Avoid costly EDI errors and chargebacks with automated transaction mapping and real-time validation. Food EDI integration ensures seamless data flow between your ERP and trading partners while maintaining GS1 compliance and FDA traceability.

Automate food operations by integrating EDI with your ERP for real-time data exchange and complete supply chain visibility.

Automate EDI transactions in your ERP to speed up orders, reduce errors, cut costs, and keep your food supply chain running smoothly.

Accelerate order processing by automating EDI transfers into your ERP for real-time updates and quick fulfillment.

Cut labor costs by replacing manual processing with automated EDI-ERP data exchange for orders, invoices, and shipments.

Meet retailer and distributor EDI requirements by ensuring accurate, standardized data flows directly into your ERP.

Reduce errors by automating EDI data capture and syncing clean, validated transactions with your ERP in real time.

Protect sensitive transactions with encrypted EDI transfers and ERP-controlled access to critical business data.

Handle growing order volumes and expand trading partner connections with an EDI system built for food industry demands.

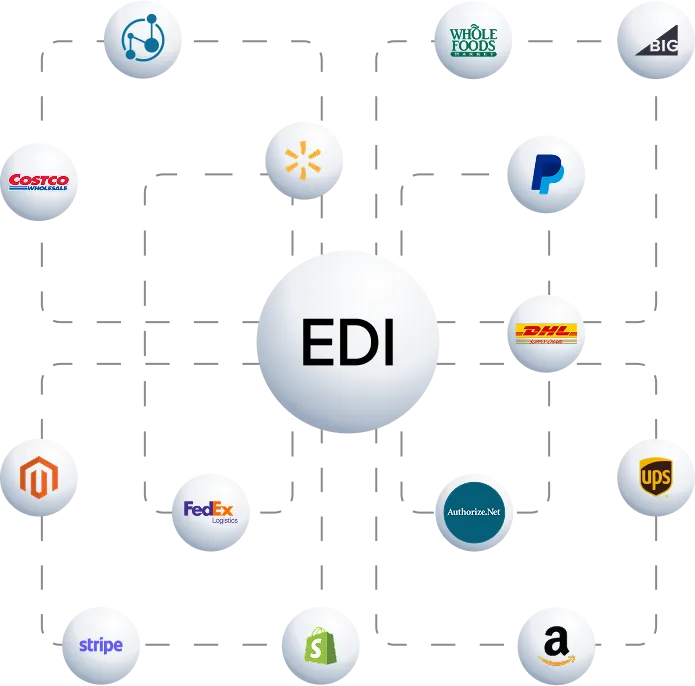

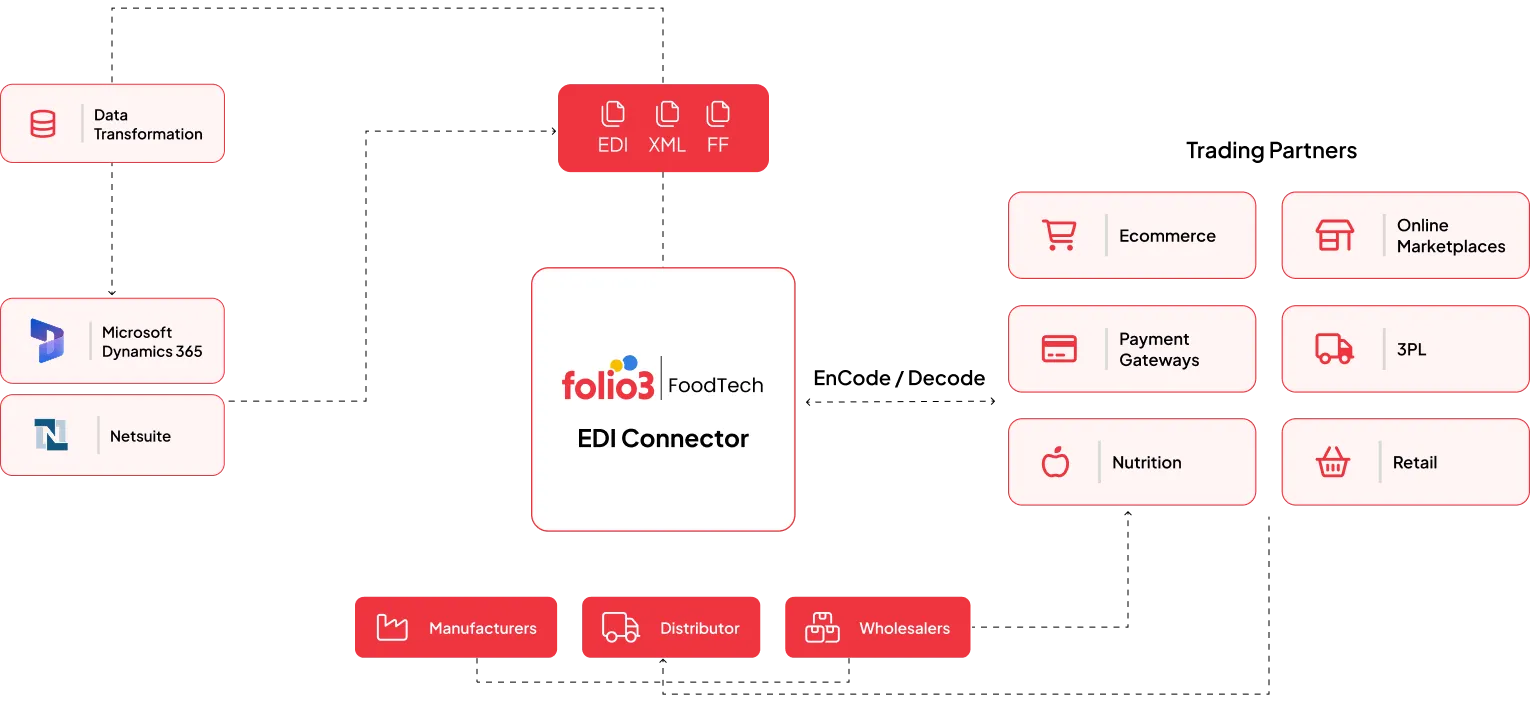

Use Folio3 EDI connector to link trading partners seamlessly with your ERP. Automate data exchange, eliminate manual entry, and ensure real-time accuracy across your food supply chain.

Achieve precision in dough mixing and fermentation while keeping ingredient costs under control.

Optimize production by ensuring batch consistency, monitoring quality, and reducing waste.

Control temperature-sensitive processes to maintain product texture and extend shelf life.

Optimize milk processing and storage while meeting strict hygiene and safety regulations.

Improve cold chain management to prevent spoilage and ensure products remain fresh.

Enhance traceability from slaughter to packaging, ensuring compliance with industry standards.

Standardize recipe formulations and maintain viscosity for a smooth, high-quality product.

Reduce seasoning inconsistencies and improve frying or baking efficiency for better output.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

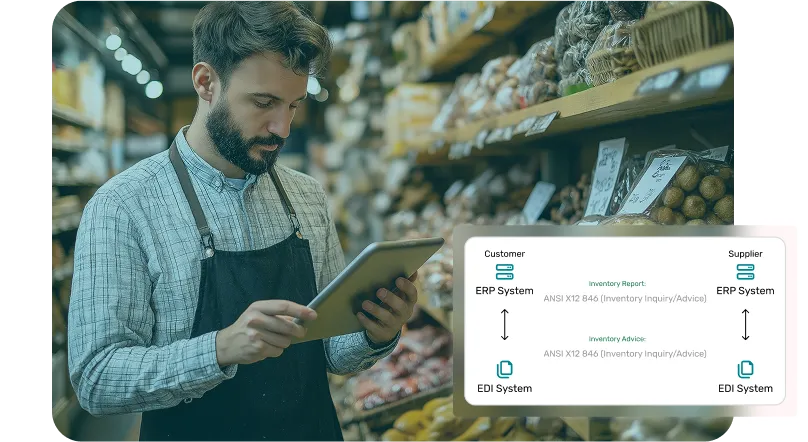

