Foodborne illnesses are alarmingly common; 1 in 6 Americans gets sick from food poisoning each year, and about 128,000 are hospitalized. Whether you’re a food processor, plant manager, or line worker, understanding food safety basics is critical. By mastering a few basic food safety practices, companies can prevent costly recalls, lawsuits, and reputational damage. The key practices for ensuring food safety also protect public health by reducing outbreaks caused by common pathogens like Salmonella and E. coli.

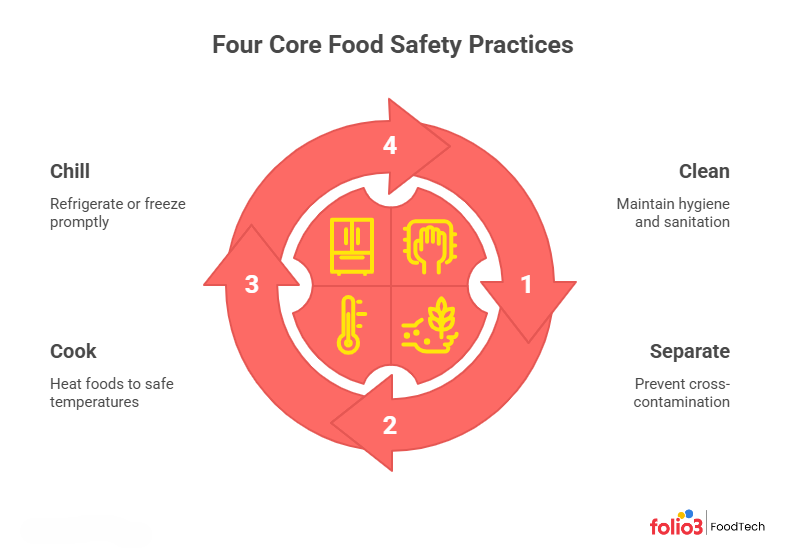

Food handling encompasses all steps in preparing, processing, and serving food, covering critical stages of food safety from receiving raw materials to the final product. Following safe food practices at each step considerably lowers contamination risks. Global agencies like USDA, FDA, and CDC have long promoted four food safety basics: Clean, Separate, Cook, and Chill.

These principles of food safety form the foundation of good manufacturing practices and food hygiene programs everywhere. In this blog, we’ll explore each core practice in detail and show how implementing these food safety steps can dramatically improve your facility’s safety performance.

What are the Four Core Food Safety Practices?

Food safety experts agree that most contamination can be prevented by focusing on four fundamental principles. Agencies worldwide, plus public initiatives campaigns, all emphasize these four steps to food safety. The four core practices, often called the 4 Cs of food safety, are:

- Clean: Emphasizes personal hygiene and the sanitation of surfaces. Keep everything that comes into contact with food (hands, equipment, counters) clean to remove harmful microbes.

- Separate: Prevent cross-contamination by keeping raw ingredients (especially meats) away from cooked or ready-to-eat foods at all times.

- Cook: Heat foods to their safe internal cooking temperatures to kill pathogens. You can’t judge safety by color; use a thermometer to be sure.

- Chill: Refrigerate or freeze foods promptly to keep them out of the bacterial “danger zone.” Proper cooling and cold storage slow microbial growth.

These practices aren’t just for home kitchens; they align closely with industry Good Manufacturing Practices (GMPs) and food safety standards required by regulatory authorities. For example, cleaning and sanitation are mandated by FDA and USDA rules, and FSMA preventive controls demand effective separation of allergens and raw vs. cooked products. By following these principles of food safety, you’ll meet many basic compliance points.

Practice 1 – Clean: Personal and Facility Hygiene

A surprising amount of food contamination comes from dirty hands and surfaces. Germs that make you sick can survive on hands, utensils, cutting boards, and countertops. In a plant setting, a single unclean conveyor belt or tool can spread bacteria to an entire batch. Robust food safety and sanitation practices are non-negotiable. Implementing preventive measures for food safety control through good hygiene breaks the chain of contamination and is one of the fundamental food safety practices underpinning all others. Regular cleaning and sanitizing of equipment, facilities, and people dramatically reduces the risk of product contamination.

How to Clean

Keeping things clean involves a mix of personal hygiene and sanitation procedures:

- Hand-Washing: Wash your hands thoroughly and often. Use plain soap and warm water, scrubbing for at least 20 seconds. Clean under your nails and between your fingers. Always wash before handling food, after handling raw meat, after using the restroom, or any time hands may have become contaminated. Dry with a clean towel or disposable paper towel.

