The meat industry in 2025 is at a crossroads. Demand is climbing fast. But so is the pressure on costs, on ethics, on the environment, and on operations.

According to the Food and Agriculture organization, the global meat consumption is expected to rise by 14% by 2030, led by poultry and pork. But with that growth comes intense scrutiny. Regulatory, consumer, and supply chain expectations are shifting. Here’s why this matters: meat producers can’t just scale up. They need to evolve. That means digitizing, optimizing, and proving accountability at every level. Let’s explore the biggest meat industry problems today and how Food ERP systems can actually solve them.

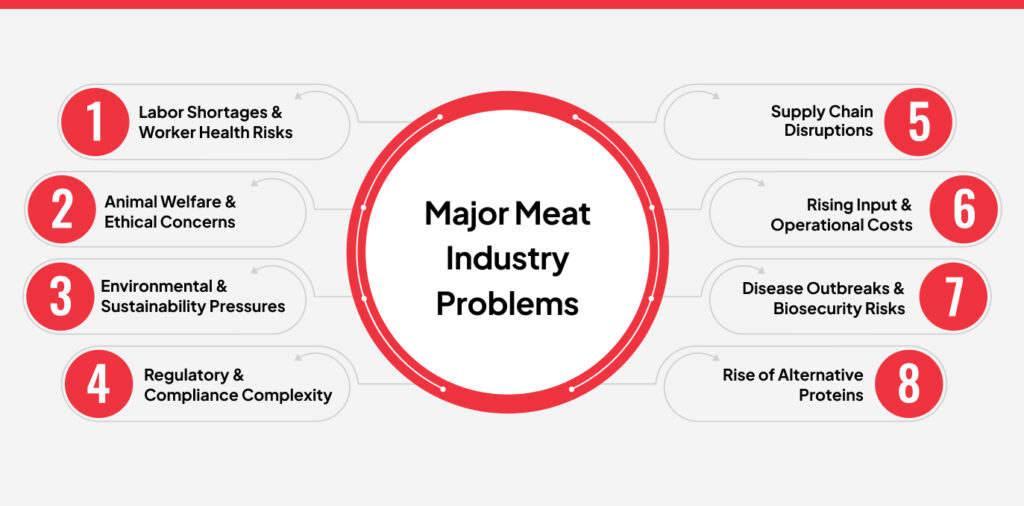

Top Challenges Faced within the Meat Industry

We’ve grouped the major issues thematically to show just how interconnected the meat industry’s struggles really are. Challenges like labor shortages and supply chain issues impact every stage of meat production on the environment. These problems rarely exist on their own. They tend to overlap, triggering a chain reaction across operations. This makes it harder to stay efficient, compliant, and competitive. That makes it harder for meat producers to keep pace. And even harder to plan ahead. Only by understanding the full picture can the industry develop effective solutions that drive lasting change.

Labor Shortages & Worker Health Risks

The meat industry has always been labor-intensive. But in 2025, labor availability is in crisis mode. Injuries, high turnover, and mental health strain are driving workers away. Plants struggle to keep shifts full, while demand for meat keeps rising. Traditional fixes like wage hikes aren’t enough anymore.

- Biological and chemical hazards remain high. Workers deal with pathogen exposure, cleaning chemicals, and zoonotic risks daily.

- Musculoskeletal injuries from repetitive tasks are common. Many roles involve heavy lifting, sharp tools, and long hours on the floor.

- Mental health and turnover are growing concerns. Constant pressure, limited mobility, and poor work-life balance drive churn.

Did you know? A 2024 report by the Bureau of Labor Statistics found that meatpacking had one of the highest injury rates across all manufacturing sectors (BLS, 2024).

Animal Welfare & Ethical Concerns

Consumers are more aware and more vocal about how animals are raised. Practices like gestation crates and antibiotic overuse are under fire. Watchdog groups demand better transparency. Ethical sourcing isn’t optional anymore, it’s expected. And failing here hurts brand trust fast.

- Intensive farming practices, like gestation crates and feedlot crowding, face global criticism.

- Antibiotic overuse in livestock is under the microscope. Regulators and consumers alike are calling for tighter controls.

- Watchdog scrutiny is intensifying. NGOs, journalists, and influencers are pushing meat industry brands to prove their welfare standards.

Consumers want meat that’s ethical and traceable. The problem? Most producers can’t prove it.

Environmental & Sustainability Pressures

One out of the major meat industry problems is the environmental impact of meat production. Methane, water waste, and deforestation are all under the microscope. New climate laws and ESG pressure are building fast. Producers are being pushed to prove sustainability or risk losing investors and markets.

- According to a research by UNEP, methane emissions from cattle alone contribute roughly 20% of global agricultural GHGs.

- Water and energy usage in meat industry processing is massive.

- Deforestation and biodiversity loss tied to feed crop expansion raise global alarms.

Investors and regulators are responding. ESG scoring is real, and meat producers without emissions data? They’re falling behind.

