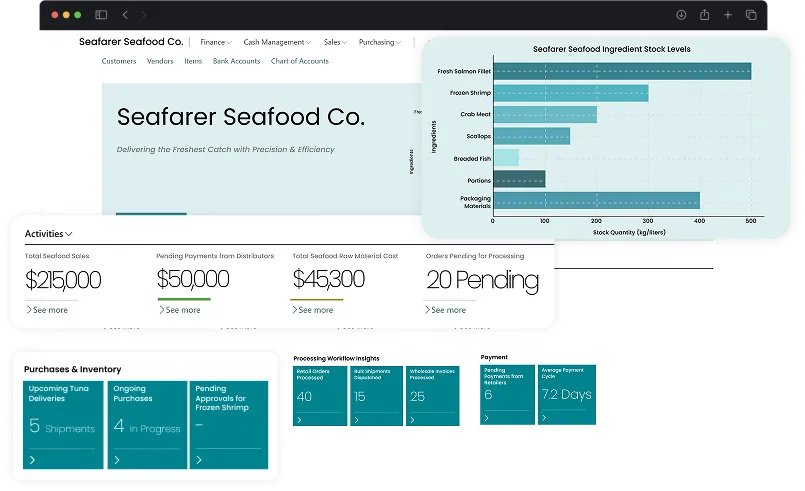

Optimize all stages of your seafood business with a purpose-built seafood ERP. Track sourcing, monitor cold storage, manage processing, and ensure compliance while maintaining peak product quality and traceability.

Address operational bottlenecks and increase profitability with ERP solutions designed to optimize every aspect of seafood processing.

Strict traceability laws make it challenging to track every fish from catch to consumer, risking penalties and lost trust.

Managing multiple stocks, such as shrimp, tuna, and shellfish, while preventing spoilage, mislabeling, and stock imbalances is a constant struggle.

Unwanted catch, discarded trimmings, and inefficient yield management reduce margins and make sustainability harder to achieve.

Water quality, disease outbreaks, and antibiotic regulations demand constant farm monitoring to protect stock and avoid financial losses.

Fluctuating fish sizes, moisture loss, and handling variations create invoicing challenges and impact profitability.

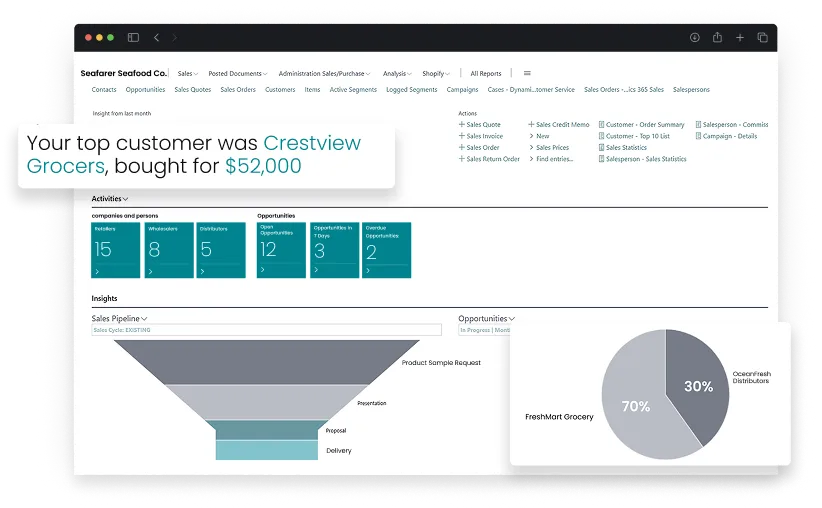

Enhance your seafood operations with ERP modules for full traceability, precise demand planning, and seamless supplier coordination.

From fishing vessels to retailers, our seafood ERP delivers end-to-end traceability, food safety, and operational efficiency.

With ERP, keep your fleet efficient and your quotas profitable. Track every haul, cut fuel waste, and stay ahead of regulations with real-time insights.

With aquaculture software, keep every farm, pond, and pen running efficiently. Plan harvests, track biomass, and manage water quality while maintaining precise stock records.

