Every step in the food manufacturing process, from sourcing ingredients to tracking inventory, ensuring compliance, and meeting consumer demands, carries weight. One delay or misstep can cause spoilage, safety risks, or profit loss. That’s where food production management becomes essential, as it connects people, processes, and data to ensure that every product leaving your facility is of high quality, traceable, and delivered on time.

Yet, managing these operations manually or with disjointed systems often leads to bottlenecks. Deloitte’s 2025 Consumer Products Industry Outlook highlights that significant risks for consumer products companies involve geopolitics and supply chain disruptions, emphasizing the importance of focusing on supply chain resilience and redundancy.

Modern manufacturers are responding by turning to smart, integrated tools, particularly food production management software systems, to manage complexity, minimize waste, and comply with evolving regulations.

In this blog, we’ll break down what food production management means and explore how an ERP system tailored to the food industry can drive smarter operations from inventory to compliance without adding more burden to your team.

What is Food Production Management?

Food production management involves coordinating all activities that efficiently, safely, and in compliance with industry standards, transform raw agricultural inputs into finished food products. It spans every stage of the production cycle, from procurement and processing to packaging and distribution.

But effective food production management isn’t just about keeping the line moving; it’s about ensuring quality, maintaining safety, meeting regulatory requirements, and minimizing waste all while keeping costs under control. Let’s take a closer look at the core components of a well-functioning food production management system:

1. Manufacturing and Processing Control

This is the heart of food production. It includes everything from recipe management and batching to equipment scheduling and yield optimization. Without a central system in place, food manufacturers risk inconsistent output and costly downtime. A reliable food manufacturing software helps standardize these processes, ensuring that production lines run smoothly and products consistently meet exact specifications.

2. Quality Assurance and Food Safety

Quality assurance (QA) is a cornerstone of food manufacturing, ensuring that every product meets safety, consistency, and regulatory standards. QA involves a comprehensive set of practices—from monitoring critical control points and validating sanitation procedures to maintaining the integrity of temperature-sensitive ingredients.

At the heart of this food quality management is the QA manager, who oversees these operations, enforces safety protocols, and ensures traceability through meticulous record-keeping. Integrated food production systems support QA managers by automating quality checks, capturing real-time data, and alerting them to deviations, enabling swift corrective actions. This not only helps prevent contamination or spoilage but also safeguards the brand from costly recalls.

3. Workforce and Production Scheduling

An efficient workforce and effective production scheduling are critical components in food manufacturing, directly impacting productivity and product quality. Scheduling isn’t just about assigning shifts; it’s about aligning the right personnel with the right machinery, batches, and sanitation windows.

Plant managers must consider labor availability, skill sets, and production goals. ERP-enabled systems streamline this process by providing dynamic scheduling tools that factor in downtime, shift overlaps, and order priorities, thereby optimizing resource allocation. This ensures balanced staffing levels, reduces bottlenecks, and enables manufacturers to maintain consistent output without overextending their resources.

4. Compliance with Regulations (FDA, FSMA, HACCP)

Compliance is not just a result but a daily operational component of food production. From FDA regulations and FSMA preventive controls to HACCP-based protocols, staying compliant means having structured systems that ensure documentation, traceability, and real-time visibility.

Regulatory compliance managers play a crucial role in ensuring audit readiness, conducting risk assessments, and implementing preventive controls. Unlike quality assurance, which focuses on product safety and consistency, compliance is about meeting legal and industry standards. Food production compliance software helps manage this complexity by organizing documentation, automating reporting, and facilitating inspections, making it easier to adapt to evolving regulatory requirements.

5. Supply Chain and Distribution Management

An efficient supply chain ensures that raw materials are sourced cost-effectively and that finished goods are delivered without delay. However, disruptions and rising costs have made this more difficult. Modern food production inventory management software offers real-time visibility into stock levels, expiration dates, and delivery schedules, enabling manufacturers to respond quickly to changes in demand and minimize spoilage.

Why Managing Food Production is Getting Tougher And What You Can Do About It?

Food manufacturing has never been simple, but recent shifts in global regulations, shifting consumer preferences, and operational risks have raised the stakes. What used to be manageable with spreadsheets and manual processes has become a logistical and compliance nightmare for many producers.