Regulatory & Compliance Complexity

Food safety compliance isn’t getting simpler, it’s getting stricter. Labeling laws, traceability rules, and antibiotic use policies keep evolving. Regional differences make compliance harder. One audit slip can mean shutdowns or recalls. And keeping up manually just isn’t scalable anymore.

- Labeling and food traceability laws are evolving fast. What’s allowed in the US may be banned in the EU.

- Antibiotic usage disclosures, animal welfare certifications, and emissions data are now required in many markets.

- Audit challenges are growing. Regional inconsistencies and paper-based processes slow everything down.

Consider this: A single mislabeled product can now trigger a multi-country recall, costing millions and damaging brand trust.

Supply Chain Disruptions

The global meat industry supply chain has never been more fragile. Labor shortages, transport delays, and export restrictions cause constant bottlenecks. One weak link and everything stalls. Market volatility adds another layer of chaos. Without real-time visibility, producers are flying blind. That’s a big risk in a low-margin industry.

- Labor shortages in logistics delay shipments. That leads to spoilage, missed contracts, and stockouts.

- Volatility in commodity prices impacts feed, packaging, and even basic utilities.

- Lack of downstream visibility makes it hard to plan for demand or react to disruptions.

Resilience isn’t just about having inventory, it’s about having insight.

Rising Input & Operational Costs

Margins in meat processing have always been tight. Now, they’re razor thin. Feed, fuel or energy everything costs more. Manual processes waste time and resources. Even small inefficiencies eat into profit. Producers need smarter ways to control costs, fast.

- Manual inefficiencies like paper-based tracking and siloed data add to operational drag.

- Compliance costs are stacking up, especially for mid-sized producers who can’t scale compliance staff.

Disease Outbreaks & Biosecurity Risks

Diseases like ASF and Brucellosis aren’t gone. In fact, they’re resurfacing. Outbreaks can wipe out entire herds and shut down trade overnight. Early detection is still a major gap. And without strong meat traceability, containment becomes chaos.

- Early detection systems are rare, especially on smaller farms.

- Outbreak tracing is often manual, relying on spreadsheets or paper logs.

- Quarantine coordination across regions is clunky, leading to delayed containment.

Research at the Food and Agriculture organization shows, In 2023, African Swine Fever outbreaks cost the Philippines over $400 million in lost pork production.

Ethical & Public Image Risks

Today’s consumer doesn’t just want meat, they want clean, traceable, and honest meat. Claims like “sustainable” or “humane” need proof. Without it, brands lose trust fast. Social media backlash can hit overnight. Transparency isn’t a nice-to-have survival.

- Sustainability claims without proof get flagged.

- Ethical sourcing labels are being challenged by watchdogs and lawsuits.

- Brand perception is tied to transparency and a weak link anywhere damages trust.

Rise of Alternative Proteins

Plant-based and lab-grown meats are no longer niche. They’re carving out real market share as consumers look for healthier, cruelty-free, and climate-friendly options. According to Bloomberg Intelligence, the global plant-based foods market could reach $162 billion by 2030, up from $29.4 billion in 2020, potentially comprising 7.7% of the global protein market.

How ERP Systems Help the Meat Industry Thrive

Here’s the good news: modern ERP platforms built for food and meat industry operations can address these problems head-on. These systems aren’t just for tracking inventory, they’re designed to tackle the core challenges we just explored.

Let’s map the solutions to each issue cluster.

Worker Health & Labor Efficiency

ERP systems automate repetitive tasks to reduce worker strain. Food safety softwares and compliance management helps prevent injuries and improve training. Scheduling tools balance workloads to avoid burnout and lower turnover. With digital oversight, managers can spot risks early and keep shifts running smoothly.

- Safety logs and incident tracking help manage risk and show compliance.

- Digital training records prove regulatory adherence.

- Smart scheduling tools reduce worker fatigue and absenteeism.

Animal Health & Welfare Management

It enables you to track animal treatments and health records in real time. This ensures compliance with welfare standards and antibiotic use policies. Traceability features document every step from birth to processing giving producers full control and transparency. It helps meet consumer and regulator demands with ease.

- Welfare scoring systems can be integrated directly into livestock modules.

- Antibiotic treatment logs ensure you stay within limits and prove it.

- Livestock tracking ensures full visibility across farms, transit, and slaughter.

That leads to better outcomes for animals and clearer proof for consumers.

Sustainability & Environmental Tracking

Modern ERPs provide detailed reports on emissions, water, and energy use. They help producers monitor resource consumption closely. This data supports ESG goals and green audits, making sustainability claims verifiable. With these insights, companies can reduce waste and improve their environmental footprint.

- Emission tracking tools help meet carbon disclosure obligations.

- Resource usage reports (water, energy, waste) support audits and certifications.

- Sustainability KPIs are centralized, no spreadsheets needed.

This turns sustainability from a PR liability into a data-driven differentiator.

