Optimize yield and improve traceability with an ERP solution for meat, seafood, and poultry processors & packers, streamlining operations from farm to fork.

Address the real challenges in your processing plant with meat ERP that help manage livestock arrival, improve production flow, reduce waste, and keep your meat business competitive.

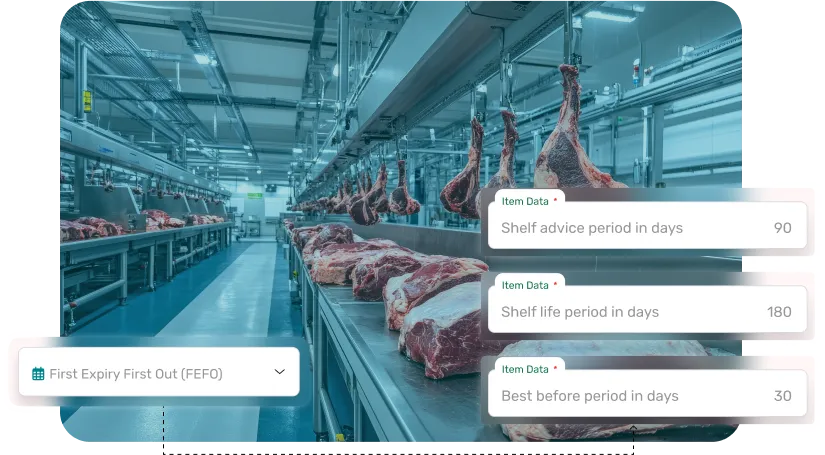

Without effective inventory management, meat products with a usual shelf life of 20 to 90 days are prone to spoilage due to microbial growth and discoloration.

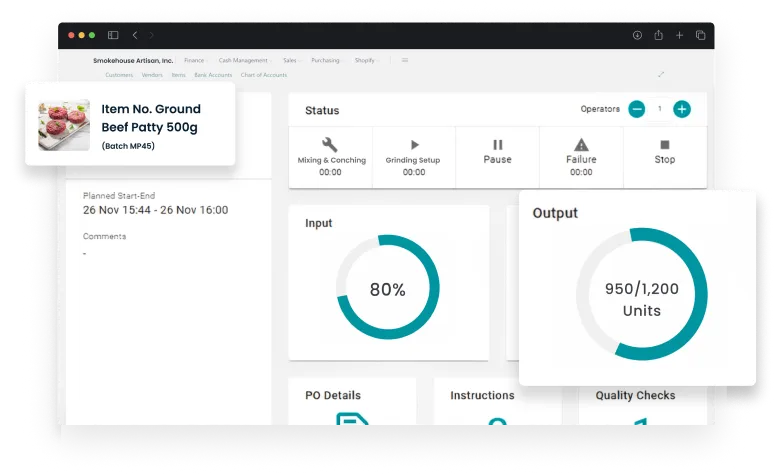

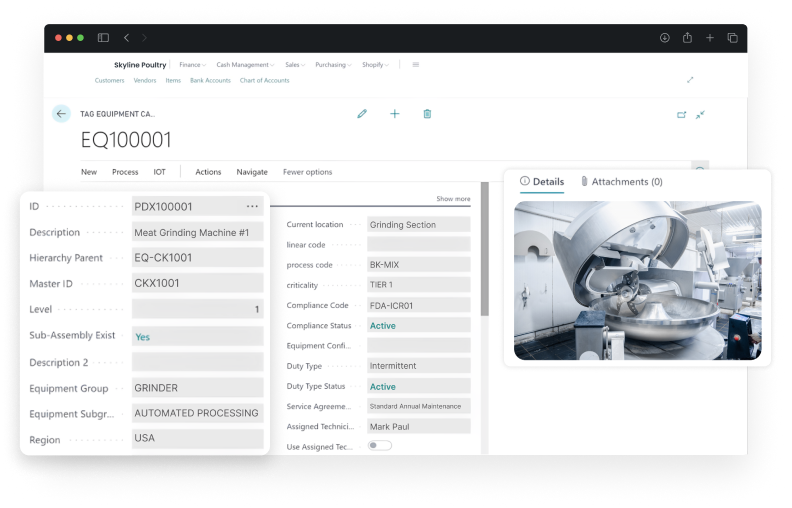

Any failure of machines that run for 16-20 hours daily, such as meat cutters or grinders, can disrupt production, leading to missed deadlines and a decline in production.

