If you manufacture or process food, shelf‑life testing isn’t a bureaucratic checkbox; it’s the key to ensuring your products remain safe and delicious until the moment they reach your customer. Roughly one‑third of all food produced for human consumption is lost or wasted globally, amounting to about 1.3 billion tonnes per year. Much of this loss results from food spoiling before it can be eaten, and some comes from consumers discarding edible food because of confusing date labels.

In the United States alone, inconsistent date labeling contributes to over four million tonnes of wasted food each year. These numbers underline why proper testing matters: you need to know how long your product will remain safe and palatable, and you need to label it clearly so your customers don’t throw it away too soon.

This guide demystifies food shelf‑life testing, covering what affects shelf life, the different methods used to measure it, and emerging innovations that can give you a competitive edge. Whether you’re launching a new snack or reformulating a classic sauce, mastering shelf‑life testing ensures your product meets regulations, maintains quality, and builds consumer trust.

Factors Affecting Food Shelf Life

Shelf life is the period during which a product maintains its safety and desired quality. It is influenced by a complex interplay of intrinsic and extrinsic factors:

Intrinsic factors

- Water activity (Aw) and moisture content: A product with water activity ≤ 0.85 is generally considered shelf‑stable. Low Aw inhibits microbial growth, which is why dried grains and biscuits last longer than fresh bread.

- pH: The acidity or alkalinity of a food determines which microorganisms can grow. High‑acid foods (e.g., pickles) are naturally less prone to spoilage than neutral or low‑acid foods.

- Nutrient composition: Proteins and fats are more susceptible to spoilage and rancidity than carbohydrates. For example, fat‑rich nuts can develop off-flavors over time.

- Natural enzymes: Enzymatic reactions continue after harvest or processing, causing color changes, textural breakdown, or flavor shifts.

Extrinsic factors

- Temperature and humidity: Elevated temperatures and humidity accelerate chemical and microbial reactions. Proper refrigeration slows these processes, extending shelf life.

- Light and oxygen exposure: Light can degrade vitamins and pigments, while oxygen promotes oxidation of fats.

- Packaging and storage conditions: Robust packaging protects against moisture ingress, oxygen, and contamination. Vacuum or modified‑atmosphere packaging can slow oxidation and microbial growth.

Key factors influencing shelf life

| Factor | Role | Example impact |

| Water activity (Aw) | Measures available water; low Aw inhibits microbial growth | Dried cereal (low Aw) has a long shelf life compared with fresh bread |

| pH (acidity) | Determines which microbes can grow | Acidic pickles resist spoilage better than neutral dairy products |

| Temperature & humidity | High temperatures and moisture accelerate deterioration | Warm storage shortens the shelf life of chocolate and oils |

| Light & oxygen exposure | Promote oxidation and nutrient loss | Clear bottles allow light in, causing oil to go rancid |

| Packaging & storage | Protects against contamination and environmental factors | Vacuum‑sealed meats stay fresher than loosely wrapped products |

| Processing & ingredients | Heat treatments and preservatives affect stability | Canned tomatoes (heat‑processed) outlast fresh tomatoes |

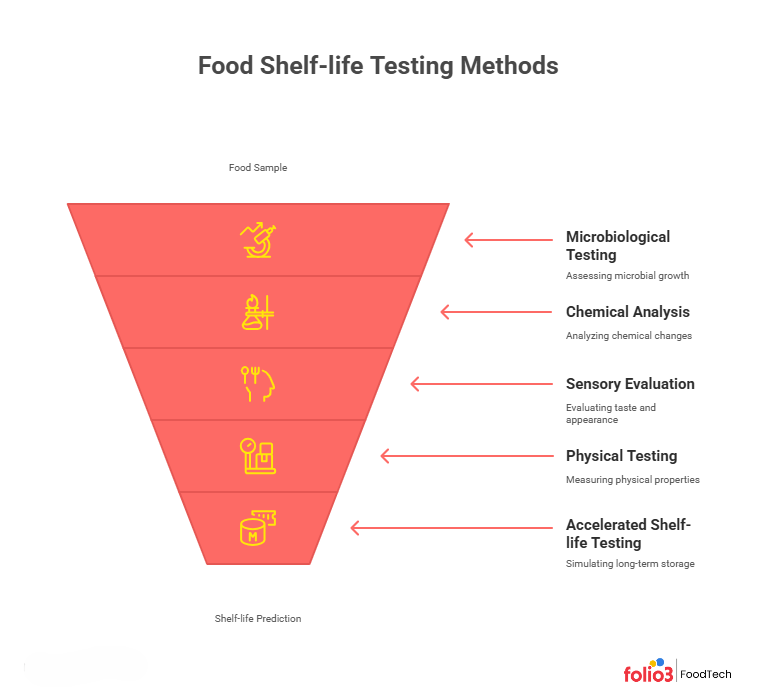

Methods of Food Shelf‑life Testing

No single test defines shelf life; a customized program combines analytical, microbiological, and sensory evaluations. Here are the primary methods:

Microbiological Testing

Microbiological tests detect spoilage organisms and pathogens. Techniques such as culture methods and polymerase chain reaction (PCR) quantify bacteria, yeast, and molds. For high‑risk products, challenge studies inoculate samples with specific pathogens (Salmonella, Listeria, Staphylococcus aureus) and monitor their growth over time. The goal is to determine when microbial counts or toxin levels exceed safe limits.

