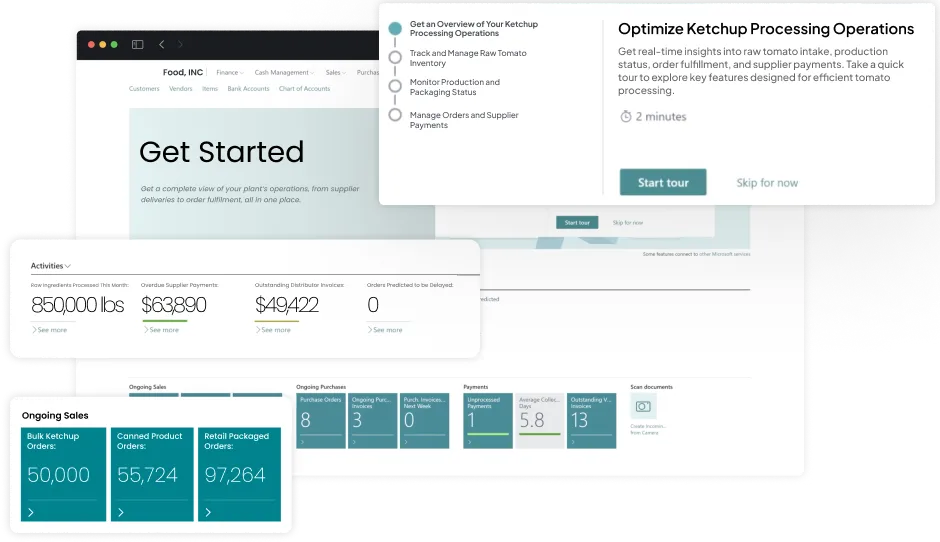

Attain optimal efficiency, food safety, supply chain visibility, and more in one intelligent ERP system. Specifically designed as a food ERP software, our solution facilitates food manufacturers, processors, and distributors across the industry. With Folio3 FoodTech, you get built-in AI capabilities that adapt to your operational persona and let your business accelerate.

Since 2004, Folio3 FoodTech has partnered with food businesses of every scale, helping artisan producers, mid-sized brands, and global enterprises alike. Whether it’s Food manufacturers seeking efficiency, compliance teams preparing for audits, or finance leaders demanding clearer visibility, our personalized ERP software for food adapts to each role’s priorities. By aligning solutions with both your size and your people, we deliver operational excellence without ever compromising on safety or quality.

Every food business is different, whether you’re a grower, processor, distributor, or manufacturer. With decades of experience, we tailor ERP solutions to match unique operational demands. Our ERP software for the food processing industry ensures compliance, efficiency, and scalability across every stage of the value chain.

Digitize recipe scaling, allergen tracking, and production scheduling to deliver consistent, compliant baked goods every time.

Ensure batch consistency, allergen control, and regulatory compliance for chocolates, candies, and sweets at scale.

Maintain milk, cheese, and yogurt freshness with real-time inventory, compliance automation, and production efficiency tools.

Protect the cold chain with optimized storage, expiration tracking, and logistics tailored for frozen food operations.

Track every cut with batch traceability, safety compliance, and yield optimization across meat processing plants.

Manage hatch-to-harvest with flock monitoring, batch tracking, and compliance tools for safe, efficient poultry production.

Control formulations, allergens, and batch consistency while optimizing efficiency for sauces and dressing production lines.

Safeguard catch-to-consumer freshness with cold-chain monitoring, traceability, and compliance tailored to seafood processors.

Your operations demand more than generic ERP features. Our food manufacturing ERP brings together the essential and unique functionalities that supply chain, operations, and compliance managers rely on daily at a food manufacturing facility. From production to trade management, every capability is designed to give you control, visibility, and scalability in one system.

Maintain centralized product specifications with version control, workflow-based approvals, and allergen/claims validation. Automate label accuracy, nutritional declarations, and compliance checks to ensure every SKU meets regulatory standards and retailer requirements without manual rework.

Design, scale, and cost recipes with precision using built-in yield, loss, and allergen analysis. Conduct what-if costing scenarios and automatically update bills of material, ensuring consistent product quality and profitability across production runs.

Plan and manage families of related SKUs simultaneously, rolling out controlled updates across variants with one action. Reduce administrative burden while maintaining accurate costing, consistent labeling, and synchronized compliance across your product portfolio.

Optimize capacity with a drag-and-drop scheduling board that accounts for changeovers, seasonal peaks, and bottlenecks. Run multiple scenarios to balance throughput, efficiency, and cost before publishing executable schedules to the shop floor.

Provide operators with a unified, touch-ready interface to execute work orders, capture yields and downtime, and enforce holds or releases. Real-time visibility empowers supervisors to track efficiency, reduce waste, and protect throughput.

Accurately record variable product weights in line with tare adjustments and automatic margin calculations. Generate precise labels and invoices based on actual weights, enabling profitability and compliance in industries where weight varies per unit.

Centralize purchase and sales contracts with indexed pricing, quantity thresholds, and expiry controls. Automated alerts prevent revenue leakage and ensure timely renegotiations, giving procurement and sales managers full visibility into obligations and margins.

Consolidate rebate programs, bill-backs, and promotional deductions in one system. Link trade spend directly to net margin, ensuring finance and sales teams manage profitability accurately without relying on spreadsheets or disconnected workflows.

Leverage live trading boards to balance supply with demand dynamically. Allocate lots, adjust priorities, and trigger price changes to stabilize fulfillment and margins when raw material availability or market conditions fluctuate.

Automate intake, grading, and settlement processes for grower deliveries with transparent deductions and premiums. Generate accurate statements instantly, improving grower relationships while ensuring compliance with industry and contractual obligations.

Enable mobile-ready workflows for supervisors and operators with offline capabilities. Push real-time alerts for inspections, deviations, or approvals, ensuring business continuity and fast decision-making across plants, warehouses, or remote operations.

Integrate and consolidate orders from retailers, distributors, and eCommerce marketplaces through standardized EDI workflows. Reduce manual entry errors, accelerate fulfillment, and maintain unified visibility into commercial and operational order flows.

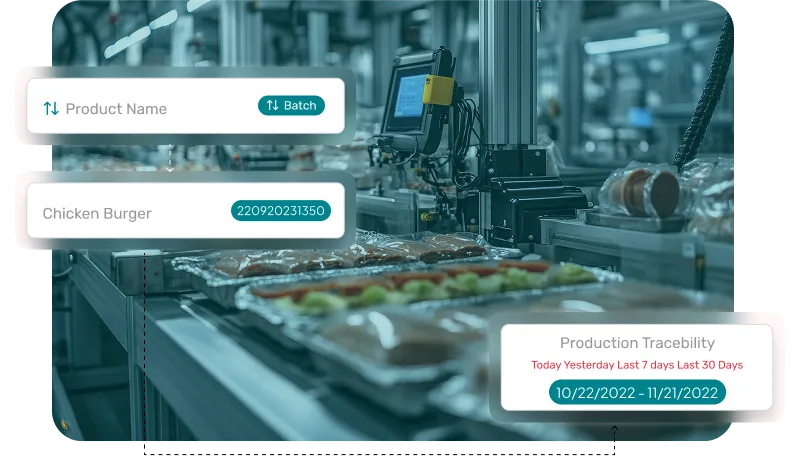

Track ingredients, intermediates, and finished goods across the entire lifecycle with instant recall capability. Maintain auditable traceability for compliance managers while giving operations real-time visibility into every lot, batch, and movement.

