Food manufacturers operate under relentless pressure from time constraints, rising costs, and operational complexity. With tight margins and ever-evolving regulations, one slip in purchasing can trigger a chain reaction of delayed deliveries, spoiled goods, excess stock, or worse, unhappy customers. That’s where an ERP system for purchasing steps in. Not just as a tool, but as a transformation.

From inventory hiccups to vendor mismanagement, businesses juggle countless variables every day. A modern ERP procurement system doesn’t just handle purchasing. It optimizes your operations, plugs financial leaks, and builds long-term supplier relationships.

And this shift is already underway. According to the precedence research, the global ERP software market was valued at USD 55.38 billion in 2024 and is projected to nearly double reaching USD 110.15 billion by 2034, growing at a CAGR of 7.1%. North America alone accounted for USD 18.58 billion in a year, showing just how fast businesses are betting on ERP to stay competitive.

In this blog, we’ll break down how it transforms purchasing. We’ll cover its key features. And we’ll explain why manufacturers need to pay attention now more than ever.

What is ERP Procurement?

ERP procurement refers to managing the purchasing of goods and services through an integrated ERP system.Tasks like ordering, approvals, and tracking happen in one connected system.. That means managing supplier data, handling purchase requisitions, generating purchase orders, and tracking payments, all in one system.

When combined with procurement automation software, ERP systems evolve into a full procurement management platform. Businesses get better visibility, lower costs, and smarter decision-making.

Let’s break down the key processes that are simplified.

What Stages of Procurement Are Managed by an ERP?

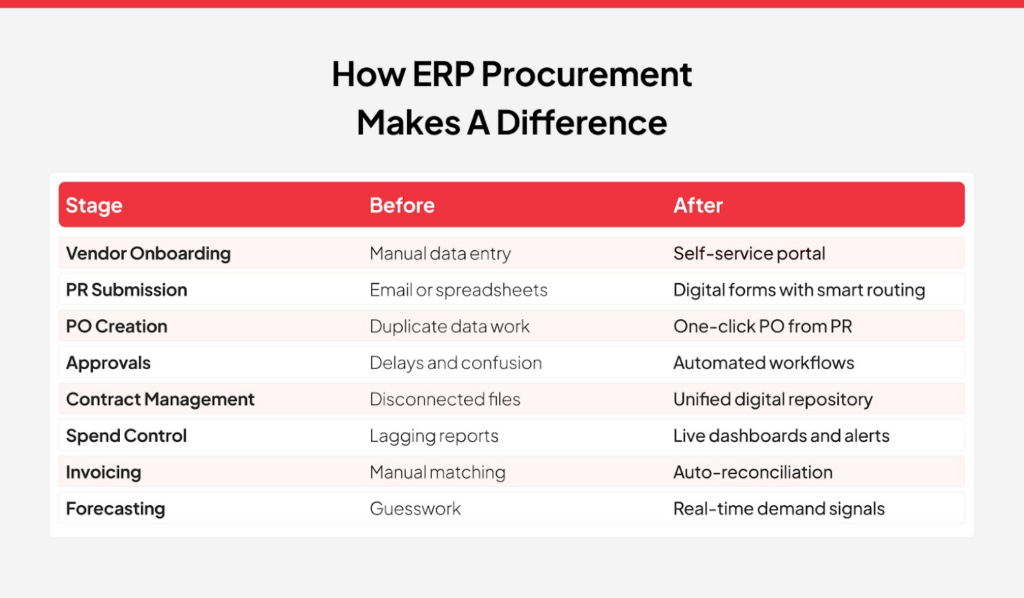

A well-integrated procurement ERP software does more than issue purchase orders. It creates a full digital workflow that touches every point of the purchasing cycle.

Here’s how each stage improves when you transition from manual to using an ERP system for purchasing.

How ERP Procurement Makes a Difference

Supplier Onboarding

With traditional procurement, supplier onboarding often means back-and-forth emails and manual data entry. Errors are common. Delays are expected. But no more.