Meat products like cuts or sausages often have variable weights, and without their precise weight tracking, it gets difficult to maintain cost accuracy and customer satisfaction.

Waste generated during meat processing, including trimmings, bones, and fat, increases operational costs and complicates disposal compliance, impacting profitability.

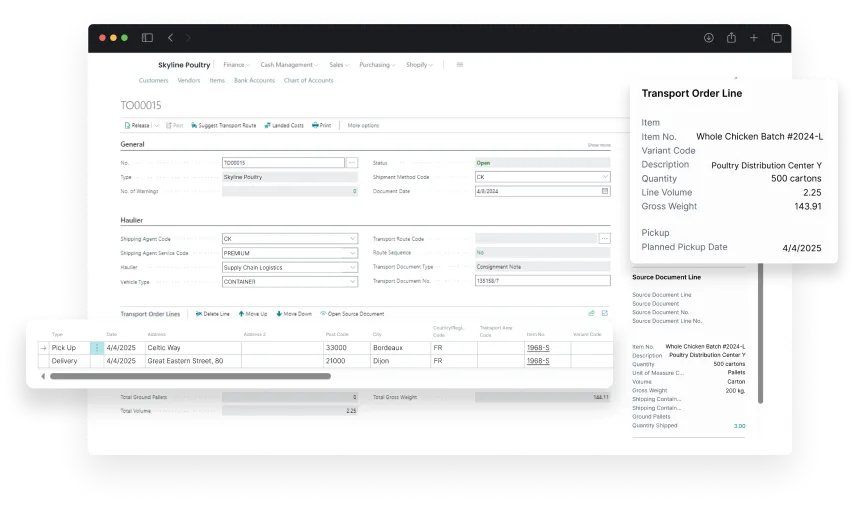

Timely delivery is critical to maintaining freshness for perishable meat products. Any delays in transportation or distribution can lead to spoilage and compromise meat quality.

