Did you know that inconsistent recipes cost food manufacturers millions in waste annually? A single miscalculated ingredient or inaccurate portioning can lead to production inefficiencies, regulatory non-compliance, and dissatisfied customers. Maintaining recipe accuracy is crucial for scalability and compliance in the food and beverage industry.

Yet, relying on spreadsheets or paper-based processes often results in errors, lost data, and inefficiencies. This is where Food Recipe Management Software transforms operations. Businesses can cut waste and boost profitability by organizing formulation, ensuring version control, and automating compliance tracking.

Let’s explore the benefits of a food recipe management system and best practices for implementation.

What is Food Recipe Management Software?

Food Recipe Management Software is a digital solution designed to help food manufacturers maintain consistency, control costs, and comply with safety regulations. It centralizes recipe data, ensuring every batch meets the same quality standards while minimizing waste and inefficiencies. Manual recipe management becomes prone to errors as food manufacturing scales, making automation essential for efficiency and compliance.

Core Features of a Food Recipe Management System

Food recipe management software does more than just store recipes. It organizes operations, reduces costs, and ensures compliance. By automating key processes, businesses can maintain consistency across production while minimizing waste. Below are the essential features that make recipe management software a must-have for food manufacturers:

1. Recipe Creation and Version Control

Accurate recipe formulation is the foundation of any food business. Recipe management software allows manufacturers to create, edit, and store recipes while maintaining a history of changes.

This prevents confusion over outdated versions and ensures that production teams always use the correct formulation. A study by the Food Industry Executive found that recipe inconsistencies lead to a 10-15% increase in production costs—something a structured system helps eliminate.

2. Ingredient Tracking and Cost Management

Raw material prices fluctuate frequently, impacting profit margins. A food recipe management software tracks ingredient usage, calculates costs in real time, and helps businesses adjust formulations based on market trends.

With food ingredient prices rising by 5.3% in 2023 (USDA), having a system that updates costs automatically prevents financial losses and optimizes pricing strategies.

3. Integration with Inventory and Production Systems

Easy and effective integration with recipe management manufacturing software ensures that ingredient quantities align with available inventory. This reduces shortages, prevents over-ordering, and minimizes food waste. McKinsey has extensively studied food waste and supply chain efficiencies, but the specific statistic regarding a 20% reduction in waste through automated inventory tracking is not directly found in their reports.

4. Compliance with Food Safety Regulations

Meeting FDA, HACCP, and FSMA standards are non-negotiable. Recipe management software for food manufacturing ensures food safety compliance by tracking allergens, nutritional values, and regulatory requirements. This reduces the risks of recalls and fines, helping businesses maintain credibility and consumer trust.

Challenges Without Food Recipe Management Software

Food manufacturers relying on outdated methods for recipe management often face costly inefficiencies, compliance risks, and missed business opportunities. Without food recipe management software, businesses struggle with inconsistencies, waste, and regulatory issues that impact profitability.

Implementing food recipe management software eliminates these risks, organizes operations, and ensures consistency, compliance, and scalability in food manufacturing.

Manual Processes = Higher Risks

Managing recipes manually using spreadsheets or paper records increases the likelihood of human error. A misplaced decimal in ingredient measurements or a miscalculated yield can disrupt production and lead to significant financial losses.

Recipe inconsistencies contribute to a 10-15% increase in manufacturing costs. Without recipe management software, tracking ingredient changes, standardizing formulations, and ensuring batch-to-batch consistency becomes an operational headache.

Compliance Nightmares

Regulatory compliance is a critical challenge in recipe management manufacturing. Food businesses must adhere to FDA, HACCP, and FSMA guidelines, ensuring accurate allergen labeling and food safety documentation.

Without recipe management software, manually updating compliance records is time-consuming and error-prone. Nearly 48% of food recalls stem from mislabeling or undeclared allergens—issues that automated systems can prevent.

Lost Opportunities

Without food recipe management software, businesses lack real-time visibility into ingredient costs, inventory levels, and production efficiency. This makes it difficult to scale operations or respond quickly to market trends.

