In the current competitive food supply chain network, distribution is not just about moving goods from point A to point B. It’s a critical function that directly impacts profitability, food safety, and customer satisfaction. With rising costs and growing demand for speed and transparency, food distribution management has become a far more complex and high-stakes operation.

But the problem is that while the complexity of food distribution has grown, the tools many teams use haven’t. Even today, many food distributors are still forced to rely on spreadsheets, manual coordination, and outdated ERPs that fail to reflect real-world complexity. When your processes aren’t built for speed or transparency, minor issues can quickly become expensive failures.

This blog will give a walk-through of how food distribution works, the kinds of players involved, and the real roadblocks they face, from cold chain bottlenecks to misaligned inventory and rising logistics costs. We’ll also explore how modern food distribution management can help you shift from reactive to responsive through Food ERP, built for the work you do every day.

Understanding The Food Distribution Landscape

The U.S. food distribution landscape is a vast, complicated system that underpins the nation’s food supply. Valued at over $11 trillion globally, the US food distribution sector alone employs more than 400,000 people and operates through approximately 17,100 distribution centers. Major players like Sysco, with 340 centers serving 730,000 customer locations, and Walmart, which is investing in automated distribution centers, exemplify the industry’s scale and innovation.

Every day, U.S. foodservice distributors move close to 33 million cases, supported by fleets that collectively travel over 4.3 billion miles annually. These operations are the backbone of retail, hospitality, healthcare, and education food supply chains.

But the system isn’t without cracks. Around 35% of all food produced is lost during distribution, and the sector accounts for nearly 20% of the nation’s energy consumption, a sign of both the challenge and the opportunity. As expectations around food traceability, delivery speed, and sustainability grow, outdated processes can no longer keep up.

Understanding how this ecosystem works is crucial for distributors looking to improve food distribution management processes, reduce waste, and stay competitive in a rapidly evolving market.

Key Players In The Food Distribution Chain

Behind every successful food delivery, whether to a grocery store, a restaurant, or a doorstep, is a coordinated chain of stakeholders. It starts with producers and processors who bring food products into the system, followed by distributors and wholesalers who handle scale, logistics, and movement. Finally, retailers and food service providers make products available to consumers. When these players are aligned, food flows efficiently, profitably, and safely.

But alignment is easier said than done. Demand fluctuations, traceability pressures, and operational silos often break the flow. That’s why understanding who does what and how they interact is the first step in improving food distribution management.

| Key Player | Role in the Distribution Chain |

| Producers | Grow crops, raise livestock, or harvest raw food materials. |

| Food Manufacturers & Processors | Convert raw food into packaged or ready-to-distribute goods. |

| Distributors | Bridge the gap between producers and processors and end markets, handling logistics and delivery. |

| Wholesalers | Buy in bulk and resell to smaller businesses, often focusing on pricing and volume. |

| Retailers & Foodservice Operators | Sell directly to consumers through stores, restaurants, or institutional channels. |

Types Of Food Distributors

Not all food distributors operate the same way. The distribution model a company chooses depends on what they sell, who they sell to, and how fast their products need to move. Broadly, food distributors fall into four main categories, each with a distinct role in the food supply chain.

1. Broadline Distributors

These are the giants in food distribution management. Broadline distributors offer a wide range of food and non-food items, often serving thousands of customers across various segments, including restaurants, hospitals, schools, and retailers. Their scale gives them pricing power, logistical efficiency, and broad geographic reach. Think of companies like Sysco or US Foods. If you’re managing large-scale food manufacturing operations, broadliners are usually the go-to, but smaller brands may struggle to get visibility in their massive catalogs.

2. Specialty Distributors

Specialty distributors focus on specific product categories, such as organic foods, dairy products, or gourmet items, in food distribution management. They cater to niche markets and often offer more personalized service and tighter quality control. They’re ideal for food businesses that need unique items or have strict sourcing requirements. For example, an artisan bakery sourcing imported flour would likely work with a specialty distributor instead of a broadliner.

