Implementing advanced digital solutions to strengthen quality management and compliance for a leading American lamb processor.

The company relied on paper-based reviews and forms, which took too long, were hard to track, and delayed incident reporting. This created a risk of missing compliance requirements.

To keep up with USDA standards without slowing down daily operations, the company needed more than just recordkeeping. They were looking for a digital system to centralize compliance tasks, get real-time visibility into plant activities, and make it easier for teams to act on issues.

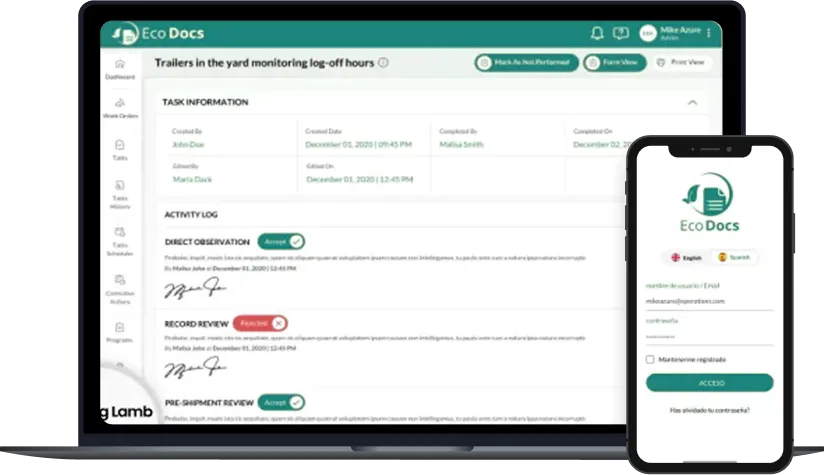

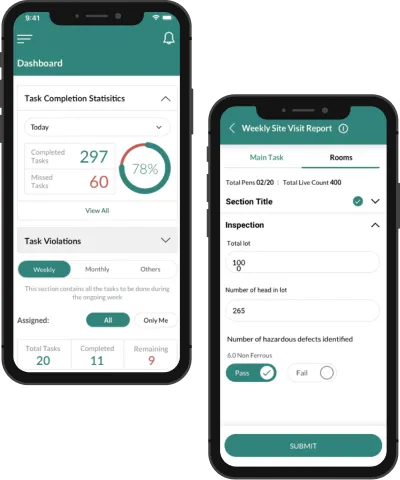

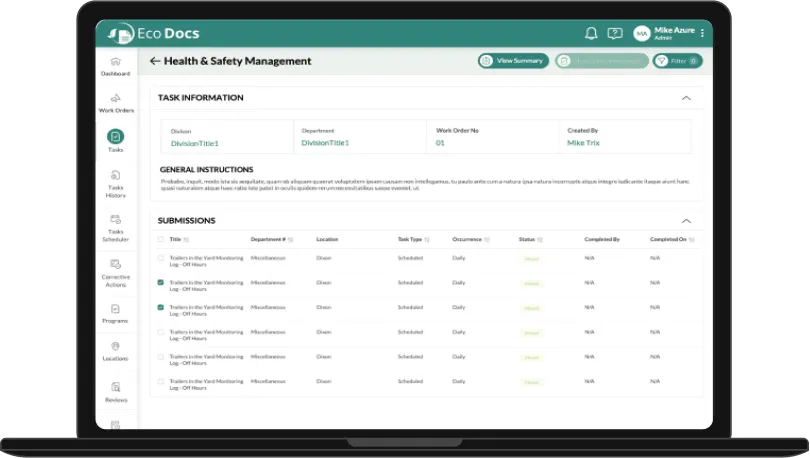

The web and iPad-based application digitized preshipment checks, record reviews, and routine forms. It helped the plant save time, reduce manual errors, and respond faster to potential issues through automated alerts. The system also gave the company a real-time view of compliance activities across all four locations.

A leading market player in the meatpacking industry, this renowned lamb processing plant operates across four locations in the United States and partners with over 1,000 family ranches. Known for its commitment to animal welfare and data management, the company recently unveiled the “greenest” lamb plant in the U.S., emphasizing sustainability and traceability.

As the lamb processing plant expanded, the company faced increasing difficulties managing its operations with outdated, manual processes. The following inefficiencies led to compliance risks and operational bottlenecks for the company:

Key Challenges:

Key features and offerings included:

Digitized 300+ forms to schedule tasks, assign users, and manage reviews automatically.

Digitized manuals and SOPs were linked to tasks to support compliance and audits.

Set up five departments and assigned user roles for focused, role-specific task tracking.

Configured four locations with user-specific access and organized records by site and time.

Introduced rule-based triggers for corrective actions and highlighted missed tasks on dashboards.

Enabled offline task entry, Active Directory login, and USDA access for smoother compliance checks.

Folio3 automated the client’s processes, delivering continuous support and enabling efficient management and tracking of daily tasks. Automated scheduling ensured consistent adherence to standard procedures, and by configuring each of the four locations and aligning workflows based on user roles, the entire system was optimized.

The team successfully digitized 300 forms, enabling seamless documentation of over 19,000 tasks within the first three months. This shift eliminated paper clutter and created a reliable digital audit trail for all activities.

Productivity increased as routine tasks became easier to manage and track. With automated scheduling and digital forms, no tasks are missed, and employees focus more on execution than paperwork.

QC staff now complete tasks using desktops or iPads at their stations or on the floor. This convenience has sped up task submissions and reviews across all departments.

With standardized digital workflows, the chance of manual entry errors and overlooked compliance steps dropped significantly, helping reduce internal and USDA violations.

Directors and management teams can now monitor operations at all four sites in real time. This visibility supports faster decisions and tighter control over daily compliance.

The company uses digital HACCP and CCP plans built into a custom FSIS compliance system. It makes it easier to maintain food safety standards and always stay audit-ready.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."