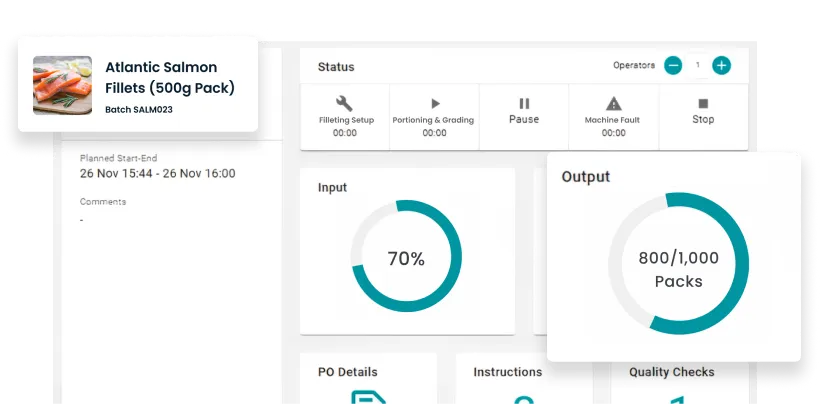

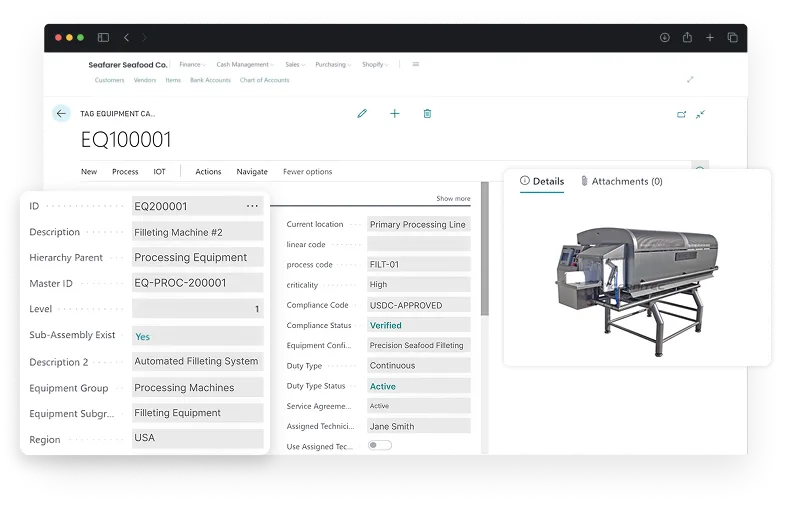

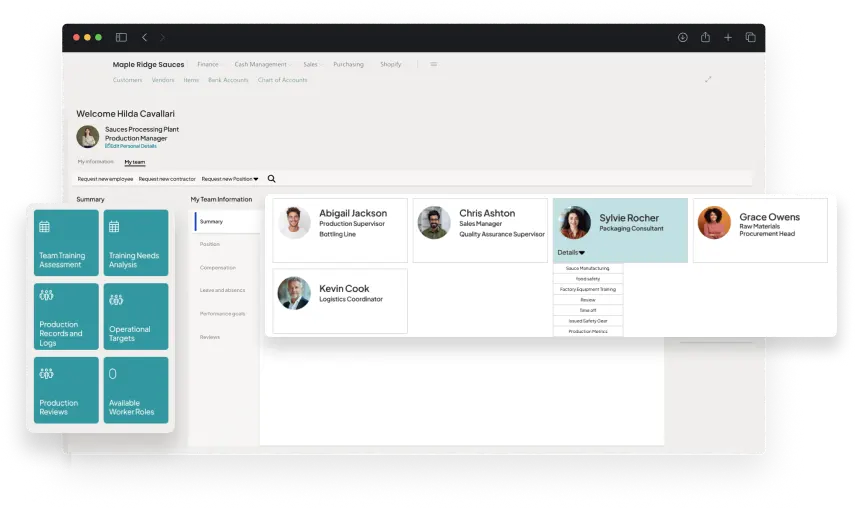

Seafood processing is fast-paced. Stay ahead with a seafood processing software that adapts to supply fluctuations, tracks catch weight accurately, and optimizes every fillet for quality and yield.

Optimize seafood packaging with precision. Automate workflows, track materials, and manage orders in real-time to maintain freshness, reduce waste, and meet market demands.

