It’s easy to lump “food processors” and “food manufacturers” into the same category, but doing so overlooks key distinctions that matter, especially for those managing complex operations across the food and beverage supply chain. A common misconception in the industry is that food processing and manufacturing are interchangeable terms.

The truth? All food processors are manufacturers, but not all manufacturers are just processors. While processors focus on transforming raw agricultural inputs into usable ingredients, manufacturers may work with raw and pre-processed components to create finished, packaged food products.

This distinction is more than semantic. It influences everything from sourcing strategies to compliance protocols. According to IBISWorld, the U.S. food processing and manufacturing sector is expected to reach an estimated $ 6.9 trillion in 2025, encompassing a broad range of activities from initial raw food treatment to final product assembly.

For operations managers, production heads, and supply chain directors, understanding where your company and vendors fall within the food processing and manufacturing industry can directly impact efficiency, quality control, and scalability.

As consolidation and innovation reshape the industry, especially within mid-to-large food processing and manufacturing companies, clarity on these roles becomes critical. This blog dives into the operational, regulatory, and strategic differences between food processors and manufacturers, helping you make informed decisions in a highly competitive and regulated sector.

Defining Food Processing

Food processing refers to transforming raw agricultural goods into usable food components. This stage begins immediately after harvest and includes cleaning, sorting, grinding, fermenting, freezing, and packaging. While these actions vary by product type, the central goal is to enhance shelf life, improve safety, and prepare food for direct consumption or further manufacturing.

Unlike food manufacturing, which may involve assembling multiple ingredients, including pre-processed ones, into final packaged products, food processing is typically the first value-adding step in the food processing and manufacturing industry.

It plays a critical role in preventing post-harvest losses, which the FAO estimates as high as 30% globally for perishable crops like fruits and vegetables. For operations and production leads, identifying where processing ends and manufacturing begins can help segment quality controls, align compliance protocols, and optimize plant floor workflows.

Key Characteristics of Food Processing

Below are the key characteristics ensuring food products’ safety, quality, and longevity:

1. Minimal Processing to Preserve Natural Qualities

Processing at this stage often aims to retain food’s natural look, taste, and nutritional content. Techniques like peeling, slicing, vacuum sealing, and pasteurization fall under this category. These methods slow spoilage without fundamentally altering the product’s core properties. According to the Institute of Food Technologists (IFT), minimal processing supports the growing demand for “clean label” foods that are safe but not heavily modified or artificial.

2. Focus on Food Safety, But with Different Priorities

While food processors and manufacturers prioritize food safety, processors emphasize the prevention of biological hazards originating from raw inputs, such as bacteria, parasites, and soil-borne contaminants. Common interventions include:

- Sanitation of equipment and water.

- Use of UV light or mild heat to kill microbes.

- Quick chilling to inhibit microbial growth.

In contrast, food manufacturing focuses more on cross-contamination prevention during multi-ingredient assembly. Understanding this distinction is crucial for facility managers when implementing Hazard Analysis and Critical Control Points (HACCP) systems tailored to each stage.

3. Usually the First Step Post-Harvest

Food processing typically occurs close to the point of harvest. For example, sugarcane is crushed within 24–48 hours of harvesting to prevent sucrose loss. Similarly, dairy must be pasteurized shortly after milking to remain safe for consumption.

These time-sensitive operations make processing highly dependent on speed, temperature control, and sanitation variables that impact both shelf life and downstream manufacturing quality.

4. Strong Link to Agricultural Supply Chains

Food processing companies work directly with farmers, cooperatives, and primary producers. This makes them more vulnerable to climate impacts, crop yields, and raw material variability than downstream manufacturers. As a result, processors must build resilience into procurement, storage, and batch processing strategies.

Defining Food Manufacturing

Food manufacturing is the stage where processed ingredients are transformed into final, consumable products. This phase encompasses a range of activities, including cooking, baking, assembling, and packaging, all aimed at producing ready-to-eat or ready-to-cook food items. Unlike food processing, which focuses on preserving and preparing raw materials, food manufacturing emphasizes product consistency, scalability, and meeting consumer demands for convenience and variety.

For instance, while food processing might involve milling wheat into flour, food manufacturing takes that flour to produce bread, pastries, or pasta. This stage often requires sophisticated machinery and automation to ensure uniformity and efficiency in large-scale production.