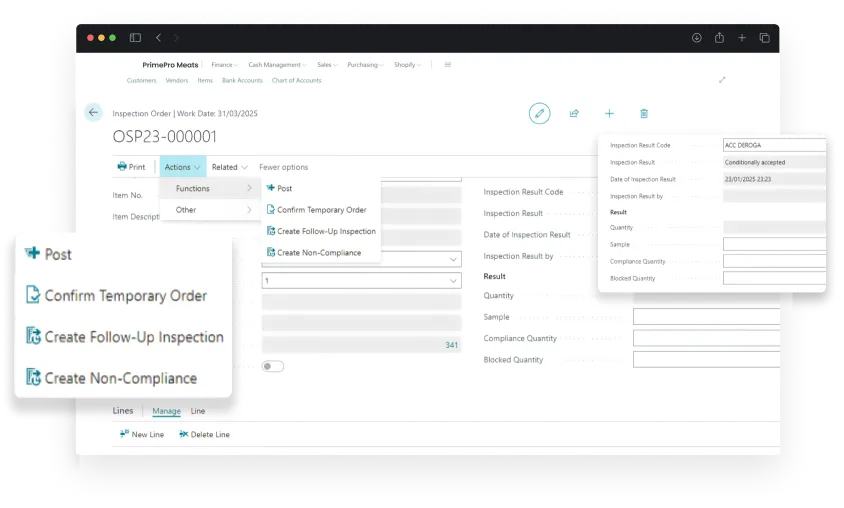

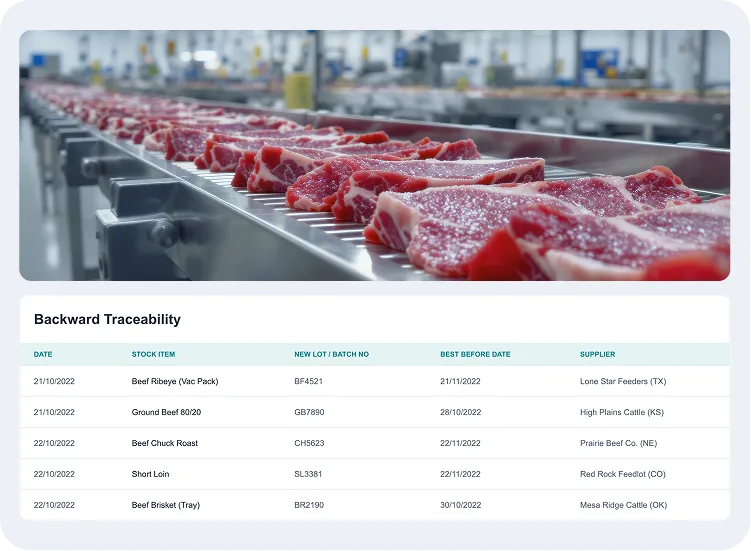

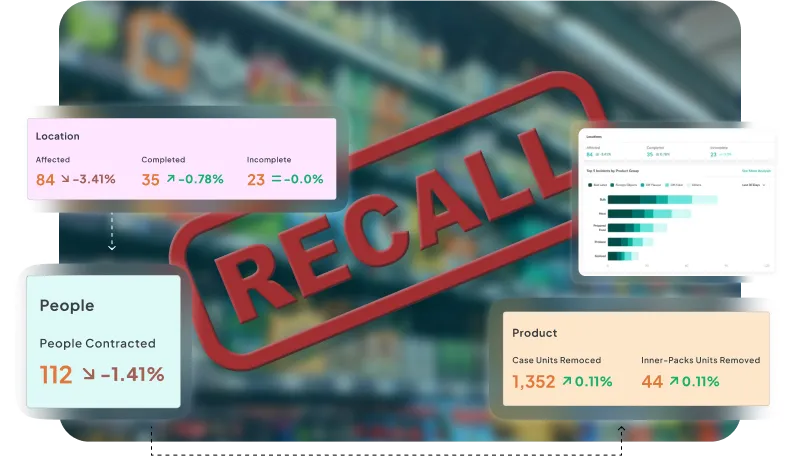

Without proper batch traceability from slaughter to packaging, pinpointing contamination sources becomes difficult, increasing the risk of costly recalls.

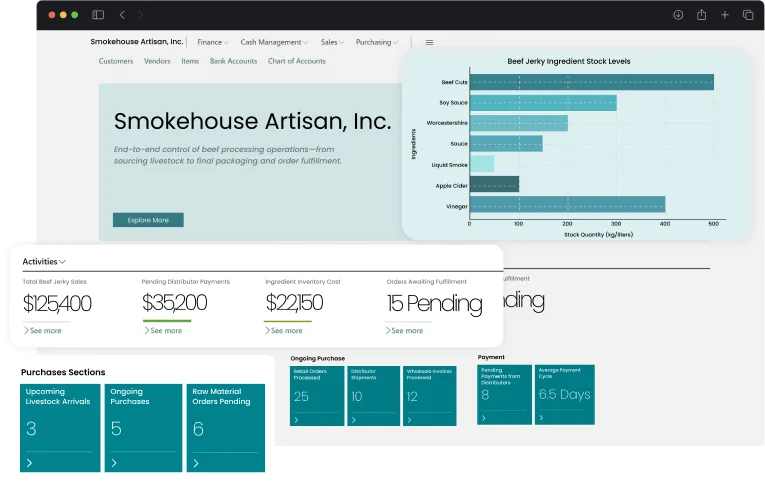

Track yields, control cuts, and handle packaging with a meat processing ERP that brings precision and efficiency to every step.