- Surfaces & Utensils: After each use, wash cutting boards, knives, dishes, and countertops with hot, soapy water. In manufacturing plants, implement scheduled cleaning for production lines, often using Clean-In-Place (CIP) systems for pipes and tanks to ensure equipment is sanitized between runs. Don’t forget “high-touch” areas like machine buttons or door handles.

- Produce Washing: Rinse fresh fruits and vegetables under running water before cutting or eating. For firm produce, scrub the surface with a clean produce brush. Do not wash raw meat, poultry, or eggs; rinsing these can actually splash bacteria around your sink and counter. Harmful pathogens on raw meat will be killed by proper cooking[9].

- Personal Protective Equipment (PPE): In food plants, appropriate PPE is required to maintain hygiene. Hairnets, beard nets, gloves, clean smocks or uniforms, and shoe covers all help keep human-borne contaminants out of food.

Practice 2 – Separate: Prevent Cross-Contamination

Even perfectly cooked or well-cleaned food can become contaminated if it touches something dirty. Cross-contamination occurs when harmful bacteria or allergens spread from one item to another. In home kitchens, this might happen by cutting vegetables on the same board used for raw chicken, one of the common food sanitation and safety mistakes that can be easily prevented. In manufacturing plants, it can happen on a much larger scale if raw meat juices drip onto a conveyor carrying cooked product, or if equipment isn’t segregated adequately between allergen-containing and allergen-free products. Separation is all about keeping potential contaminants confined so they don’t cross into other foods.

Separation Tactics

How can you maintain separation? Here are the best practices:

- Use Separate Equipment: Dedicate specific utensils and surfaces for raw vs. cooked foods. For example, use one cutting board for raw meat/poultry and a different board for produce or cooked items. Many kitchens color-code cutting boards (red for raw meat, green for veggies) to make this easier. In food factories, consider separate production lines or tools for allergenic ingredients to avoid cross-contact. Never reuse a utensil or container that holds raw meat unless it has been thoroughly cleaned and sanitized first.

- Strict Storage Rules: Keep raw foods physically separated from cooked and ready-to-eat foods in storage. In refrigerators, always store raw meat, poultry, seafood, and eggs below other foods (or in dedicated bins) so their juices can’t drip onto anything else. Use sealed containers or plastic wrap to contain raw items and minimize leaks.

- Facility Zoning and Workflow: At a facility level, zoning and workflow design help prevent cross-contamination. Ideally, create dedicated raw and ready-to-eat (RTE) zones. If space is limited, sequence production so raw processing happens first, followed by complete sanitation before RTE work begins. Physical dividers, separate tools, and strict personnel flow rules, such as handwashing and PPE changes between zones, are used to strengthen control.

- Never Wash Raw Poultry or Meat: Do not rinse raw poultry (or other meats) under the faucet. Washing chicken can spray bacteria up to three feet away, contaminating your sink and surfaces. Proper cooking will kill the bacteria, whereas washing just spreads them around.

- Sanitary Transport: Maintain sanitary transport from the dock to the destination. Clean trucks, pallets, and crates thoroughly, and avoid reusing raw-meat containers for produce unless sanitized. Many companies now use IoT sensors to monitor transport hygiene and temperature, helping maintain the cold chain and quickly detect issues before contamination spreads.

Practice 3 – Cook: Achieve Safe Internal Temperatures

Heat is one of the most potent weapons against pathogens. Most harmful bacteria, viruses, and parasites in food are killed when the food is cooked to the right temperature. Undercooking is a leading cause of foodborne illness outbreaks and recalls. Understanding how to prevent food safety failures through proper cooking is critical for protecting consumers. According to the CDC and USDA, foods are safely cooked only when they reach specific minimum temperatures that are hot enough to kill germs. You can’t reliably judge this by color or texture; use a calibrated food thermometer to check. Cooking is a critical control point: it’s often the last chance to destroy any bacteria that slipped through the previous steps.

Temperature Targets and Tools

Every food handler should be familiar with the safe cooking temperature guidelines. Below is a quick-reference chart of safe minimum internal temperatures :

| Food Category | Safe Minimum Internal Temperature |

| Whole cuts of beef, pork, lamb, veal (steaks, roasts, chops) | 145 °F (63 °C) + 3-minute rest |

| Fish with fins (e.g., salmon, cod) | 145 °F (63 °C) (or until flesh is opaque and flakes easily) |

| Ground meats (beef, pork, etc.) | 160 °F (71 °C) |

| All poultry (ground or whole) | 165 °F (74 °C) |

| Leftovers and casseroles | 165 °F (74 °C) |

Important notes on these food safety steps for cooking:

- Whole-muscle meats like steaks can be cooked to 145 °F as long as you let them rest for 3 minutes before cutting or serving.