Key Characteristics of Food Manufacturing

Food manufacturing goes beyond simple preparation, transforming raw and semi-processed ingredients into consistent, branded, and ready-to-distribute products at scale. Below are the key characteristics that define this complex, compliance-driven phase of the food processing and manufacturing industry.

1. Involves Complex Processes and Machinery

Food manufacturing facilities are equipped with advanced machinery designed for mass production. These machines handle tasks such as mixing, cooking, forming, and packaging with precision and speed. Automation plays a significant role, enabling manufacturers to maintain consistent product quality while meeting high-volume demands.

2. Emphasis on Consistency, Branding, and Packaging

Consistency is paramount in food manufacturing. Consumers expect the same taste, texture, and appearance every time they purchase a product. Achieving this requires strict adherence to standardized recipes and processes. Branding and packaging are crucial for product differentiation in a competitive market. Attractive, informative packaging appeals to consumers and ensures compliance with labeling regulations.

3. Requires Stringent Quality Control and Compliance Measures

Given the production scale and potential impact on public health, food manufacturing is subject to rigorous quality control protocols. Manufacturers implement comprehensive food safety management systems, such as Hazard Analysis and Critical Control Points (HACCP), to identify and mitigate risks throughout production. Compliance with national and international food safety standards is a regulatory requirement and essential for maintaining consumer trust.

4. Diverse Aspects of Food Safety

While both food processing and manufacturing prioritize food safety, the focus areas differ. In food manufacturing, the complexity of combining multiple ingredients increases the risk of cross-contamination and allergen exposure. These measures are critical in safeguarding public health and maintaining the integrity of the food supply chain. Therefore, manufacturers must implement stringent controls, including:

- Allergen Management: Ensuring allergens are properly identified, segregated, and labeled to prevent unintended exposure.

- Traceability Systems: Maintaining detailed records of ingredient sources and production batches to facilitate swift action in case of recalls.

- Sanitation Protocols: Regular cleaning and sanitizing of equipment and facilities to prevent microbial contamination.

Key Differences Between Food Processing and Food Manufacturing

Understanding these distinctions is crucial for stakeholders in the food industry, as each phase requires specific expertise, equipment, and compliance with different regulatory standards to ensure the safety and quality of food products.

| Aspect | Food Processing | Food Manufacturing |

| Stage | Initial transformation of raw agricultural products into edible forms. | Final production of packaged, market-ready food products. |

| Processes Involved | Includes cleaning, cutting, grinding, pasteurization, fermentation, etc. | Involves blending, cooking, assembling, packaging, and labeling. |

| Output | Semi-processed ingredients (e.g., flour, pasteurized milk). | Fully processed, packaged foods (e.g., bread, canned soup). |

| Equipment Used | Basic machinery like grinders, mixers, and pasteurizers. | Advanced automated systems like assembly lines, industrial ovens, and packaging machines. |

| Regulatory Focus | Emphasis on food safety standards like HACCP and ISO 22000. | Compliance with Good Manufacturing Practices (GMP) and quality control systems. |