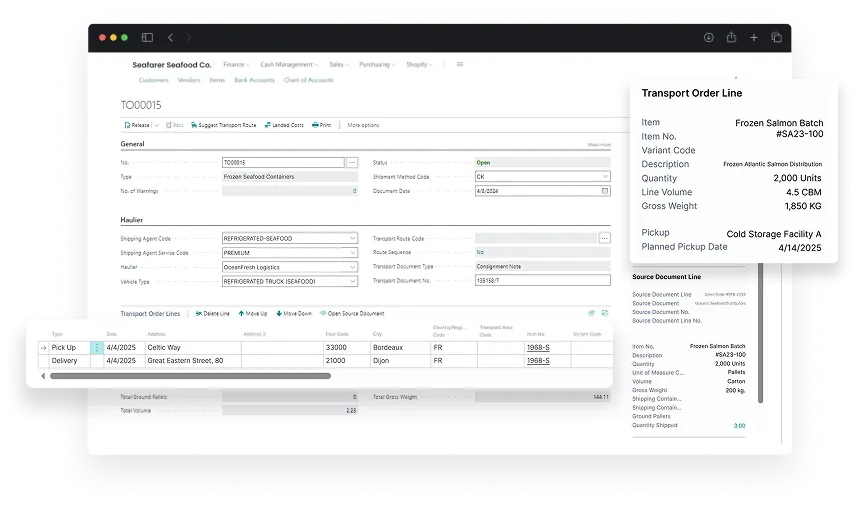

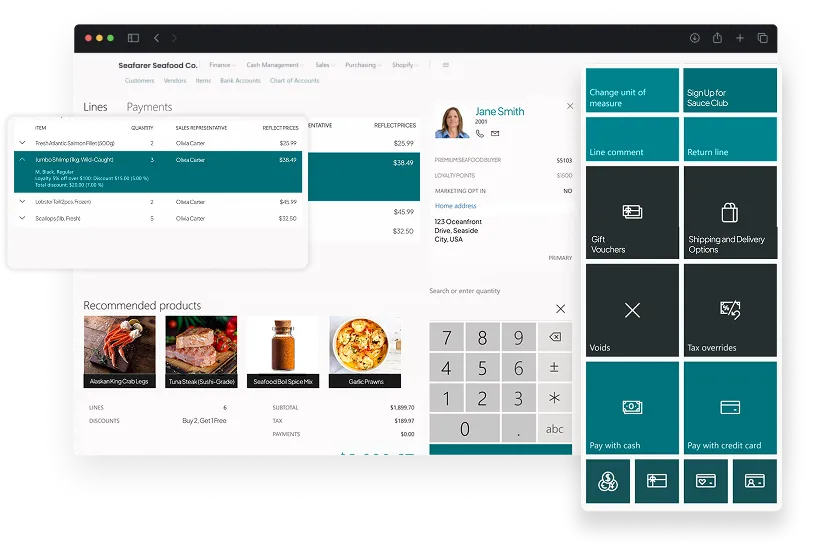

Move seafood faster with complete visibility into inventory, orders, and logistics. Use seafood distribution software to prevent spoilage, manage pricing, and ensure timely, accurate deliveries.

Make seafood retail effortless. Track inventory in real-time, prevent spoilage, and automate restocking to keep displays fresh and customers satisfied.

Get a seafood software that adapts to your variety, whether it’s catfish or lobster, with advanced tracking, processing, and food safety management.

Manage finfish operations efficiently by tracking water conditions, optimizing feeding, and automating processing for Cod, Salmon, Tuna, and Snapper. Ensure sustainability and compliance in farmed and wild-caught fisheries.

Enhance shellfish harvesting with real-time tracking, cultivation management, and automated processing for Shrimp, Lobster, Crab, and Scallops. Improve quality control and traceability across seafood operations.

Optimize roe harvesting by monitoring spawning, automating grading, and ensuring premium quality for Caviar, Salmon Roe, Lumpfish Roe, and Trout Roe. Enhance efficiency in seafood processing.

Streamline cephalopod processing with sourcing data, preservation techniques, and automated cleaning for Squid and Octopus. Improve efficiency while maintaining seafood quality standards.