3. Cash-and-Carry Distributors

Popular with small restaurants, caterers, and food trucks, cash-and-carry distributors operate warehouse-style outlets where buyers purchase products directly, often in bulk. These distributors don’t offer delivery; instead, customers pick up what they need on their own schedule. It’s a low-cost model that works well for businesses that value flexibility and price over convenience.

4. Redistributors

In a food distribution management system, redistributors serve other distributors. They purchase products in bulk from manufacturers and break them down into smaller quantities for regional distributors who can’t meet the minimum order requirements directly. This model helps manufacturers expand their market reach while allowing smaller distributors to offer a broader range of products without managing massive inventories. In such a system, ensuring distribution center security is essential to protect goods, maintain supply chain integrity, and prevent disruptions.

Challenges Faced In Food Distribution & How To Overcome Them With ERP?

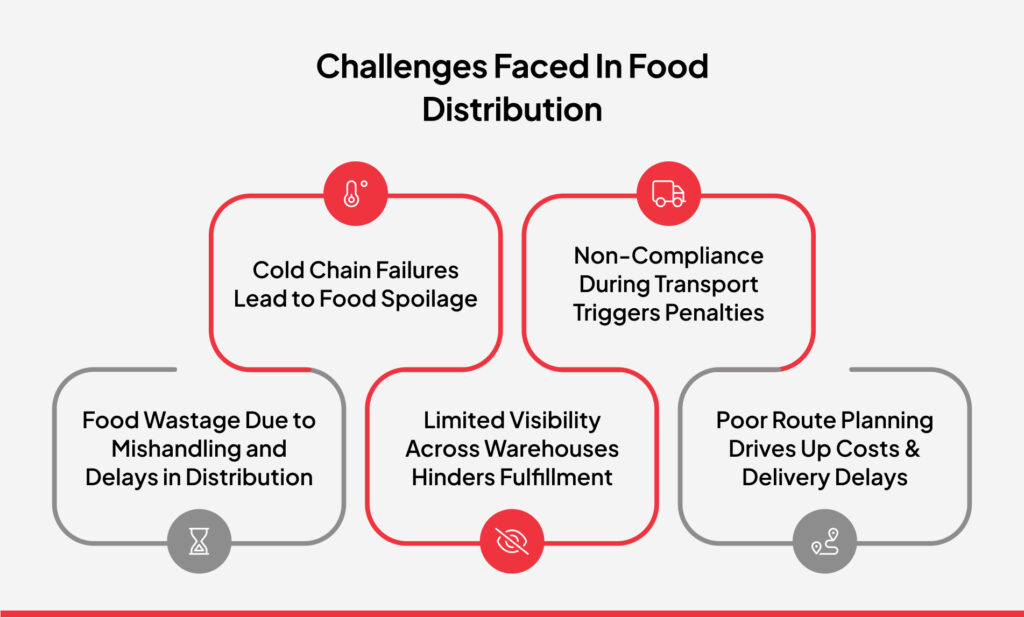

In food distribution management, the stakes are high; cold chain failures, regulatory risks, allergen management, and inefficient logistics can quickly derail operations. These issues not only threaten product quality and profitability but also customer satisfaction. However, with the right ERP solutions, these challenges can be turned into opportunities for optimization.

Let’s take a look at some of the common challenges companies face in food distribution management and how a food distribution ERP can help turn these barriers into smooth and efficient operations.

1. Cold Chain Failures Lead to Food Spoilage

In a food distribution management system, even a slight break in the cold chain can result in thousands of dollars’ worth of spoiled goods. Perishable items, such as dairy, seafood, and fresh produce, rely on tightly controlled temperatures throughout transit and storage.

A delayed truck or a malfunctioning reefer unit can compromise product integrity before it reaches shelves. For example, a brief temperature spike during last-mile delivery can render an entire shipment of yogurt unsellable. Without real-time monitoring, these failures often go unnoticed until it’s too late.

How To Overcome?