Chemical Analysis

Chemical tests monitor changes in pH, moisture, fat rancidity, and nutrient degradation. Methods like chromatography and spectrometry identify chemical reactions that affect taste, texture, and nutrition. Measuring peroxide values in oils, for instance, reveals the onset of oxidation.

Sensory Evaluation

Trained panels or consumers assess changes in taste, texture, and appearance. Sensory data complements laboratory measurements by capturing the point at which a product no longer meets consumer expectations. Descriptive analysis and hedonic scaling are common techniques.

Physical Testing

Physical tests evaluate packaging integrity and changes in texture or water activity. Texture analysis instruments measure hardness, chewiness, and brittleness, while water‑activity meters gauge moisture migration.

Accelerated Shelf‑life Testing (ASLT)

Accelerated testing acts like a “fast‑forward button.” Products are stored under controlled, harsher conditions, such as higher temperatures, increased humidity, or intense light, to hasten deterioration. Methods include high‑temperature vetting, humidity examination, and photosensitivity examination. ASLT condenses months or years of storage into weeks. Crucially, the final packaging must be used because it influences the results. Although ASLT speeds up data collection, it is not a one‑size‑fits‑all solution; conditions must be tailored to the product, and results should be confirmed with real‑time studies.

Testing methods and suitable products

| Method | Key purpose | Suitable products/examples |

| Microbiological | Identify the growth of bacteria, yeasts, and molds | Ready‑to‑eat meals, fresh juices, dairy |

| Chemical | Measure pH, moisture, and rancidity | Oils, nuts, baked goods |

| Sensory | Assess taste, texture, and appearance | Beverages, snacks, dairy |

| Physical | Test packaging integrity and texture | Packaged snacks, meat products |

| Accelerated (ASLT) | Rapidly estimate shelf life using high temperature/humidity | Confectionery, dry powders, cereals; must confirm with real‑time results |

Step‑by‑step Process for Conducting Shelf‑life Testing

A successful study follows a structured workflow. Here’s how to do it:

1. Sample selection & preparation

Choose representative batches that mirror your final product and package them exactly as consumers will receive them. Proper handling prevents contamination or premature spoilage.

2. Define protocols & storage conditions

Determine which parameters to test (microbial counts, pH, water activity, sensory attributes) and set storage conditions that mimic real‑world scenarios. Document everything, including temperature, humidity, light exposure, and time.

3. Periodic testing & data collection

At predetermined intervals, conduct microbiological, chemical, sensory, and physical assessments. Collect enough data points to identify trends; frequency depends on the expected shelf life (e.g., weekly for short‑life products, monthly for shelf‑stable foods).

4. Data analysis & interpretation

Use appropriate statistical methods to interpret changes over time and identify the point at which the product fails to meet safety or quality standards. Plotting trends helps visualize when spoilage accelerates.

5. Establish expiration dates & labeling

Assign expiration or “best before” dates based on your analysis. Include a “Best if Used By/Before” date to indicate peak quality and reduce waste; differentiate it from “Sell‑By,” “Use‑By” and “Freeze‑By” dates. According to USDA/FSIS guidance, “Best if Used By/Before” dates convey quality, not safety. Always validate ASLT results with real‑time data for accuracy.

Real‑time vs Accelerated Shelf‑life Testing

Real‑time testing

Real‑time, or traditional, shelf‑life testing stores products under normal conditions for their entire expected shelf life. It provides the most accurate representation of product behavior and is often required to validate accelerated results. The drawback is time: it can delay product launch by months, or even years, and tests only one set of storage conditions.

Accelerated shelf‑life testing (ASLT)

ASLT subjects products to harsher conditions, such as elevated temperature and humidity, to condense degradation time. This approach yields rapid insights and allows you to evaluate multiple storage scenarios. Accelerated testing is valuable when launching products quickly or when a product has a very long real‑time shelf life. However, ASLT is not suitable for every product; certain foods deteriorate in ways that elevated temperatures cannot replicate. Always use final packaging and confirm results with real‑time testing.

Choosing between methods

If your product will reach consumers within a few days (e.g., fresh salads), real‑time testing is essential. For long‑life products or when working under tight timelines, ASLT can provide early indications and help refine formulations. In many cases, a combined approach of initial accelerated testing followed by real‑time validation delivers both speed and accuracy.