- Ground meats require a higher temperature (160 °F) because bacteria can be mixed throughout the meat during grinding.

- Poultry and stuffed foods have the highest standard because they are especially prone to harboring dangerous bacteria like Salmonella deep inside.

- Any reheated leftovers or casseroles should be heated to 165 °F since bacteria may have grown during cooling/storage.

- Always use a thermometer; you can’t rely on visual cues alone. Hamburger meat can remain pink even when safely cooked, or turn brown before it’s actually safe.

Cooking in Manufacturing Context

In industrial food processing, “cook” can mean anything from baking to pasteurization or UHT treatment. The principle is the same: reach the required time–temperature combination to eliminate target pathogens. Under FSMA’s HARPC rules, these cooking steps are often classified as preventive controls that require monitoring and verification. Technology is a tremendous asset here. Modern systems use digital HACCP tools and IoT-enabled ovens to continuously monitor cooking temperatures, creating automatic documentation showing that each batch hit its critical limit.

Practice 4 – Chill: Temperature Control, Storage & Thawing

After cooking, keeping food cold is the next critical step. Harmful bacteria multiply rapidly between about 40 °F and 140 °F; this range is known as the “danger zone”. If cooked food cools slowly through this range, or if refrigerated foods warm above 40 °F, microbes can multiply in numbers. Therefore, proper chilling is as necessary as adequate cooking. For processors and distributors, managing the cold chain from post-cook chilling to warehouse storage to transportation and retail is a major focus. The goal is simple: keep cold foods cold. By minimizing time in the danger zone, you effectively put bacteria “to sleep” or slow their growth to a crawl.

Proper Refrigeration

Here are the core rules for safe chilling and cold storage:

- Refrigerate Promptly: Get perishable foods into the refrigerator (or freezer) as soon as possible, ideally within 2 hours of cooking or taking them out of refrigeration. If the ambient temperature is above 90°F, say a hot summer day, you have only 1 hour to safely get the food chilled. In operations, this might mean using blast chillers or ice baths to cool cooked products rapidly before packaging.

- Maintain Cold Temperatures: Keep your refrigerators at 40 °F (4 °C) or below, and freezers at 0 °F (-18 °C) or below. Use appliance thermometers in your cold storage units to verify they’re holding temperature. Many facilities now use digital temperature monitoring with alerts that if a cooler goes above 41 °F, a supervisor gets a notification to take action. This kind of real-time oversight, often via IoT sensors, helps ensure that a refrigeration malfunction doesn’t go unnoticed.

- Cold Storage Hygiene: Even while cold, food should be protected. Store foods in covered, leak-proof containers to prevent cross-contamination. Also, FIFO (First-In, First-Out) should be the rule: use the oldest stock first and clearly label all items with dates.

Storage & Thawing

Safe cooling also involves how you handle foods during refrigeration and freezing:

- Cool Foods Fast: Store leftovers or large batches in shallow containers to cool them faster. A big pot of soup will cool very slowly in the fridge (staying in the danger zone for hours). Dividing it into smaller containers can make a huge difference. In industrial kitchens, use blast chillers for rapid cooling of soups, sauces, and cooked foods.

- Never Thaw at Room Temperature: Never thaw food at room temperature on a counter. The three safe ways to thaw are: in the refrigerator, under cold running water, or in the microwave, followed by immediate cooking. Thawing in the fridge is slow but safest.

- Freezing Doesn’t Kill Germs: Freezing food is excellent for long-term storage, but it inactivates microbes, and it doesn’t reliably kill them. Bacteria or parasites go dormant at 0 °F, then can revive when the food is thawed. That’s why frozen foods still need proper cooking after thawing.

Beyond the Core Four: Sustainable & Digital Food Safety Practices

Implementing the four core practices goes a long way toward basic safety. But forward-thinking food companies are now expanding their focus to sustainable food safety practices and digital solutions that enhance these basics:

Sustainable Practices

Sustainability and food safety go hand in hand. Many processors adopt principles from the WHO’s “golden rules,” which emphasize choosing foods processed for safety, storing and reheating cooked foods correctly, and using only safe, potable water throughout production.