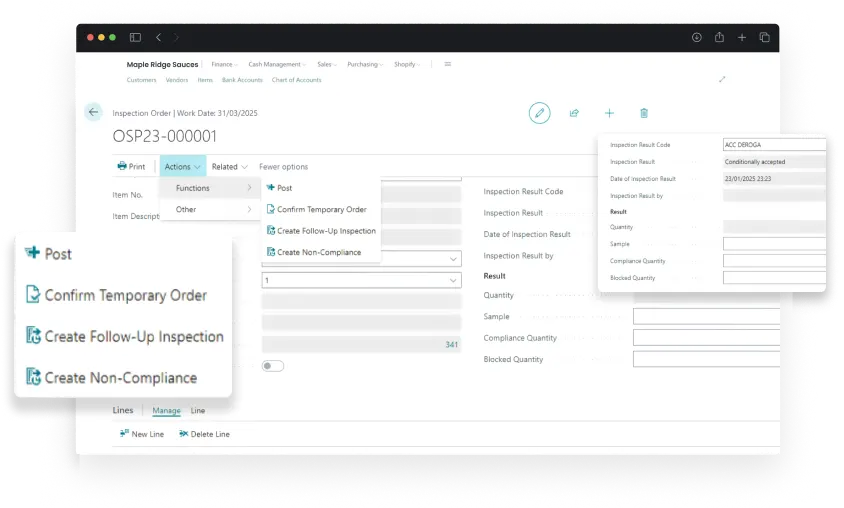

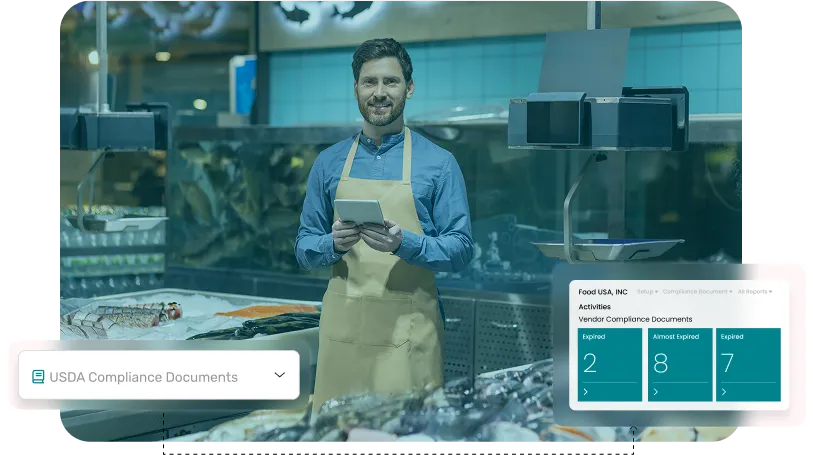

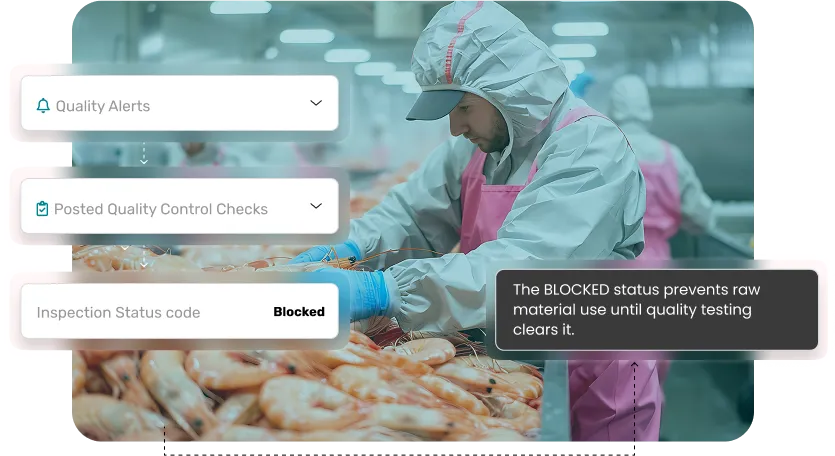

Protect seafood quality with a powerful suite of food safety solutions, enabling rigorous compliance checks, real-time monitoring, and full traceability from catch to consumer.

Ensure compliance with FDA Seafood HACCP, FSMA 204, EU, and global seafood safety standards. Automate critical control point (CCP) monitoring for temperature, handling, and pathogen risks.

Track histamine, listeria, mercury, and biotoxin levels in real time. Automate organoleptic tests, cold storage validation, and rapid microbial detection to maintain seafood freshness and export compliance.