Vendors now enter their own company information through a self-service portal. That data flows into the system with minimal manual input. It’s faster, more accurate, and improves compliance from day one.

Purchase Requisition Intake

Employees can create purchase requisitions using guided forms. These forms auto-fill data like budget codes, item categories, and preferred vendors.

The result? Fewer errors and faster approvals.

Every request follows a standardized workflow, reducing the need for back-and-forth with the procurement team.

Automated PO Creation

Once a requisition is approved, the ERP system can automatically generate a purchase order (PO). No need to re-enter data. Understanding the purchase order process helps ensure smooth coordination between departments and timely fulfillment of requests.

That reduces duplicate effort, cuts errors, and speeds up the buying cycle.

PO Approval Routing

Pushing a PO through multiple stakeholders can slow everything down. With ERP procurement, approvals follow predefined workflows based on rules like department, value, or category. Alerts are sent automatically. Stakeholders can approve from any device eliminating bottlenecks and miscommunication throughout.

Electronic Contract Repository

Contracts don’t belong in filing cabinets or on scattered desktops. It includes a centralized, digital contract library. All users with permission can view, track, and renew supplier agreements. It ensures accountability and prevents missed renewals or outdated pricing.

Real-Time Spend Analytics

Good procurement is driven by data. With built-in data analytics for food, teams can monitor actual spend versus budgets. They can spot trends, avoid overspending, and evaluate supplier performance. Dashboards make everything clear. Decisions become data-driven, not gut-based.

Key Benefits of ERP Procurement

Modern procurement is no longer just about placing orders and chasing approvals. It’s about strategy, visibility, and control. When you bring procurement into your ERP system, the impact goes far beyond the procurement team. It touches finance, operations, compliance, and the bottom line. Here’s how ERP purchasing delivers value where it matters most:

Time and Cost Savings

Manual processes eat time. Errors eat money.

Automated workflows slash processing time for purchase orders, invoices, and approvals. That translates into real cost savings month after month.

Centralized Collaboration

When all procurement data lives in one system, everyone sees the same thing.

Procurement, finance, legal, and department managers can work off the same contracts, requisitions, and reports. No duplication. No misalignment. It creates a culture of accountability and speeds up decision-making.

Workflow Automation

Approvals, routing, and document uploads happen automatically based on custom rules. No chasing emails and no guessing who needs to sign off. It ensures consistency, even as order volume grows.

Paperless Procurement

Digital records replace paper trails. Invoices, contracts, and receipts are stored securely in one system. There’s no need for printed copies or manual filing. Every action is tracked, time-stamped, and easy to retrieve. This makes audits faster and ensures nothing slips through the cracks.

Smarter Supplier Management

You can track delivery timelines, cost fluctuations, and quality issues as they happen. This data builds over time and gives you a clear picture of supplier reliability. It also helps your team renegotiate stronger contracts or switch to vendors who meet your standards consistently.

Better Spend Visibility

Every dollar spent is accounted for.

Every transaction is tracked and categorized, by project, department, or vendor. Live dashboards turn raw data into insights that help you control costs, spot trends, and plan better for future purchases.

Common Challenges with ERP Procurement

ERP systems are great for structure. But procurement needs often go beyond standard features. Teams struggle with rigid workflows and clunky interfaces.

These gaps slow things down. Here are the most common issues businesses run into:

Lack of Flexibility

Many ERP systems come with rigid procurement modules. Customizing approval flows or integrating third-party vendors can be difficult and expensive.

That’s especially true for older, non-cloud ERPs.

Poor Collaboration

Traditional ERPs aren’t built for collaboration.

Cross-functional teams struggle to access the same purchase order or contract. Communication happens outside the system through emails or spreadsheets which leads to misalignment.

Weak User Experience

Legacy ERPs often have outdated interfaces. Navigating through forms, approvals, and dashboards isn’t intuitive. That slows down adoption and frustrates teams.