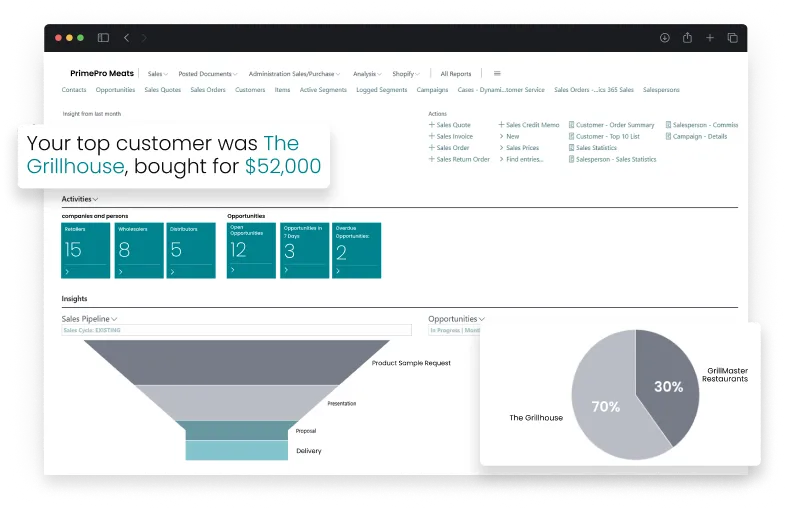

Use a comprehensive ERP system to fit your specific meat types and business needs, giving you real-time insights, optimized workflows, and complete control over your operations.

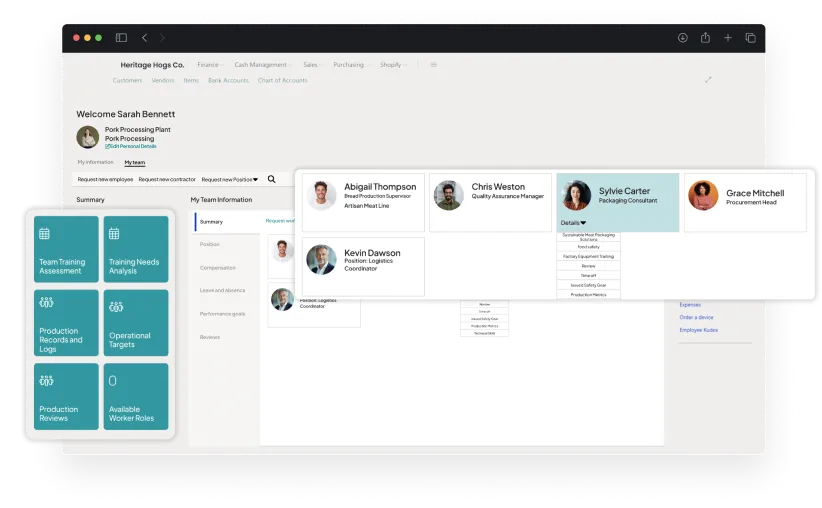

Efficiently manage livestock, seafood, and poultry production with ERP, from breeding and feed management to health tracking, ensuring optimal growth and compliance with animal welfare standards.

Manage slaughtering, boning, primary and secondary processing, and value-added production with ERP, enhancing yield tracking, batch management, and regulatory compliance, ensuring consistent quality and traceability across all meat types.

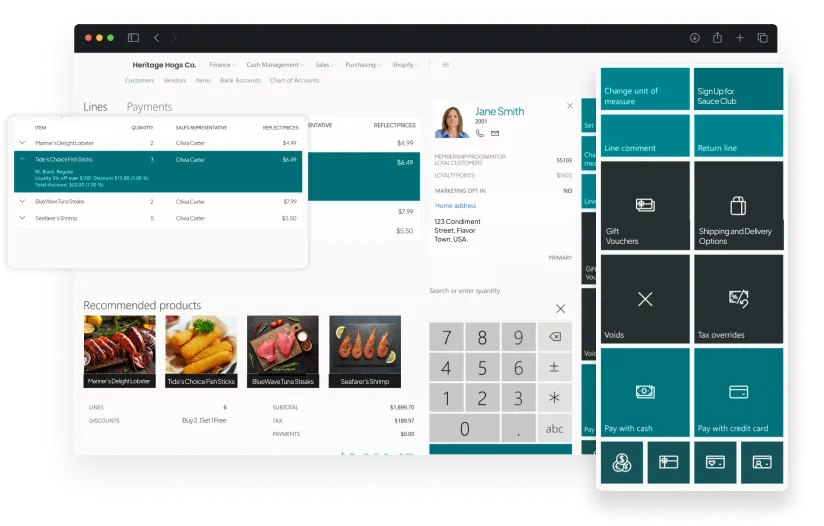

Optimize packing, inventory management, and distribution processes with ERP, ensuring timely deliveries, precise order fulfillment, and effective cold storage management for various meat products.