Food manufacturers using automated systems see up to a 20% reduction in waste and a 15% improvement in production efficiency. Without recipe management software, manufacturers risk losing competitive advantages, missing cost-saving opportunities, and struggling to meet growing demand.

Key Benefits of Food Recipe Management Software

Implementing food recipe management software offers numerous advantages for food and beverage manufacturers, enhancing efficiency, ensuring compliance, and fostering innovation. Incorporating food recipe management software into operations empowers manufacturers to maintain consistency, reduce costs, ensure compliance, foster innovation, manage inventory effectively, and scale operations easily.

Solutions like ERP for food by Folio3 FoodTech exemplify how advanced recipe management, real-time data, and compliance tools can be tailored to meet the unique needs of the food manufacturing industry. Below are the key benefits:

Consistency Across Production

Maintaining uniform product quality is essential for customer satisfaction and brand reputation. Manual recipe management can lead to inconsistencies, resulting in variable product quality.

Automated recipe management systems ensure that every batch adheres to standardized formulations, minimizing deviations and enhancing product reliability. For instance, Folio3’s FoodTech ERP automates recipe workflows, providing complete production control and ensuring consistency across batches.

Cost Reduction and Waste Minimization

Effective cost control for food manufacturing is vital in the competitive food industry. Recipe management software provides detailed insights into ingredient usage and costs, enabling manufacturers to identify areas for savings.

These systems help reduce waste and optimize resource utilization by tracking raw materials in real-time and automating recipe workflows. Folio3’s FoodTech ERP, for example, assists in monitoring raw materials and expiration dates, preventing overstocking and spoilage.

Regulatory Compliance Made Simple

Navigating complex food safety regulations is challenging. Recipe management software simplifies compliance by maintaining accurate ingredients, allergens, and nutritional information records. This ensures that products meet regulatory standards and reduces the risk of costly recalls.

Folio3’s Food Safety Software delivers consistent quality through precise recipe management and optimized safety measures, aiding in compliance with regulations like FDA, HACCP, and FSMA.

Improved Collaboration and Innovation

Innovation is key to staying competitive. Recipe management systems facilitate collaboration among R&D, production, and quality assurance teams by providing a centralized platform for sharing and updating formulations.

This organizes the development of new products and accelerates time-to-market. Additionally, these systems offer detailed analytics on recipe performance, enabling data-driven decisions and menu optimization.

Staying Updated With Inventory Levels of Ingredients

Accurate inventory management prevents production delays and reduces waste. Recipe management software integrates with inventory systems to provide real-time updates on ingredient stock levels, alerting teams to reorder when necessary.

This ensures that production schedules are met without overstocking, which can lead to spoilage. Folio3’s Food Manufacturing ERP offers real-time tracking of raw materials, ensuring efficient inventory management.

Scalability for Growth

As businesses expand, managing many recipes and production processes becomes complex. Recipe management software supports scalability by standardizing processes and providing tools to manage more extensive operations effectively.

This adaptability ensures that quality and efficiency are maintained during growth phases. Folio3’s Food ERP supports every stage of the food business, ensuring efficiency and adaptability from sourcing to distribution.

Best Practices to Employ with Food Recipe Management Software

Implementing Food Recipe Management Software is a strategic move for food and beverage manufacturers aiming to enhance efficiency, ensure product consistency, and maintain compliance with industry regulations. To fully leverage the capabilities of such a system, it’s essential to adopt best practices that optimize its functionality and align with your business objectives. Below are key strategies to consider:

Centralize Your Recipe Database

Maintaining a single, centralized repository for all recipes ensures that every team member has access to the most current and accurate formulations. This approach eliminates discrepancies from multiple versions stored in different locations, enhancing consistency across production lines.

A centralized database also simplifies updating recipes, as changes are made once and reflected universally. For instance, Folio3’s FoodTech ERP offers a unified platform where recipes, ingredient specifications, and production methods are stored, ensuring easy access and management.

Standardize Recipe Formats

Uniformity in recipe documentation is crucial for clarity and precision. Standardizing formats—detailing ingredient names, quantities, preparation steps, and cooking parameters—reduces the risk of misinterpretation and errors during production. Standardized recipes serve as clear guidelines for staff, promoting consistency in product quality.