Limited Spend Analysis

ERP systems may track spend, but not all of them provide deep analytics or insights. Without real-time data, companies miss trends, overspend, or lock into poor vendor contracts.

How Modern Procurement Systems Extend ERP Capabilities

ERP systems are powerful, but they aren’t built for everything. As procurement needs grow more complex, gaps begin to show. Manual approvals slow things down. Limited spend visibility makes planning harder. Custom workflows? Often out of reach. A purchasing ERP system with automation capabilities ensures faster processing of requisitions, streamlined vendor management, and fewer errors compared to outdated tools

According to the procurement insight report by Coupa, 51% of the companies using a procurement tool report a decrease in paper volume as their biggest improvement.

That’s why manufacturers are adding procurement automation to the mix. These systems integrate with your ERP to fill in the blanks. They bring flexibility, efficiency, and better control.

No more back-and-forth emails. No more manual tracking. It doesn’t replace your ERP, it makes it stronger. This is how the capabilities are extended:

Integrations with Accounting and CRM

Modern procurement platforms can connect with ERP systems like NetSuite and Microsoft Dynamics. They also link with CRM tools like Salesforce, creating a unified ecosystem that supports the entire procure-to-pay journey.

From demand forecasting to AP automation, the entire process becomes seamless.

Full Procure-to-Pay Automation

Procurement automation platforms offer a complete digital procurement lifecycle.

You can:

- Set budgets and procurement policies.

- Collect and validate vendor data.

- Automate purchase requisition and PO creation.

- Route approvals instantly.

- Track deliveries and flag order discrepancies.

- Match invoices to deliveries and auto-pay vendors.

Everything is digitized. Everything flows through a unified dashboard.

ERP Procurement in the Food Industry: Why It Matters More Than Ever

As digital procurement in food industry operations becomes the norm, food manufacturers are expected to adopt smarter tools that align purchasing with compliance and real-time inventory needs. Procurement isn’t just a workflow here, it’s a survival strategy. Margins are thin. Regulations are strict. Ingredient availability shifts fast. One procurement mistake can cost thousands in spoiled goods, missed deliveries, or rejected batches. Let’s see what a food industry ERP software simplifies to smoothen the workflows throughout:

Industry-Specific Procurement Controls

Unlike generic ERPs, Food ERP includes purchasing workflows made for food manufacturers specifically.

From compliance tracking to ingredient-level traceability, it’s built for the challenges of food supply chains. You can set vendor quality benchmarks, get alerts on expiring ingredients, and track shipments in real-time.

Quality & Compliance Checks

Procurement isn’t just about price. It’s about safety. Food ERP includes checks to ensure all ingredients meet regulatory standards before purchase. Certificates, licenses, and supplier audits are managed digitally. No gaps. No guesswork.

Inventory Sync Across Locations

Inventory levels across plants and warehouses are updated in real-time. That means no overbuying. No last-minute scrambling. Procurement stays aligned with actual stock levels helping you cut costs and avoid waste.

Freight Optimization

Shipping costs can quietly drain budgets.

It helps optimize freight by consolidating loads, picking the best routes, and selecting cost-effective carriers. Every delivery is tracked from order to arrival.

How ERP Procurement Applies Specifically to the Food Industry

Let’s narrow the lens. Why does all this matter even more for food manufacturers?

Because food is perishable. Timing is critical. Compliance is non-negotiable. And margins are often little. Here’s how a food industry ERP software addresses food-specific challenges:

Shelf Life and Freshness Management

ERP procurement systems integrated with inventory management help ensure perishable goods are used before expiration. The system can recommend FIFO (first-in-first-out) purchasing and track supplier delivery times to reduce spoilage risk.

Traceability and Compliance

Food companies are held to strict standards. ERP procurement enables food traceability from supplier to production line. In case of a recall, you know exactly where every ingredient came from and where it went.