To overcome this challenge in food distribution management, an industry-specific ERP system equipped with cold chain management features is essential. These systems integrate real-time temperature monitoring tools, via IoT sensors, directly into the distribution workflow.

For example, a seafood distributor shipping salmon from Alaska can use seafood ERP with integrated sensors to track reefer temperatures. If a spike is detected during transit, the system alerts the team and suggests rerouting to a nearby cold storage.

2. Non-Compliance During Transport Triggers Penalties

Failure to comply with food transport regulations, such as the FDA’s Food Safety Modernization Act (FSMA) or the Sanitary Transportation Rule, can lead to costly fines and even supply chain disruptions.

For instance, if a dairy shipment fails sanitation checks, it can be flagged at delivery, which may lead to food safety issues and delays. These lapses often occur when records are not updated in real-time, making compliance more challenging in food distribution management.

How To Overcome?

A food ERP solution with built-in compliance tracking helps food distributors stay ahead of regulatory pitfalls. It automates documentation, such as temperature logs, sanitation checklists, and carrier certifications. Custom alerts notify food distribution management teams of any deviations or missed checks before they become violations.

For example, a dairy ERP distribution module can auto-log reefer temperature at every checkpoint and generate audit-ready FSMA reports, providing seamless compliance across shipments.

3. Food Wastage Due to Mishandling and Delays in Distribution

Food wastage is a major challenge in distribution, particularly for perishable goods like dairy and meat. Even minor delays or mishandling can result in spoilage. For example, a brief delay in refrigerated transport can cause meat to spoil, making it unsellable. Inefficiencies in monitoring or improper handling during transit can lead to significant waste, affecting profit margins.

How To Overcome?

An advanced food ERP system can optimize inventory management and improve handoff processes between warehouses and distribution points. With features like real-time tracking and automated stock alerts, the system ensures that perishable items are not exposed to unnecessary delays or mishandling, which ensures that products reach their destination intact.

4. Limited Visibility Across Warehouses Hinders Fulfillment

When inventory data is scattered across systems or not updated in real-time, fulfillment becomes guesswork. Food distributors often struggle to locate products across multiple warehouses, which can lead to missed orders or expired inventory going unnoticed. Say a high-demand SKU, like organic berries, is available in one facility but remains unseen by sales due to siloed systems, it’s a missed opportunity and a potential loss.

How To Overcome?

To overcome this, ERP systems with integrated warehouse management modules (WMS) enable real-time tracking of inventory across all locations. For example, a specialty sauce distributor managing SKUs like sriracha or chipotle aioli across regional warehouses can instantly see where stock is available using a specialized sauces ERP. With barcode scanning and centralized dashboards, sales teams avoid double orders or overlooked inventory nearing expiry.

5. Poor Route Planning Drives Up Costs & Delivery Delays

Inefficient routing not only burns more fuel but also risks missing tight delivery windows, especially for temperature-sensitive products. Without optimized fleet utilization in food distribution management, trucks may run half-empty or take longer routes, which can impact profit margins and customer satisfaction.

How To Overcome?

An ERP system can directly address poor route planning by integrating real-time GPS tracking, delivery schedules, and load optimization. For instance, a meat distributor can use an ERP for meat to allocate deliveries based on proximity, ensure trucks are fully loaded, and automatically reroute deliveries in response to traffic or weather conditions.

Smarter Food Distribution

Starts With the Right ERP

We help food businesses move from generic or patchworked systems to a fully

integrated ERP, purpose-built for the industry, and designed for you.

Talk to an ERP Specialist

Simplify Food Distribution Management With Folio3 FoodTech

By now, it’s clear that food distribution isn’t just logistics, it’s a high-stakes operation shaped by perishability, food safety compliance, and thin margins. This is precisely where Folio3 FoodTech ERP delivers targeted value. Built specifically for the food and beverage industry, it’s not a generic platform with food labels added. It’s engineered with real-world distribution challenges in mind.

