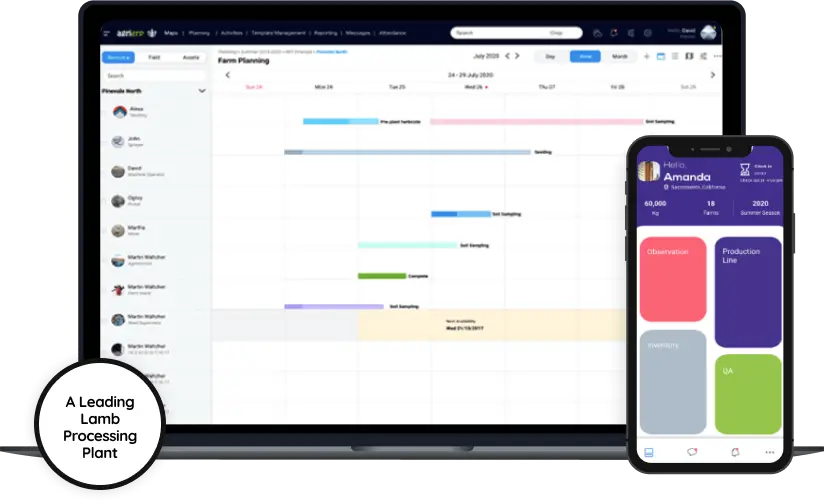

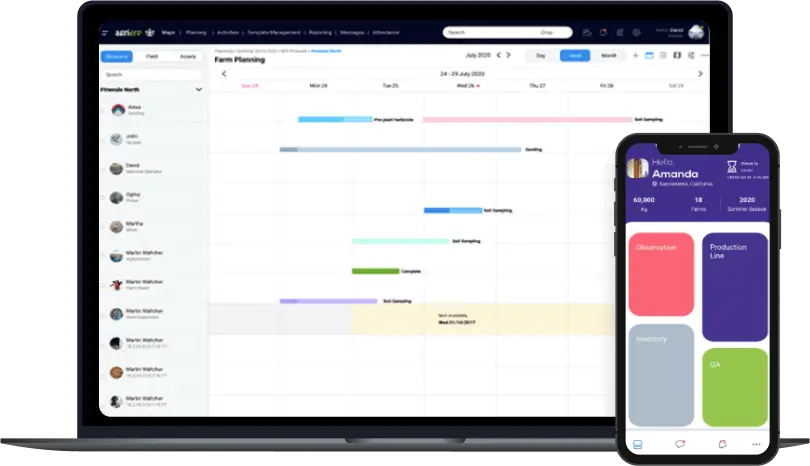

Integrated ERP System Optimized Resource Management, Production, and Logistics.

Traditional record-keeping methods were fragmented and inefficient, leading to inconsistent workflows and limited visibility across the business cycle, affecting productivity, traceability, and overall efficiency.

The company needed a fully integrated solution to automate workflows and operations, provide real-time visibility, and ensure efficient management from animal breeding to product distribution.

AgriERP digitized the processor’s operations by eliminating paper-based silos, centralizing data, and optimizing workflows from master planning to shipments, enhancing efficiency, accuracy, and control across the entire supply chain.

As North America’s largest lamb processor and marketer, the company partners with over 1,000 family-run ranches, prioritizing sustainability and ethical animal care. With an annual revenue exceeding $280 million, it is dedicated to responsible resource management and advancing the meat processing industry through innovation, efficiency, and a commitment to quality. It aims to set new industry standards while ensuring sustainable livestock farming and meat production in the future.

As the business grew, manual processes and disconnected data made it harder to track resources, manage farm activities, and keep operations in sync, slowing growth and decision-making. A modern, integrated solution was essential to simplify operations and drive efficiency.

Key Challenges:

Tracked fertility, weight gain, and growth milestones to ensure SOP compliance and quality assurance. Animal profiles with EIDs recorded all farm activities, while treatment and vaccination histories, paired with condition scoring, supported USDA regulatory compliance.

Enabled centralized planning across coverage, cutting, and production. Ethical slaughter schedules, recipe-based meat cut planning, and demand-driven forecasts simplified production alignment and operational oversight.

Digitized production started via the Production app with route-specific execution. Customer-specific label printing with batch and serial tracking enabled precise packaging, while auto-inventory allocation reduced manual errors and delays.

Native warehouse app with scan gun and offline support accelerated sales shipments. Bulk scanning for Transfer Orders and rapid palletization with license plating made large-scale dispatch faster and more efficient.

AgriERP transformed siloed operations into a unified system, connecting livestock operations, production, and dispatch while enhancing compliance, resource planning, and end-to-end traceability across the supply chain.

By digitizing livestock management with EID tracking and condition scoring, the client reduced manual record-keeping errors by half, ensuring 80% USDA compliance and improving traceability by 35%.

With integrated production planning, the client saw improvement in resource allocation efficiency and a 25% reduction in planning time, aligning operations directly with sales forecasts.

Real-time order execution and automated inventory handling reduced production errors and decreased turnaround time by 15%, boosting throughput without compromising quality.

Warehouse efficiency improved with the scan gun-supported system, while palletization time was reduced by 40%, cutting dispatch delays and improving order fulfillment.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."