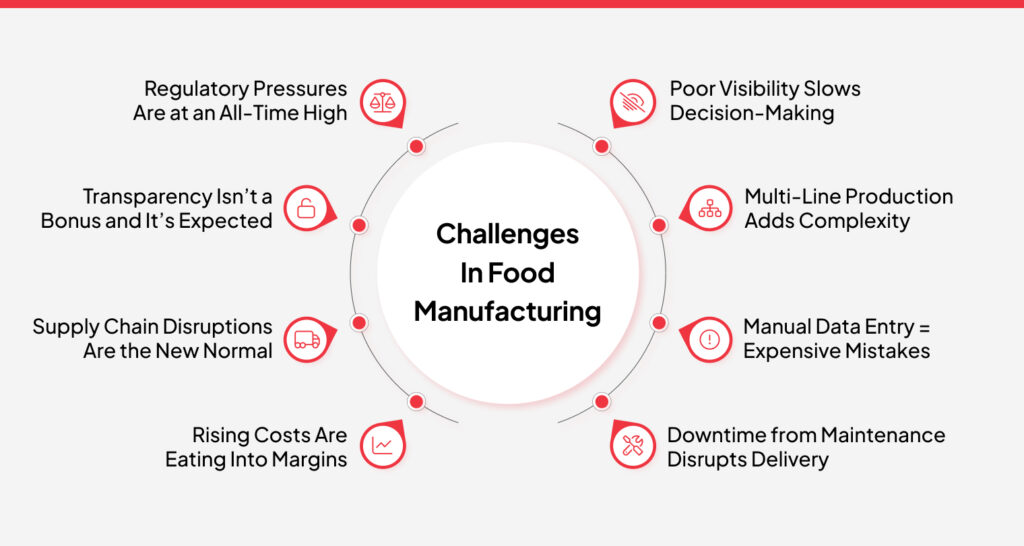

Here’s a look at the biggest challenges facing the food industry today and how solutions like Folio3 FoodTech ERP system are helping manufacturers regain control.

1. Regulatory Pressures Are at an All-Time High

The days of loosely documented food production processes are over. With the FDA’s FSMA regulations, HACCP protocols, and global food safety standards tightening every year, even a minor oversight in compliance can result in product recalls, legal penalties, or loss of certifications.

How to Stay Ahead?

Folio3 FoodTech food safety management software simplifies compliance by centralizing documentation, automating inspection logs, and providing real-time reporting. It supports audit readiness and ensures every product meets safety benchmarks before it leaves the facility.

2. Transparency Isn’t a Bonus and It’s Expected

Modern consumers expect detailed insight into how their food is sourced, processed, and packaged. Whether it’s allergen labeling, organic certifications, or farm-to-fork traceability, there’s growing pressure on manufacturers to provide complete transparency.

How to Respond?

With Folio3 FoodTech Traceability Software for Food, manufacturers can track raw ingredients from supplier to shelf. This ensures clean, accurate labeling and real-time traceability capabilities in the event of a food safety issue.

3. Supply Chain Disruptions Are the New Normal

From ingredient shortages to freight delays, the global food supply chain is under pressure. And when critical ingredients don’t arrive on time, production grinds to a halt.

How to Keep Moving?

Folio3 FoodTech Supply Chain Management Module provides a more innovative approach to planning, food procurement, managing vendor relationships, and tracking deliveries. With built-in alerts and planning tools, it helps you avoid last-minute surprises and maintain steady production flow.

4. Rising Costs Are Eating Into Margins

Ingredient prices, labor costs, packaging, and energy expenses have all surged, and these increases are often unpredictable. When waste goes unchecked or stock is mismanaged, profit margins disappear quickly. In sectors like meat packaging, where cold chain logistics and strict compliance add extra layers of cost, even minor inefficiencies can eat away at profitability.

How to Protect Your Bottom Line?

Folio3 FoodTech Inventory Management System gives manufacturers a real-time view of stock levels, expiration dates, and usage rates. It supports a first-expiry-first-out (FEFO) logic, helping to reduce spoilage and optimize procurement decisions to avoid overstocking or underutilization.

5. Poor Visibility Slows Decision-Making

When key production and inventory data is spread across spreadsheets, whiteboards, or disconnected systems, teams make decisions based on yesterday’s numbers or worse, guesswork.

How to Move Faster?

Folio3 FoodTech Manufacturing Management ERP Module offers real-time dashboards that connect data from every stage of production. Whether it’s machine uptime, batch progress, or raw material availability, managers can make informed decisions on the fly.

6. Multi-Line Production Adds Complexity

Running multiple product lines increases the risk of inconsistencies, mislabeling, and inefficient use of equipment or labor. Without a centralized system, it is challenging to maintain quality across every batch and shift.

How to Stay Consistent?

With Folio3 FoodTech Production and Batch Management Tools, manufacturers can efficiently schedule jobs, set quality standards for each product line, and ensure production consistency, regardless of the number of lines in operation.

7. Manual Data Entry = Expensive Mistakes

Handwritten logs and spreadsheet entries not only consume time, but they also often contain errors that can compromise quality control, traceability, and compliance documentation.

How to Eliminate Human Error?

Folio3 FoodTech integrated Food ERP system connects your departments, automatically capturing data from Food purchasing, production, inventory, and QA. No more double entries, no more discrepancies. Just accurate, up-to-date records that are audit-ready.