The food distribution module is designed to solve problems that food distributors know all too well, like locating near-expiry inventory across multiple warehouses, maintaining cold chain integrity during transportation, and responding quickly to shifts in demand. For example, a specialty sauce distributor using Folio3 Food ERP can track exact lot numbers and expiry dates across all facilities, ensuring FIFO practices and traceability for every batch. If a temperature excursion is detected during shipping, the system flags it immediately, helping you act before a recall becomes a risk.

What sets Folio3 apart is domain expertise. This isn’t ERP retrofitted for food, it’s built by professionals who understand FSMA, HACCP, and how critical compliance is for your brand. And with flexible cloud deployment, scalability and data security are built in from day one.

Here are some reasons why Folio3 FoodTech is the right choice to optimize your food distribution management:

| Feature | Why It Matters |

| Real-Time Multi-Warehouse Visibility | Know exactly where each SKU is, including its expiry date and batch location. |

| Cold Chain Monitoring & Alerts | Built-in temperature tracking during transit with instant alerts if thresholds are breached, protecting quality and compliance. |

| Automated FIFO & FEFO Inventory Handling | Ensure product freshness and minimize waste, especially for items with short shelf lives, such as ready-to-eat meals or fresh produce. |

| Integrated Route Optimization | Plans delivery routes based on traffic, load, and temperature sensitivity, which reduces costs and avoids delays. |

| Full Traceability & Recall Management | Lot-level tracking enables a rapid response to food safety issues, which is vital for FSMA and HACCP compliance. |

| Cloud-Based & Scalable | Supports multi-location growth, remote access, and tighter data security, without the cost of on-premise hardware. |

| Industry-Specific Expertise | Designed and supported by teams with deep food industry experience, not a generic ERP team learning as they go. |

ERP and Profitability: A CFO’s Guide to Smarter Distribution Ops

ERP isn’t just about managing logistics it’s about protecting margins, streamlining compliance, and scaling smart. If you’re a financial leader evaluating long-term tech investments, this CFO’s Guide to Implementing a Food and Beverage ERP covers everything from cost structures to rollout strategy tailored for distribution-heavy operations.

Conclusion

Food distribution management today is all about a balancing act between speed, food safety, and efficiency, and the risks of getting it wrong have never been higher. As we’ve seen, multiple food distribution management challenges, such as cold chain failures and regulatory pressure, can quickly disrupt operations and affect profits. But the solution isn’t to work harder with outdated tools; it’s to work smarter with systems built to handle modern food logistics.

Folio3 FoodTech ERP brings the visibility and control today’s distributors need to perform effectively. With purpose-built food ERP modules for supply chain and distribution management, it’s designed to turn operational chaos into a smooth, data-driven system. Because this isn’t just about managing food, it’s about protecting your margins, reputation, and customers.

FAQs

What Is The Food Distribution System?

The food distribution system is the network through which food moves from producers (farmers) to processors, then to distributors, wholesalers, and retailers before finally reaching the consumer. This system ensures that food products are available across various sectors in the market.

How Do You Organize Food Distributions?

To organize food distribution, you need to first identify your target recipients. Next, establish logistics, which involves coordinating transportation, storage, and inventory management. You also need to plan for volunteers or staff, manage product quality (especially perishable goods), and set up efficient distribution points.

How To Start a Food Distribution Business?

Starting a food distribution business requires several key steps. First, conduct market research to understand demand and competition. Obtain the necessary licenses and permits, including health and safety certifications. Build relationships with food manufacturers or suppliers to secure the products you need. The last step is to establish a reliable transportation and warehouse system and implement inventory management tools to provide timely delivery and stock tracking.

How Does Food Distribution Work?

Food distribution works by connecting producers to consumers through a series of intermediaries. After food is produced or processed, it is transported to distributors, who manage logistics and supply products to retailers, wholesalers, or foodservice providers.

How Many Food Distributors Are There In The U.S?

There are roughly 408,000 food distributors across the U.S., spanning a variety of sectors from large-scale distributors to smaller, niche players.