The food industry is transforming significantly as manufacturers, processors, and distributors navigate an increasingly complex landscape. From managing supply chain disruptions to ensuring compliance with ever-evolving regulations, businesses must embrace innovative solutions to stay competitive. One of the most pivotal areas driving this evolution is Enterprise Resource Planning (ERP).

Once viewed as mere back-office tools, ERP systems have emerged as strategic assets for streamlining operations, enhancing decision-making, and meeting customer demands. As we enter 2025, ERP trends are shifting to address the food industry’s unique challenges, such as traceability, sustainability, and digital transformation.

The role of ERP systems has expanded significantly in recent years, addressing critical needs such as real-time inventory management, enhanced supply chain visibility, and advanced analytics for data-driven decision-making. As the food industry prepares for 2025, understanding ERP trends becomes crucial for businesses aiming to maintain a competitive edge in an increasingly dynamic market.

67% of food businesses prioritize ERP upgrades to incorporate artificial intelligence and cloud-based solutions to enhance supply chain resilience and meet sustainability goals. These trends reshape companies’ operations, helping them adapt to global challenges and future opportunities.

Let’s explore the top 7 ERP trends and predictions for 2025, highlighting actionable insights tailored to food manufacturers, processors, and distributors.

Trend 1 – Integration of Artificial Intelligence (AI) and Machine Learning (ML)

Artificial Intelligence (AI) and Machine Learning (ML) are no longer futuristic concepts—they are becoming essential components of modern ERP systems. These technologies are transforming how businesses in the food industry operate, offering solutions beyond traditional ERP functionalities.

As AI and ML become integral to ERP systems, they bring advanced capabilities like predictive analytics, process automation, and real-time decision-making, aligning with the latest ERP trends for 2025. According to a survey, the adoption of AI within ERP systems is depicted as having shown remarkable growth. In 2022, only 6% of respondents considered AI critical in ERP systems, with the majority in the “piloting use cases” (32%) or “limited adoption” (34%) stages.

However, the landscape is set to shift significantly by 2025, with 38% of businesses expected to classify AI as critical to their operations. Additionally, widescale adoption is projected to rise from 11% in 2022 to 30% in 2025. This demonstrates how AI and ML are increasingly considered indispensable tools for achieving operational efficiency and real-time decision-making.

AI and ML in ERP Systems: What’s Changing?

Integrating AI and ML into ERP systems allows for intelligent data analysis, enabling businesses to identify patterns, predict future trends, and make proactive decisions. For instance, AI can automate repetitive tasks like data entry or invoice processing, reducing human error and freeing up valuable time for employees to focus on strategic initiatives. ML, on the other hand, improves over time by learning from historical data, providing increasingly accurate insights into areas like production planning and inventory management.

Benefits for the Food Industry

In the food sector, where precision and efficiency are critical, AI and ML embedded within Food ERP systems offer substantial advantages:

- Predictive Analytics for Demand Forecasting: Demand forecasting is challenging for many food businesses, especially given seasonal variations and fluctuating consumer preferences. AI-driven ERP systems analyze historical sales data, market trends, and external factors like weather conditions to predict demand accurately. According to a recent study, 82% of food companies using AI-enhanced ERP systems reported a 30% improvement in forecast accuracy, leading to reduced waste and optimized inventory levels.

- Enhanced Quality Control: Quality control is vital in the food industry to ensure compliance with safety regulations and maintain brand reputation. ML algorithms can analyze production data in real-time to identify potential quality issues before they escalate. For example, AI-powered ERP systems can detect anomalies in temperature readings during food processing, allowing immediate corrective actions to avoid spoilage or contamination.

- Streamlined Supply Chain Management: AI and ML contribute to supply chain resilience by identifying inefficiencies and suggesting improvements. They can predict disruptions, optimize delivery routes, and ensure timely procurement of raw materials. A 2024 report revealed that 68% of food manufacturers implementing AI in ERP systems saw a 20% reduction in supply chain disruptions.