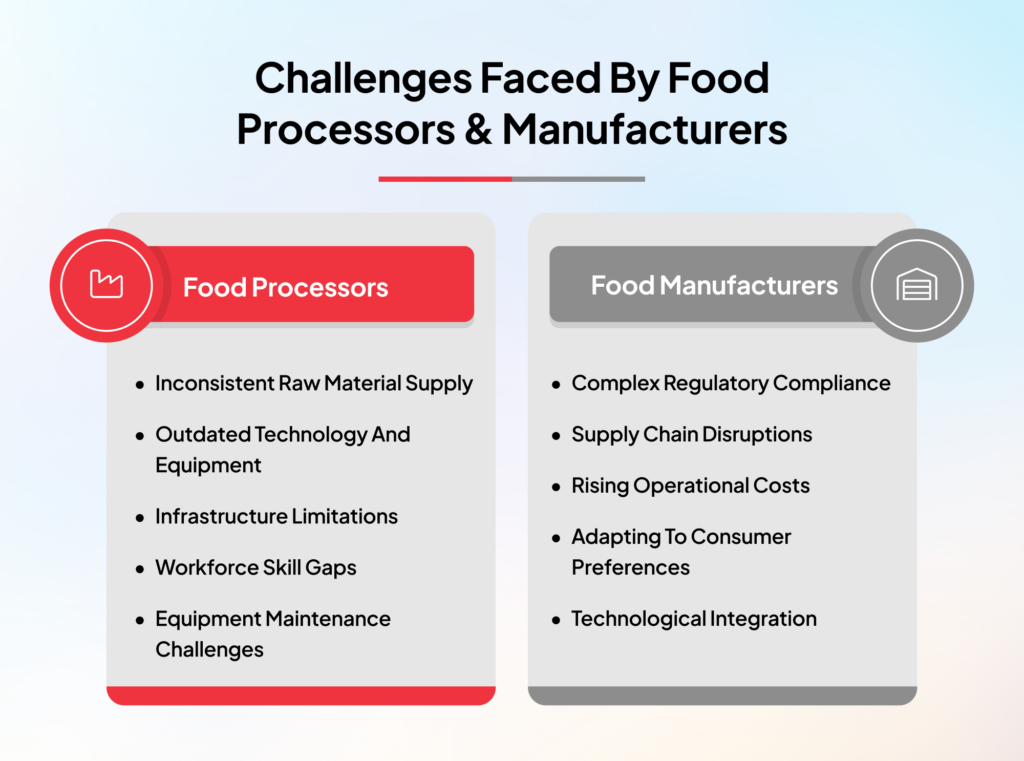

Challenges Faced by Food Processors and Manufacturers

For Food Processors

Food processors are the critical link between agriculture and manufacturing, converting raw, perishable ingredients into safe, usable components. However, this foundational role comes with operational challenges distinct from those faced further down the supply chain.

From unreliable raw material quality to aging infrastructure, processors often operate within tight margins while ensuring product integrity and safety. Below are some of the most pressing issues currently affecting the food processing sector.

Inconsistent Raw Material Supply

Processors often grapple with fluctuations in the availability and quality of raw agricultural products. Factors such as seasonal variations, climate change, and fragmented farming practices can disrupt consistent supply, impacting production schedules and product quality.

Outdated Technology and Equipment

Many processing facilities, especially in developing regions, operate with antiquated machinery. This hampers efficiency and makes it challenging to meet modern food safety standards and adapt to new processing techniques.

Infrastructure Limitations

Inadequate infrastructure, including unreliable electricity, poor transportation networks, and insufficient cold storage facilities, can increase post-harvest losses and hinder the timely processing of perishable goods.

Workforce Skill Gaps

A shortage of trained personnel proficient in contemporary food processing methods and safety protocols poses a significant challenge. Continuous training and capacity-building initiatives are essential to bridge this gap.

Equipment Maintenance Challenges

Processing equipment is subjected to rigorous use, leading to wear and tear. Regular maintenance is crucial, but many processors lack the resources or expertise to implement effective maintenance schedules, resulting in frequent downtimes.

For Food Manufacturers

Food manufacturers operate at a larger, more complex scale, transforming raw and semi-processed inputs into consumer-ready products. With high output volumes and multiple SKUs, the challenges at this stage revolve around efficiency, compliance, and customer satisfaction.

Manufacturers must constantly balance innovation with regulation while responding swiftly to market and supply chain fluctuations. Let’s explore manufacturers’ specific hurdles in the food processing and manufacturing industry.

Complex Regulatory Compliance

Manufacturers must navigate a labyrinth of food safety regulations that vary significantly across regions. Staying updated with evolving standards and ensuring compliance across all operations is resource-intensive and critical to avoid legal repercussions.

Supply Chain Disruptions

Global events like pandemics or geopolitical tensions can disrupt supply chains, leading to ingredient shortages or delays. Manufacturers need robust contingency plans to mitigate these risks and maintain production continuity.

Rising Operational Costs

Escalating energy, labor, and raw materials costs strain profit margins. Manufacturers must find innovative solutions to enhance efficiency and reduce expenses without compromising product quality.

Adapting to Consumer Preferences

The modern consumer demands healthier, sustainable, and ethically produced food products. Manufacturers must continuously innovate and reformulate products to meet these evolving preferences while ensuring scalability and affordability.

Technological Integration

Implementing advanced technologies like automation, AI, and IoT can optimize manufacturing processes. However, integrating such technologies requires substantial investment and a skilled workforce to manage and maintain them.

Role of ERP Systems for Food Processing and Manufacturing

The operational complexities are substantial, whether running a large-scale food processing facility or managing a multi-line manufacturing plant. From handling perishable raw materials to ensuring precise batch production and meeting regulatory standards, every step demands precision and visibility. This is where Food ERP system becomes indispensable.

How ERP Systems Support the Food Industry?