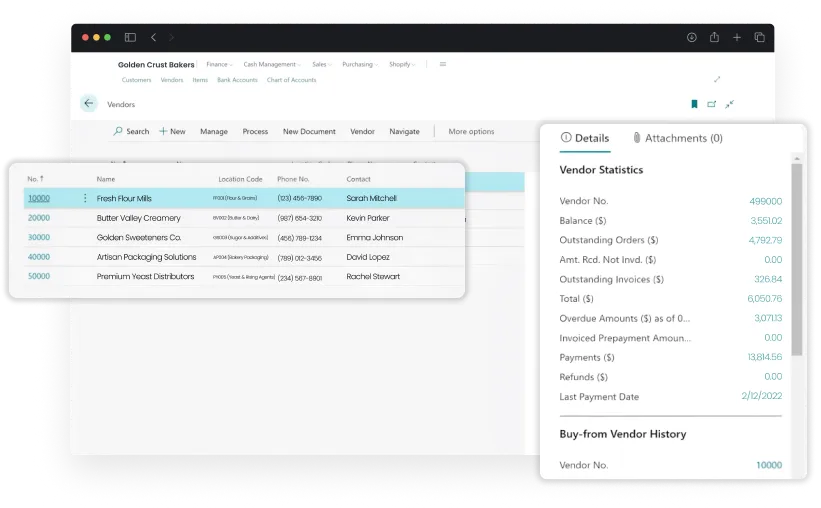

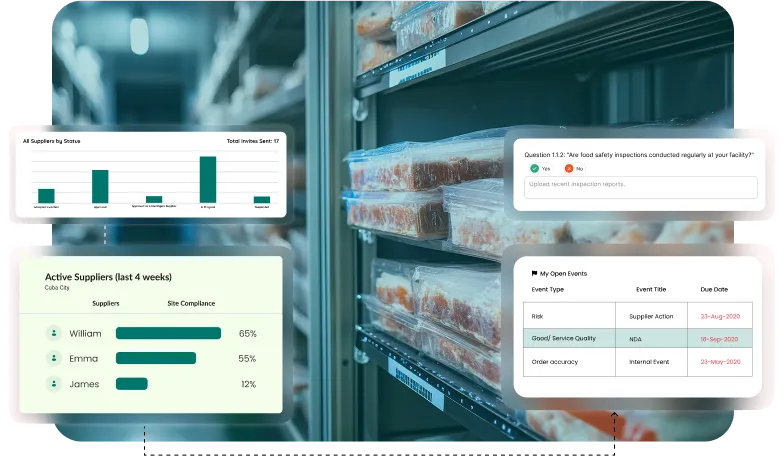

Vet suppliers for sustainable fishing, antibiotic-free aquaculture, and legal sourcing. Automate vendor certifications, import documentation, and COA checks to prevent fraud.

Enable full-chain traceability from catch to consumer with seafood traceability software. Capture vessel IDs, aquaculture lot tracking, freezing records, and processing batch history to prevent mislabeling and regulatory penalties.

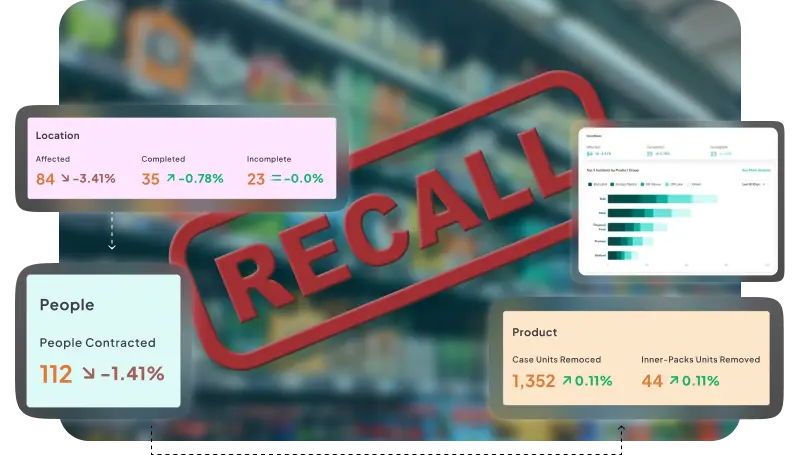

Accelerate seafood recalls with automated batch tracing, pathogen alerts, and withdrawal workflows. Instantly identify contaminated lots, notify distributors, and meet seafood safety recall mandates.

