Did you know the global confectionery market is projected to reach $242.53 billion by 2030, fueled by growing demand for premium treats, functional ingredients, and seasonal favorites? Yet, despite this sweet outlook, candy and confectionery manufacturers face tough challenges—from rising ingredient costs and fluctuating consumer preferences to strict regulatory standards and complex inventory requirements.

In such a competitive and fast-evolving landscape, staying ahead isn’t just about making great candy—it’s about having the right systems to support production, quality, and profitability. This is where ERP for candy and confectionery manufacturing steps in as a game-changer.

Whether you’re struggling with batch traceability, delayed order fulfillment, or inefficiencies in production planning, modern ERP for candy and confectionery can help organize operations, reduce waste, and improve margins—without compromising product quality or compliance.

In this blog, we’ll break down the key benefits of ERP software for candy and confectionery manufacturers and explore how embracing the right digital tools can transform challenges into growth opportunities. If you’re ready to get more control over your confectionery business, keep reading.

Understanding ERP in the Confectionery Industry

Enterprise Resource Planning (ERP) is no longer just a tool for large-scale manufacturers—it has become necessary for candy and confectionery businesses looking to thrive in a competitive, margin-sensitive market. With the confectionery industry seeing rising input costs and increasing demand for customization, ERP for candy and confectionery helps organize operations, reduces overhead, and supports long-term scalability.

What is ERP in the Context of Confectionery Manufacturing?

At its core, ERP for candy and confectionery is a centralized software solution that integrates core business functions—like inventory management, procurement, production, quality control, sales, and compliance—into one cohesive system. For confectionery manufacturers, this means having real-time visibility across their supply chain, from sourcing ingredients to shipping finished goods.

Unlike generic systems, ERP for candy and confectionery is designed to manage industry-specific challenges such as:

- Batch and recipe management.

- Lot traceability.

- Regulatory compliance (e.g., FDA, FSSAI, CFIA).

- Shelf-life tracking and expiration control.

- Multi-packaging and seasonal product variants.

Why Confectionery Manufacturers Are Turning to ERP Now?

The shift toward digital solutions in the food industry is accelerating. For confectionery producers, this trend is being driven by several pressing needs:

- Managing Rising Input Costs: The prices of sugar, cocoa, and dairy have been volatile due to global supply chain disruptions and climate-related challenges. ERP systems allow better cost forecasting and procurement planning.

- Meeting Consumer Expectations: Customers today demand not only variety but also transparency. ERP allows manufacturers to track every ingredient and process, boosting efficiency and trust.

- Ensuring Compliance and Safety: With increasing audits and regulations in food safety, ERP helps manufacturers stay audit-ready by maintaining detailed digital records and ensuring traceability.

How ERP Differs from Traditional Management Tools?

Spreadsheets and legacy systems might have served their purpose once, but simply can’t keep up with the confectionery business’s evolving dynamics. ERP systems provide automation, integration, and data-driven decision-making capabilities that go beyond basic record-keeping. This kind of control and insight is essential, especially when a tiny production hiccup can lead to delayed deliveries, product spoilage, or regulatory non-compliance.

With ERP for candy and confectionery, you can:

- Generate real-time production reports.

- Automate material requirement planning (MRP).

- Improve inventory accuracy by over 90%.

- Reduce downtime through predictive maintenance features.

Key Benefits of ERP for Candy and Confectionery Manufacturers

The confectionery industry may seem sweet on the surface, but behind the scenes, there lies a complex web of challenges: volatile ingredient prices, strict food safety standards, seasonal demand spikes, and evolving consumer tastes. Whether you’re producing molded chocolates, gummies, hard candies, or filled bars, keeping production consistent and compliant while managing costs is no small feat.

This is where an ERP for candy and confectionery manufacturing proves its worth. It’s more than just software—it’s a strategic backbone that connects your entire operation. Below, we explore the key benefits ERP offers, explicitly tailored to the needs of confectionery businesses.

