Food safety isn’t just another box to tick; it is fundamental to protecting consumers and sustaining your business. If you manufacture or handle food, food safety standards are no longer just paperwork; they’re your safety net and your growth engine.

Rising global foodborne illness events and sharper consumer expectations are pushing regulators to tighten the screws. In the United States alone, unsafe food sickens about 48 million people, hospitalizes 128,000, and causes 3,000 deaths annually. Moreover, recent moves like U.S. actions to ban brominated vegetable oil, restrict Red Dye No. 3 in foods, and enforce new FDA traceability rules, setting the tone for a stricter 2025.

To stay ahead, you need a practical view of food safety regulations and standards and how they connect to food quality standards across markets. This guide gives you the playbook that covers the key global frameworks, what they mean, how they map to national rules, and the steps to implement them

Why Food Safety Standards Matter

Food safety standards protect your customers and your reputation by preventing contamination and ensuring consistent product quality. They build trust, reduce waste, and safeguard your business from costly recalls.

Protecting Public Health and Your Brand

Unsafe food is a public health crisis, but it also threatens businesses. Foodborne illness outbreaks cost the U.S. economy about $75 billion a year and can permanently damage consumer trust. Understanding how food safety investments drive profitability helps CFOs and executives justify compliance spending while protecting bottom-line performance. When you implement rigorous safety standards, you’re not just complying with the law; you’re protecting your customers and your reputation.

Reducing Illness and Waste

Food safety standards reduce the incidence of foodborne illnesses by preventing contamination and ensuring safe processing. Globally, the WHO estimates that unsafe food leads to 600 million illnesses and 420,000 deaths annually, with children under five suffering 30 % of deaths. Following standardized hygiene practices reduces waste by preventing spoilage and expensive recalls.

Regulatory Compliance and Market Access

Complying with standards is mandatory to operate legally and maintain market access. Knowing what food safety compliance truly entails, from documentation requirements to third-party audits, helps you build systems that withstand regulatory scrutiny.

The U.S. Food Safety Modernization Act (FSMA) requires preventive controls and recordkeeping, and similar regulations exist worldwide. Therefore, certification under globally recognized schemes such as ISO 22000 demonstrates that your facility meets international benchmarks, which is increasingly important when exporting products.

Core Food Safety Standards and Regulations

What are the food safety standards? Food safety standards are specific requirements that govern the production, handling, and distribution of food. These requirements may dictate acceptable levels of additives, microbial limits, hygiene practices, and labeling. Regulations, on the other hand, are laws enacted by governments to enforce compliance; non‑compliance can lead to legal penalties.

Key U.S. Regulations

The Food Safety Modernization Act (FSMA) is the centerpiece of U.S. food safety law. It shifts the focus from responding to contamination to preventing it. The FSMA Final Rule on Traceability (Section 204) requires food businesses to maintain additional record‑keeping for foods on the Food Traceability List. The rule will speed up identification and removal of contaminated products, and the Food and Drug Administration (FDA) has proposed extending the compliance deadline to July 20, 2028.

The Food Allergy Safety, Treatment, Education, and Research (FASTER) Act added sesame as the ninth major allergen in the U.S. on January 1, 2023. Major allergens like milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat, soybeans, and sesame must now be clearly identified on labels.

International Standards

Globally, countries align with the Codex Alimentarius, developed by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO) to harmonize food safety and trade. The Codex sets benchmark standards for additives, contaminants, and hygiene practices. Many nations also adopt the Hazard Analysis and Critical Control Point (HACCP) system, which focuses on identifying and controlling hazards throughout the supply chain.

For a deeper understanding of how safety and quality systems work together, explore our comprehensive food safety and quality assurance guide.

Global Food Safety Frameworks & Key Organizations

Get oriented with the frameworks and organizations that shape how the world defines food safety standards. You’ll see how these bodies align science, risk assessment, and trade so your compliance travels smoothly across borders.

International Frameworks

Understand how the following frameworks translate into practical controls, audits, and food quality standards. You can use them as your blueprint to harmonize supplier programs and certifications across multi-country operations.

Codex Alimentarius Commission (Codex)

Codex sets international food standards, guidelines, and codes of practice covering additives, contaminants, residues, hygiene, and labeling. Countries use Codex standards to align national regulations and facilitate trade.

World Health Organization (WHO) & Food and Agriculture Organization (FAO)

Provide scientific advice, coordinate global surveillance, and support capacity building in food safety. Their joint work has shaped the Codex, and the WHO’s global estimates of foodborne disease highlight the scale of the issue.