Trend 2 – Shift to Cloud-Based ERP Solutions

The shift to cloud-based ERP systems is one of the most significant ERP trends shaping the future of the food industry. As businesses prioritize scalability, flexibility, and operational efficiency, cloud ERP solutions are becoming the go-to choice for food manufacturers, processors, and distributors. Unlike traditional on-premise systems, cloud-based ERPs offer many advantages that cater specifically to the industry’s dynamic and fast-paced nature.

Why Are Cloud ERP Systems On the Rise?

Cloud ERP systems operate on a subscription model, allowing businesses to access their data and software online rather than maintaining costly hardware on-site. This approach ensures seamless upgrades, lower IT maintenance costs, and enhanced scalability to adapt to fluctuating business needs.

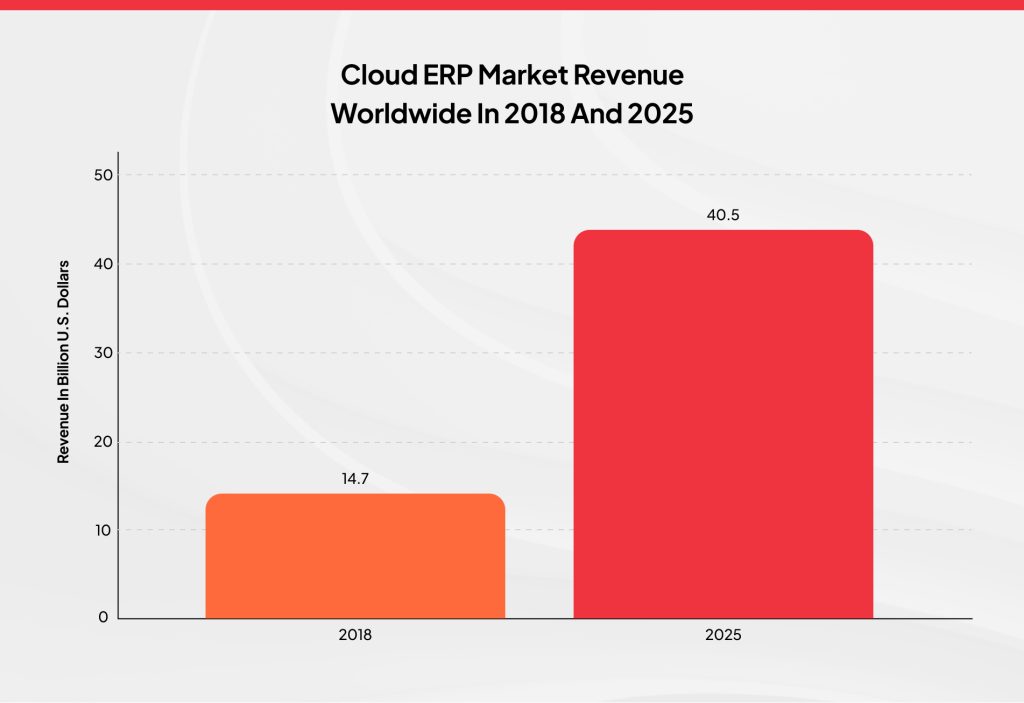

Reports indicate that the cloud ERP market is projected to grow at a compound annual growth rate (CAGR) of 13.6% by 2025. Due to their unique requirements, food companies are leading the adoption curve.

Advantages for Food Manufacturers

Given its time-sensitive operations and strict regulatory demands, the food industry benefits significantly from cloud ERP systems’ flexibility and functionality.

- Scalability to Support Growth: Cloud ERP solutions can quickly scale up or down to meet a business’s changing needs. Cloud systems enable rapid expansion of capabilities without significant upfront investments for food manufacturers experiencing seasonal demand surges, such as during the holiday season.

- Remote Access and Collaboration: In a globalized supply chain, having access to critical business data from anywhere is vital. Cloud ERP systems allow teams to collaborate authentically, whether managing factory floor operations, tracking warehouse inventory, or engaging with suppliers remotely. A 2024 survey found that 73% of food businesses using cloud ERP systems reported improved team productivity due to enhanced remote access capabilities.

