Managing the movement of perishable goods from farm to fork has never been more complex or critical. For food distributors, even minor inefficiencies in the supply chain can result in costly spoilage, compliance failures, or missed delivery windows. That’s why the distribution module in ERP systems has become an essential backbone for food industry logistics, helping companies gain control over inventory, improve traceability, and streamline operations from suppliers to end consumers.

This specialized ERP distribution module coordinates every stage of the supply chain from procurement and warehousing to order fulfillment and transportation. It supports real-time decision-making and ensures that the right products arrive at the right place and time with minimal waste. Food ERP systems can improve order accuracy, directly impacting bottom-line performance for food distributors.

Stricter food safety regulations and growing consumer expectations for transparency also drive the demand for tighter supply chain management in food distribution.

Moreover, the ERP distribution module equips food distributors with powerful tools to efficiently manage order fulfillment, track inventory levels, and optimize transportation logistics.

Syncing real-time data across the supply chain enhances the accuracy and timeliness of deliveries, minimizing delays and reducing costs. These capabilities enable smarter logistics optimization in food distribution, which is crucial in an industry where margins are tight and on-time delivery is critical.

This blog explores how the distribution module in ERP transforms traditional food supply chains, boosts operational resilience, and empowers decision-makers to stay ahead in a competitive market.

Core Functionalities of the ERP Distribution Module in Food Supply Chains

The distribution module in ERP systems is more than just a digital upgrade; it’s a strategic asset that brings control, visibility, and efficiency across the food supply chain.

Here’s how its core functionalities directly support food distributors and supply chain managers in overcoming day-to-day operational challenges:

1. Warehouse and Inventory Management

Efficient inventory control, with limited shelf life, is non-negotiable in the food industry. The ERP distribution module offers real-time stock visibility, automated reorder points, and batch management to minimize spoilage and stockouts. IBM’s research indicates that companies automating their inventory and order management systems can achieve a 25% decrease in inventory holding costs. The system also supports FIFO and FEFO methods, crucial for managing perishable goods.

2. Order Management and Fulfillment

Timely and accurate order fulfillment is crucial for maintaining strong customer relationships. The ERP distribution module optimizes the entire distribution process, from inventory management to picking, packing, and shipping, ensuring that orders are fulfilled quickly and accurately.

When these tasks are automated, the ERP system reduces manual errors, improves operational efficiency, and enhances customer satisfaction. This is especially important in food distribution, where meeting tight delivery schedules and ensuring the freshness of products are essential to maintaining supply chain efficiency.

3. Transportation and Logistics Optimization

Logistics optimization in food distribution relies heavily on precise route planning and load balancing. The distribution module in ERP enables transportation scheduling, carrier selection, and cost tracking all within one unified platform.

4. Sales and Distribution Analytics

Advanced reporting tools within ERP’s sales and distribution module allow decision-makers to track sales trends, identify slow-moving inventory, and monitor customer buying behaviors. These insights are essential for demand forecasting and pricing strategies, helping food distributors stay agile in fluctuating markets.

5. Real-Time Order Tracking and Status Updates

With consumer demand for transparency growing, real-time order tracking is no longer optional. Companies can offer live status updates to customers and internal teams through ERP integration in food distribution. This improves communication, boosts trust, and reduces inquiries and complaints.

6. Load Planning and Dispatch Scheduling

The distribution module in ERP allows logistics teams to plan vehicle loads efficiently and schedule dispatches with precision. This is particularly valuable for mixed-product shipments where space, weight, and handling requirements vary. Proper load planning ensures reduced fuel consumption and fewer trips, supporting cost savings and sustainability efforts.

7. Cross-Docking and Multi-Warehouse Fulfillment

Many food distributors use cross-docking to speed up delivery and reduce storage costs. The ERP distribution module facilitates the direct transfer of inbound shipments to outbound carriers, minimizing warehouse handling time. It also supports coordination between multiple warehouse locations, allowing companies to fulfill orders from the nearest or best-stocked site, which is essential for regional and national operations.

8. Integrated Cold Chain Logistics

Maintaining the cold chain is vital for dairy, meat, and frozen goods. ERP systems with integrated cold chain logistics tools monitor temperature-sensitive items across transport and storage. The distribution module in ERP ensures these metrics are logged, reported, and traceable, which helps meet regulatory compliance and food safety standards.

Benefits of the ERP Distribution Module for Food Supply Chains

A well-integrated ERP distribution module does more than streamline daily operations – it significantly enhances the efficiency and effectiveness of the entire food supply chain.