Managing a food business requires more than a single feature; it needs an integrated suite. With our ERP for food manufacturing, you gain connected modules spanning production, quality, distribution, and finance. Each module is purpose-built to address industry realities while empowering your team to operate with speed and confidence.

Power Consistency and Control in Every Batch

Streamline recipe management, batch production, and yield control in one connected system. This ERP software, built for food manufacturing, enables operations managers to minimize waste, handle co/by-products, and maintain consistent output quality at scale.

Smarter Stock Control That Protects Margins and Safety

Gain real-time control over stock levels, lots, expiry, and catch-weight items. Designed as an ERP for food manufacturing, this module helps warehouse managers balance safety, compliance, and profitability across dynamic food supply chains.

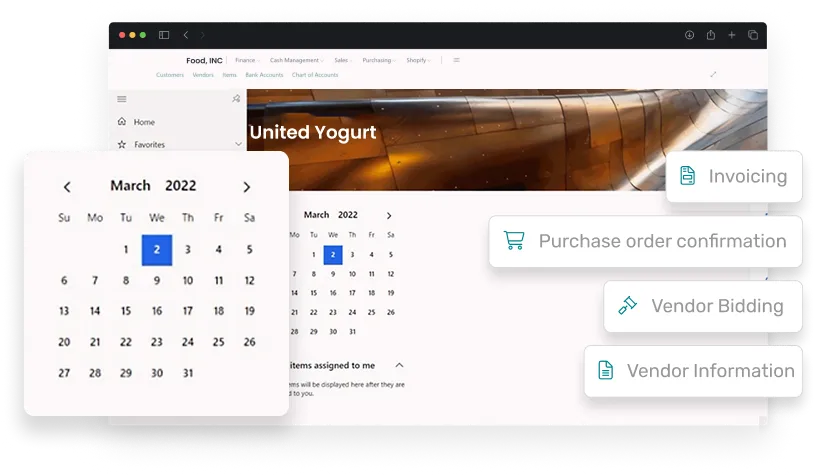

Source Smarter, Spend Better, Stay Compliant

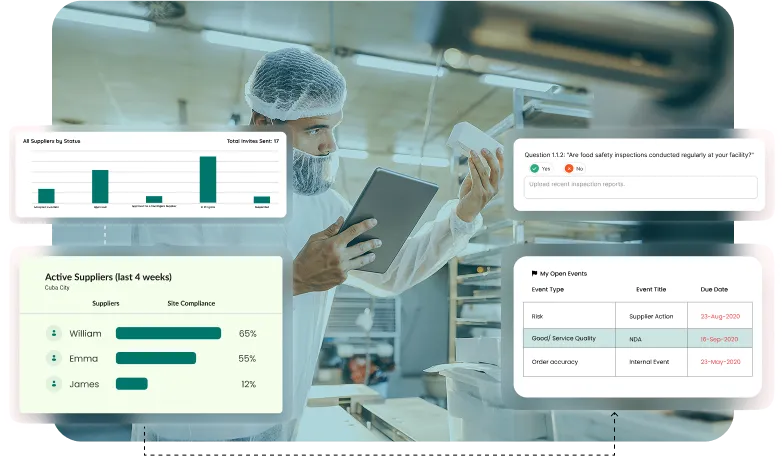

Digitize supplier contracts, approvals, and pricing agreements in one hub. Our ERP system, tailored for food manufacturers, empowers procurement teams to prevent revenue leakage, ensure compliance, and build stronger supplier partnerships through transparency.

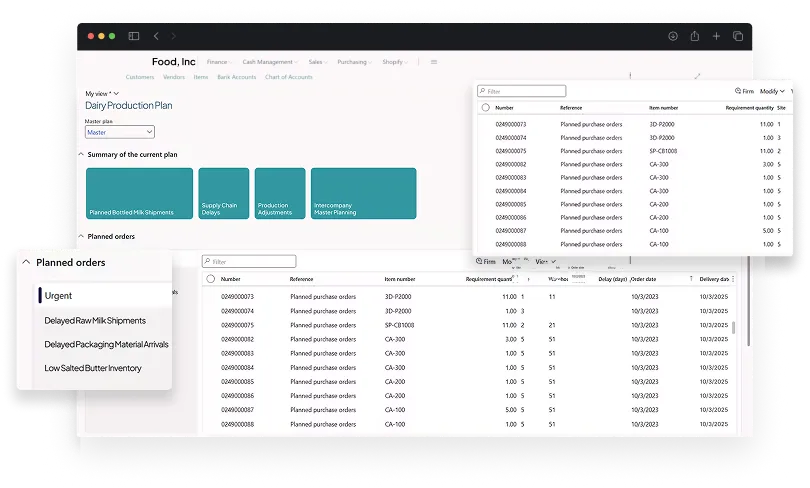

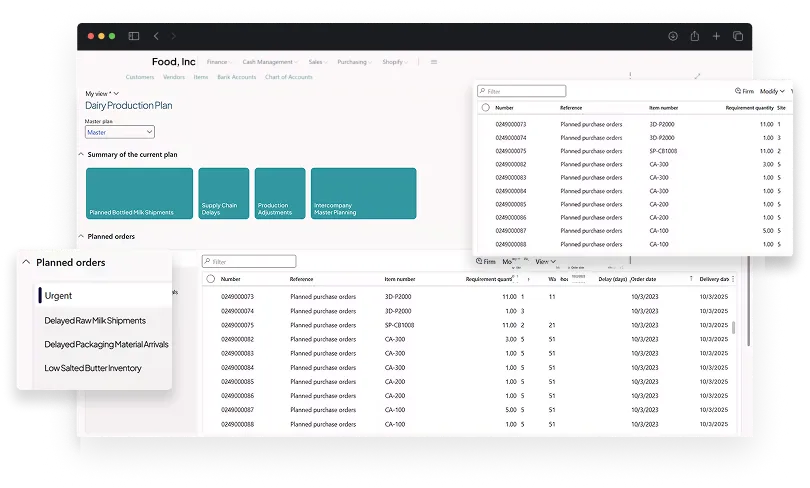

Plan with Precision, Deliver with Confidence

Balance raw material supply with real demand using predictive planning tools. Our ERP system for food manufacturers helps planners reduce shortages, control costs, and maintain production continuity across fluctuating market conditions.

