For food manufacturers and distributors, keeping the right products in the right place at the right time is an everyday balancing act. You need to meet demand for a wide range of finished goods—often perishable—while controlling logistics and storage costs.

Global statistics show why good distribution planning matters. According to the Food and Agriculture Organization (FAO), 13.2 % of food is lost between harvest and retail, and 19 % is wasted at retail and household levels. For operations managers, every shipment or pallet that arrives late or spoils in transit reduces service levels, ties up capital, and damages customer relationships.

Distribution Requirement Planning (DRP) is designed to help you navigate these challenges and its a crucial part of the food supplychain. In this blog, we will break down the concept of DRP, discuss how it works in food manufacturing and distribution, explore its benefits, and guide you through the steps of implementing DRP in your business. So, let’s jump ont the core Distribution Requirement Planning defintion and then proceed with the further aspects.

What Is Distribution Requirements Planning?

What is DRP? Distribution Requirements Planning (DRP) is a systematic process for determining which goods, in what quantities, and at which location are required to meet anticipated demand. It starts by using a demand forecast for finished products and then calculates replenishment schedules for each DC and downstream location. DRP aims to maximise product availability while minimising ordering, transportation, and holding costs. Unlike ad‑hoc reorder or (R, Q) policies, DRP uses a time‑phased schedule that coordinates ordering across all echelons of the distribution network, similar to the way MRP plans sub‑assemblies in manufacturing.

DRP is sometimes called Distribution Resource Planning because it extends beyond inventory to consider capacity, lead times, transport modes, and cost constraints. It is essentially the implosion of MRP: instead of exploding a bill of materials into component requirements, DRP works backward from demand to determine when finished goods should be replenished from upstream DCs or manufacturing plants. Inputs to a DRP system include sales forecasts, current on‑hand inventory, safety stock policies, lead times, and lot sizes. The output is a time‑phased replenishment plan for each location, indicating when and how much to order or move to meet forecasted demand.

DRP Goals and Objectives

What is the goal of DRP? The primary goal of DRP is straightforward: ensure the right quantity of goods is available at the right location and time to meet forecasted demand while controlling costs. To achieve this, DRP systems seek to synchronise supply and demand across multiple echelons of the distribution network so that you avoid both stockouts and excessive inventory. Additional objectives include:

- Maintain Customer Service Levels: DRP ensures that products are consistently available, meeting customer demand and maintaining high satisfaction levels.

- Reduce Bullwhip Effect: By improving demand forecasting and inventory visibility, DRP reduces demand fluctuations as orders move up the supply chain.

- Enhance Collaboration: DRP fosters better communication and coordination among supply chain stakeholders, including suppliers, warehouses, and distributors, ensuring that everyone is on the same page.

Core Elements & Techniques of DRP

Effective DRP relies on a few essential elements. Each component must be properly defined and maintained to create an accurate replenishment plan.

Forecast Demand

The demand forecast is the starting point for DRP. Forecasts may be generated using historical sales data, market intelligence, or advanced techniques such as machine learning. They represent projected demand over future periods, often broken into weekly buckets. Because inaccurate forecasts can cause either inventory surplus or stockouts, companies frequently combine statistical models with input from sales and marketing.

Current Inventory

Knowing how much product you have at each location is crucial. DRP systems track on‑hand inventory, in‑transit shipments, and open orders for every DC. Inventory records must be accurate and timely; otherwise, replenishment calculations will be incorrect. The case study on DRP automation at Juhayna Foods showed that after automating DRP within an ERP system, accuracy improved to 80–85 % and the planning process was reduced from three hours to thirty minutes, highlighting the impact of reliable data.

Target Safety Stock

Safety stock protects against forecast errors and lead‑time variability. DRP calculates safety stock for each item and location, often based on service level targets and demand variability. In food supply chains, safety stock must also consider shelf life. Carrying excess perishable inventory can lead to waste and higher carrying costs, which industry sources estimate to be 25–55 % of inventory value.

Recommended Order Quantities

DRP uses the forecast, on‑hand inventory, and safety stock to compute recommended order quantities. It calculates when to place replenishment orders and in what lot sizes, often based on economic order quantities (EOQ) that minimise the sum of ordering and holding costs. For multi‑echelon networks, DRP also considers truckload optimization and capacity constraints.

