Food businesses operate in a landscape where safety, consistency, and compliance are essential for protecting consumers and maintaining brand trust. A food safety risk assessment is one of the most important tools used to identify where hazards may appear, how severe they could be, and what steps are needed to control them before they lead to contamination or product failure. As modern food production becomes more complex, risks grow alongside it.

Global sourcing, multi-ingredient products, rapid processing lines, and extended distribution networks all increase the possibility of unintentional contamination. This is why a structured and practical food safety risk assessment is necessary at every stage of the supply chain. Each year, about 600 million people, nearly one in ten worldwide, fall ill after eating contaminated food, which shows how essential proper food safety risk assessment is for both public health and industry credibility.

Food safety professionals such as FSQA managers, plant managers, and QA leads are increasingly tasked with managing complex risks across production, processing, and distribution. Producers, processors, and food handlers now face pressures from climate variability, evolving pathogens, allergen sensitivities, and stricter regulatory expectations. Without clear visibility into potential hazards, small issues can escalate into costly recalls, operational disruptions, or safety violations. A robust food safety risk assessment equips these professionals to identify weak points early, assign accountability, and strengthen control programs before problems occur, ensuring both compliance and operational resilience.

In this blog, you will learn how food safety risk assessment works in practice. We will cover hazard identification, exposure and risk evaluation, priority setting, and real-world control strategies. You will also see how monitoring, documentation, and digital tools support safer and more resilient food operations.

What Is Food Safety Risk Assessment?

Food safety risk assessment is a structured process used to evaluate the likelihood and severity of harm that a food hazard can cause. It provides a scientific foundation for food safety decisions and helps manufacturers, regulators, and auditors understand which hazards require immediate control and which pose a lower food safety risk. A hazard refers to anything that can cause harm, such as pathogens, allergens, or chemical residues. Risk refers to the probability that the hazard will cause harm under specific conditions. This distinction is essential because not every hazard results in significant risk unless there is exposure.

Risk assessors typically focus on the scientific evaluation side. They identify hazards, estimate exposure levels, and determine the level of risk to consumers. Risk managers use these findings to make operational decisions and apply measures for food safety control inside processing plants or supply chains. Regulatory bodies rely on independent risk assessors, while food businesses use internal experts to support their own FSMS decisions.

Various global frameworks support consistent food safety risk assessment in the food industry. ISO 22000 and broader Food Safety Management Systems outline how organizations should identify and manage hazards throughout production. HACCP remains the most widely adopted preventive system, guiding teams to evaluate process steps, identify critical control points, and verify the effectiveness of monitoring procedures. These frameworks help businesses strengthen food safety compliance and reduce the chance of biological hazards in food products moving undetected through the chain.

When applied correctly, food risk assessment becomes a decision making tool that aligns science, regulation, and operational practice, allowing teams to work proactively instead of reacting to incidents after they occur.