Manage retail operations with ERP, from inventory tracking and pricing to sales and traceability, ensuring fresh, safe, and compliant meat products reach your customers efficiently and on time.

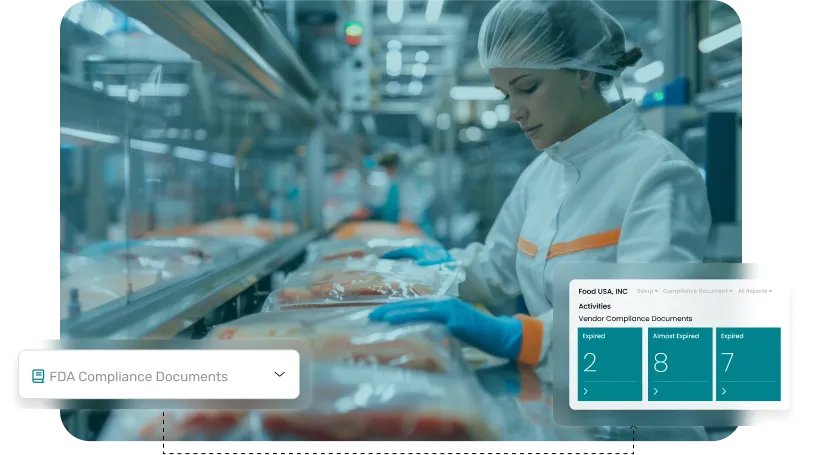

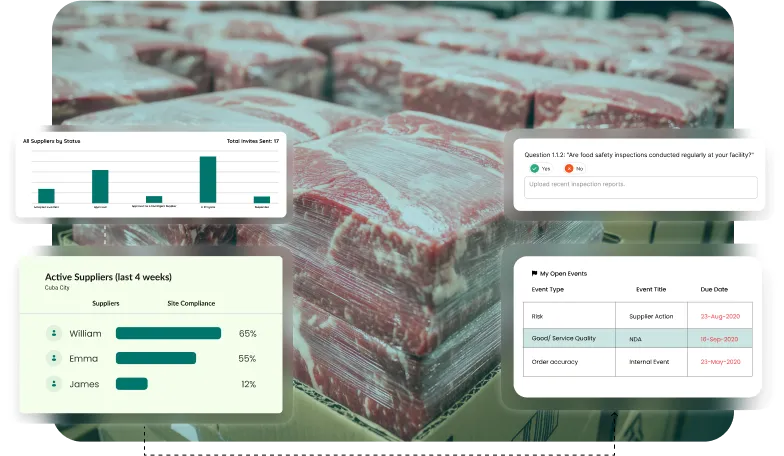

Comply with USDA, FDA, and other critical regulations to meet food safety standards, prevent contamination, and protect both your operations and consumer trust.

Ensure adherence to USDA and FDA regulations, including meat labeling, slaughtering standards, and safe handling practices.

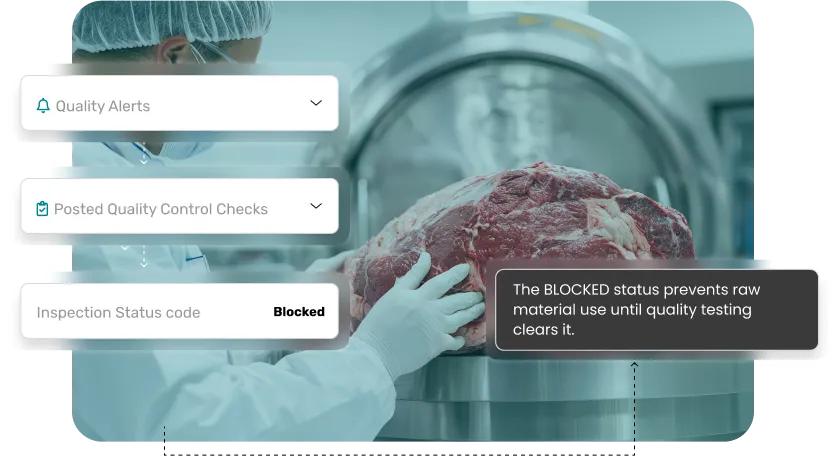

Monitor critical control points, such as temperature, microbial contamination, and packaging integrity, to maintain product quality throughout every batch.