Streamlined Production Management

ERP for candy and confectionery optimizes multi-stage workflows (e.g., recipe scaling and batch consistency). In candy production, precision is everything. Even slight variations can affect taste, texture, and shelf life, from tempering chocolate to ensuring uniformity in jellybean coatings.

One of the main challenges confectionery manufacturers face is maintaining batch-to-batch consistency, especially when recipes scale for large production runs. With ERP for candy and confectionery, you can:

- Digitize and standardize recipes across all facilities.

- Automate batch scheduling, ingredient weighing, and process control.

- Track production metrics in real-time—temperature, cooking time, moisture levels, etc.

Enhanced Inventory and Raw Material Tracking

Prevents overstocking or shortages of perishable ingredients like chocolate or sugar. Sugar, glucose syrup, and cocoa butter are not just key ingredients but commodities that fluctuate in price and shelf life. Without proper inventory oversight, you risk tying up capital in excess stock or halting production due to shortages.

An ERP for candy and confectionery allows:

- Real-time visibility into raw materials, semi-finished goods, and packaging supplies.

Automated reorder alerts based on forecasted demand and lead times. - First-expiry-first-out (FEFO) inventory logic to minimize spoilage.

Improved Regulatory Compliance and Food Safety

Automates compliance with allergen labeling, GMO regulations, and traceability mandates. Confectionery products often contain allergens (nuts, dairy, soy), artificial colorants, and GMO ingredients. Regulations vary across regions, and non-compliance can lead to costly recalls or import rejections. Traceability is no longer optional—it’s a legal obligation.

With ERP, you can:

- Maintain digital records for each lot, covering sourcing, processing, packaging, and shipping.

- Generate automated food safety compliance reports for FDA, FSSAI, and EU directives.

- Track allergens and cross-contamination risks using ingredient-level tracking.

- Instantly trace and isolate affected products in the event of a recall.

Cost Control and Profitability

Reduces waste, optimizes ingredient use, and identifies cost-saving opportunities. Margins in the confectionery industry can be razor-thin, especially when competing against private labels or global giants. Add rising vanilla, dairy, and packaging costs to the mix; every gram of waste counts.

For example, your marshmallow line runs below efficiency during the afternoon shift. ERP can highlight this trend, enabling you to retrain staff or schedule maintenance. Over time, this leads to noticeable savings across your cost of goods sold (COGS). ERP for candy and confectionery identifies:

- Yield loss patterns (e.g., chocolate wasted during tempering or molding).

- Energy and labor cost spikes in multi-shift operations.

- Ingredient substitutions that preserve quality while reducing costs.

Scalability for Seasonal Demand

Adjusts production and inventory for peak seasons (e.g., Halloween, Christmas). Holidays are make-or-break for many confectionery businesses. According to the National Confectioners Association (2023), Halloween alone accounts for over $3.6 billion in U.S. candy sales. However, meeting demand during such spikes requires careful forecasting and flexible operations.

With ERP, manufacturers can:

- Use historical data and current trends to plan production.

- Allocate resources for high-volume SKUs (e.g., Halloween mix bags).

- Manage third-party co-packers and seasonal labor seamlessly.

- Automate production line changeovers between product types

Efficient Recipe Management and R&D Integration

Accelerates new product development while maintaining cost and compliance control. The demand for new flavors (think chili mango gummies or lavender-infused chocolates), clean labels, and dietary alternatives (sugar-free, keto, vegan) is ever-growing. However, creating and scaling recipes in an ad-hoc Excel sheet no longer cuts it.

An ERP for candy and confectionery:

- Centralized formulation data with version control.

- Automatically calculates nutritional profiles and allergen declarations.

- Simulates costs and yield for new recipes before production.

- Ensures regulatory compliance during product development.

More intelligent Demand Forecasting and Sales Planning

Balances production with actual market demand to reduce stockouts or dead inventory. Overproduction of Easter-themed chocolate that doesn’t sell post-season? A common problem. ERP for candy and confectionery integrates sales data, historical trends, and market forecasts to:

- Build seasonal sales projections.