Global Food Safety Initiative (GFSI)

An industry‑driven collaboration that benchmarks food safety certification schemes against a set of requirements. Certifications recognized by GFSI (e.g., FSSC 22000, BRCGS, SQF) help organizations demonstrate compliance with global standards.

National Authorities and Laws

Map global frameworks to local food safety regulations and standards like FDA/FSMA (U.S.), EFSA/FSA (EU/UK), CFIA (Canada), and FSANZ (Australia). You’ll know who regulates what, which rules apply to you, and how to streamline labeling, allergens, and traceability.

United States

Agencies include the FDA, U.S. Department of Agriculture (USDA), and Centers for Disease Control and Prevention (CDC). FSMA establishes preventive controls, and Section 204 of the FSMA Final Rule requires enhanced record‑keeping for traceability by 2026 (proposed to extend to 2028). The USDA’s Food Safety and Inspection Service (FSIS) has introduced a final determination declaring Salmonella levels ≥ 1 CFU/g in not‑ready‑to‑eat breaded stuffed chicken products to be an adulterant, effective May 1, 2025. It means producers must control Salmonella at extremely low levels or face product recalls.

European Union/United Kingdom

The Food Standards Agency (FSA) and European Food Safety Authority (EFSA) oversee food safety. The EU’s General Food Law sets the legal framework, and the UK’s Food Safety Act requires hazard controls and labeling. The EU identifies 14 allergens that must be declared, including celery, cereals containing gluten, crustaceans, eggs, fish, lupin, milk, mollusks, mustard, nuts, peanuts, sesame, soy, and sulfites.

Canada

Health Canada and the Canadian Food Inspection Agency (CFIA) identify priority allergens such as eggs, milk, mustard, peanuts, crustaceans/mollusks, fish, sesame, soy, sulfites, tree nuts, and wheat. These allergens must be clearly labeled on pre‑packaged foods. The Safe Food for Canadians Act consolidates regulations around preventive controls, traceability, and import/export requirements.

Australia and New Zealand

Food Standards Australia New Zealand (FSANZ) administers the Food Standards Code. The new Standard 3.2.2A requires that category‑1 (high‑risk) businesses implement three tools: a certified food safety supervisor, food handler training, and substantiation of critical controls. Category‑2 retailers must at least have a food safety supervisor and trained handlers. Record‑keeping or evidence demonstrating compliance is mandatory for high‑risk activities.

2025 Regulatory Updates and Emerging Trends

Track what’s changing BVO and Red Dye No. 3 actions, FSMA 204 traceability, and Salmonella controls so that you can stay audit-ready. Plus, leverage digital tools to turn new rules into proactive risk reduction and competitive advantage.

FDA Bans on Additives

In July 2024, the FDA revoked regulations allowing brominated vegetable oil (BVO) in food. The rule is effective August 2, 2024, and manufacturers must reformulate by August 2, 2025. In January 2025, the FDA announced that it will revoke the authorization for FD&C Red No. 3 in food and ingested drugs; manufacturers have until 2027–28 to reformulate.

Increasing Allergen Regulation

The FASTER Act’s recognition of sesame as the ninth major allergen brings the U.S. closer to the EU’s broader allergen list. Expect more harmonization as trade partners negotiate mutual recognition.

Traceability and Digitalization

FSMA’s traceability rule demands digital records for faster recalls. Globally, regulators are exploring blockchain and IoT sensors to improve supply chain transparency.

Comparing Food Safety Standards around the World

Food safety regulations vary widely, reflecting local risk perceptions and cultural preferences. Understanding these differences is essential when selling products internationally.

Top countries according to the Global Food Security Index

The Economist Impact’s Global Food Security Index (GFSI) 2022 ranked 113 countries on affordability, availability, quality, and safety. Finland, Ireland, and Norway topped the list with scores of 83.7, 81.7, and 80.5, respectively. High-income European countries dominated the top ten, while Japan (79.5) and Canada (79.1) completed the leaders. These countries benefit from strong regulatory frameworks, investment in agricultural research, and effective public health surveillance.