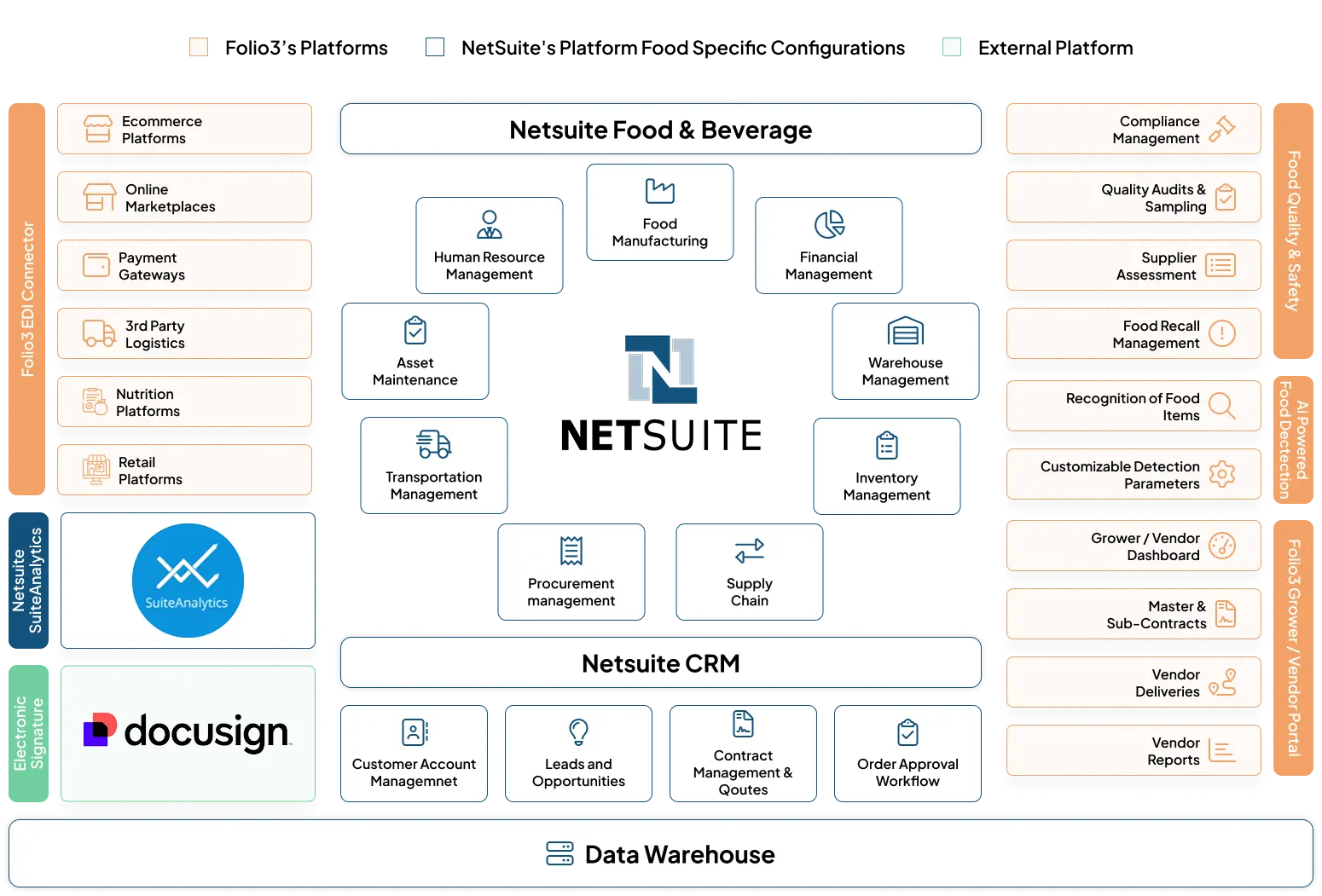

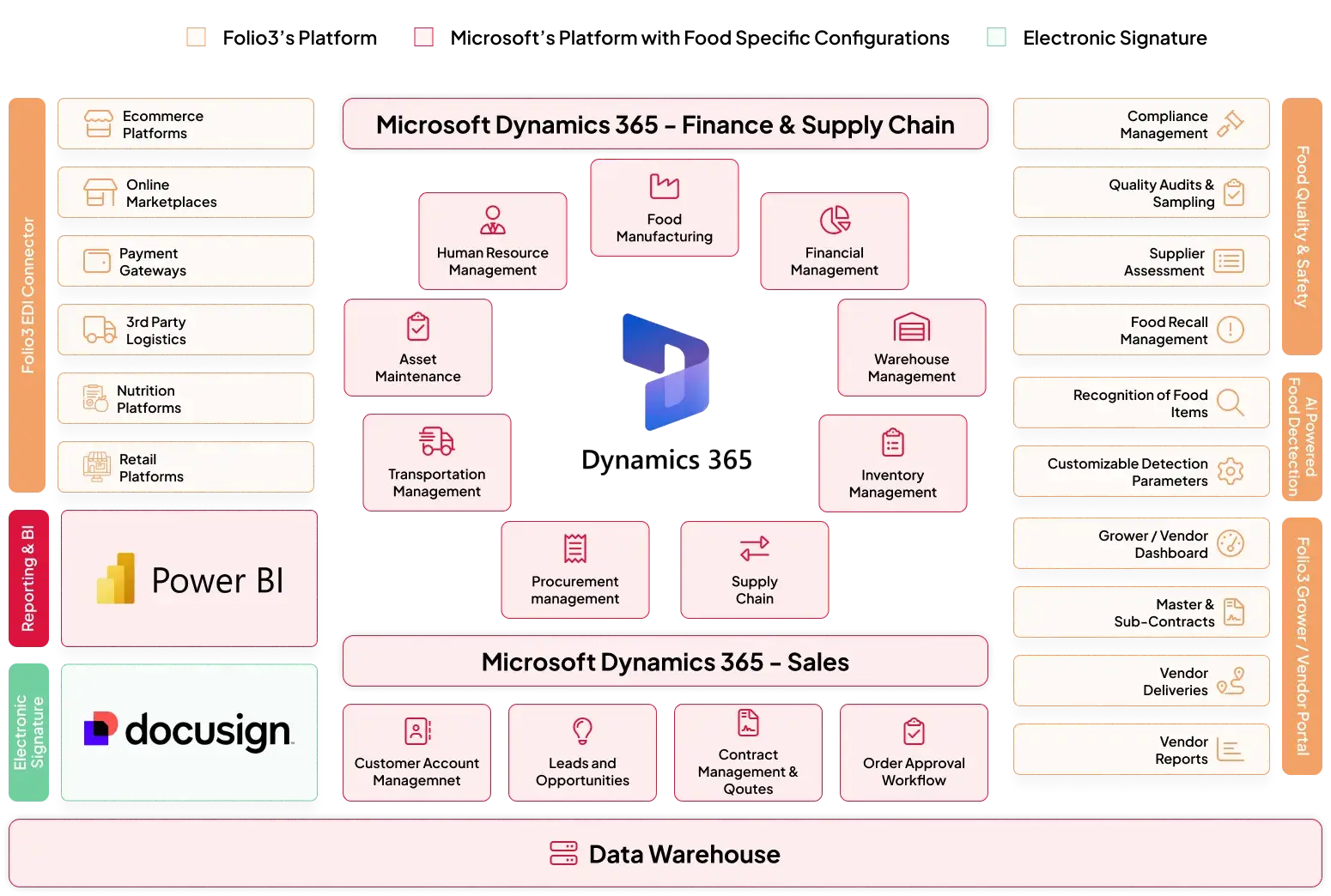

Connect every app you use to manage your seafood operations with seafood ERP software and access real-time data without switching between systems.

We lay the foundation for a successful ERP rollout with a clear process that ensures a smooth transition and minimal disruption.

We start by analyzing your seafood business’s unique operations, ensuring the ERP solution aligns with industry-specific challenges like traceability and inventory management.

We map out clear project objectives, timelines, and budgets while identifying potential risks like data inconsistencies and supply chain disruptions to ensure a smooth transition.

We customize the seafood ERP software to fit your business, whether upgrading an existing solution or adding seafood-specific functionalities.

We rigorously test the ERP system at every stage to verify its accuracy, performance, and reliability, ensuring it can handle the complexities of seafood operations.

We seamlessly connect ERP with existing seafood management tools, linking procurement, processing, distribution, and compliance tracking for a unified operation.

We securely transfer all critical data from legacy systems, ensuring precision in inventory records, supplier details, and regulatory documentation.

We launch the ERP in a live seafood business environment, ensuring minimal operational disruptions while optimizing all kinds of workflows.

We provide hands-on training and ongoing support to ensure your team fully adopts the ERP and maximizes seafood sourcing, sales, and logistics efficiency.

Keep milk, cheese, and yogurt fresh with better inventory control, compliance tracking, and production planning.

Perfect every batch with smart recipe management, real-time tracking, and seamless regulatory compliance.

Never break the cold chain—optimize storage, logistics, and expiration tracking for frozen products.

Balance art and precision with automated recipe scaling, ingredient traceability, and shelf-life monitoring

Manage sugar processing, allergen control, and batch consistency for chocolates, candies, and sweets.