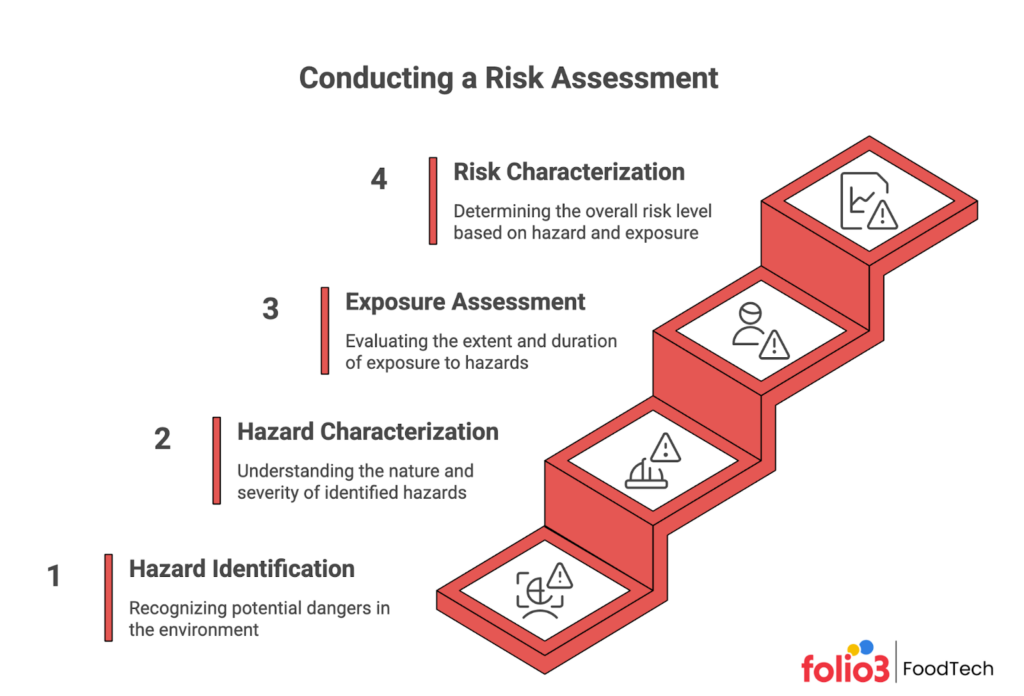

The Four Key Steps of Food Safety Risk Assessment

A food safety risk assessment follows a structured scientific process that allows organizations to evaluate food safety hazards with accuracy and consistency. These four steps help teams move from identifying potential hazards to estimating the real level of risk that consumers may face and support stronger food quality assurance across all operations.

1. Hazard Identification

Hazard identification is the first step in any food safety risk assessment because it defines what threats exist within a process or product. These hazards fall into four main groups: biological, chemical, physical, and allergen-related. Biological hazards include pathogens such as Salmonella, E. coli, and Listeria. Chemical hazards may involve pesticide residues, cleaning agent traces, or natural toxins. Physical hazards include metal fragments, glass pieces, or plastic particles. Allergen hazards occur when products contain undeclared allergens or experience cross-contact. Identifying hazards at every process step helps teams prepare for later stages of evaluation and supports effective food safety audit planning.

2. Hazard Characterization

Hazard characterization evaluates the nature and severity of the adverse effects linked to each hazard. This step considers infectious dose, toxicological limits, allergenic thresholds, and the potential impact on different segments of the population. For example, Listeria poses a greater threat to pregnant individuals and immunocompromised consumers. Chemical hazards may require reviewing acceptable daily intake or maximum residue limits. This step ensures that the organization understands how dangerous each hazard can be and aligns mitigation plans with recognized food safety standards.

3. Exposure Assessment

Exposure assessment examines how likely it is that consumers will encounter the hazard and at what level. This involves studying consumption patterns, contamination levels, processing steps, ingredient sources, and the influence of environmental conditions. Exposure may increase during long storage times, temperature abuse, or poorly controlled processing zones. This step provides insight into who is at risk, how often exposure might occur, and whether the contamination is significant enough to cause harm. Strong exposure data helps facilities prioritize controls and tighten preventive practices.

4. Risk Characterization

Risk characterization combines the findings from hazard identification, hazard characterization, and exposure assessment to determine the overall food safety risk assessment outcome. It provides a numerical or descriptive estimate of the likelihood and severity of harm under real-world conditions. The final outcome guides decision makers on which controls to implement, which processes require improvement, and how to maintain food quality assurance over time. This step also supports transparent communication with regulators and aligns the organization with global food safety standards. Naturally, we all want to avoid food that could potentially put our health at risk. This is especially important for those managing issues like menopause belly fat, where safe, nutritious food supports overall health

A complete and consistent assessment helps producers minimize food safety risk, maintain compliance, and deliver safe products that protect both consumers and brand integrity.

Practical Hazard Identification in Food Businesses

Hazard identification is a hands-on, practical step in managing food safety risk. It allows businesses to pinpoint threats in their operations and create effective controls to prevent contamination. Understanding common hazard types and where they can occur along the food chain is critical for a comprehensive food safety risk assessment.

Common Hazard Types

- Microbiological hazards: Pathogens such as Salmonella, E. coli, Listeria, and Norovirus that can contaminate raw ingredients or finished products.

- Chemical hazards: Pesticide residues, cleaning agents, allergens, heavy metals, or mycotoxins.

- Physical hazards: Foreign objects such as glass, metal fragments, plastic pieces, or wood splinters.

- Allergen hazards: Cross-contact of undeclared allergens during processing or packaging, including nuts, dairy, gluten, or soy.