Ensure Role-Based Access Control

Restricting access based on user roles enhances security and minimizes errors. Recipe management software should allow different levels of permissions—ensuring that only authorized personnel can modify recipes while others can view or execute them. This prevents unauthorized changes and ensures version integrity.

Integrate with Inventory and Supply Chain

Smooth and easy integration between your recipe management system and inventory control is vital for efficient operations. This connectivity allows for real-time tracking of ingredient usage, automatic stock level updates, and timely reordering alerts.

Such integration minimizes production delays caused by ingredient shortages and helps maintain optimal inventory levels, reducing waste and storage costs. Folio3’s FoodTech ERP facilitates this integration, providing real-time inventory and supply chain activity data, thereby enhancing operational efficiency.

Utilize Real-Time Data for Decision-Making

A robust food recipe management software should provide real-time data analytics, helping businesses monitor ingredient costs, production efficiency, and compliance status. With instant access to performance metrics, manufacturers can make proactive decisions, adjusting recipes or sourcing strategies to maintain profitability and quality. Folio3’s FoodTech ERP integrates real-time tracking and analytics, ensuring better oversight of manufacturing processes.

Implement Batch Scaling Capabilities

Scaling recipes accurately is essential for meeting production demands while maintaining consistency. The recipe management software for food manufacturing should have built-in batch scaling functionalities that adjust ingredient quantities automatically based on batch size. This feature helps manufacturers optimize production without compromising taste, texture, or compliance requirements.

Use Version Control

In dynamic production environments, recipes may undergo frequent modifications to improve quality or adapt to new regulations. Implementing robust version control within your recipe management software ensures that all changes are documented and previous versions are archived.

This practice maintains a clear food audit trail and allows for easy rollback to earlier versions if needed. It ensures that production teams continuously work with the approved and most up-to-date recipes, maintaining consistency and compliance.

Automate Compliance Checks

Compliance with food safety standards such as FDA, HACCP, and FSMA is non-negotiable in the food and beverage industry. Automating compliance checks within your recipe management system ensures that all formulations meet regulatory requirements.

Features like allergen tracking, nutritional analysis, and labeling compliance can be managed effectively, reducing the risk of violations and recalls. Folio3’s Food Safety Software integrates these compliance tools, organizing the process of adhering to industry regulations.

Conduct Routine Data Audits

Regularly auditing recipe data ensures accuracy, consistency, and compliance. Businesses should establish a schedule for reviewing formulations, ingredient specifications, and labeling data to identify inconsistencies or outdated information. Automated audit trails in recipe management manufacturing systems help track modifications and ensure accountability.

Train Your Team Effectively

Any software’s effectiveness is contingent upon its users. Comprehensive training programs should be implemented to ensure staff members are proficient in using the recipe management system.

Training should cover not only the technical aspects of the software but also emphasize the importance of data accuracy and adherence to standardized procedures. Regular refresher courses and updates on new features will further enhance user competency and system utilization.

Analyze and Optimize Regularly

Continuous improvement is key to maintaining a competitive edge. Regular analysis of production data, waste reports, and compliance records can identify areas for optimization. Utilizing the analytical tools within your recipe management software can provide insights into ingredient performance, cost trends, and production efficiencies.

This data-driven approach enables informed decision-making and fosters innovation in product development. Regular system audits ensure the software evolves with your business needs and industry advancements.