- Align procurement and production with expected orders.

- Offer automated reallocation of overstock to alternative markets or products.

Optimized Packaging and Label Management

Reduces packaging errors and supports frequent label changes for regulatory or marketing needs. Candy and confectionery packaging is a world of colorful wrappers, seasonal designs, QR codes, barcodes, ingredient panels, and promotional tags, and managing it manually can be a nightmare.

Whether printing allergen-free labels for nut-free gummies or multi-lingual wrappers for export markets, ERP for candy and confectionery ensures packaging always matches the product and market. ERP for candy and confectionery streamlines this with the following:

- Integrated packaging BOMs (Bill of Materials) linked to each SKU.

- Automated label versioning with built-in regulatory templates.

- Real-time link between product specs and packaging instructions

Vendor and Ingredient Traceability

Tracks ingredient sourcing and vendor quality to maintain brand integrity. Sourcing premium cocoa, natural colorants, or organic sugar isn’t just about price but consistency and safety. This is critical in a time when consumers care about traceability—from “bean to bar” or “farm to fruit chew.” Food ERP ensures you can tell the whole story. ERP for candy and confectionery helps confectionery brands:

- Monitor vendor performance and delivery timelines.

- Evaluate ingredient quality across batches.

- Record sustainability certifications or fair-trade sourcing data.

Allergen Control and Cross-Contamination Prevention

Manages allergen segregation with precision across recipes, lines, and shifts. Cross-contamination is a top reason for product recalls in the confectionery sector. If your facility produces nut-based products one day and nut-free gummies the next, managing allergens is non-negotiable.

This ensures that a “nut-free” claim is backed by actual process-level segregation, not just hope. ERP for candy and confectionery enables:

- Allergen mapping at the ingredient, batch, and equipment level.

- Scheduling tools to separate allergen-containing and allergen-free runs.

- QA workflows that ensure line clean-up validation before production switches.

Bring Unparalleled Efficiency to Your

Candy & Confectionery Business

From recipe control to real-time inventory and QA checks, our ERP is built to unify your

confectionery processes for smoother operations, sweeter margins, and full compliance.

See How It Works

Why Does Folio3 FoodTech’s Candy and Confectionery ERP Stand Out?

Regarding sweets, precision isn’t a luxury—it’s a necessity. Whether tempering chocolate, boiling sugar, or enrobing caramel-coated wafers, one small deviation in temperature, ingredient ratio, or timing can lead to major product inconsistencies and compliance issues. Generic ERP for candy and confectionery wasn’t built to handle that kind of nuance. But Folio3 FoodTech’s ERP for candy and confectionery was.

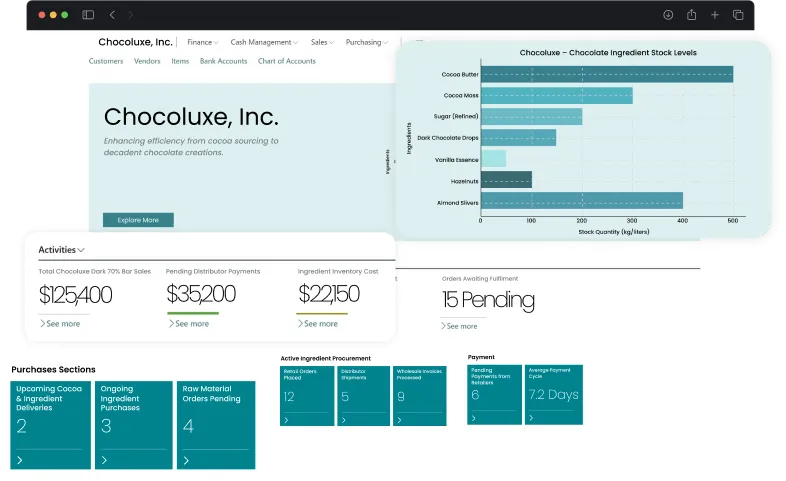

Designed specifically for the operational demands of candy and confectionery manufacturers, this ERP goes far beyond simple automation. It empowers manufacturers, packaging companies, distributors, and retailers to control every aspect of their business—from recipe to retail—with unmatched accuracy and efficiency.