Electronic Data Interchange (EDI) is the automated exchange of business documents between trading partners in a standardized electronic format. In the food and beverage industry, EDI facilitates the seamless transmission of purchase orders, invoices, shipment notices, and inventory data, enhancing operational efficiency and reducing manual errors.

Implementing EDI in the food industry offers numerous advantages, including improved supply chain management, enhanced inventory tracking, faster order processing, reduced paperwork, and better compliance with regulatory requirements. These benefits lead to cost savings and improved business relationships.

EDI integration enhances food safety and traceability by enabling accurate and timely exchange of information related to product origins, processing, and distribution. This real-time data exchange ensures that all parties have up-to-date information, facilitating swift responses to potential food safety issues and compliance with traceability regulations

Yes, EDI can be integrated with existing Enterprise Resource Planning (ERP) solutions. This integration allows for seamless data flow between internal systems and external partners, improving operational efficiency and reducing the likelihood of errors.

Common EDI transactions in the food and beverage industry include:

EDI contributes to inventory management by providing real-time data on stock levels, order statuses, and product movements. This visibility enables businesses to optimize inventory levels, reduce overstock situations, and prevent stockouts, leading to more efficient operations and cost savings.

Challenges in implementing EDI for food and beverage companies may include:

EDI improves supply chain visibility by enabling the real-time exchange of critical information such as order statuses, shipment tracking, and inventory levels. This transparency allows businesses to monitor and manage their supply chains more effectively, leading to better decision-making and responsiveness to market demands.

EDI plays a crucial role in regulatory compliance by ensuring accurate and timely reporting of necessary data to regulatory bodies. This includes information related to food safety, traceability, and product recalls, helping companies meet legal requirements and maintain consumer trust.

Small to medium-sized food businesses can adopt EDI by choosing cloud-based solutions that integrate with their existing ERP, ensuring compliance with trading partner requirements, and working with an experienced EDI implementation partner for smooth adoption and support.