Comparison Table for National Approaches

| Region | Primary Laws/Agencies | Allergen labelling | Additive bans & GMO labeling |

| United States | FSMA is regulated by FDA and USDA | Nine major allergens must be labeled | BVO banned; Red No. 3 to be revoked by 2027–28; national GMO labeling law requires disclosure of bioengineered ingredients. |

| European Union/UK | EU General Food Law; Food Standards Agency | 14 allergens must be labeled | Prohibits chlorine‑washed poultry; GMO labeling mandatory; stricter pesticide residue limits. |

| Canada | Safe Food for Canadians Act; Health Canada/CFIA | Priority allergens must be declared | Bioengineered food labeling is mandatory; allowed additives must meet strict safety assessments. |

| Australia & New Zealand | FSANZ Food Standards Code | Allergenic foods must be declared on labels | Requires food safety supervisors and training; GMO labeling is mandatory for genetically modified ingredients. |

Levels of Food Safety Standards

If you are curious about food safety standards come from what levels, then you must know that food safety standards operate at multiple levels. Therefore, understanding these levels helps you navigate overlapping rules and choose the right certifications for your products.

- Company level: Individual brands may set internal standards that exceed legal requirements. For example, retailers might impose stricter microbiological criteria or ban certain additives.

- National level: Laws like FSMA, the Safe Food for Canadians Act, and the Food Standards Code establish mandatory controls, labeling requirements, and enforcement mechanisms.

- Regional level: Groups of countries (e.g., the EU or ASEAN) harmonize rules to facilitate trade and protect consumers. Codex guidelines often serve as a foundation.

- International level: Global initiatives such as Codex, WHO’s International Health Regulations, and the GFSI foster global harmonization and benchmarking. Certification schemes (ISO 22000, FSSC 22000) are recognized worldwide.

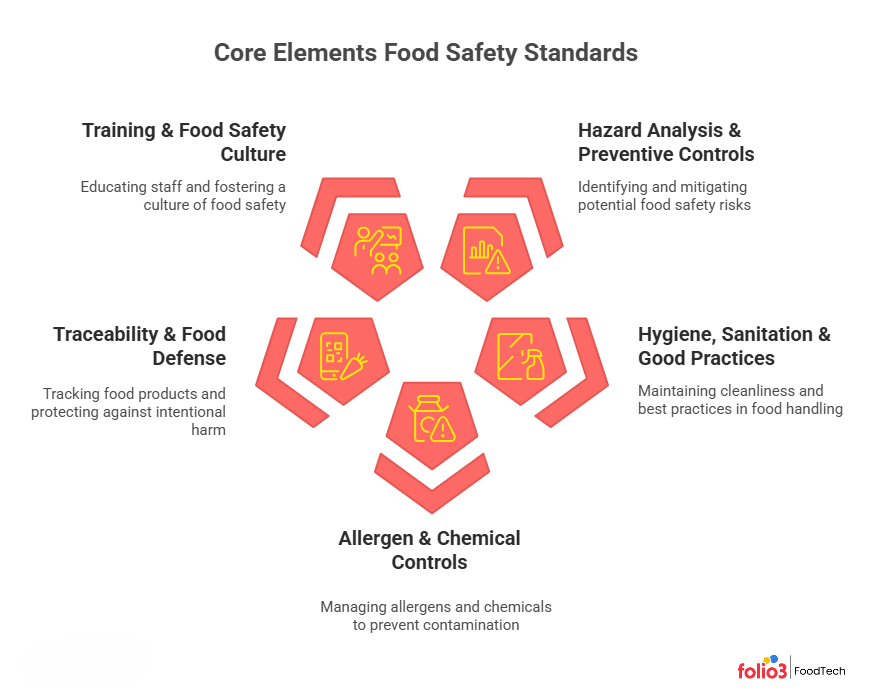

Core Elements of Effective Food Safety Standards

Strong food safety standards start with prevention, identifying risks early, maintaining hygiene, and ensuring food traceability. When every process, from sourcing to storage, follows documented best practices, you protect both your consumers and your brand’s integrity.

Hazard Analysis & Preventive Controls

An effective program starts with identifying hazards and putting controls in place to prevent them. The HACCP system requires you to analyze potential biological, chemical, and physical hazards. Further, you can establish critical control points, set critical limits, monitor performance, implement corrective actions, and keep records. Under FSMA, preventive controls expand on HACCP by requiring risk‑based approaches, supplier verification, and recall plans.

Hygiene, Sanitation & Good Practices

Poor hygiene is a significant source of contamination. Standard operating procedures should address:

- Personal hygiene: Encourage handwashing, correct glove use, and illness reporting. You need to clean, separate, cook, and chill to prevent cross‑contamination and ensure proper cooking temperatures.

- Facility sanitation: Regular cleaning and sanitizing of equipment, utensils, and surfaces prevents biofilm formation and chemical contamination. Avoiding common food sanitation and safety mistakes ensures your protocols actually protect consumers rather than creating false confidence.