Keep your plant audit-ready every day with real-time meat traceability software that unites safety, efficiency, and accountability. From animal origin to final packaging, gain complete visibility and control across every stage of production.

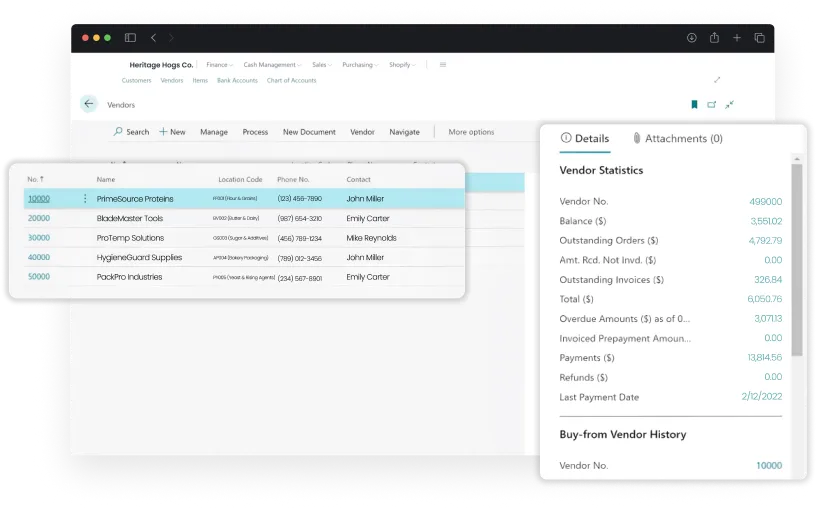

Evaluate and monitor livestock, feed, and material suppliers to secure reliable inputs and maintain seamless operations.

Quickly trace and isolate defective or contaminated batches with entire lot and batch visibility for fast and effective recalls.

No matter if you're processing beef, poultry, or any other species, our ERP solution is built to meet the unique needs of each production process.

Replace the chaos of switching between apps for recording yields, lot traceability, and equipment maintenance by integrating everything into a meat ERP software.

Get your meat processing plant up and running smoothly with our ERP system, designed for quick implementation and rapid operational improvements.

We begin by analyzing your meat processing plant's challenges, such as yield management, traceability, and food safety compliance, to design an ERP solution that meets your unique needs.

We create a detailed project plan for your meat production processes, addressing potential risks like meat spoilage, regulatory compliance, and operational downtime.

We design ERP features to manage meat-specific processes, such as batch tracking, cutting schedules, and packaging, ensuring the solution aligns with your plant’s goals.

We thoroughly test ERP modules to ensure they handle essential tasks like temperature control, meat traceability, and quality consistency across all production runs.

We integrate the ERP system with your existing tools for inventory tracking, slaughter management, and quality assurance to streamline meat processing operations.

We securely transfer vital meat processing data, including slaughter data, production schedules, and compliance records, to ensure smooth ERP functionality.

We deploy the ERP system in your meat processing environment and optimize it for real-time slaughter, cutting, packaging, and regulatory compliance monitoring.

We offer comprehensive training and ongoing support to help your team fully utilize ERP features like yield tracking, inventory management, and compliance reporting.

Keep milk, cheese, and yogurt fresh with better inventory control, compliance tracking, and production planning.

Perfect every batch with smart recipe management, real-time tracking, and seamless regulatory compliance.

Never break the cold chain—optimize storage, logistics, and expiration tracking for frozen products.

Balance art and precision with automated recipe scaling, ingredient traceability, and shelf-life monitoring

Manage sugar processing, allergen control, and batch consistency for chocolates, candies, and sweets.