Regulatory Compliance & Labeling

ERP systems automatically update to reflect changing food safety laws and labeling requirements. They provide full traceability from farm to fork, ensuring audit trails are complete and easy to access. This reduces the risk of costly recalls and helps meet regional regulations without the manual headache.

- Auto-updated compliance modules reflect local, regional, and global law changes.

- Digital lot traceability ensures recall readiness and audit proof.

- Labeling automation ensures allergen and nutritional accuracy at scale.

ERP turns compliance into a process, not a panic button.

Supply Chain Optimization

The supply chain modules improves inventory planning and logistics tracking, giving full visibility across the supply chain. Demand forecasting helps avoid overproduction or shortages. By syncing suppliers and transport schedules, the system reduces delays and bottlenecks. This boosts efficiency in a fragile market.

- Live inventory dashboards sync with warehousing and logistics.

- Supplier performance tools help forecast delays or shortages.

- Demand planning engines analyze sales data for smarter production decisions.

That leads to better inventory management and less waste.

Cost Control & Resource Efficiency

ERP platforms optimize feed formulation and resource use to cut unnecessary expenses. Profitability dashboards highlight waste and inefficiencies in real time. This lets producers make smarter decisions to protect razor-thin margins and improve overall cost control.

- Batch costing and real-time P&L dashboards help managers see where money is leaking.

- Feed and formula optimization tools reduce overfeeding and waste.

- Asset maintenance modules reduce unplanned downtime.

Disease Control & Biosecurity

ERP systems manage vaccination schedules and provide early outbreak alerts. Farm-to-fork traceability helps contain disease fast and meet quarantine protocols. This reduces the impact of outbreaks like ASF and Brucellosis and keeps operations running smoothly.

- Vaccination logs and animal health history are digitized.

- Geo-tracking enables quick quarantine responses.

- Digital traceability ensures rapid source identification in an outbreak.

This isn’t just about safety, it’s about continuity.

Ethical Transparency

ERPs generate exportable reports to prove sustainability and ethical sourcing claims. Marketing-ready dashboards build consumer trust by showing clear, verified data. This transparency turns ethical commitments into competitive advantages.

- Exportable sustainability reports support ESG claims.

- Consumer-facing dashboards show real welfare, emissions, and safety stats.

- Certifications and audits become easier to manage, renew, and publish.

Transparency isn’t just a buzzword. It’s a strategic advantage.

The Way Forward for Meat Producers

The meat industry faces deep and complex challenges in 2025. Labor shortages, rising costs, regulatory hurdles, and increasing demands for sustainability and ethics are reshaping the landscape. But these problems are not unsolvable.

With the right technology, meat producers can not only survive, they can lead. Folio3 FoodTech’s Food ERP is built specifically to tackle these exact issues. It simplifies operations, boosts compliance, enhances transparency, and drives cost efficiency, all in one unified platform.

If you’re ready to digitize your meat production and stay ahead of the curve, Food ERP is your smartest investment yet to be made.

Modernize Your Meat Business

with an ERP Built for the Industry

From slaughter to shelf, we design Meat ERP solutions that handle every cut, spec, and compliance need—

helping you track, trace, and scale with confidence.

Talk to a Meat ERP Specialist

Case Study — Scaling North America’s Largest Lamb Processor with FoodERP by Folio3 FoodTech

North America’s largest lamb processor, partnering with 1,000+ family ranches and generating $280M+ annually, faced major challenges scaling with manual, siloed systems. Tracking resources, managing farm activities, and coordinating production became complex and slowed growth.

Folio3 FoodTech’s Food ERP provides a unified digital platform that broke down data silos and centralized operations. From livestock management and ethical slaughter planning to digitized production and accelerated shipments, the solution improved visibility, compliance, and efficiency across the board. The result? Connected precision replaced manual chaos, enabling smarter planning, faster production, and seamless dispatch.

FAQs

Why Is There Meat Shortage In 2025?

The 2025 meat shortage is driven by labor shortages, disease outbreaks, climate-related feed disruptions, and ongoing supply chain challenges. Stricter regulations and rising operational costs have also slowed production across key sectors.

What Is The Future Of The Meat Industry?

The future of the meat industry hinges on technology, sustainability, and transparency. Producers are exploring smarter tools to cut waste, improve traceability, and adapt to ethical and environmental demands.

What Are The Challenges Facing The Meat Industry?

Major challenges include labor gaps, rising input costs, regulatory pressure, and public demand for ethical sourcing. Many producers are adopting meat production solutions to navigate these issues and modernize their operations.

What Will Replace Meat In The Future?

Plant-based proteins, lab-grown meat, and fermentation-based alternatives are leading the shift. These options are designed to match meat’s taste and nutrition. But they come with a lower environmental impact. They may not fully replace traditional meat, but they’re gaining ground fast. As demand for ethical and sustainable food grows, these innovations are becoming key meat production solutions for the future.