- Temperature control: Maintain cold chain integrity for perishables and ensure proper cooking and hot‑holding temperatures. Failure to control temperature is a major contributor to outbreaks.

Allergen & Chemical Controls

Allergens are the leading cause of product recalls. Implement allergen risk assessments, dedicated storage, and clear labeling. In the U.S., the FASTER Act mandated labeling of nine major allergens, while Canada and the EU require broader lists. Cross‑contact must be controlled during production and cleaning.

Chemicals and additives require careful evaluation. The FDA has recently banned brominated vegetable oil and is revoking Red No. 3. Stay alert to changing regulations and ensure suppliers provide certificates of analysis.

Traceability & Food Defense

Traceability is critical for rapid recalls and consumer confidence. FSMA’s Section 204 requires detailed records for foods on the Food Traceability List. Businesses must document key data elements at critical tracking events. Globally, blockchain and digital traceability systems are being adopted to improve data integrity.

Moreover, food defense goes beyond accidental contamination to address intentional adulteration. Develop vulnerability assessments and mitigation strategies to protect against intentional contamination or sabotage.

Training & Food Safety Culture

A robust safety culture is built on training and leadership. FSANZ’s Standard 3.2.2A requires food handlers to complete training covering safe handling, contamination prevention, cleaning, and personal hygiene. A food safety supervisor with recent certification must oversee high‑risk operations.

In the U.S., industry best practice recommends refresher training annually or whenever processes change. Leadership must model safe behaviors and empower employees to report issues without fear.

Food Safety Standards and Certifications Recognized by GFSI

Global certification schemes benchmarked by the Global Food Safety Initiative provide a structured framework for compliance. Common standards include:

- ISO 22000: Integrates ISO 9001 quality management principles with HACCP, focusing on risk‑based thinking and continuous improvement.

- FSSC 22000 (Food Safety System Certification): Builds on ISO 22000 but adds sector‑specific prerequisite programs (PRPs) and is recognized by GFSI. Suitable for high‑risk manufacturing.

- BRCGS Global Standard for Food Safety: Developed by the British Retail Consortium, this standard emphasizes product safety, quality management, and senior management commitment.

- SQF (Safe Quality Food): A three‑level program covering primary production through distribution. Level 2 integrates HACCP principles, while Level 3 adds product quality management. For detailed guidance on implementing this certification, see our comprehensive SQF food safety guide for manufacturers.

- IFS (International Featured Standards): Focuses on food safety and quality for private label suppliers and is popular in Europe.

Challenges in Enforcing Food Safety Standards

What makes enforcing safety standards a challenge for the Food and Drug Administration? Even with clear food safety regulations and standards, enforcement can falter without coordination, resources, or technology. Recognizing these gaps helps businesses go beyond compliance by building resilient systems that work even when oversight falls short.

Fragmented Regulatory Landscape

In the U.S., more than 30 federal laws and 15 agencies play a role in food safety. This fragmentation leads to overlapping jurisdictions and inconsistent enforcement. For example, the FDA regulates most foods, while the USDA oversees meat, poultry, and egg products. Coordinating across multiple agencies slows decision‑making and makes compliance burdensome for businesses.

Underreporting and Surveillance Limitations

One of the biggest challenges in enforcing food safety standards is the lack of reliable, real-time data on outbreaks. Many foodborne illness cases go unreported because symptoms resemble common flu or stomach issues, creating major blind spots for regulators. Without accurate surveillance and consistent reporting, it becomes harder to identify problem sources, assess risks, and implement timely interventions across supply chains.

Resource Constraints and Varying Standards

State and local health departments often face resource limitations, leading to inconsistent inspection frequencies and enforcement. Globally, developing countries struggle with limited laboratory capacity and training. Additionally, countries differ in how they assess risk, like the EU, which bans certain additives that the U.S. has historically allowed. These variations make it challenging for multinational companies to develop uniform safety protocols.

Economic Pressures and Small Business Burdens

Compliance can be costly, especially for small and medium‑sized enterprises (SMEs). Installing traceability systems, obtaining certification, and meeting record‑keeping requirements need investment. Balancing safety with profitability remains a significant challenge. Beyond understanding enforcement gaps, manufacturers must implement proactive strategies to prevent food safety failures before they occur, building resilience into every process from receiving to shipping.

Emerging Trends & Innovations in Food Safety

The future of food safety is shaped by technology, sustainability, and evolving consumer expectations:

- Blockchain & digital traceability: Pilot programs around the world use blockchain to create transparent, immutable records. It could drastically reduce the time needed to trace contaminated products and minimize the recall scope.