8. Downtime from Maintenance Disrupts Delivery

Unplanned equipment failures can delay production schedules, increase waste, and impact customer commitments, especially when maintenance is reactive rather than proactive.

How to Reduce Downtime?

While Folio3 FoodTech ERP isn’t a dedicated maintenance tool, its Manufacturing Module allows you to integrate preventive maintenance workflows. By tracking usage patterns and downtime trends, you can schedule equipment servicing before a failure occurs.

Fix the Gaps in Your Operations

with an ERP That Speaks Food

We help food businesses move from generic or patchworked systems to a fully

integrated ERP, purpose-built for the industry, and designed for you.

Talk to an ERP Specialist

Why Folio3 FoodTech ERP is Built for You?

Unlike generic ERP systems, Folio3 FoodTech ERP is purpose-built for better food production management. It’s designed with the unique needs of food and beverage manufacturers, processors, and distributors in mind. Whether you’re dealing with allergen tracking, dynamic shelf life, or managing seasonal supply chains, Folio3 FoodTech offers:

- End-to-end traceability.

- Integrated quality and compliance tools.

- Real-time production visibility.

- Smart inventory control.

- Flexible deployment options (cloud, hybrid, on-premise).

And because it’s modular, you only pay for what you need, whether it’s manufacturing, inventory, supply chain, or food distribution management. Managing food production is complex, but it doesn’t have to be chaotic. With the right ERP solution, such as Folio3 FoodTech, you gain the control, insight, and flexibility needed to run a safe, efficient, and profitable operation.

Case Study: How A Lamb Processor Transformed Operations with Folio3 FoodTech?

As North America’s largest lamb processor and marketer, this enterprise partners with over 1,000 family-owned ranches, generating annual revenue exceeding $280 million. While the company is committed to sustainability and ethical livestock management, its growth was being held back by fragmented systems, manual record-keeping, and inefficient operations spread across disconnected departments.

The Challenge – Scaling Operations Amid Siloed Data and Manual Workflows

Despite its scale, the processor relied heavily on outdated processes. Key issues included:

- Disconnected operations with no centralized data source.

- Limited real-time visibility into production, logistics, and inventory.

- Inconsistent workflows are causing errors in scheduling, planning, and execution.

- Difficulty in managing livestock, from breeding to shipment.

- A lack of end-to-end traceability poses risks to both compliance and quality.

The Solution – A Fully Integrated ERP Built for the Food Industry

To address these challenges, the company partnered with Folio3 FoodTech to implement a customized version o that is specifically designed for food producers and processors. The implementation focused on unifying operations, digitizing workflows, and enabling real-time insights across the business.

Key Modules and Capabilities Delivered

- Livestock Management: Electronic identification (EID) tracking, health records, vaccinations, and USDA compliance automation

- Master Planning: Centralized production planning tied to demand forecasts, ethical slaughter schedules, and recipe-based meat cut planning

- Meat Production Execution: Batch tracking, customer-specific label generation, and automated inventory allocation for fast, error-free production, all crucial for minimizing waste and understanding the broader impact of meat production on both margins and sustainability

- Dispatch & Shipments: Scan-gun support, offline capabilities, pallet-level tracking, and accelerated fulfillment through warehouse automation

The Results – From Manual Chaos to Connected Precision

Following the implementation of FoodTech ERP system, the lamb processor experienced measurable operational improvements:

- 35% boost in traceability through digitized livestock management and condition scoring.

- 80% compliance automation with USDA standards.

- 25% reduction in production planning time, thanks to real-time master planning tools.

- 15% faster production cycles, enabled by automated order execution and inventory handling.

- A 40% decrease in palletization and dispatch time, resulting in improved shipment accuracy and faster fulfillment speed.

Conclusion

Achieving efficiency, traceability, and compliance is no longer optional it’s essential. A tailored ERP system, such as Folio3 FoodTech ERP, empowers manufacturers to streamline operations, centralize data, and scale with confidence. From livestock tracking to production and dispatch, Folio3 FoodTech delivers end-to-end visibility and control.

So, if you’re ready to modernize your food processing operations and boost productivity, partner with Folio3 FoodTech, your trusted expert in food ERP solutions.

FAQs

What Is Management In Food Production?

Food production management involves overseeing the planning, processing, quality control, and distribution of food products to ensure efficiency and compliance with regulations.

What Is The Meaning Of Food Production And Management?

Food production and management refers to coordinating raw materials, labor, and processes to ensure timely and safe food manufacturing operations.

What Are The Four Stages Of Food Production?

The four key stages in food production management are processing, packaging, distribution, and retail, each of which is critical for delivering quality products to consumers.

What Does A Food Product Manager Do?

A food product manager oversees product development, compliance, and market strategy, playing a vital role in streamlining food production management.