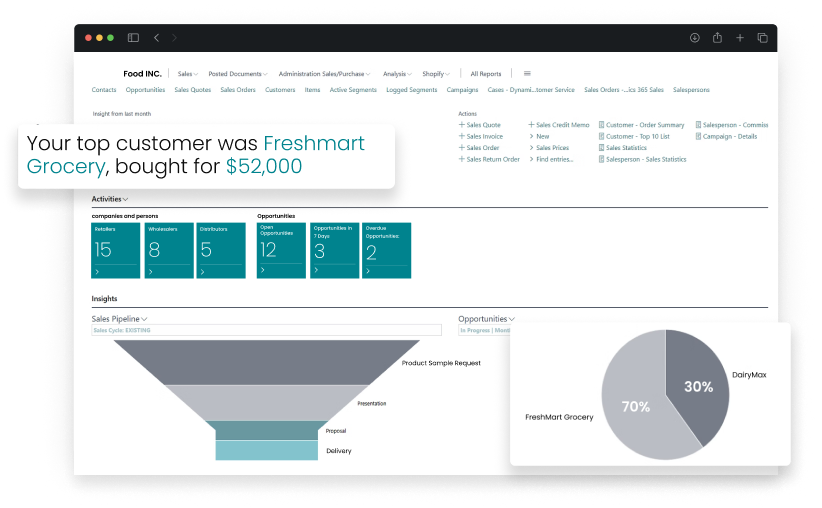

Faster Orders, Happier Customers, Higher Profits

Automate order capture, pricing, and fulfillment to keep customers satisfied. A food manufacturing ERP system like ours ensures sales teams gain visibility across promotions, allocations, and delivery commitments while protecting profitability.

Financial Clarity That Drives Smarter Growth

Consolidate financials, cost tracking, and reporting in one platform. Our ERP software is designed for food manufacturing and equips CFOs to monitor margins, automate compliance, and make better budgeting decisions.

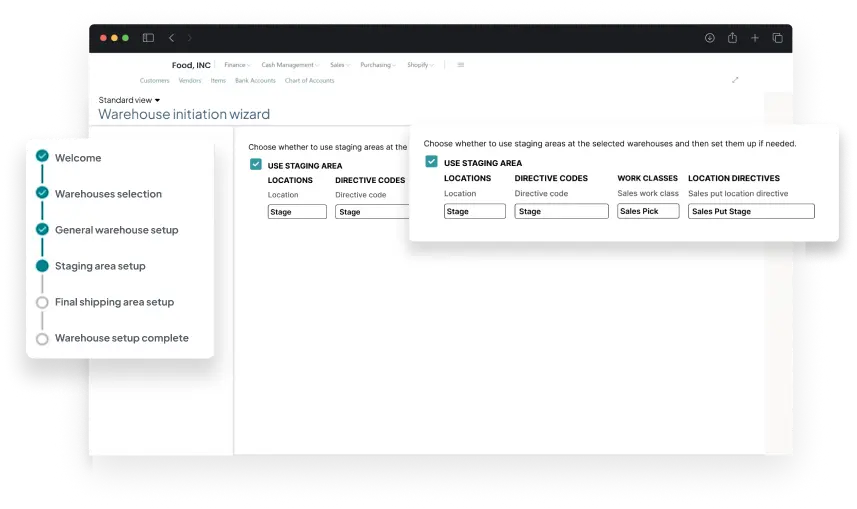

Warehouse Accuracy at the Speed of Food

Digitize warehouse operations with barcode-driven workflows, bin optimization, and FEFO rules. Using our ERP software for the food processing industry, you can ensure accurate storage, efficient picking, and real-time control over goods in cold-chain and ambient environments.

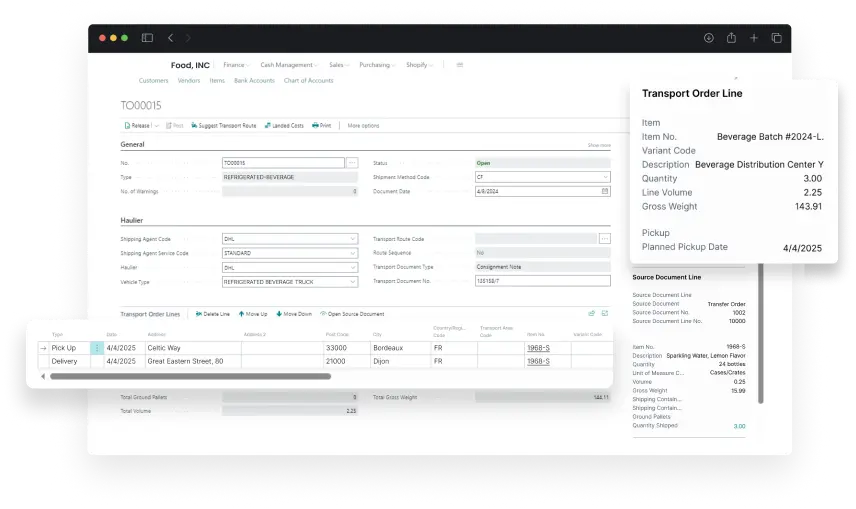

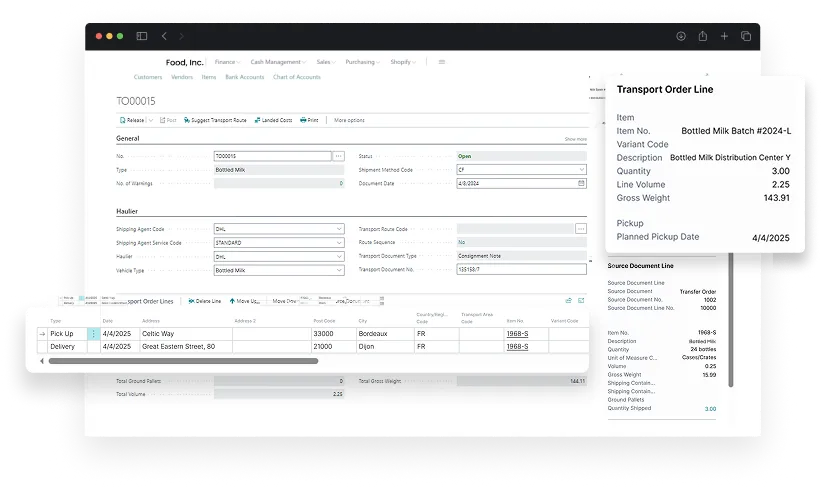

Deliver on Time, Every Time, at Lower Cost

Plan, optimize, and track shipments across fleets and carriers. Our food and beverage ERP software integrates transportation planning with compliance monitoring to cut freight costs while ensuring deliveries remain on time and in condition.