Replenishment Lead Times

Lead times include the time to process the order, manufacture or pick product, ship it from the upstream DC or plant, and receive it at the destination. DRP plans orders far enough in advance to account for these lead times so that goods arrive just in time to meet demand. In cold‑chain logistics, lead times may also include time for pre‑cooling, quality checks, and documentation for regulatory compliance.

Push vs Pull Techniques

Traditional DRP uses a push method, where replenishment orders are generated based on forecasted demand and pushed through the network. This approach works well when forecasts are reliable and inventory policies are consistent.

Alternatively, pull methods such as Just‑in‑Time (JIT) or demand‑driven DRP (DDDRP) trigger replenishment based on actual consumption signals. DDDRP combines the benefits of push and pull by placing strategically sized buffers and pulling product between them.

Simulation studies comparing DRP and DDDRP showed that demand‑driven systems can reduce working capital and improve on‑time shipping rates across varying demand scenarios. Choosing between push and pull depends on your product characteristics, demand variability, and supply‑chain agility.

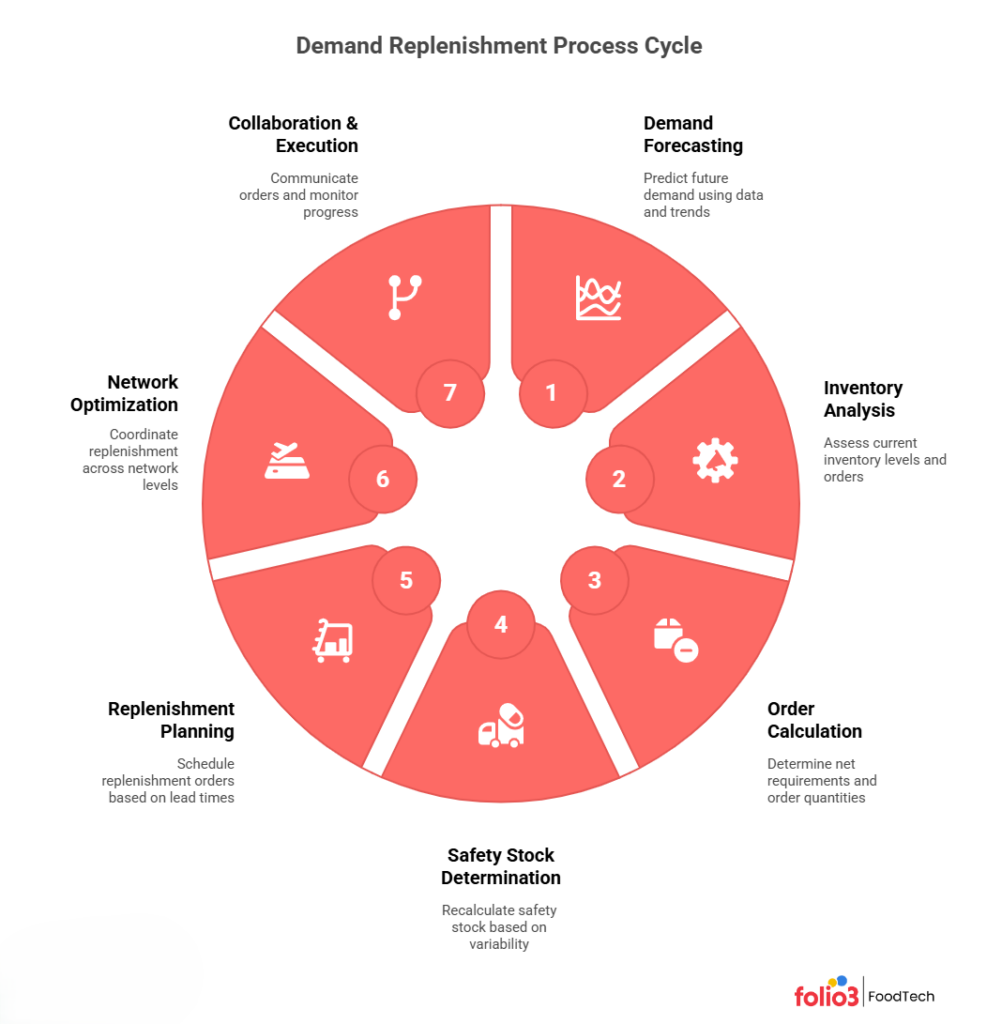

How DRP Works: Step‑by‑Step Process

DRP translates demand forecasts into a detailed replenishment schedule through a series of steps. Understanding this workflow helps you implement or troubleshoot a DRP system.