Here’s what sets our ERP for candy and confectionery apart:

Custom ERP Modules for Every Candy Operation

Whether you’re producing hard candies, chocolate truffles, gummy bears, or sugar-free mints, your production process has unique variables—temperature, mixing times, ingredient ratios, and more. With Folio3, you get an ERP for candy and confectionery that adapts to your needs, not vice versa.

From artisanal confectioners to large-scale manufacturers, our modules are built for every stage of the candy-making process. Our solution lets you:

- Design and control recipe/formula-based production with full version tracking.

- Manage daily production schedules and finite loading for processes like molding and packaging.

- Precisely monitor temperature for sugar boiling and chocolate tempering.

- Track nutritional content, ingredient mixing, and cooling times.

- Handle complex BOMs by SKU, including packaging variants and seasonal items.

Smart Procurement and Ingredient Control

Managing confectionery inventory isn’t just about keeping shelves stocked—it’s about ensuring ingredients are fresh, safe, and cost-effective. Our ERP for candy and confectionery is tailored to help manufacturers balance cost and quality across multiple vendors and seasonal fluctuations.

It’s ideal for manufacturers who rely on sensitive ingredients like milk powders, flavor concentrates, natural sweeteners, or gelatin—all of which have strict storage and expiration requirements. With our procurement module, you can:

- Track bulk ingredient discounts and multiple vendor quotes.

- Forecast inventory based on seasonal demand and production cycles.

- Handle returned ingredients, manage purchase orders, and organize vendor catalogs.

- Avoid waste by managing ingredient shelf life, density conversions, and cold storage.

Packaging and Distribution Made Seamless

Packaging is critical to branding and compliance, whether you’re wrapping mini bars or boxing up assorted pralines. Folio3’s ERP for candy and confectionery makes this easier with features tailored for flexibility and food safety.

From primary packaging to final palletization, our ERP for candy and confectionery ensures accuracy, efficiency, and traceability. Key features include:

- Nutritional labeling and allergen compliance are integrated into the packaging module.

- Support label variants, QR/barcode readers, and custom weight tracking.

- Integration with 3PLs, including freight rate matrices, shipment planning, and container tracking.

- Streamlined cross-docking and multi-level warehouse management to maintain product freshness.

Built-in Sales, Demand & Financial Forecasting

Seasonal peaks heavily drive the candy and confectionery industry—Valentine’s Day, Halloween, Easter, and Christmas often account for a huge chunk of annual sales. Our ERP helps businesses forecast with confidence using real-time sales, inventory, and demand data.

This makes it easy to prepare for a surge in candy corn demand or anticipate a lull in post-holiday sales. You get:

- Master production scheduling and materials requirements planning (MRP).

- Real-time order promising and drop shipment planning.

- Innovative budgeting tools, cost accounting, and electronic payments.

- Complete visibility into cash flow, multi-currency transactions, and reconciliation.

Quality & Food Safety You Can Count On

Confectionery manufacturers must meet stringent food safety and compliance regulations, especially when dealing with allergens, GMOs, and nutritional claims. Folio3’s ERP embeds quality checks into every phase of the supply chain.

This gives QA teams full control over certifications, making audits less stressful and more efficient. Our food safety tools include:

- Lot-based quality audits and sampling workflows.

- Automated allergen tagging and traceability from batch to package.

- Supplier management, food recall readiness, and compliance dashboards.

Plant Maintenance & Downtime Prevention

Candy production often involves complex machinery, such as tempering drums, extruders, enrobing lines, and wrapping stations. Any unplanned downtime can result in massive losses. That’s why our ERP includes a dedicated asset and plant maintenance module.