- Real-Time Data Sharing for Better Decision-Making: Cloud ERP systems provide a unified platform where data is updated in real-time, ensuring decision-makers have access to the latest information. For example, a food distributor can monitor inventory levels, track shipments, and manage customer orders in real-time, reducing errors and improving service quality.

- Cost Savings and Reduced Downtime: Cloud ERP eliminates the need for costly hardware and extensive IT infrastructure. It also ensures continuous updates and minimal downtime, which is critical for food manufacturers, as delays can lead to spoilage or compliance issues.

Trend 3 – Enhanced User Experience and Mobility

In the race to make ERP systems more accessible and efficient, enhancing user experience (UX) and enabling mobility have emerged as prominent ERP trends for 2025. As the food industry grows increasingly dynamic, businesses demand ERP systems that are not only powerful but also user-friendly and mobile-ready. Intuitive interfaces and mobile accessibility are now key factors in driving operational efficiency, especially for on-the-go managers and workers in the food sector.

Intuitive Interfaces for Seamless Operations

Modern ERP systems are shifting from clunky, outdated designs to streamlined, intuitive interfaces that require minimal training. These interfaces prioritize ease of navigation, clear visualizations, and user-centric workflows, enabling teams to focus on their tasks rather than struggling with complex software.

For example, dashboards that display real-time inventory levels, production metrics, and sales data in an easily digestible format help food manufacturers make faster, informed decisions. A 2024 report revealed that 65% of ERP users in the food industry cited improved decision-making as a direct benefit of enhanced UX features.

Mobility – ERP Systems on the Go

With the rise of mobile technology, ERP systems are no longer confined to desktop computers. Mobile ERP applications allow managers and workers to access critical data, update records, and manage tasks anytime. This is especially beneficial in the food industry, where managers may need to oversee multiple facilities or respond to supply chain disruptions on the fly.

- Field Operations Made Easier: For food distributors and logistics teams, mobile ERP systems enable real-time tracking of shipments, inventory updates, and communication with suppliers and customers. Workers can report issues or update statuses directly from their devices, reducing delays and streamlining operations.

- On-the-Go Decision-Making: Plant managers and executives often need to make quick decisions away from their desks. Mobile accessibility ensures they can monitor production progress, approve purchase orders, and review real-time performance metrics, improving responsiveness and efficiency.

Impact on the Food Sector

Enhanced UX and mobility in ERP systems directly contribute to better operational efficiency and worker productivity. For instance:

- A food manufacturer using a mobile ERP app can instantly identify a production bottleneck and redirect resources to resolve the issue.

- A distributor can provide real-time delivery updates to customers, improving service quality and satisfaction.

Trend 4 – Integration with Internet of Things (IoT) Devices

Integrating Internet of Things (IoT) devices with ERP systems revolutionizes how food manufacturers, processors, and distributors manage their operations. As a growing focus in ERP trends, this synergy enables businesses to harness real-time data from connected devices, offering unprecedented visibility into every aspect of the supply chain.

IoT and ERP – A Connected Ecosystem

IoT devices, such as sensors, RFID tags, and smart meters, continuously collect data from equipment, vehicles, and storage units. When integrated with ERP systems, this data flows seamlessly into a centralized platform, providing actionable insights and streamlining operations. This real-time connectivity improves decision-making and minimizes downtime and waste, which are critical concerns in the food industry.

Applications in the Food Industry

- Monitoring Equipment Performance: IoT sensors can monitor equipment in real time, tracking metrics like temperature, humidity, and operational efficiency. For example, a food processing plant can use IoT-enabled sensors to detect fluctuations in a refrigeration unit. If an anomaly occurs, the ERP system immediately generates an alert, allowing teams to address the issue before it compromises product quality or safety. According to a 2024 study, food manufacturers using IoT-integrated ERP systems reduced equipment downtime by 25% and maintenance costs by 15%.