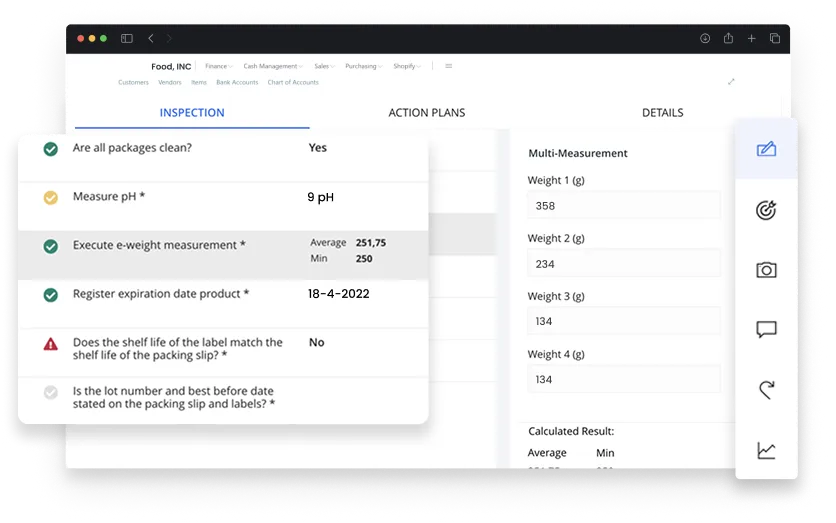

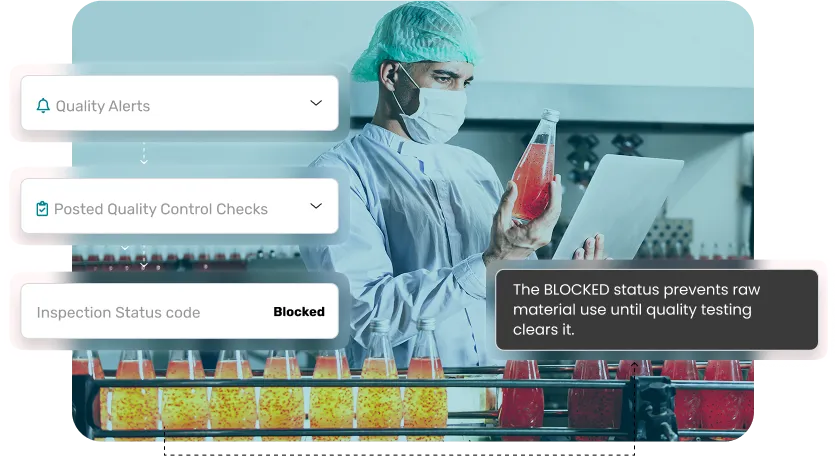

Built-in Quality with Proven Safety Measures

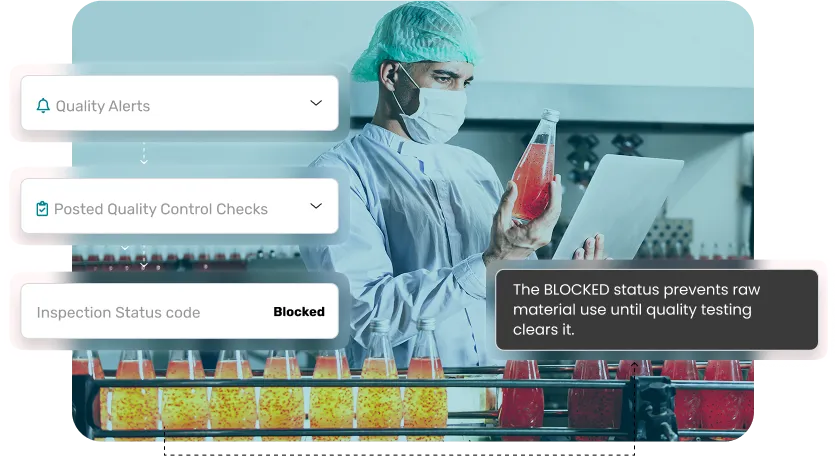

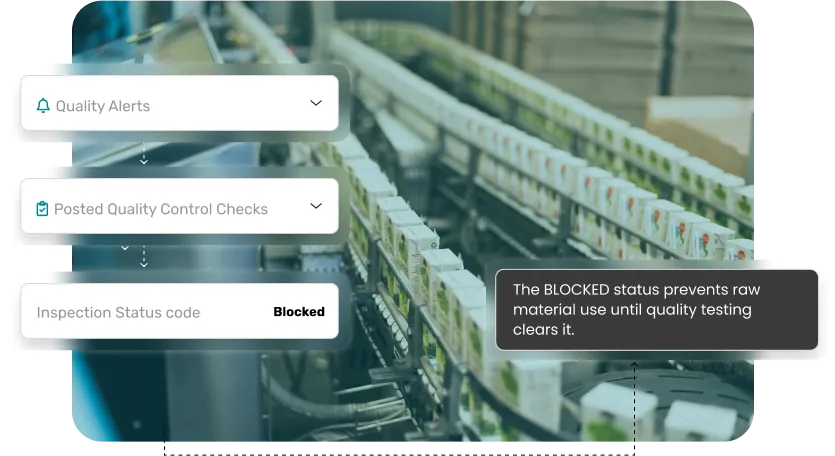

Enforce spec-driven inspections at receiving, in-process, and final, plus non-conformance and CAPA in one hub. Designed as an ERP for food manufacturers, it keeps issues visible early, holds control, and audits evidence ready, so quality becomes assurance, not a checkpoint.

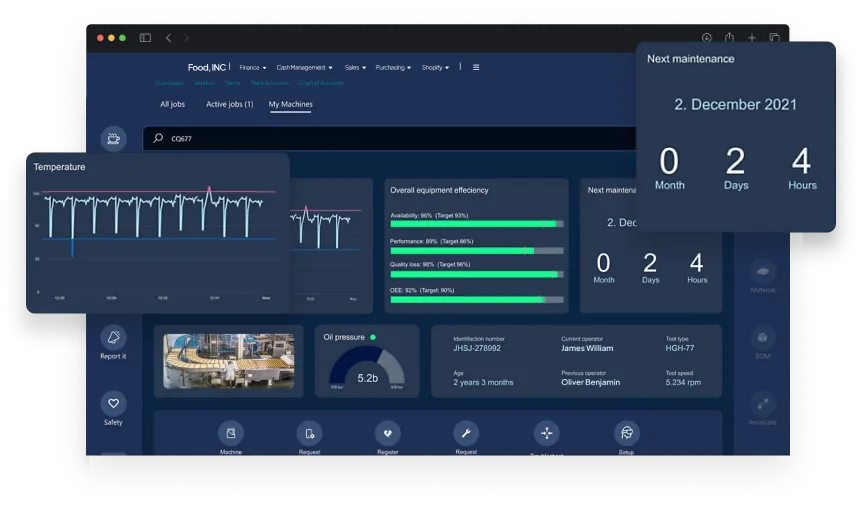

Keep Equipment Reliable, Production Steady, and Costs Down

Schedule preventive and predictive maintenance across production assets to cut downtime. Food ERP systems integrate asset health with operations, giving plant managers full visibility to align equipment reliability with consistent output and regulatory compliance.