Handle large-scale snack production with real-time inventory, ingredient sourcing, and quality control.

Track every cut from slaughterhouse to store while ensuring food safety and compliance.

Control formulations, batch consistency, and allergens while optimizing production efficiency.

Watch how ADM Agriculture improved its processes and achieved grow using NetSuite SuiteSuccess.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

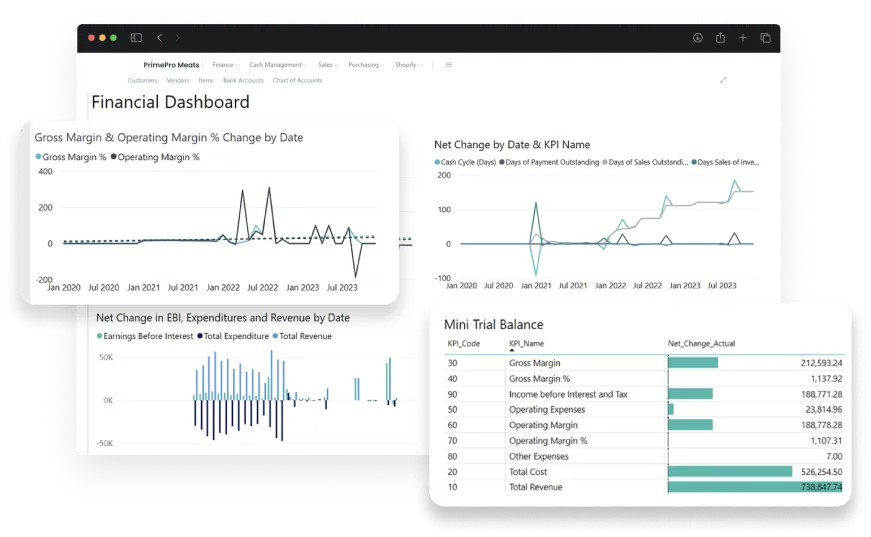

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

Meat ERP software is an industry focused ERP used by meat, poultry, and seafood businesses to manage purchasing, processing, inventory, quality, traceability, costing, and order fulfillment in one connected workflow.

Meat operations rely on variable weights, grades and cuts, yield and shrink control, cold chain inventory, and tight lot traceability across multiple processing steps. Meat ERP is built to handle those protein specific realities without forcing teams into spreadsheets and manual workarounds.

Catch weight is the actual weight of each item, case, or batch that varies from unit to unit. Meat ERP uses catch weight to keep inventory, costing, pricing, and invoicing accurate based on real weights captured during processing, packing, and shipping.

Meat ERP supports product structures that reflect how proteins are produced and sold, such as carcass or lot to primals, subprimals, portions, and packaged SKUs. This helps teams manage cut specs, pricing by cut, and visibility into where each pound goes.

Carcass to case traceability means linking incoming animals or lots to each processing step and then to finished cases and shipments. Meat ERP supports this by connecting IDs, lots, weights, and movements so teams can trace backward and forward quickly during investigations, customer questions, or recalls.

It ties inputs, outputs, trim, rework, and losses to each run and cut activity, then compares actuals to targets. This makes it easier to spot where yield is slipping, where shrink is happening, and which products or lines are driving margin loss.

Yes. Meat ERP can track case breaks, repacks, relabeling, and rework while keeping lot traceability and weight accuracy intact, so inventory and shipment records still match what actually moved.

It helps by keeping batch and lot records, quality checks, holds and releases, nonconformance logs, corrective actions, and audit history tied to the same production and shipment records, so evidence is easier to retrieve when auditors or customers request it.

Yes. Meat ERP is commonly integrated with scales and scanners to capture weights and movements in real time and reduce manual entry. Integrations also help keep receiving, production, packing, and shipping aligned to the same record.

Folio3 FoodTech Meat ERP software is positioned to support core meat processing needs like catch weight control, traceability, and compliance ready operations. In a demo, validate how it handles variable weight capture, lot tracing in both directions, yield and shrink reporting, holds and releases, and integrations with your scales and scanning setup.