- Artificial intelligence & predictive analytics: AI can analyze weather data, supplier histories, and lab results to predict contamination risks. Early warning systems could alert manufacturers to potential hazards before they reach the marketplace.

- Smart sensors & IoT: Wireless sensors provide continuous monitoring of temperature, humidity, and time, ensuring cold chain integrity and immediate alerts when conditions deviate.

- Sustainability & climate resilience: Food safety standards are beginning to incorporate environmental considerations such as reduced food waste, energy efficiency, and resilience to climate‑related disruptions. For instance, some certification schemes now evaluate sustainable sourcing and packaging.

- Regulation of novel foods and materials: As plant‑based meats, cultured cells, and edible insects gain popularity, regulators are developing new frameworks to assess safety. Packaging materials such as PFAS (perfluoroalkyl substances) are also under scrutiny.

- State‑level additive bans: In the U.S., states like California have begun banning additives ahead of federal action. So, expect more state or regional initiatives driving change.

Tips for Food Manufacturers & Processors to Comply with Food Safety Standards

Achieving compliance requires a combination of technical controls, documentation, and culture. By proactively implementing the following steps, you reduce risk, improve efficiency, and build trust with regulators and customers.

- Know your applicable standards: Identify all relevant laws and retailer requirements. If you export, consider the importer’s regulations, including allergen labeling and additive bans.

- Conduct a gap analysis: Compare current practices against legal requirements and certification schemes. Prioritize high‑risk areas, like raw meat handling and allergen management.

- Deploy a Robust Food Safety Management System: Build a food safety management system that fully complies with food safety and quality regulations, ensuring every process, record, and audit meets global compliance standards.

- Leverage technology: Your food safety system should use smart tools like IoT sensors, digital checklists, and automated alerts for real-time monitoring. Use blockchain for traceability and AI analytics to predict risks before they escalate.

- Train and empower staff: Provide role‑specific training on hygiene, allergens, cross‑contamination prevention, and emergency response. Ensure a food safety supervisor holds a recognized certification and is available during operations while encouraging employees to report hazards without fear of retaliation.

- Document and verify: Maintain comprehensive records of food safety audits, temperature logs, sanitation checklists, and product testing. Use digital tools or blockchain to improve accuracy and accessibility. Verify procedures through internal audits and corrective actions.

- Plan for recalls: Develop a recall plan and practice mock recalls to ensure you can quickly remove contaminated products. Clear communication with authorities, distributors, and consumers is essential.

Conclusion & Key Takeaways

Food safety is a dynamic field shaped by science, technology, and consumer expectations. In 2025, several trends are converging: stricter additive bans, enhanced traceability requirements, new Salmonella adulterant rules, and broader allergen labeling. To stay competitive, food manufacturers and processors must understand global differences, implement robust management systems, and cultivate a culture of safety.

Remember that food safety standards exist to protect consumers and safeguard your business. Investing in prevention pays off through fewer recalls, lower costs, and stronger brand loyalty. By staying informed about emerging regulations and innovations, you can not only comply with the law but also demonstrate leadership in providing safe, high‑quality food.

FAQs

Which Countries Have the Strictest Food Safety Standards?

According to the Global Food Security Index 2022, Finland, Ireland, and Norway ranked highest on quality and safety. Japan and Canada also appear in the top ten. These countries invest heavily in surveillance, research, and regulatory enforcement.

How Can Digital Tools Aid Compliance?

Digital tools like IoT sensors provide real‑time monitoring of temperature and humidity, reducing the risk of spoilage. Blockchain and cloud‑based traceability systems facilitate rapid identification of contaminated lots and improve record‑keeping. AI can analyze data to predict hazards and optimize sanitation schedules. These technologies simplify audits and help prove compliance with regulations.

What are the 5 C’s Of Food Safety?

The 5 C’s include Cleaning, Cooking, Chilling, Cross-Contamination Prevention, and Communication from the foundation of food safety. Proper cleaning stops bacteria, safe cooking ensures thorough heating, chilling preserves freshness, and good communication keeps every team member aligned on hygiene practices.

How Do Food Safety Standards Improve Food Quality?

By enforcing consistent hygiene, handling, and inspection protocols, food safety standards ensure products remain contaminant-free and meet consumer expectations. They help companies maintain uniform quality, extend shelf life, and earn customer trust.

How Can I Ensure My Food Safety System Meets Compliance Requirements?

Implement a strong Food Safety Management System (FSMS) that complies with ISO 22000, HACCP, or GFSI-recognized standards. Conduct routine audits, train staff, and continuously review procedures to stay compliant and improve performance over time.