For food distributors, this technology plays a key role in maintaining freshness, reducing waste, and ensuring timely deliveries, all while optimizing costs and compliance efforts. In an industry with tight margins, every second and penny saved counts.

Here’s how the distribution module of ERP systems delivers real value to food distributors and logistics managers:

Faster Order Fulfillment Cycles

Speed is critical in food distribution, especially when dealing with perishable goods. The ERP distribution module automates order processing, seamlessly connecting inventory, sales, and logistics teams in real time.

This integrated system eliminates delays in order approvals, picking, and shipping, ensuring faster fulfillment. Studies show that companies leveraging ERP systems can reduce fulfillment cycles by up to 30%. This means products like fresh produce, meats, and dairy arrive on time, ensuring quality and customer satisfaction.

Reduced Distribution Costs

Managing distribution costs in food logistics, from fuel to storage fees, can be challenging. ERP systems help food distributors lower operational costs by optimizing delivery routes, automating inventory control, and reducing errors.

Food distributors are saving in logistics and handling costs by preventing overstocking and spoilage and minimizing unnecessary mileage. These cost savings directly impact profitability, especially for distributors handling large volumes of goods with limited storage capacity.

Improved Delivery Accuracy and Timeliness

The food distribution industry thrives on punctuality and precision. ERP’s distribution module helps distributors plan and dispatch shipments accurately by integrating real-time order tracking, automated alerts, and load planning.

This enables them to meet delivery deadlines and consistently exceed customer expectations. When ERP systems are in place, an order accuracy rate is achievable, helping ensure food safety standards are met and maintaining customer trust.

Enhanced Product Traceability and Recall Readiness

Traceability in the food industry is essential, particularly when dealing with recalls or safety inspections. ERP distribution modules track products by batch, lot, and expiration date, providing complete visibility into every item’s journey from farm to fork.

In the event of a recall, food distributors can quickly trace affected products, ensuring compliance with regulations such as those set by the FDA or USDA. This capability protects brand reputation and ensures the company is always prepared for regulatory audits.

Better Warehouse Utilization

For food distributors, efficient warehouse management can directly influence operational costs and inventory turnover. An ERP distribution system helps optimize warehouse space in real-time, ensuring that storage is effectively utilized.

With advanced space optimization, smart slotting, and fast cross-docking, food distributors can minimize idle space, reduce picking time, and ensure efficient product movement.

Additionally, ERP systems support multi-warehouse coordination, allowing distributors to manage inventory across multiple locations, ensuring that stock levels remain consistent and demand is met promptly.

How Folio3 FoodTech Empowers Food Distributors with Scalable ERP Solutions?

Food distribution isn’t just about moving products, but it’s about moving them with precision, speed, and accountability. As supply chains become more complex, the need for intelligent ERP solutions becomes non-negotiable. That’s where Folio3 FoodTech stands out.

Folio3 FoodTech specializes in tailoring ERP implementations specifically for the food and beverage industry. Whether organizing warehouse operations, ensuring traceability, or enabling cold chain logistics, its solutions address fundamental challenges in food supply chains.

By using the distribution module in ERP, Folio3 FoodTech helps businesses automate key workflows, reduce human error, and gain visibility into everything from inventory levels to order statuses. Their expertise in ERP integration in food distribution has made them a trusted partner for many growing brands.

Smarter Food Distribution

Starts With the Right ERP

We help food businesses move from generic or patchworked systems to a fully

integrated ERP, purpose-built for the industry, and designed for you.