Why Folio3 FoodTech Food ERP Stands Out

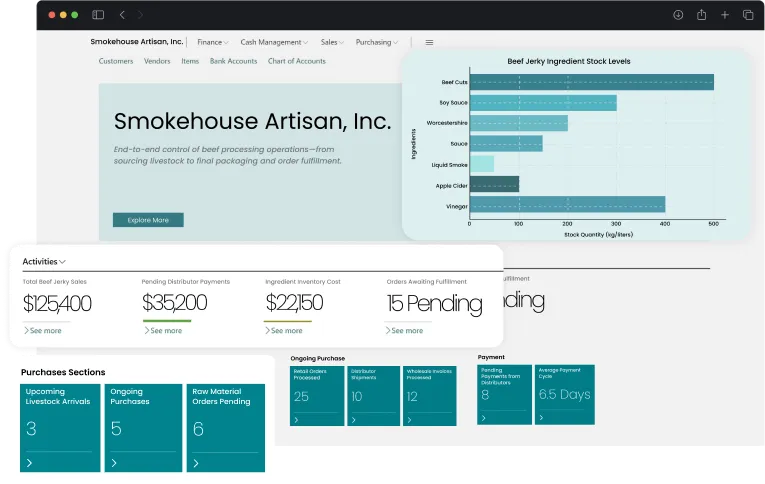

In an industry where precision, compliance, and efficiency define success, Folio3 FoodTech Food ERP emerges as a game-changer for manufacturers seeking advanced food recipe management software.

Unlike generic ERP solutions, Folio3’s platform is designed specifically for food and beverage businesses. It integrates recipe management software, inventory management, compliance automation, and real-time analytics into one smooth and organized system.

Advanced Recipe Management with Version Control

Food manufacturers face the challenge of maintaining consistency across multiple production batches. Folio3’s food recipe management software offers version control, ensuring every update in a recipe is tracked and documented. This prevents errors from outdated formulations and provides a clear history of modifications, a crucial feature for compliance and quality assurance.

Smooth and Easy Integration with Inventory & Production Systems

One of the biggest bottlenecks in recipe management manufacturing is ingredient availability. Folio3 FoodTech ERP connects recipes with real-time inventory tracking, automatically adjusting procurement needs based on production demand. This integration reduces ingredient waste, prevents stock shortages, and optimizes supply chain efficiency.

Automated Compliance & Regulatory Support

Food manufacturers must adhere to strict FDA, HACCP, FSMA, and other regulatory requirements. Folio3 FoodTech ERP simplifies compliance by offering automated audit trails, allergen tracking, and nutritional labeling tools.

The system generates real-time reports, reducing the risk of compliance breaches and helping businesses prepare for inspections without last-minute scrambling.

Real-Time Cost & Waste Management

Fluctuating ingredient prices can significantly impact profit margins. Folio3’s recipe management module in the food manufacturing solution provides real-time cost tracking, allowing manufacturers to adjust recipes or sourcing strategies dynamically. Additionally, waste reduction tools analyze production efficiency, helping businesses cut down on unnecessary losses.

Scalability for Growth

Managing multiple production facilities, new product lines, and complex supply chains becomes challenging as businesses expand. Folio3’s food recipe management system is built for scalability, supporting multi-location operations while maintaining recipe consistency, compliance, and cost efficiency.

Conclusion

Effective Food Recipe Management Software is more than just a digital tool—it’s a strategic asset for food and beverage manufacturers. Without it, businesses struggle with inconsistencies, compliance risks, ingredient waste, and inefficiencies that hinder profitability and growth.

A strong food recipe management system ensures recipe consistency, cost control, regulatory compliance, and operational scalability, giving businesses a competitive edge. Folio3 FoodTech ERP takes recipe management to the next level by offering real-time tracking, automated compliance, easy inventory integration, and scalability, making it an ideal choice for food manufacturers.

FAQs

What is Food Recipe Management Software?

Food Recipe Management Software is a digital solution designed for food manufacturers to manage recipes, ingredient tracking, compliance, and cost control. By integrating with other business systems, it ensures consistent production quality, regulatory adherence, and efficient inventory management.

How Does Recipe Management Software Help Food Manufacturing Businesses?

It reduces errors from manual processes, ensures consistent ingredient measurements, helps with cost optimization, and organizes compliance with food safety regulations like HACCP and FSMA.

Can Food Recipe Management Software Integrate With Existing Inventory and Production Systems?

Yes, modern recipe management software food manufacturing solutions, such as Folio3 FoodTech ERP, easily integrate with inventory, supply chain, and production management systems, ensuring real-time ingredient tracking and preventing stock shortages.

What Are The Key Features To Look For In A Recipe Management System?

Key features include recipe creation, version control, ingredient cost tracking, inventory integration, compliance automation, and scalability to support business growth.