Build Trust and Transparency with Every Grower

Digitize grower intake, grading, and settlement processes for upstream suppliers. Our food and beverage ERP creates transparency by issuing automated statements, helping procurement managers strengthen grower trust while maintaining compliance with industry standards.

Smarter Allocation for Profitable, On-Time Deliveries

Manage allocations, priorities, and fulfillment channels to stabilize service levels. A food distribution ERP empowers planners to balance demand with availability, ensuring customers receive accurate, timely deliveries even under volatile conditions.

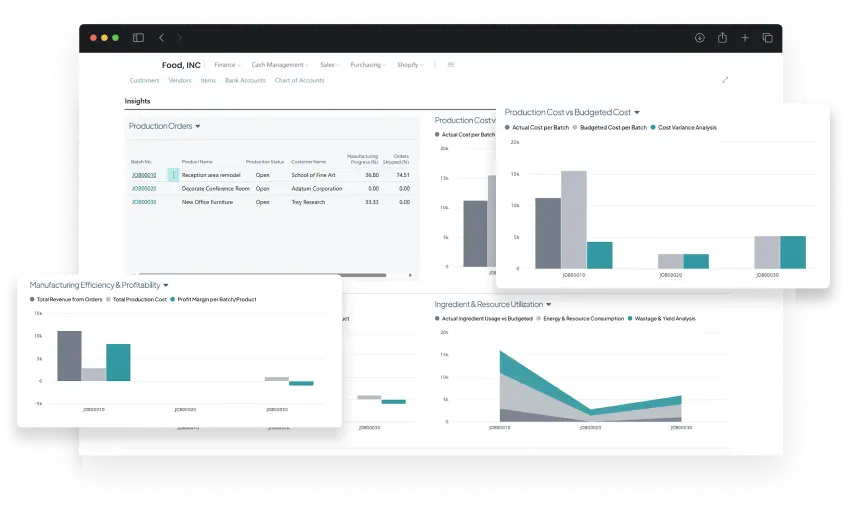

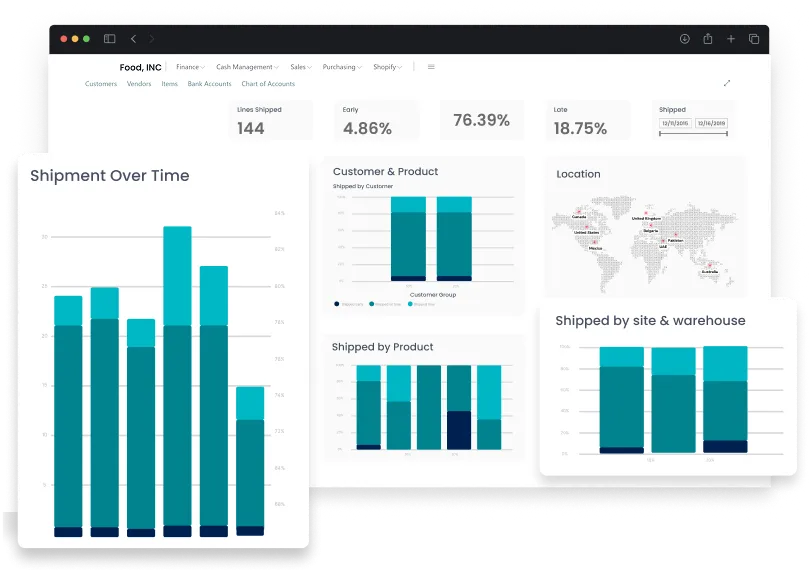

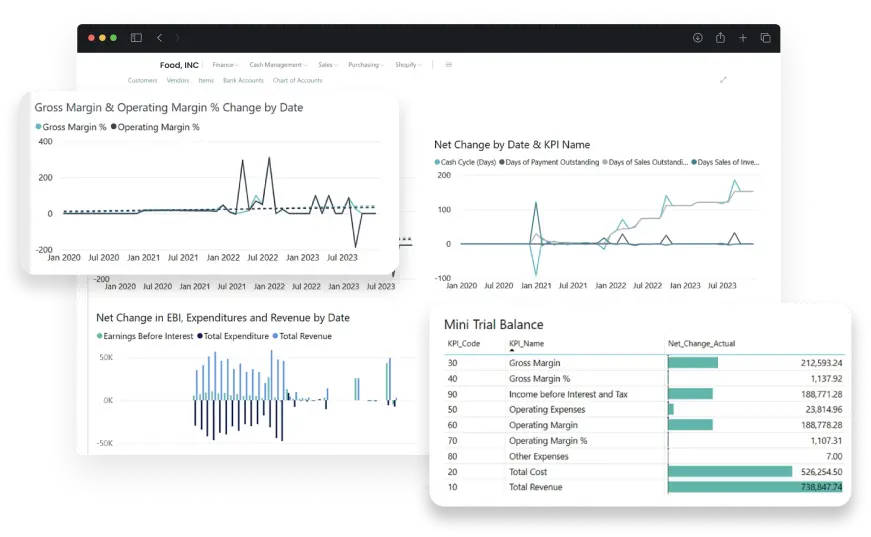

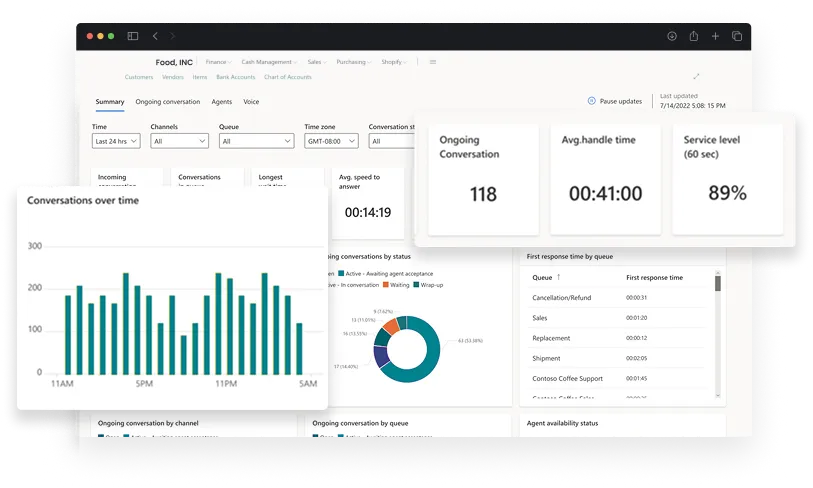

Turn Data into Decisions That Drive Performance

Turn operational data into real-time insights with dashboards, KPIs, and predictive analytics. This food production ERP module equips managers with self-service tools to track performance, identify inefficiencies, and guide smarter, faster business decisions.