Talk to an ERP Specialist

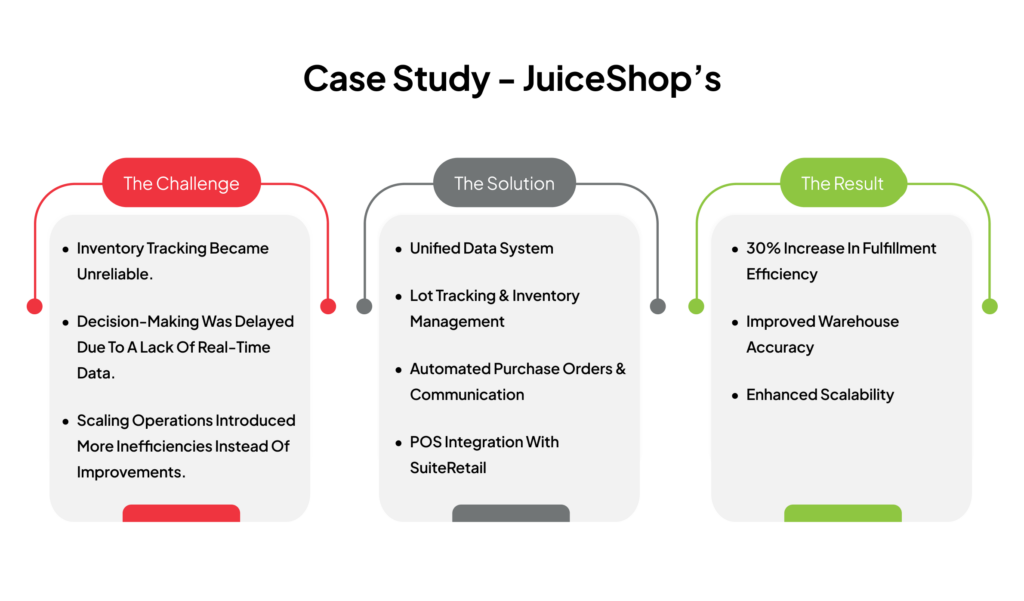

Case Study – JuiceShop’s Transformation with Folio3 FoodTech

JuiceShop is a California-based retailer and distributor known for premium organic juices and cleanse products. As demand surged and operations scaled, their patchwork of disconnected systems began to hold them back.

The Challenge – Disconnected Systems & Disorganized Growth

JuiceShop’s rapid expansion brought a critical challenge: managing financial, inventory, and operational data across multiple platforms. They needed more than just software. They needed a strategic partner to unify and streamline their end-to-end processes. As a result:

- Inventory tracking became unreliable.

- Decision-making was delayed due to a lack of real-time data.

- Scaling operations introduced more inefficiencies instead of improvements.

The Solution – Custom ERP Implementation with NetSuite

These customizations gave JuiceShop complete control and traceability, which is essential in food supply chain management. Folio3 FoodTech deployed a tailored NetSuite solution that integrated every aspect of JuiceShop’s operations, from finance to warehousing. Key enhancements included:

- Unified Data System: Consolidated financials, inventory, and sales data into one platform.

- Lot Tracking & Inventory Management: Introduced custom modules for managing lot-numbered items, which are critical for perishables.

- Automated Purchase Orders & Communication: Developed intelligent forms and automated procurement workflows to cut delays.

- POS Integration with SuiteRetail: Enhanced visibility across retail and distribution channels.

The Result – Operational Clarity, Cost Control & Scalable Growth

With centralized workflows and ERP-driven automation, JuiceShop could focus on growth, not survival. The transformation enabled them to meet demand, reduce manual tasks, and operate with agility. Following the implementation, JuiceShop experienced measurable improvements:

- 30% increase in fulfillment efficiency thanks to streamlined operations

- Improved warehouse accuracy through real-time tracking

- Enhanced scalability without compromising traceability or delivery standards

Conclusion

A strong distribution module in ERP can transform how you manage orders, inventory, logistics, and safety compliance across your supply chain. From faster fulfillment to better traceability, the right ERP solution empowers you to scale confidently. Folio3 FoodTech offers customized ERP implementations explicitly designed for the food industry, helping businesses like JuiceShop overcome inefficiencies and accelerate growth. So, if you’re ready to organize operations, improve traceability, and future-proof your food distribution business, partner with Folio3 FoodTech, your expert in smart ERP integration for lasting impact.

FAQs

What Is Distribution In ERP?

Distribution in ERP refers to managing the flow of goods from suppliers to customers, covering inventory, order processing, and logistics to streamline supply chain operations.

What Are The Four 4 Different Modules Of The ERP System?

The four core ERP modules are Finance, Human Resources, Manufacturing, and Distribution. Each supports key business functions with integrated data.

What Is The Sales And Distribution Module?

ERP’s Sales and Distribution module handles order-to-cash processes, including sales order processing, shipping, invoicing, and customer management.

Why Is ERP Functional In The Distribution Industry?

ERP streamlines warehouse, inventory, and logistics operations, improving order accuracy, reducing costs, and boosting efficiency in the distribution industry.

What Is The Role Of ERP In Sales And Distribution?

ERP enhances sales and distribution by automating order management, tracking inventory, ensuring timely delivery, and improving customer satisfaction.

What Does MRP Stand For?

MRP stands for Material Requirements Planning, a system for managing manufacturing processes by ensuring materials are available for production.

Is SAP ERP Or MRP?

SAP is an ERP system that includes MRP functionality. It offers end-to-end solutions for managing enterprise-wide operations and supply chains.

What Does MRO Stand For?

MRO stands for Maintenance, Repair, and Operations, referring to the equipment and materials used to maintain business assets and infrastructure.

What Does PLM Stand For?

PLM stands for Product Lifecycle Management, which manages a product’s entire journey from design to retirement within ERP or standalone systems.