Stay ahead of maintenance before breakdowns affect your batch integrity or delivery timelines. Features include:

- Preventive maintenance scheduling and automated alerts.

- Downtime tracking and labor journal entries.

- Integration with IoT sensors to monitor machine health.

- Inventory tracking for spare parts and repair logs.

Sales, CRM & Retail Integrations

Our ERP acts as a single source of truth for retailers and wholesalers. It helps manage sales pipelines, customer inquiries, B2B ecommerce portals, and even promotions—all while syncing data with production and inventory.

This supports retail chains and ecommerce sellers aiming to personalize the customer experience while keeping operations efficient. Sales and CRM tools offer:

- Sales order and invoice automation.

- Campaign pricing and email logging.

- Support for rebates, promotions, and return orders.

- Real-time customer insights, allergen visibility, and lot tracking.

Vendor and Customer Portals

Efficiency doesn’t stop at your factory walls. Our ERP offers self-service portals for vendors and customers, ensuring a smooth flow of information and reducing the need for endless back-and-forth emails.

It’s everything your partners need—without the paperwork. With our portals, you can:

- Let vendors view delivery schedules, contracts, and performance reports.

- Allow B2B/B2C buyers to place, track, and repeat orders.

- Display product quality metrics, allergens, and pricing online.

An ERP That Fits Every Candy Business

Folio3 FoodTech’s ERP is not a one-size-fits-all system. No matter what corner of the candy business you’re in, our ERP becomes the digital backbone of your operation. It’s a suite of fully integrated modules that support:

- Confectionery manufacturers: Focus on batch consistency, flavor profile accuracy, and regulatory compliance.

- Packaging companies: Deliver accurate labeling, allergen transparency, and packaging innovation.

- Distributors: Ensure traceability, manage inventory freshness, and optimize logistics.

- Retailers: Respond to consumer trends, run loyalty programs, and easily manage seasonal spikes.

Conclusion

ERP for candy and confectionery organizes your operations, from managing complex recipes and allergen traceability to optimizing packaging and distribution.

Folio3 FoodTech’s ERP for Candy and Confectionery is purpose-built to meet the unique demands of sweet goods production. It offers customizable modules that drive efficiency, ensure compliance, and boost profitability. Whether you’re a manufacturer, distributor, or retailer, our solution helps you deliver quality products faster and smarter.

Ready to transform your confectionery operations? Partner with Folio3 and take the next sweet step!

Bring Unparalleled Efficiency to Your

Candy & Confectionery Business

From recipe control to real-time inventory and QA checks, our ERP is built to unify your

confectionery processes for smoother operations, sweeter margins, and full compliance.

See How It Works

FAQs

How Does ERP For Candy and Confectionery Help Improve Batch Consistency In Confectionery Production?

ERP ensures precise recipe control, ingredient tracking, and version management. This reduces human error and supports consistent quality across batches, whether you’re producing caramels, gummies, or hard candies.

Can ERP For Candy and Confectionery Handle Allergen and Food Safety Regulations?

Yes. A candy and confectionery ERP system helps automate allergen labeling, track GMO ingredients, and manage lot traceability, ensuring full compliance with global food safety regulations like FSMA, SQF, or BRCGS.

How Does ERP for Candy and Confectionery Help with Seasonal Demand in the Industry?

ERP provides advanced demand forecasting tools, allowing manufacturers to scale production for high-demand periods like Halloween, Christmas, or Valentine’s Day without overproducing or facing stockouts.

Is ERP Suitable for Small or Mid-Sized Candy Manufacturers?

Absolutely. ERP for candy and confectionery is scalable and can be tailored to fit the specific needs of small or growing businesses. It helps organize operations without requiring an enterprise-level investment.

How Does ERP for Candy and Confectionery Improve Profitability for Confectionery Manufacturers?

By reducing ingredient waste, optimizing production cycles, and offering insights into cost structures, ERP helps identify areas for savings, directly improving your bottom line.