Designing a Shelf‑life Study with Questions & Considerations

Before sending your product to a lab, be ready to answer key questions. Laboratories tailor each study, and the following considerations will shape the protocol:

- What is the product? Describe its composition and formulation.

- Water activity and pH: Have these been measured? Provide values.

- Storage conditions: Does it require refrigeration, is it frozen, or shelf‑stable?

- Packaging: Is the packaging single‑use or multi‑serve? Final packaging must be used in tests.

- Processing: Describe any heating process (time and temperature) and whether ingredients are commercially processed.

- Desired shelf life: How long do you want the product to last?

Based on these answers, the laboratory will design appropriate food‑safety tests (e.g., inoculation with pathogens for high‑risk foods) and quality tests (monitoring color, aroma, taste, and texture). Remember that no standardized method exists for all products; the study must reflect your product’s unique formulation and market conditions.

Regulatory & Labeling Guidelines

Understanding date labeling helps you communicate shelf life clearly and comply with regulations. The USDA/FSIS defines several terms:

- Best if Used By/Before: Indicates when a product has peak quality, not safety.

- Sell‑By: Tells retailers how long to display the product and is not a safety date.

- Use‑By: The last date recommended for peak quality; required only for infant formula.

- Freeze‑By: Indicates when to freeze for best quality.

The bipartisan Food Date Labeling Act of 2025 seeks to establish a uniform system distinguishing quality dates from safety dates. Until federal standards are in place, adopting clear “Best if Used By” labels helps reduce food waste and consumer confusion.

Innovations & Future Trends in Shelf Life Testing for Food

The technological advancements have shaped the shelf-life testing for the food industry with optimal efficiency, which makes it easier and more accurate. Below are the latest and promising trends:

Predictive Modeling & AI Integration: Artificial intelligence and machine learning are transforming food product shelf life analysis and testing by predicting spoilage patterns through real-time data. These models learn from temperature, humidity, and microbial activity data to forecast shelf-life with far greater accuracy than static tests.

Modified Atmosphere Packaging (MAP): By adjusting oxygen, carbon dioxide, and nitrogen levels inside the package, MAP slows down microbial growth and oxidation, extending shelf life naturally.

Real-Time Shelf-Life Monitoring: IoT-enabled sensors now allow continuous tracking of food quality from production to retail shelves. Businesses can identify degradation early, reducing recalls and ensuring compliance in shelf life testing for food products.

Smart Packaging & Intelligent Labels: Smart labels embedded with time-temperature indicators or freshness sensors show consumers and distributors actual product conditions, improving transparency and trust.

Supply-Chain Integration: Linking shelf-life data with Food ERP and inventory systems helps forecast demand, minimize waste, and optimize distribution routes to create a smarter, more sustainable food ecosystem.

Conclusion

Shelf‑life testing requires expertise in microbiology, chemistry, sensory science, and regulatory compliance. When selecting a laboratory, look for accreditation, experience with your product category, and clear communication. Discuss your goals, product specifics, and desired shelf life up front. A good lab will guide you through designing the study, interpreting results, and making data‑driven decisions.

By investing in rigorous shelf‑life testing, you protect your consumers, comply with regulations, and strengthen your brand. Clear labeling reduces waste and empowers your customers. Combining real‑time and accelerated methods, leveraging new technologies, and working with experienced partners ensures your products deliver quality and safety from production to the very last bite.

FAQs

What Is The Cost Of Shelf Life Testing?

Shelf life testing costs vary depending on the product type, study duration, and testing method. Basic, stable products may cost just a few hundred dollars, while complex studies with multiple samples or test points can reach several thousand. On average, expect to invest $500 – $12,000 based on whether you need real-time or accelerated testing and the number of parameters evaluated.

What Is The 10-Day Rule For Shelf Life?

The “10-day rule” applies to chilled, vacuum-packed, or modified-atmosphere packaged (VP/MAP) foods. It recommends limiting shelf life to no more than 10 days unless validated controls such as specific pH, salt, or temperature conditions are in place to prevent growth of Clostridium botulinum, a harmful bacterium that can cause foodborne illness.

How Long Will Food Last If Vacuum Sealed?

Vacuum sealing can dramatically extend food freshness by reducing oxygen exposure. Dry foods can last 1 – 2 years, while frozen meats may stay safe and flavorful for 2 – 3 years. The actual duration depends on the food category and storage environment whether refrigerated, frozen, or stored at room temperature.

How Often Should Manufacturers Conduct Shelf Life Testing?

Testing frequency depends on product type and storage stability. Short-shelf-life foods (like dairy or ready-to-eat meals) may need weekly or monthly testing, while long-lasting or bulk ingredients typically undergo annual verification. Manufacturers should always re-test after recipe, packaging, or process changes to ensure accuracy and compliance.