- Enhancing Supply Chain Logistics: IoT devices provide real-time visibility into supply chain operations, from farm to table. GPS-enabled trackers on delivery trucks, for instance, allow distributors to monitor shipment locations and conditions, ensuring products reach their destination fresh and on time. Research shows that IoT-enabled logistics systems in the food industry can improve on-time delivery rates by up to 30%, reducing losses due to spoilage or delays.

- Quality Assurance and Compliance: IoT devices play a vital role in ensuring compliance in an industry heavily regulated for food safety. For example, automated tracking of temperature and storage conditions provides the data needed to meet regulatory requirements and produce audit-ready reports through the ERP system.

Trend 5 – Emphasis on Data Security and Compliance

As ERP systems evolve, robust data security and compliance have become non-negotiable components of modern ERP solutions. Among the ERP trends shaping 2025, the focus on protecting sensitive information and meeting industry regulations stands out, especially in the highly regulated food industry. Food manufacturers, processors, and distributors handle vast amounts of data daily, from proprietary recipes to supply chain records, making data security a top priority.

Importance of Robust Data Security Measures

ERP systems process sensitive information, including supplier details, customer data, and financial transactions. Data breaches can lead to economic losses, reputational damage, and compliance violations.

- According to a 2024 report, the global cost of a data breach averages $4.45 million, emphasizing the critical need for strong security protocols.

- For food manufacturers, a breach could also expose trade secrets or compromise the safety of food supply chains.

Modern ERP systems address these challenges by incorporating advanced security features such as:

- End-to-End Encryption: Ensures data is protected during transmission and storage.

- Role-Based Access Controls: Limits access to sensitive information to authorized personnel only.

- Real-Time Threat Detection: Uses AI and analytics to identify and respond to potential security threats.

Ensuring Compliance with Industry Regulations

The food industry operates under stringent regulations such as the Food Safety Modernization Act (FSMA) in the United States and similar frameworks worldwide. A 2024 study showed that businesses in the food industry using compliance-focused ERP solutions reduced audit preparation times by 40%, demonstrating the tangible benefits of these systems. ERP systems play a pivotal role in ensuring compliance by:

- Automating Record-Keeping: ERP systems can maintain detailed records of production, inventory, and supply chain activities, making compliance audits faster and easier.

- Enforcing Standards: Built-in compliance features help businesses meet traceability, quality control, and labeling requirements.

- Providing Audit Trails: ERP systems offer transparent, tamper-proof logs of all system activities, essential for regulatory reporting.

Trend 6 – Advanced Analytics and Real-Time Reporting

Among the most impactful ERP trends for 2025 is the increasing use of advanced analytics and real-time reporting capabilities. These tools enable food manufacturers, processors, and distributors to make data-driven decisions, optimize processes, and stay ahead in a highly competitive industry.

Utilizing Advanced Analytics for Informed Decision-Making

Advanced analytics within ERP systems empower businesses to extract meaningful insights from vast data. These insights are critical for understanding market trends, improving operational efficiency, and identifying potential risks.

According to a survey by Accenture, 79% of enterprise executives believe that businesses failing to adopt data analytics risk losing their competitive advantage. For example, predictive analytics can help:

- Demand Forecasting: Food manufacturers can accurately predict future demand by analyzing historical data and market trends, reducing overproduction and waste.

- Supplier Performance Evaluation: Businesses can assess supplier reliability, cost-effectiveness, and lead times to strengthen supply chain efficiency.

Benefits of Real-Time Reporting

Real-time reporting provides instant access to critical operational data, ensuring that businesses can respond promptly to changing conditions. For food manufacturers and distributors, this is particularly important in areas such as:

- Inventory Management: Real-time data allows businesses to track inventory levels, reduce stockouts, and optimize storage costs. A McKinsey study highlighted that companies leveraging real-time reporting reduced inventory costs by 20-30%.