Mapping Risk Across the Food Chain

- Receiving: Inspect incoming ingredients for contamination and proper storage.

- Storage: Monitor temperature, humidity, and segregation of allergens.

- Processing: Identify points where hazards could enter or proliferate, e.g., chopping, mixing, or cooking.

- Packaging: Check for contamination from materials, machinery, or human handling.

- Transport: Ensure safe handling, temperature control, and traceability during distribution.

Engaging Staff in Hazard Spotting

- Form cross-functional teams including production, quality, and maintenance staff.

- Train frontline workers to recognize potential contamination risks in their daily tasks.

- Encourage reporting of near-misses or unsafe practices to improve preventive measures.

Practical hazard identification ensures that food safety risk assessment is grounded in reality, enabling businesses to implement targeted controls, reduce risk exposure, and maintain high levels of food safety compliance. Regular reviews and updates keep the system effective as processes, ingredients, or regulations change.

Risk Evaluation and Prioritization

After identifying hazards, the next step in a food safety risk assessment is to evaluate and prioritize them. Not all risks pose the same level of threat, so businesses must focus resources where they will have the greatest impact on safety and compliance.

Using a Risk Matrix

A practical approach is to assess the likelihood and severity of each identified hazard:

- Likelihood: How often a hazard is expected to occur under current processes.

- Severity: The potential impact on consumer health or operational continuity if the hazard occurs.

Plotting hazards on a risk matrix allows teams to visualize which threats are most critical, guiding intervention efforts.

Prioritizing Hazards

- High-risk hazards require immediate and robust controls, such as critical AI in food safety monitoring systems to prevent contamination.

- Medium-risk hazards may be managed with regular checks, employee training, or updated procedures.

- Low-risk hazards can be monitored without heavy resource investment but should be documented to avoid oversight.

Creating Practical Control Plans

Effective control plans integrate food safety failures analysis and operational realities:

- Focus on measures that are realistic for daily operations.

- Include clear responsibilities, timelines, and verification steps.

- Combine preventive, monitoring, and corrective actions to maintain food safety consistently.

By systematically evaluating and prioritizing hazards, food businesses can make informed decisions, allocate resources efficiently, and reduce the likelihood of contamination incidents, ensuring both compliance and consumer protection.

Control Measures & Risk Mitigation Strategies

Once hazards have been identified and prioritized, the next step in a food safety risk assessment is implementing robust control measures. Effective strategies combine preventive, operational, and verification processes to minimize risk throughout the food chain.

Preventive Controls

Preventive measures are designed to stop hazards before they occur. Key steps include:

- Maintaining strict sanitation practices for equipment, surfaces, and storage areas.

- Vetting and monitoring suppliers to ensure ingredient safety.

- Following process hygiene protocols such as proper handling, cleaning, and sterilization.

Operational Controls

Operational controls manage risks during daily food handling and processing:

- Monitoring temperature-sensitive products to prevent microbial growth.

- Avoiding cross-contamination by segregating raw and cooked foods.

- Implementing allergen control procedures, including labeling and dedicated equipment, to reduce the risk of exposure.

Verification and Monitoring

Verification ensures that control measures are effective and hazards are managed consistently:

- Regular testing of products and surfaces to confirm safety.

- Conducting internal audits and checks of critical control points (CCPs) within HACCP frameworks.

- Using monitoring data to adjust procedures in real-time for ongoing risk management.

Documentation and Continuous Improvement

Thorough documentation strengthens accountability and supports continuous improvement:

- Recording all preventive and operational measures.

- Assigning clear responsibilities to staff for compliance.

- Maintaining logs of inspections, corrective actions, and performance reviews to feed into future risk assessments.

Together, these strategies create a comprehensive system for managing food sanitation and safety. When applied consistently, they reduce the likelihood of contamination, protect consumer health, and ensure that the business maintains regulatory compliance while supporting long-term operational efficiency.

Making Risk Assessment Practical

A food safety risk assessment is only valuable if it is actionable. Many operations reduce assessments to a compliance exercise, completing paperwork without translating findings into day-to-day practices. This approach fails to prevent hazards and can lead to costly food safety failures.

Avoiding Common Pitfalls

- Treating risk assessment as a one-time activity rather than an ongoing process.