Supplier Auditing

ERP systems keep digital records of supplier certifications such as USDA, ISO, or Halal. If a certification is due to expire, you’ll receive a notification. No manual checks are required. This protects your company from compliance management risks.

Forecasting Seasonal Demand

Many food companies deal with seasonal ingredients or demand spikes. Procurement ERP software integrates with sales forecasts to help purchasing teams order the right quantity at the right time, avoiding costly overstock or missed opportunities.

Procurement for Multi-Location Operations

Large food manufacturers often run operations across many plants or regions. An ERP purchasing system brings all procurement into one place. It cuts duplication, keeps processes consistent, and supports centralized buying. A centralized purchasing ERP system ensures that procurement stays consistent across all sites, helping large food manufacturers reduce costs and avoid duplication.

Why Food Industry Leaders Are Making the Shift

Manufacturers across industries are turning to integrated ERP procurement systems to gain speed, control, and visibility. But in the food industry, the stakes are higher.

Every purchase decision affects food safety, compliance, and profitability. Industry leaders are moving away from siloed systems and manual workflows. They’re investing in modern, automated procurement platforms to gain a competitive edge. These systems don’t just digitize purchasing. They transform it into a strategic asset.

According to a research by Naspo, the procurement departments using ERP-integrated e-procurement platforms achieve 40% faster requisition processing and 45% shorter invoice cycles, while directing $2 billion annually through centralized ERP purchasing systems

Yet in the food industry, many businesses still struggle with outdated procurement workflows that can’t keep up with supply chain volatility, perishability, and complex compliance demands. This is where specialized food ERP procurement solutions, like Food ERP by Folio3 FoodTech, shine.

How Folio3 FoodTech ERP Is Transforming Business Operations Across the Food Industry

The food industry is complex, fast-moving, and highly regulated. With perishable goods, shifting demand, and multiple warehouses, there’s zero room for error. Strict food safety laws only raise the stakes. That’s why manufacturers are rapidly turning to purpose-built ERP for food manufacturers like Folio3 FoodTech’s Food ERP to take control of their operations.

Unlike generic ERP systems, ERP for food manufacturers are made specifically for the needs of food businesses. It goes beyond just digitizing your procurement process. It transforms how you operate from sourcing raw materials to delivering the final product.

At the core of this transformation are powerful Food ERP features that work together to support every stage of your supply chain:

- Price & Demand Forecasting

- Invoice & Payment Reconciliation

- Order Deviation Detection

- Compliance & Quality Control

- Procurement Budget Control

- Procurement Approval Workflows

- Multi-Location Inventory Sync

- Freight & Route Planning

- Order & Contract Management

ERP procurement isn’t just about efficiency. It’s about control. With the right system in place, your teams spend less time on admin and more on strategy. Food businesses that automate now are setting the pace. The rest will catch up later.

Bring Order to Your Food Business with Food ERP

Connect your production, inventory, and sales,

and finally get the control you’ve been missing.

Talk to an ERP Specialist

FAQs

What Does ERP Stand For?

ERP stands for Enterprise Resource Planning. It’s a system that helps manage core business functions like finance, inventory, HR, and procurement. Everything runs on a central database, so teams work smarter and faster.

What Is The Procurement Process In ERP?

It’s how businesses buy goods and services using an ERP system. The process includes creating purchase requisitions, approving POs, managing vendors, and tracking spend. Automation ensures accuracy, speed, and compliance at every step.

What Are The 4 Types Of Procurement?

The four main types are direct, indirect, services, and goods procurement. Direct involves raw materials used in production. Indirect covers everyday operational needs. Services include external labor or expertise. Goods are tangible items not directly used in production.

What Are The 3 Common Types Of ERP?

The three types of ERP are Cloud ERP, On-Premise ERP, and Hybrid ERP. Cloud ERP is hosted online which is flexible and scalable. An on-premise ERP is installed locally and offers full control while the hybrid ERP blends both for businesses that want flexibility without losing data control.