1. Demand Forecasting

Begin by creating a time‑phased forecast for each finished product at each distribution location. Many food companies still rely on Excel spreadsheets, but advanced planning systems leverage statistical models, machine learning, and collaborative forecasting. A good forecast incorporates seasonality (e.g., holiday demand for confectionery), promotions, and market trends. For perishable goods, you may also apply dynamic shelf‑life models or IoT sensor data to adjust predictions.

2. Inventory Analysis

Next, update your system with current inventory balances and outstanding orders at each location. Include on‑hand stock, safety stock, goods in transit, and planned receipts. Accurate data is vital; in the Juhayna Foods case, automation improved data accuracy and eliminated manual errors. Without reliable numbers, the system will either recommend too much product (increasing carrying costs) or too little (risking stockouts).

3. Order Quantities Calculation

The system then calculates the net requirements for each period: forecast demand plus safety stock minus available inventory. It generates recommended order quantities and due dates, considering lot size rules (e.g., full truckloads), minimum order quantities, and packaging constraints. For multi‑product trucks, DRP may consolidate orders across items to optimise transportation.

4. Safety Stock Determination

Safety stock is recalculated periodically based on updated demand variability and desired service levels. In cold chains, safety stock must consider shelf‑life degradation; carrying too much inventory may lead to spoilage. Emerging technologies like sensor‑enabled dynamic shelf‑life systems can extend shelf life by 7.3–16.4 % across perishable categories, reducing the need for excessive safety stock.

5. Replenishment Planning

Based on the net requirements and lead times, DRP schedules replenishment orders. This step determines when orders should be released and arrive at each location. For example, if the lead time from your plant to a regional DC is five days, and inventory falls below safety stock in week 4, the DRP may recommend placing an order in week 3 so that it arrives by the start of week 4. Many DRP systems also perform capacity checks to ensure that production and transportation resources are available.

6. Distribution Network Optimization

In a multi‑echelon network, DRP coordinates replenishment across several levels: factories, central warehouses, regional DCs, and local depots. Optimizing this network might involve transhipment decisions, cross‑docking, and aligning truckloads with route planning. DRP may also feed into transportation management systems (TMS) to generate optimal routing and vehicle utilisation. When integrated with advanced planning and scheduling (APS) systems, DRP can simulate different scenarios to evaluate cost and service impacts.

7. Collaboration & Execution

Finally, the recommended orders must be communicated to procurement, production, warehouses, and logistics teams. Modern DRP tools integrate with enterprise resource planning (ERP) systems, automatically releasing purchase orders or transfer orders. Execution teams must monitor progress, adjust orders if demand deviates from forecasts,and handle exceptions such as rush orders or transportation delays.

Benefits of DRP

Implementing DRP can produce significant operational and financial benefits:

- Lower inventory carrying costs. Since carrying costs account for 25–55 % of inventory value, reducing excess stock can free up substantial capital. By accurately planning replenishment, DRP helps you minimize safety stock without sacrificing service.

- Reduced ordering and shipping expenses. By avoiding stockouts and planning replenishment in economic order quantities, DRP cuts ordering, shipping, and inventory costs. Consolidated shipments also lower transportation expenses.

- Improved service levels and fill rates. Time‑phased scheduling ensures that products arrive when needed, increasing the proportion of orders filled on time. Simulation studies comparing DRP and DDDRP indicate that demand‑driven strategies can improve on‑time shipping rates to nearly 100 % under specific scenarios.

- Greater data accuracy and visibility. Automating DRP within an ERP system improves forecast accuracy and reduces manual errors. In the Juhayna Foods case, automation improved DRP accuracy to 80–85 % and reduced planning time from three hours to 30 minutes.

- Reduced bullwhip effect. Coordinated planning across echelons dampens demand variability and prevents upstream order amplification. With shared data and time‑phased ordering, upstream suppliers see smoother demand patterns, leading to lower variability in production and inventory.