Get the definitive, practitioner-written guide to modernizing food operations with ERP. Inside, you’ll find maturity models, FSMA/HACCP program blueprints, integration patterns (eCommerce/3PL/Labs), and KPI benchmarks specific to food manufacturing. Use the practical roadmap, ROI model, and vendor scorecard to de-risk selection and accelerate value. Written for COOs, CFOs, Ops, and QA leaders who need results, not jargon.

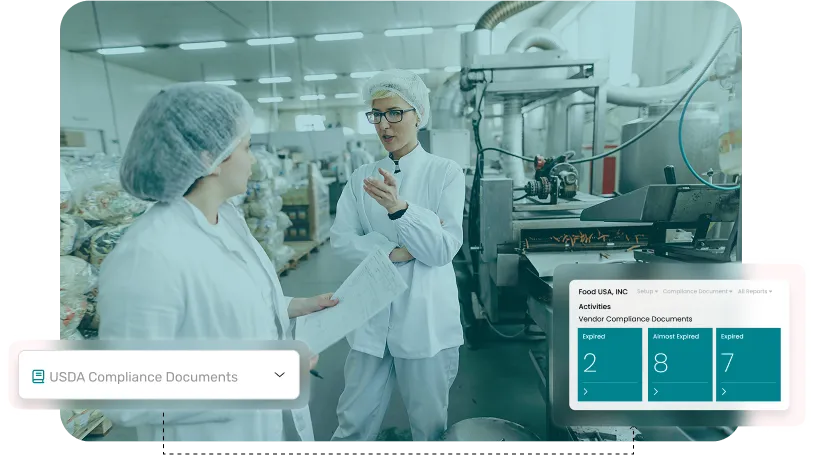

Food safety is the backbone of trust. Our food manufacturing ERP software unifies compliance programs, supplier verification, monitoring, and recall readiness. With all safety modules connected, food manufacturers gain transparency, faster audits, and confidence in every lot shipped.

Turn Compliance Into a Continuous, Controlled Process

Manage policies, licenses, and labeling through a centralized hub. With food ERP software built for regulated industries, compliance leaders transform fragmented obligations into auditable workflows that provide proactive alerts and documented proof across plants.

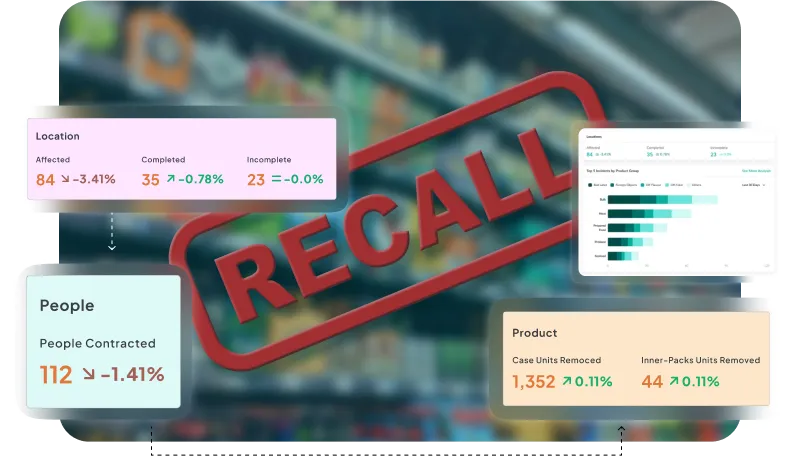

Be Ready to Recall in Minutes, Not Days

Execute recalls swiftly with end-to-end lot traceability. Our ERP for food industry empowers safety teams to identify affected shipments instantly, assign tasks, and close the loop with regulator-ready documentation and effectiveness checks.

Detect Issues in the Environment Before They Reach Production

Design monitoring programs with swabs, allergen tests, and trend analysis. Using food industry ERP software, QA teams can spot hotspots early, enforce corrective actions, and prevent contamination risks long before they impact finished goods.

Strengthen Supplier Relationships While Reducing Compliance Risk

Centralize supplier onboarding, approvals, and certifications in one system. Our ERP software for food helps procurement leaders monitor compliance, track expiries, and ensure every material sourced meets safety and regulatory standards consistently.

Simplify FSMA Requirements With Built-In Controls and Records

Create and maintain FSMA-aligned food safety plans, including hazard analysis, preventive controls, and verification activities. Our food and beverage ERP software equips compliance managers to manage deadlines, track controls, and present regulators with audit-ready documentation.

Keep CCPs in Control With Digital HACCP Plans

Build HACCP plans with product flows, hazards, CCPs, and critical limits in one system. Our food manufacturing ERP helps QA teams capture monitoring, manage deviations, and simplify inspections with transparent documentation.

Trace Every Ingredient From Source to Shelf Instantly

Track ingredients, intermediates, and finished goods across the supply chain with full lot genealogy. Our ERP for food manufacturers equips operations and compliance teams to run instant recalls, strengthen audit trails, and enforce shelf-life controls.

Make Quality a Built-In, Not Bolt-On, Process

Plan inspections, enforce NC/CAPA, and digitize QA processes in one hub. With ERP for food manufacturing, quality teams prevent issues early, manage holds effectively, and maintain consistent standards across facilities.

At Folio3 Foodtech, innovation means impact, and you experience that through our food and beverage ERP software. Our Food ERP system is purpose-designed for manufacturers, processors, and distributors, which leads them to faster compliance, smarter production, and better margins. We enable all this by being a disruptor in the food tech industry based on our following USPs:

Benefit from consultants who visit your facility to understand operations firsthand. We design ERP solutions aligned to real workflows, ensuring a precision fit for food manufacturers.

Connect quickly with retailers, distributors, and eCommerce platforms through pre-built integrations. Food ERP users reduce chargebacks, accelerate onboarding, and gain unified order visibility.

Harness AI-enabled ERP features like food detection and anomaly alerts. Quality managers gain real-time insights that cut waste, boost compliance, and protect margins.

Work with one partner for ERP, CRM, mobile apps, and analytics. We extend value beyond ERP to cover every touchpoint of food business growth.

Stay audit-ready with HACCP, FSMA, recall, and supplier management embedded directly into our ERP platform. Compliance becomes a natural output, not an afterthought.

Scale confidently with ERP designed for single-entity firms and global enterprises alike. Our solutions adapt to organizational complexity, ensuring growth without system replacement.

Experience a working ERP prototype within weeks. This approach aligns stakeholders early, reduces delivery risks, and proves value before large-scale rollout begins.

Given our vast array of experience in the food industry, we specialize in engineering on-demand Food ERP solutions from scratch. If your requirements are unique, we’ll map your workflows and build a system that fits precisely.