Food ERP systems are designed to handle the unique needs of processors and manufacturers, without forcing them into a one-size-fits-all mold. Food processors focus on managing raw material variability, safety checks, and timely processing. Meanwhile, manufacturers require more sophisticated tools for scheduling, packaging, branding, and regulatory compliance.

An industry-focused ERP like Folio3’s Food ERP provides a strong, scalable solution tailored to these needs. With deep domain knowledge in food and beverage operations, Folio3’s solution offers tools and integrations that organize workflows, reduce manual errors, and improve agility across the supply chain.

Strategic ERP Adoption Starts with CFO-Led Planning

Implementing an ERP for food processing and manufacturing isn’t just an IT decision—it’s a strategic investment. If you’re a financial leader looking to justify and steer ERP adoption, explore our CFO’s Guide to Implementing a Food & Beverage ERP. It outlines ROI frameworks, implementation best practices, and financial planning insights tailored for the industry.

Explore The CFO’s Guide to Implementing a Food and Beverage ERP System

Key Integration Capabilities

ERP systems are the operational backbone, connecting all departments and processes in real time. From raw material procurement to production, inventory, quality assurance, and final product distribution, a centralized platform ensures every team operates with a unified source of truth.

Fix the Gaps in Your Operations

with an ERP That Speaks Food

We help food businesses move from generic or patchworked systems to a fully

integrated ERP, purpose-built for the industry, and designed for you.

Talk to an ERP Specialist

Benefits of ERP for Food Processors & Manufacturers

- Real-Time Inventory Management: Maintain complete visibility into raw materials, work-in-progress, and finished goods. This is especially vital for processors dealing with short shelf-life ingredients and manufacturers juggling multiple SKUs.

- Enhanced Traceability and Compliance Tracking: Automated traceability from source to shelf helps meet strict food safety regulations such as FSMA, SQF, and HACCP. In the event of a recall, the system pinpoints affected batches within minutes, reducing risk and liability.

- Improved Demand Forecasting and Production Planning: Use historical data and predictive analytics to optimize batch sizes, reduce waste, and align production with seasonal demand and retail cycles.

- Quality Control at Every Step: Folio3 FoodTech ERP allows for customizable quality checks and real-time data capture, ensuring consistency and compliance from receiving raw inputs to packaging final products.

- Regulatory and Audit Readiness: Built-in compliance modules support food-specific documentation, certifications, and audit trails, keeping businesses ready for inspections without last-minute scrambles.

Conclusion

While food processing and manufacturing are often used interchangeably, the distinction between them is critical, especially for operations managers, production heads, and supply chain leaders aiming to streamline their workflows. Food processors focus on converting raw ingredients into safe, usable forms, while manufacturers build upon those inputs to create branded, packaged, and consumer-ready products. Both play vital but distinct roles in the food processing and manufacturing industry.

However, they share a growing need for smarter, more integrated operations. As regulatory demands intensify and market pressures increase, businesses can no longer afford inefficiencies, data silos, or reactive decision-making. That’s where a customized solution like Folio3’s Food ERP becomes a game-changer. Designed specifically for the food processing and manufacturing sector, it helps companies gain real-time visibility, ensure compliance, manage traceability, and optimize production all from a single platform.

FAQs

What Is Food Processing And Manufacturing?

Food processing involves converting raw ingredients into safe, usable products, while food manufacturing takes these processed inputs to create consumer-ready food products through more complex processes, packaging, and branding.

What Is The Difference Between Food Processing And Manufacturing?

Food processing focuses on transforming raw materials into ingredients or semi-finished products. At the same time, manufacturing involves taking these ingredients and creating final, market-ready food products, emphasizing consistency, branding, and packaging.

What Are The 4 Types Of Food Processing?

The four main types of food processing are primary processing (harvesting, milling), secondary processing (cooking, fermenting), tertiary processing (packaging, freezing), and quaternary processing (additive processing like fortification).

What Is The Processing And Production Of Food?

Food processing involves transforming raw materials into usable products, while food production refers to the entire process from sourcing ingredients to creating finished food products ready for distribution and consumption.

What Is Called Food Processing?

Food processing is the process of transforming raw ingredients, such as vegetables, grains, and meats, into finished food products through mechanical, chemical, or thermal methods to ensure safety, shelf life, and edibility.

What Is The Best Food Processor?

The best food processor depends on your specific needs, but top models feature powerful motors, versatile attachments, and user-friendly interfaces.