- Support for strategic decision‑making. DRP provides visibility into future inventory positions and replenishment needs, enabling you to plan promotions, capacity expansions, or shifts in sourcing. It also helps evaluate “what‑if” scenarios such as demand surges or supply disruptions.

Challenges & Limitations

Despite its benefits, DRP is not a silver bullet. Several challenges can hinder successful implementation:

- Forecast accuracy: DRP relies on accurate demand forecasts; errors can propagate across the network. Seasonal demand, promotions and market volatility make forecasting difficult in the food industry, where consumers may shift quickly.

- Data quality and integration: Inaccurate inventory records or disconnected systems can lead to faulty replenishment plans. Many businesses still rely on spreadsheets, causing errors and inefficiencies.

- Complex multi‑echelon networks: Managing multiple DCs, cross‑docks, and transportation routes increases complexity. DRP models must consider various lead times, transport modes, shelf‑life constraints, and regulatory requirements (e.g., temperature monitoring) across echelons.

- Technology and cost barriers: Implementing DRP software and integrating it with ERP, TMS, and warehouse management systems requires investment in technology, training, and change management. Smaller firms may struggle with the resources necessary.

- Dynamic demand and perishability: For perishable goods, DRP must respond quickly to demand shifts and shelf‑life decay; static safety stock policies may lead to waste. Adoption of dynamic shelf‑life models and real‑time monitoring can mitigate this limitation.

Role of DRP in the Supply Chain for Food Industry

Food supply chains pose unique challenges for distribution planning. Finished goods often have short shelf lives, require temperature‑controlled storage, and must meet stringent safety standards. DRP is crucial for addressing these challenges.

Perishable goods and cold chain logistics

Perishable foods such as meat, dairy, and produce have high economic value but limited shelf life. The U.S. Department of Agriculture states that perishable foods are costly to transport because of their short shelf life and special handling requirements. Cold chain networks rely on refrigerated trucks and facilities, and any temperature excursion can lead to spoilage. DRP helps plan replenishment so that products move quickly through the network, reducing dwell time.

Seasonality and Demand Fluctuations

Food demand is often seasonal, think of holiday turkeys, summer beverages, or Ramadan dates. DRP integrates seasonality into forecasts so that you stock the right amount in each period. Proper planning prevents overstocking during slow seasons and understocking during peaks.

Compliance and Traceability

Food safety regulations require accurate records of product origin, handling conditions and distribution routes. DRP systems integrated with food‑specific distribution ERP modules can track batch numbers, expiration dates, and recall information. Emerging technologies such as blockchain provide unprecedented traceability. In a well‑publicized case, Walmart used a Hyperledger Fabric blockchain to trace the origin of mangoes in a test and reduced the time to trace a specific mango from seven days to 2.2 seconds. Such rapid traceability supports faster recalls and builds consumer trust.

Temperature‑controlled Distribution and IoT sensors

IoT and sensing technologies are transforming food distribution. Sensors that monitor temperature, humidity, and ethylene levels provide real‑time visibility into product conditions, enabling proactive interventions. These technologies allow DRP models to adjust replenishment schedules based not only on forecasted demand but also on real‑time product quality, reducing waste and greenhouse‑gas emissions.

Integration with Food ERP Systems

Food‑focused ERP systems incorporate modules for recipe management, lot tracking, allergen management, and food compliance. When these systems include a DRP engine, they help manage both production and distribution. This integration allows the company to keep factories’ warehouses less congested, newly produced goods gets shipped directly to distribution centres, and warehouses.

Best Practices for Food Supply‑Chain DRP

- Use dynamic demand forecasting that combines statistical models with market insights and accounts for seasonality and promotions.

- Maintain accurate inventory records with real‑time updates from warehouses and in‑transit shipments. It includes tracking lot numbers and expiration dates.

- Set safety stock based on shelf life and service levels, and adjust it when product conditions change. Consider using sensor‑enabled dynamic shelf‑life models to better estimate usable life.

- Integrate cold‑chain data temperatures, humidity, shock sensors into your DRP system to prioritise shipments and avoid spoilage.

- Strengthen collaboration between sales, production, procurement, and logistics teams, sharing a single DRP plan.

- Use technology for traceability, such as blockchain or advanced ERP modules, to meet food safety and recall requirements.

