

Logistics Optimization

AI plays a critical role in food industry logistics, ensuring timely and cost-efficient delivery of goods.

- Route Optimization: AI in food service logistics uses real-time traffic data and predictive analytics to identify the fastest and most fuel-efficient delivery routes. This reduces transportation costs while ensuring perishable food items arrive fresh.

- Supply Chain Visibility: AI technology in food industry logistics provides end-to-end visibility, allowing businesses to track shipments in real-time. This reduces delays and ensures quick responses to unexpected disruptions, such as weather conditions or mechanical failures.

Inventory Management

AI in food industry inventory systems ensures stock levels are accurately maintained to avoid shortages or surpluses.

- Automated Stock Monitoring: AI tools monitor inventory in real time, alerting businesses when stock levels are low or nearing expiration. This proactive approach ensures that shelves are always stocked with fresh items.

- Smart Reordering Systems: Gen AI in food industry operations supports smart reordering by automatically placing orders based on predictive demand and current stock levels. This reduces the risk of overstocking or running out of essential products.

- Reducing Costs: Effective AI-powered inventory management helps minimize holding costs, shrinkage, and waste.

Challenges and Considerations

While the use of AI in food industry processes offers transformative benefits, its adoption comes with challenges that businesses must address. From safeguarding data privacy to managing implementation costs and ensuring personnel are equipped with the right skills, overcoming these barriers is essential to maximizing the benefits of AI in food industry operations.

Data Privacy

Handling sensitive information is one primary concern when deploying AI technology in food industry systems. AI systems often rely on vast amounts of data, including consumer preferences, supplier details, and proprietary recipes, which can raise privacy concerns.

- Handling Sensitive Information: Businesses must ensure that AI systems comply with data protection regulations like GDPR or CCPA to safeguard customer and company data. Data breaches or mishandling can lead to reputational damage and legal penalties.

- AI Ethics: As gen AI in food industry applications expands, ethical considerations, such as how data is collected, stored, and used, become critical. For instance, predictive analytics might inadvertently reveal consumer patterns that could be exploited if not ethically handled.

Implementation Costs

Integrating AI in the food industry requires significant financial investment, particularly for small- and medium-sized enterprises (SMEs). However, the long-term benefits often outweigh the initial costs.

- High Upfront Investment: Purchasing AI tools, customizing solutions, and upgrading infrastructure to support AI technology can be expensive. For example, setting up AI in food industry applications like contamination detection systems or predictive maintenance software can cost thousands of dollars.

- Return on Investment (ROI): Despite the high costs, many businesses achieve substantial ROI through increased efficiency, reduced waste, and better decision-making.

- Financial Aid for Adoption: Governments and international organizations are increasingly providing grants and funding to support the adoption of AI technology in food industry operations, particularly for solutions that enhance food safety.

Skill Requirements

The successful implementation of AI in the food industry depends on personnel’s ability to collaborate effectively with these advanced systems.

- Training Needs: Employees need training to operate, maintain, and interpret AI system insights. For instance, understanding predictive analytics or troubleshooting AI-enabled contamination detection tools requires specific skill sets.

- Upskilling the Workforce: The role of AI in food industry processes has created a demand for specialized roles such as AI analysts or technicians. Companies must invest in upskilling their workforce to bridge the gap.

- Labor and AI Collaboration: While automation powered by gen AI streamlines operations in food industry applications, human expertise is still vital for decision-making and addressing complex issues.

- Balancing Automation and Employment: While the use of AI in food industry operations enhances efficiency, businesses must also balance automation with job retention to maintain a motivated workforce.

Conclusion

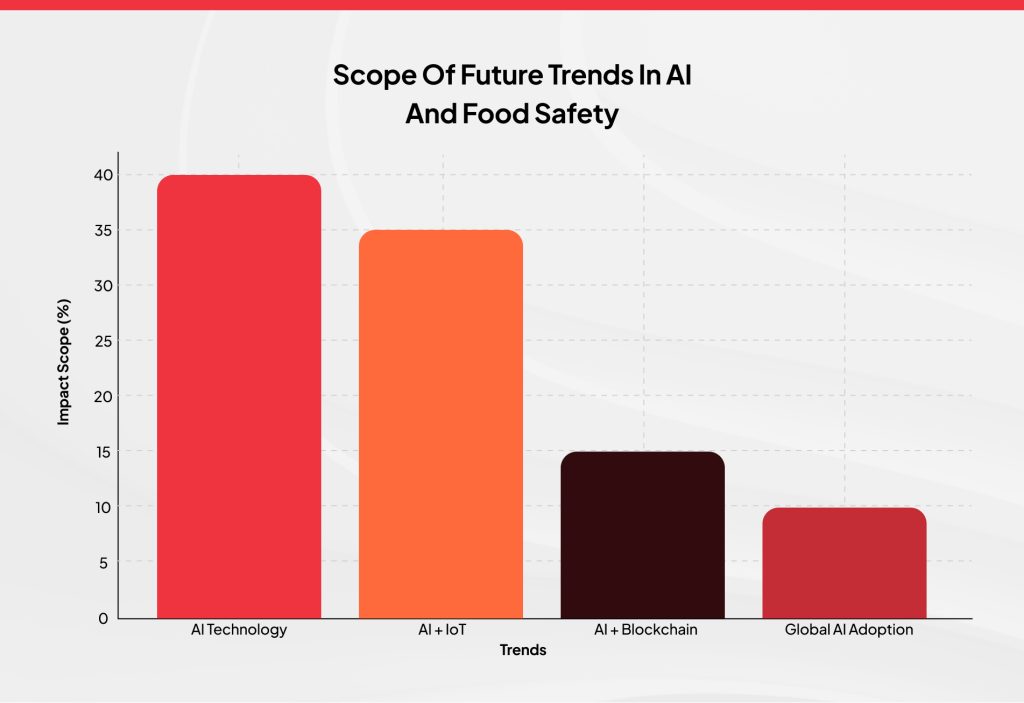

AI is transforming the food industry, driving innovation in food safety, traceability, and risk management. With advancements in AI technology, businesses can enhance quality control, predict potential hazards, and ensure compliance with global standards.

The future of food safety lies in the seamless integration of AI with IoT, blockchain, and other emerging technologies. As the industry continues to embrace these changes, companies that leverage AI will be better equipped to safeguard food quality and meet growing consumer expectations.

For those looking to implement these solutions, Folio3’s FoodTech services offer the latest AI-powered tools to help businesses thrive.

FAQs

How Is AI Being Used In The Food Industry?

AI is used in the food industry to optimize supply chains, improve food safety, enhance quality control, and predict consumer demand through advanced analytics.

What Is The Future Of AI In Food?

The future of AI in food will see greater integration with technologies like IoT and blockchain, enhancing traceability, food safety, and operational efficiency across the global food supply chain.

How Can AI Solve Food Waste?

AI can solve food waste by predicting demand more accurately, optimizing inventory management, and identifying spoilage risks in real-time, thereby reducing overproduction and waste.

How Can AI Help In Cooking?

AI can assist in cooking by providing recipe recommendations, automating cooking processes, monitoring cooking conditions, and ensuring food quality through real-time adjustments.

What Are The Applications Of AI In Food Safety?

AI in food safety includes contamination detection, predictive risk analysis, real-time monitoring of storage conditions, and ensuring compliance with regulatory standards to maintain food quality and safety.