Food businesses face different constraints: freshness windows, labeling, multi-channel fulfillment, and fast audits. Our food and beverage ERP software solves these realities with integrated finance, operations, quality, and commerce. Below are brands we’ve helped cut manual work, scale confidently, and deliver on time.

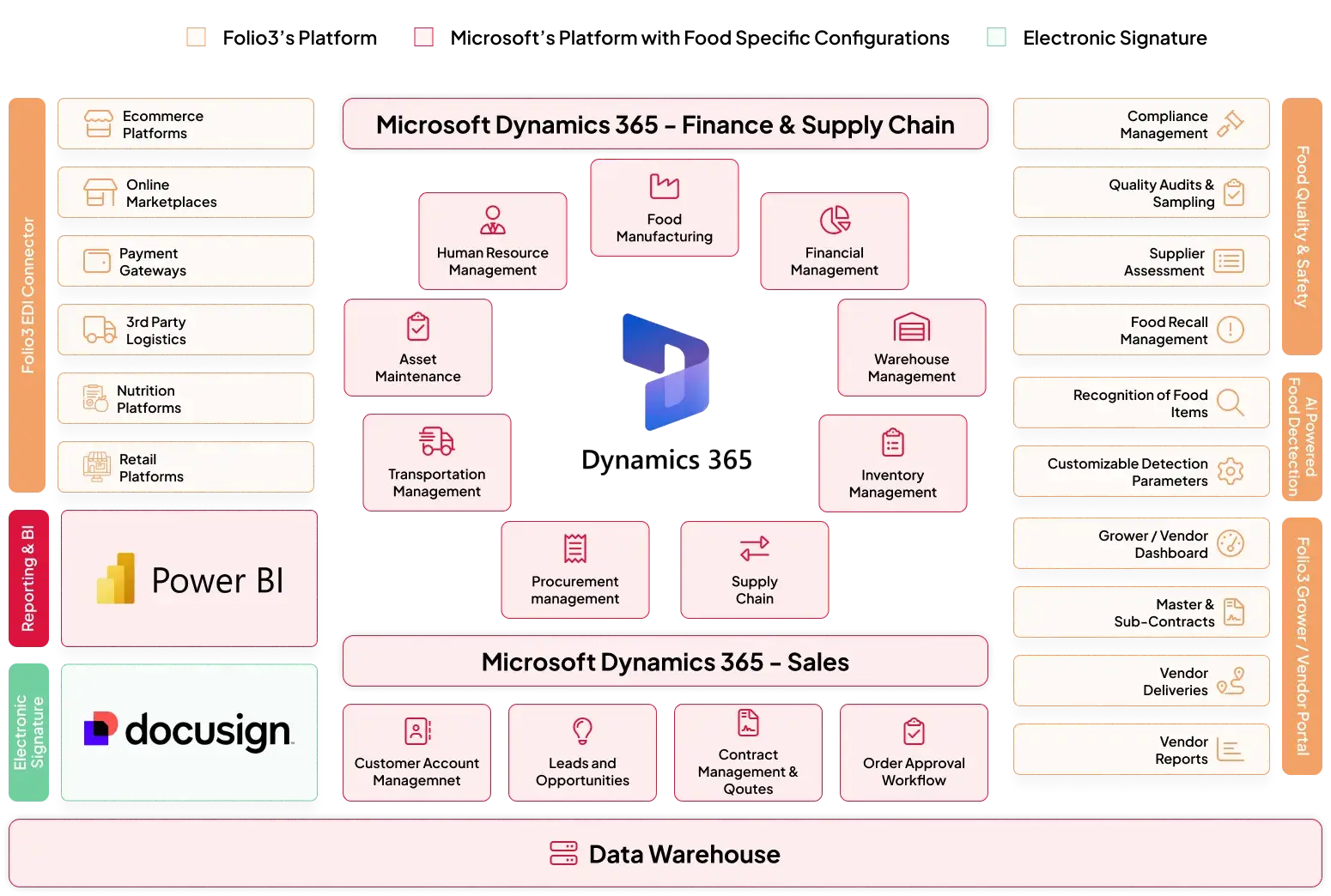

Food operations stretch across storefronts, marketplaces, logistics, labs, and support desks. We connect them all into one ERP built for food manufacturers and processors, so teams see the same truth. With unified data, you move faster, cut errors, and scale without rework.

Every food business runs differently and deserves a delivery plan that respects that reality. Our diverse team maps your operations, then engineers the fit. With food ERP software for manufacturers, we tailor scope, sequence, and success metrics to your unique requirements.

Map Reality Before We Build

Map current processes, constraints, and KPIs through on-site walkthroughs and stakeholder interviews. This creates a fact-based baseline for ERP for food manufacturers, aligning business goals with the capabilities we’ll configure.

Blueprint the Win, De-Risk the Delivery

Define the delivery blueprint scope, sprints, RACI, risks, and change plan. That structure keeps your food industry ERP program predictable, transparent, and aligned with dates the business can stand behind.

Configure What Fits, Extend What Matters

Configure core modules and extend only where the process demands recipes, catch-weight, QA holds, labeling, and allocations. By shaping food manufacturing ERP software to your flows, we reduce customization and future technical debt.

Prove It Works, Before It Works for You

Validate end-to-end scenarios, happy paths and edge cases with data subsets and controlled exceptions. This proves ERP software built for food manufacturers can withstand audits, recalls, and real production pressure before go-live.

Connect Every System, Operate as One

Connect ecommerce, 3PL, labs, POS, and finance so ERP becomes the operating backbone. As ERP for food processors and manufacturers, it turns external signals into clean, actionable workflows.

Move Clean Data, Start Day One Right

Cleanse master and transactional data, then migrate in rehearsed waves. A disciplined approach ensures your food ERP system starts day one with reliable items, lots, suppliers, and open balances.

Go Live Without the Guesswork

Launch with the right strategy pilot, phased, or big-bang based on risk and readiness. This makes your manufacturing ERP for food switch-on predictable, with hypercare standing by.

Enable People to Sustain Value

Enable users with role-based training, SOPs, and admin playbooks. As teams adopt ERP for food manufacturers, ongoing support and success reviews keep value compounding after go-live.

Ops, supply chain, and quality leaders share how they cut manual work, passed audits faster, and shipped on time with our ERP. Brief, specific, and role-relevant stories to give you a real picture. If your challenges look similar, these results show what’s possible.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

Food ERP software is an industry-specific solution designed to help food businesses manage production, inventory, traceability, quality, compliance, finance, and distribution within one integrated system. It offers real-time visibility into operations, automates workflows, reduces manual errors, and supports compliance with food safety regulations such as FDA, FSMA, and SQF. Whether you're scaling or streamlining, Our ERP empowers smarter, traceable food operations that drive better decisions and long-term profitability.