- Ignoring input from frontline staff who interact with food products daily.

- Relying solely on documentation instead of connecting findings to operational changes.

Embedding Risk Assessment into Daily Routines

Practical implementation involves making risk assessment part of everyday operations:

- Conduct regular “hazard walks” through production, storage, and packaging areas to identify potential risks in real-time.

- Encourage cross-functional teams, including operators, supervisors, and quality staff, to participate actively in monitoring and reporting hazards.

- Use checklists, visual cues, and simple tracking systems to ensure hazards are consistently managed.

Building a Food Safety Culture

A strong culture ensures that risk assessment is more than a formality:

- Provide ongoing training to staff on hazard recognition and mitigation practices.

- Assign accountability for food safety at all levels, from operators to management.

- Review and update practices continuously based on observations, audit results, and emerging risks.

By embedding food safety risk assessment into operational routines and fostering a culture of vigilance, businesses can move beyond paperwork and achieve tangible safety outcomes. This approach reduces incidents, strengthens compliance, and ensures that risk management contributes directly to product quality and consumer protection.

How Folio3 FoodTech is Supporting Food Businesses with Customized Solutions

Folio3 FoodTech has been delivering custom food technology solutions for food businesses for decades, helping organizations optimize operations, maintain compliance, and ensure product quality. Our experience spans across processing, storage, distribution, and retail segments, serving industry leaders with scalable, tailored systems.

By understanding the unique challenges of each food operation, from complex supply chains to regulatory requirements, we design solutions that streamline workflows, enhance visibility, and support informed decision-making. Our approach ensures that processes are data-driven, efficient, and aligned with best practices, no matter the size or complexity of the business.

Whether it’s improving traceability, monitoring product quality, or digitizing operational records, Folio3 FoodTech’s solutions adapt to the needs of each client. This flexibility allows companies to address emerging risks proactively and maintain the highest standards in food safety, efficiency, and operational excellence.

With decades of experience in the industry, our expertise ensures that businesses not only meet today’s food safety and operational demands but are also prepared to adapt to future challenges.

Conclusion

Food safety risk assessment is a cornerstone of modern food production, ensuring that hazards are identified, evaluated, and controlled before they reach consumers. By understanding the distinction between hazard and risk, and applying structured steps, hazard identification, characterization, exposure assessment, and risk characterization, food businesses can proactively protect both public health and brand reputation. Practical implementation goes beyond documentation, requiring continuous monitoring, staff engagement, and integration into daily operations.

The combination of preventive and operational controls, supported by verification, monitoring, and thorough recordkeeping, provides a robust framework to mitigate risks effectively. Embedding these practices into a company’s culture enhances accountability, reduces the likelihood of food safety failures, and strengthens compliance with regulatory standards.

Technology now plays a critical role in making risk assessment actionable. Digital tools, real-time monitoring, and predictive analytics allow for faster, data-driven decisions that maintain consistent quality and safety across the food chain.

Ultimately, a disciplined approach to food risk assessment empowers organizations to safeguard consumers, optimize operational efficiency, and uphold industry best practices. Companies that prioritize risk assessment not only minimize hazards but also build long-term trust, resilience, and sustainable growth in a complex food landscape.

FAQs

What are the 5 C’s of food safety?

The 5 C’s of food safety are Cleaning, Cooking, Chilling, Cross-contamination prevention, and Checking. Together, they provide a practical framework to prevent foodborne illnesses and ensure proper handling throughout the supply chain.

What are the 5 things a risk assessment should include?

A thorough food risk assessment should include identifying potential biological, chemical, physical, and allergen hazards, evaluating the severity and potential impact of each hazard, determining who may be exposed and at what levels, combining hazard and exposure data to estimate overall risk, and developing strategies to prevent, mitigate, or monitor hazards effectively.

What are the 4 types of risk assessments?

The four common types of risk assessments are qualitative, semi-quantitative, quantitative, and dynamic, each varying in data requirements and precision for estimating potential food safety risks.

What are the 7 steps of a risk assessment?

The seven steps typically involve establishing context, identifying hazards, analyzing risks, evaluating risks, identifying control measures, implementing controls, and monitoring and reviewing the process. Following these steps ensures a structured and proactive approach to managing food safety hazards.