Handle large-scale snack production with real-time inventory, ingredient sourcing, and quality control.

Track every cut from slaughterhouse to store while ensuring food safety and compliance.

Control formulations, batch consistency, and allergens while optimizing production efficiency.

Watch how ADM Agriculture improved its processes and achieved grow using NetSuite SuiteSuccess.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

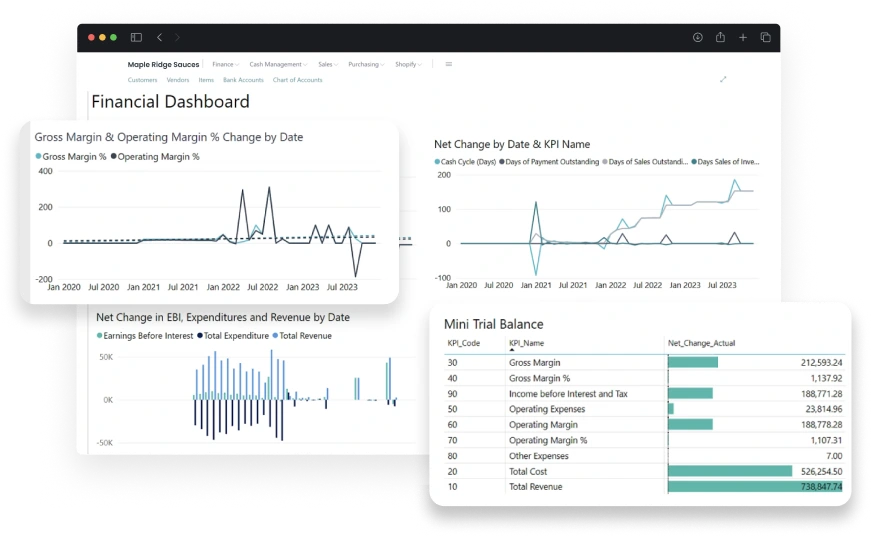

The ERP for seafood businesses enhances supply chain efficiency by tracking inventory in real-time to prevent stock shortages and optimizing cold storage management to reduce spoilage and maintain product quality.

It manages catch-weight pricing by automatically adjusting costs based on real-time weight fluctuations. It integrates weight-based inventory tracking to ensure accurate invoicing, reducing bulk seafood sales and processing errors.

An ERP allows small to mid-sized processors to start with core features like inventory and traceability and then expand to advanced modules like yield optimization and automated compliance as their business grows.

ERP for seafood tackles traceability compliance by tracking every catch from source to sale, ensuring regulatory adherence. It also solves inventory wastage with real-time stock monitoring, automated shelf-life alerts, and catch-weight tracking to reduce spoilage and optimize yield.

Our seafood processing ERP software provides end-to-end traceability by linking each batch to harvest data, supplier records, and processing details. It automates FDA and HACCP compliance with digital logs, real-time temperature tracking, and recall readiness, reducing contamination risks and regulatory penalties.

The ERP seafood solution supports centralized management of multiple facilities, enabling seamless coordination across various locations.

Our seafood ERP systems encompass inventory management, production planning, quality control, sales, procurement, and financial reporting modules.

Our ERP is fully customizable to fit unique seafood operations. From multi-species inventory tracking to custom processing workflows, traceability tagging, and compliance automation, it adapts to your needs, ensuring seamless integration with existing processes.

ERP for seafood processing includes advanced forecasting tools to predict and manage seasonal variations, ensuring optimal inventory levels and resource allocation.

The ERP seafood solution is designed to seamlessly integrate your current systems, enhancing overall operational efficiency.

We prioritize data security by incorporating robust encryption protocols, user authentication mechanisms, and regular security audits within the seafood ERP systems.

Ocean farming software helps manage offshore aquaculture by monitoring environmental conditions, optimizing cage management, and reducing stock loss. It enables precise yield forecasting and efficient resource utilization for sustainable seafood production.

Fish software optimizes workflows by managing grading, portioning, and byproduct utilization while tracking yield in real time. With precise inventory control and automated compliance checks, the software ensures efficiency and full traceability.

The software optimizes fish farming by tracking biomass growth, automating feeding schedules, and monitoring water quality in real time. It also simplifies compliance reporting and ensures full traceability from hatchery to harvest.

Ocean farming software helps manage offshore aquaculture by monitoring environmental conditions, optimizing cage management, and reducing stock loss. It enables precise yield forecasting and efficient resource utilization for sustainable seafood production.