Folio3 FoodTech’s ERP is purpose-built for a diverse range of food and beverage industries including manufacturers, importers, distributors, co-packers, private-label brands, and direct-to-consumer operators. Whether you run a frozen supply chain, manage perishable goods, or coordinate regional fulfillment, the system adapts to your operational model and regulatory landscape with precision. Built on the highly scalable Microsoft Dynamics ERP platform, Folio3’s industry-specific modules ensure seamless fit for frozen, DTC, and distribution-centric businesses providing flexibility and depth regardless of size or complexity.

Folio3 FoodTech’s ERP supports multiple food and beverage sectors, including: Frozen foods, Seafood, Meat, Poultry, Dairy, Bakery, Beverages, Sauces & Dressing, Snacks, Confectionery and more. Each vertical is equipped with modules that support shelf-life tracking, batch control, cold chain management, compliance, and recall readiness, ensuring your unique operational needs are met without compromise.

Folio3 FoodTech’s ERP includes a complete set of modules to support the day-to-day operations of food businesses. These modules cover food manufacturing and processing, supply chain management, distribution management, warehouse management, and transportation management. The system also includes inventory management tools to track stock movement and availability in real time. For internal operations, it provides support for asset and plant maintenance as well as human resource management. Reporting and business intelligence features are built in to help teams monitor performance, identify issues early, and make informed decisions. Built on Microsoft Dynamics 365 Finance and Supply Chain Management, these modules are further enhanced by Folio3’s food-industry templates, offering specialized capabilities like cold chain features and compliance tracking that provide complete operational visibility and control.

Not at all. Our Food ERP software is designed to serve businesses of all sizes, from growing startups to multi-facility manufacturers. The solution is modular and scalable, allowing you to begin with essential functions and expand as your business evolves. Whether you’re a niche processor or a global food brand, the system is configured to meet your operational scope, complexity, and goals. Leveraging both Microsoft Dynamics 365 Business Central for small to mid-sized businesses and Dynamics 365 Finance & Supply Chain Management for larger enterprises, Folio3 offers unmatched flexibility to scale the ERP based on your growth stage.

No. Our Food ERP supports scalable user access and grows with your team. While Microsoft Dynamics licenses users under a "named user" model, Folio3 offers flexibility through customized configurations such as user pooling or custom access logic to accommodate both lean teams and large enterprise workforces. This ensures you can scale operations without facing restrictive license caps, enabling smoother collaboration across departments and locations.

Yes. Folio3 FoodTech’s ERP provides detailed profitability analytics at the SKU, customer, location, and delivery route levels. By capturing both direct and indirect costs, such as ingredients, labor, packaging, storage, freight, spoilage, and discounts it offers a clear view of product and customer performance. Built on Microsoft Dynamics 365, the system uses tools like Dimensions and Power BI to track profitability, and Folio3 enhances it further with logic that supports route-based analysis. Executives and finance leaders can make confident, data-driven decisions to improve margins and operational efficiency.

Our ERP software is built to align with major global food safety regulations including FSMA, HACCP, SQF, and BRC. It automates monitoring of critical control points, maintains digital inspection logs, flags deviations, and supports corrective actions. With audit-ready reporting and digital traceability from intake to distribution, you’ll meet regulatory demands efficiently while minimizing risk and downtime.

Yes, our Food ERP includes built-in food EDI capabilities designed to meet the requirements of major retailers. It automates transactions, invoicing, labeling, ASN generation, and reporting based on retailer-specific compliance formats. Powered by Microsoft Dynamics 365, the system supports EDI through trusted third-party integrations such as SPS Commerce and TrueCommerce. Folio3 also offers pre-built connectors to streamline setup, so you can manage complex retailer relationships with confidence and eliminate manual workflows that introduce errors or delays.

Yes, our Food ERP software supports multi-site, multi-language, and multi-currency operations, providing centralized visibility with localized compliance. Built on Microsoft Dynamics 365, which is cloud-native and designed for multi-location businesses, the system ensures your teams stay connected. Whether managing regional warehouses or international partners, your staff can access the platform remotely from desktops, tablets, or mobile devices, keeping operations aligned and responsive at all times.

Folio3 FoodTech’s ERP is hosted on enterprise-grade cloud platforms including Microsoft Dynamics 365 and Oracle NetSuite. Data is encrypted in transit and at rest, isolated by the tenant, and monitored continuously. Microsoft provides built-in security aligned with global standards like SOC, ISO, and GDPR, along with high uptime SLAs. Folio3 builds on this secure foundation by applying additional controls and multi-layered safeguards to ensure your financial, production, and quality-control data remains protected, private, and always accessible.

Yes. The system is highly configurable to reflect your exact workflows, regulatory priorities, and reporting needs. From custom modules and dashboards to purpose-built workflows and integrations, our Food ERP is designed to fit the way your business actually operates, no one-size-fits-all constraints. Built on Microsoft Dynamics, it supports extensive customization and can be extended further through Power Platform-based enhancements delivered by Folio3’s expert team.

ERP Implementation timelines depend on your business size and complexity. We follow a structured rollout process that includes discovery, blueprinting, development, testing, integration, data migration, training, and go-live support. Our food industry consultants guide each phase to ensure a smooth transition with minimal operational disruption.

Yes, our team handles comprehensive data migration, including products, inventory, bill of materials, pricing, customer records, financials, and historical transactions. We map your existing datasets to the new environment to ensure clean, validated data entry, maintaining continuity across departments.

Folio3 FoodTech’s ERP is supported by high-availability cloud infrastructure, hosted on Microsoft Azure, with built-in failover and backup systems. In the rare event of downtime, our technical teams follow strict disaster recovery protocols to restore services quickly. With continuous monitoring, real-time alerting, and redundancy measures in place combined with Folio3’s multi-tiered (L1-L3) support framework system uptime and business continuity are strongly safeguarded.

We provide full lifecycle support, including Tier 1 (basic training and functional help), Tier 2 (technical diagnostics and resolution), and Tier 3 (deep technical support, custom fixes, and advanced issue resolution). Clients receive 24/7 access to support resources, onboarding led by domain experts, dedicated success managers, and proactive feature enablement based on customer feedback. This multi-tiered approach ensures that your team is supported at every stage, from go-live to continuous improvement.

As certified Gold Partners of Microsoft Dynamics and Alliance Partners of Oracle NetSuite, we offer early access to updates, priority vendor support, and solution architecture built on globally trusted platforms. This partnership ensures that your ERP is future-proof, performance-driven, and continuously enhanced with the latest innovations. Customers benefit from smoother rollouts, fewer bugs, and implementation best practices backed by deep product expertise.

Yes. We offer personalized demos so you can experience the platform firsthand. During the walkthrough, our specialists showcase the modules most relevant to your operations, answer business-specific questions, and demonstrate how Folio3 FoodTech’s ERP aligns with your goals. With over 20 successful ERP implementations in the food and beverage industry, we bring food-specific configurations and real-world insights that help you evaluate the system with confidence.