- Production Planning: Immediate access to production data ensures that manufacturing schedules align with demand, minimizing downtime and maximizing output.

- Quality Assurance: Real-time reporting helps identify quality issues early in production, preventing costly recalls and ensuring customer satisfaction.

Trend 7 – Focus on Sustainability & Green Initiatives

The global focus on sustainability reshapes business operations across industries, and the food sector is no exception. One of the most prominent ERP trends for 2025 is the integration of sustainability metrics and green initiatives into ERP systems. These tools empower food manufacturers, processors, and distributors to monitor, measure, and reduce their environmental impact while staying aligned with consumer expectations and regulatory requirements.

Sustainability Metrics & Tracking In ERP Systems

ERP systems can generate detailed reports on how much energy is consumed per production cycle or track packaging material usage. This data provides actionable insights, helping companies adopt greener practices. A 2024 survey shows 62% of businesses using ERP solutions with sustainability features reported reduced operational waste. Modern ERP systems are increasingly equipped to track a wide range of sustainability metrics, including:

- Energy Usage: Monitoring energy consumption across production facilities.

- Carbon Footprint: Calculating greenhouse gas emissions from operations and transportation.

- Waste Management: Tracking food waste and implementing strategies for reduction.

- Water Usage: Monitoring water consumption to optimize resource usage.

How Does ERP Support Sustainability Goals?

The food industry has a significant environmental footprint, accounting for about 25% of global greenhouse gas emissions (FAO, 2024). As consumers demand greener practices, adopting sustainability-focused ERP tools allows food businesses to reduce their impact, enhance operational efficiency, and strengthen their market position.

1. Improved Resource Management

ERP systems enable food companies to optimize resource usage, reducing waste and inefficiency. By analyzing production data, businesses can adjust processes to minimize excess energy or raw material consumption.

2. Regulatory Compliance

Governments and global organizations are enforcing stricter environmental regulations, such as the EU’s Green Deal. ERP systems help ensure compliance by maintaining records, generating reports, and automating necessary documentation.

3. Supply Chain Transparency

Sustainability extends beyond internal operations; it includes the entire supply chain. ERP systems provide visibility into supplier practices, enabling businesses to partner with environmentally responsible vendors. A study by McKinsey found that companies adopting supply chain transparency through ERP systems improved sustainability performance by 30%.

4. Sustainability Reporting

With ERP systems, businesses can create comprehensive sustainability reports to share with stakeholders, investors, and customers. These reports enhance accountability and build brand trust among increasingly eco-conscious consumers.

Conclusion

Staying ahead of ERP trends is crucial for food manufacturers, processors, and distributors to remain competitive. By advancing and following ERP trends, businesses can enhance efficiency, improve decision-making, and achieve compliance and sustainability goals. ERP systems are key to driving innovation, whether through cloud scalability, mobile access, or IoT integration.

If you’re ready to transform your food business with cutting-edge ERP solutions, consult an experienced provider like Folio3 FoodTech. Our customized ERP services help simplify processes, improve productivity, and drive growth tailored to your unique needs.

FAQs

What Is The ERP Trend For 2025?

The ERP trend for 2025 focuses on integrating AI and ML, IoT connectivity, cloud-based solutions, advanced analytics, and sustainability tracking to enhance operational efficiency and support green initiatives.

What Is The Future Of The ERP System?

The future of ERP systems lies in greater automation, real-time data insights, enhanced mobility, seamless integration with IoT devices, and robust security measures, driving efficiency and sustainability in industries.

What Is The Fastest-Growing ERP?

Cloud-based ERP systems, like NetSuite and SAP S/4HANA, are among the fastest-growing due to their scalability, flexibility, and ability to provide real-time data access.

What Are The New Trends Of ERPs?

The latest ERP trends include AI and ML integration, cloud-based ERP adoption, IoT connectivity for real-time data, enhanced mobility and user experience, advanced analytics, real-time reporting, data security and compliance focus, and sustainability and green initiatives tracking.