DRP Implementation Roadmap & Checklist

Implementing DRP is a multi‑step journey. The following roadmap provides a structured approach for food manufacturers and logistics providers:

- Data Preparation: Gather accurate data on demand, on‑hand inventory, lead times, production capacities, and transportation constraints. Data quality is critical, and with automation you can improve DRP accuracy. For food products, include shelf‑life data and regulatory requirements.

- Evaluate Processes and Resources: Map your current distribution network, including plants, DCs, retailers, and transport routes. Identify capacity constraints, cold‑chain requirements, and collaboration points between departments. Evaluate how demand flows through your network and where the bottlenecks are.

- Choose a DRP/APS System: Select software that aligns with your business needs. Look for features such as multi‑echelon planning, integration with ERP and warehouse management, support for AI/ML forecasting, and the ability to use sensor data. For food operations, ensure the system supports lot tracking, shelf‑life monitoring, and compliance.

- Pilot and Training: Start with a pilot project, perhaps one product line or regional DC, to validate assumptions and refine parameters. Train cross‑functional teams on using the system and interpreting DRP outputs.

- Monitor & Adjust: Once live, continuously monitor key performance indicators (KPIs) such as fill rate, inventory turnover, order cycle time, spoilage rate, and carrying costs. Compare actual versus planned performance and adjust forecasts, safety stocks, and lead‑time assumptions. Use scenario planning to prepare for disruptions or demand surges.

DRP Future Trends

Distribution Requirements Planning is evolving in step with broader technological advances. Several trends will shape its future in the food industry:

- AI/ML Forecasting: Artificial intelligence and machine learning models can analyze large datasets (point‑of‑sale data, weather patterns, social media) to produce more accurate, granular forecasts. These models learn and adapt over time, helping to reduce the bullwhip effect and improve service levels.

- IoT Data Collection: IoT devices in trucks, warehouses, and retail shelves provide real‑time temperature, humidity, and location data. When integrated with DRP, this information enables dynamic adjustments to replenishment plans. Sensor‑enabled dynamic shelf‑life systems have already been shown to extend shelf life and reduce millions of tonnes of waste.

- Cloud‑Based Platforms: Cloud‑native DRP and APS solutions provide scalability and easier integration with other systems. They allow your teams to access planning information from anywhere and facilitate collaboration with suppliers and logistics providers.

- Blockchain for Traceability: Blockchain technology records immutable data on product origin, handling, and movement. It helps to reduce traceability time, demonstrating how distributed ledgers can improve safety and recall processes.

- Integration with Advanced ERP Systems: Modern ERP systems embed DRP, enabling what‑if simulations and collaborative planning. As more food companies adopt these systems, DRP will become a core part of enterprise operations.

In conclusion, Distribution Requirements Planning offers a structured way to synchronize demand and supply across the food supply chain. By translating forecasts into time‑phased replenishment schedules, DRP helps you maintain service levels, minimize costs, and reduce waste. By following the implementation roadmap and leveraging these innovations, you can ensure your products are at the right place. Further, you can consult with our Footech experts for the deployment of DRP integrating with an ERP.

FAQs

What is DRP in Supply Chain Management?

DRP (Distribution Requirements Planning) is a method used to determine the right quantities of products to move across a supply chain network. It ensures that inventory is available at the right place, time, and cost to meet forecasted customer demand.

How Does Distribution Requirement Planning Differ From MRP?

MRP (Material Requirements Planning) focuses on production, ensuring raw materials are available for manufacturing. DRP extends this logic to distribution, making sure finished goods are efficiently replenished and delivered across warehouses, retailers, and customers.

Why is DRP Critical for the Food Industry?

In the food industry, DRP helps manage perishability, reduce waste, and align supply with fluctuating demand. It ensures timely replenishment, compliance with safety standards, and supports traceability in case of recalls.

What Are the Biggest Challenges of Implementing DRP?

Challenges include inaccurate demand forecasts, poor data integration, high implementation costs, and complexity in coordinating across large, multi-tiered distribution networks.

How Can ERP Software Support Effective DRP?

ERP systems integrate data from sales, inventory, procurement, and logistics, enabling real-time visibility. This improves demand forecasting, automates replenishment, and optimizes distribution planning for higher efficiency and accuracy.