Beyond these basics, sustainable food safety also means reducing waste, lowering water use in cleaning operations, and switching to eco-friendly sanitizers wherever possible. These changes not only support the environment but also strengthen your facility’s long-term safety and operational efficiency.

Training & Certification

Strong systems rely on strong people. Regulations increasingly require trained oversight according to the FDA Food Code; every establishment must have a Person in Charge responsible for ensuring proper cooking, cooling, and holding temperatures. Regular training and certification keep your team aligned with evolving rules and help maintain consistent execution across shifts.

Digital Transformation

Digital tools allow you to go beyond manual checks. Digital HACCP systems, IoT temperature sensors, and smart traceability platforms provide real-time visibility across your process. Automated refrigerator and freezer sensors help you respond immediately to temperature deviations, while digital checklists reduce documentation errors and improve the readiness of food safety audit.

Integrating ERP Platforms

Finally, connecting your food safety program with integrated Food ERP systems brings everything together. These platforms can automate sanitation schedules, centralize training records, manage corrective actions, and track compliance to give you a single source of truth for food safety management.

Implementation Tips for Food Processors & Manufacturers

Knowing the guidelines is one thing; implementing them consistently on the factory floor is another. Here is an implementation checklist of food safety best practices:

- Build a Food Safety Culture: Leadership must set the tone. Management should visibly prioritize hygiene and safety, like following gowning procedures themselves, or allocating budget for sanitation upgrades. When everyone understands that food safety is part of their job, not just the QA department’s job, you create a culture that naturally upholds Clean, Separate, Cook, and Chill practices.

- Develop SOPs & Checklists: Translate the core practices into clear Standard Operating Procedures. For example, have detailed SOPs for equipment cleaning (Clean), allergen changeovers and storage protocols (Separate), cooking procedures (Cook), and cooler temperature monitoring (Chill). Use simple language and post SOPs at the point of use. Then implement checklists to track that these tasks are done.

- Continuous Training: Regularly train and refresh staff on food safety and sanitation practices. New employees should get training in basic food safety practices from day one. Seasoned employees need refreshers too, like brief toolbox talks or quarterly trainings, which can reinforce key points like proper hand-washing or thermometer use.

- Audit & Verification: Periodically audit your own facility to ensure procedures are followed. Conduct internal audits or “walk-throughs” focusing on sanitation efficacy, temperature logs, storage segregation, etc. Modern digital tools for food safety can make audits easier by producing organized records on demand.

- Leverage Technology: IoT sensors, mobile apps, and analytics platforms help you monitor temperatures, equipment status, and hygiene compliance in real time. These tools strengthen food safety, improve traceability, and support more sustainable operations.

Conclusion

Food handlers at all levels should remember that food safety basics truly matter. The simple act of keeping your hands clean or storing raw chicken on a lower fridge shelf can prevent someone from getting gravely ill.

Now is a good time to evaluate your own operations: Where are there gaps in cleaning schedules? Are raw and cooked materials ever in risky proximity? Do cooking staff use thermometers correctly? Is your cooling process fast enough? Identify any weak spots and take action, whether that means retraining staff, investing in new tools, or updating procedures. Plus, you can consult with our Foodtech experts to ensure optimal food safety across your operations by digitizing it through a suitable solution.

FAQs

Why Is It Important to Separate Raw and Ready-to-Eat Foods?

Separation prevents cross-contamination, one of the leading causes of foodborne illness. By keeping raw meat, poultry, and seafood away from produce and cooked foods, you stop harmful bacteria from spreading through tools, surfaces, storage shelves, or employee handling.

What Is Considered Proper Cleaning in Food Safety?

Proper cleaning goes beyond wiping surfaces. It includes handwashing, sanitizing equipment, following SOPs, and maintaining consistent hygiene practices across shifts. Effective cleaning removes food particles, microorganisms, and allergens that jeopardize product safety.

What Are Sustainable Food Safety Practices?

Sustainable practices include using safe water, minimizing waste, choosing processed-for-safety ingredients, using eco-friendly sanitizers, and reducing water usage during cleaning. These practices support both safety and operational sustainability.

How Can Digital Tools Improve Food Safety Compliance?

Digital HACCP, IoT sensors, and mobile checklists make food safety monitoring faster, more accurate, and easier to document. They provide real-time temperature tracking, automated alerts, and audit-ready records, helping facilities strengthen compliance and traceability.

How Do ERP Systems Support Food Safety?

Integrated ERP platforms help centralize sanitation schedules, temperature logs, training records, and corrective actions. This unified approach improves visibility, reduces manual errors, and strengthens compliance during audits.