Adapt to changing tastes and demand shifts with snack industry ERP solutions, ensuring real-time batch tracking, quality control, and supply chain management for snack brands.

Manage shifting tastes, ingredient shortages, and production bottlenecks with snack industry ERP solutions

designed to optimize production and growth.

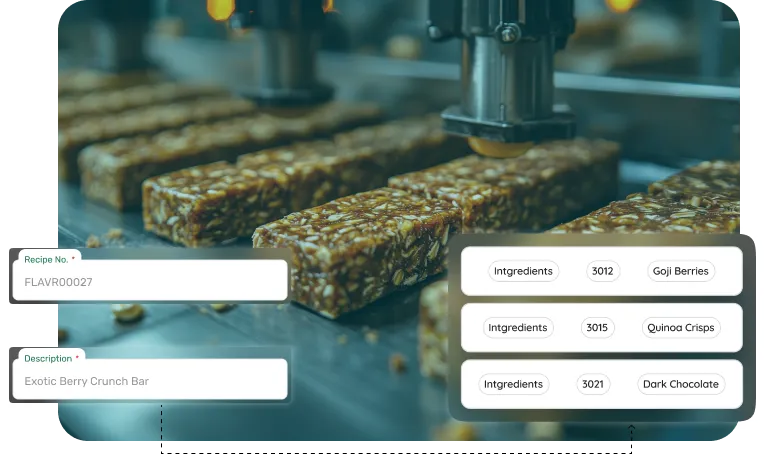

Rapidly changing consumer tastes demand faster product development cycles for snacks like flavoured chips, protein bars, or trail mixes. Delays mean lost market share.

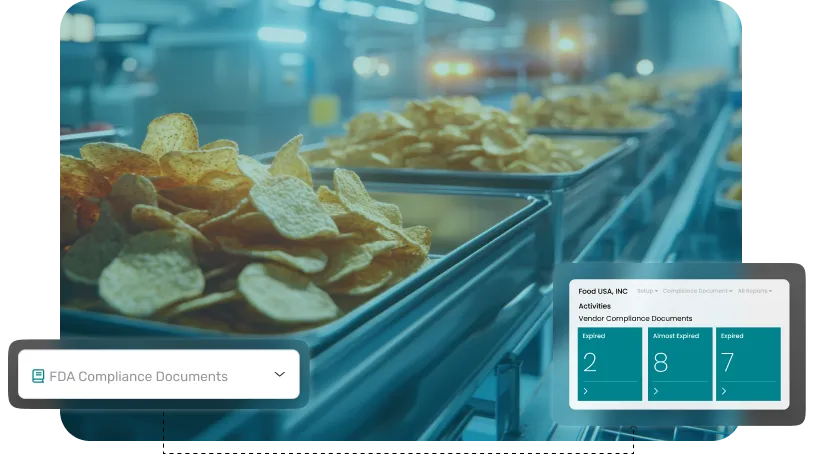

Meeting strict allergen labelling, organic certifications, and non-GMO standards is critical—but a logistical nightmare without the right tools.

Shifting toward healthier snacks (e.g., low-sodium chips or gluten-free bars) increases regulatory complexity and ingredient sourcing challenges.

Limited shelf space for snacks in retail stores forces producers to meet tight delivery windows, maintain freshness, and reduce stock outs.

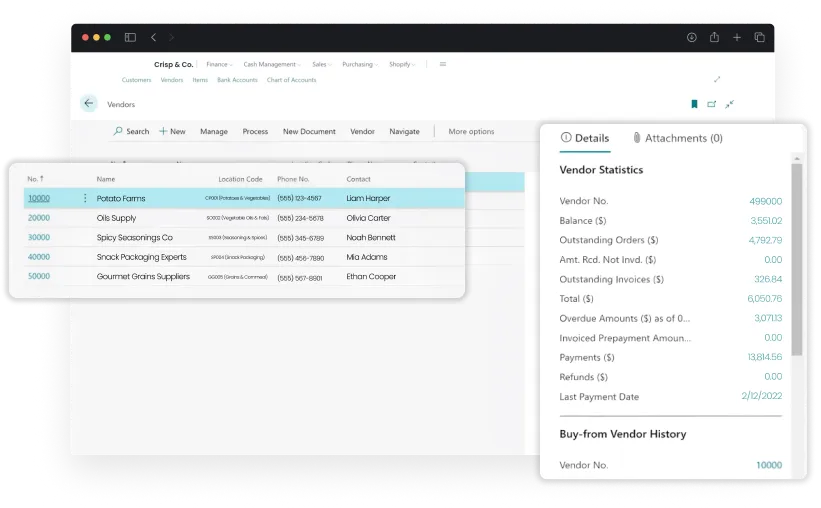

Key ingredients like cocoa, corn, and nuts face global supply chain disruptions, directly impacting costs and availability for snack producers.

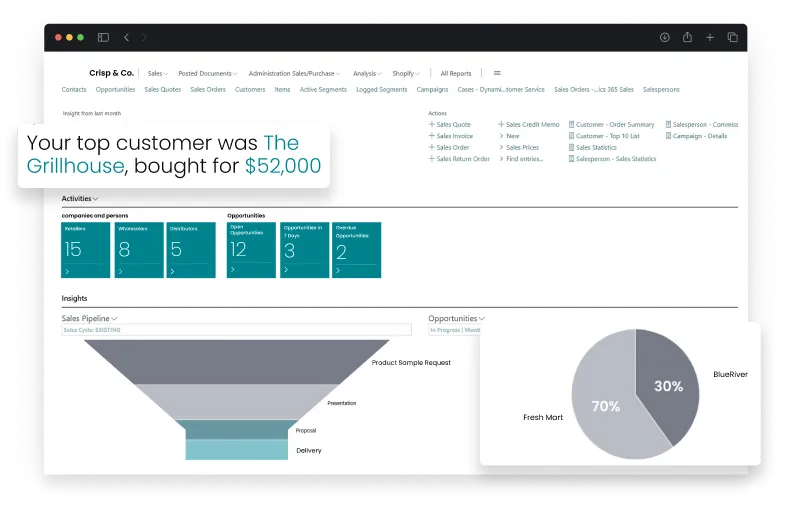

Navigating the complexities of DTC snack models demands flexible order management and effective, cost-efficient shipping workflows.

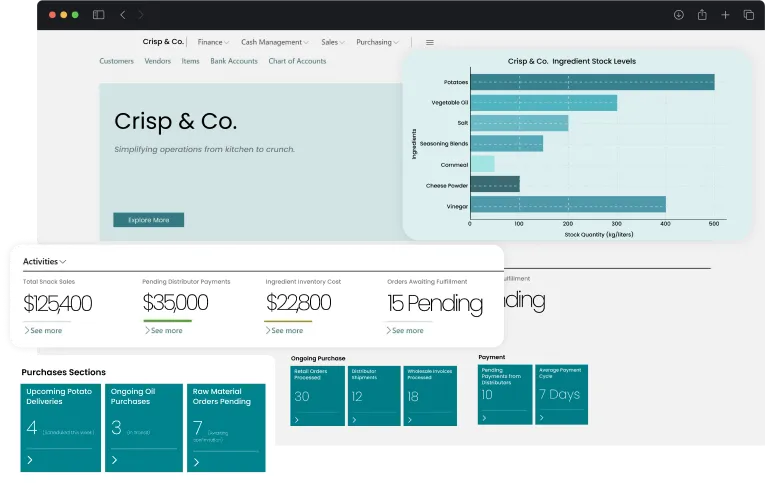

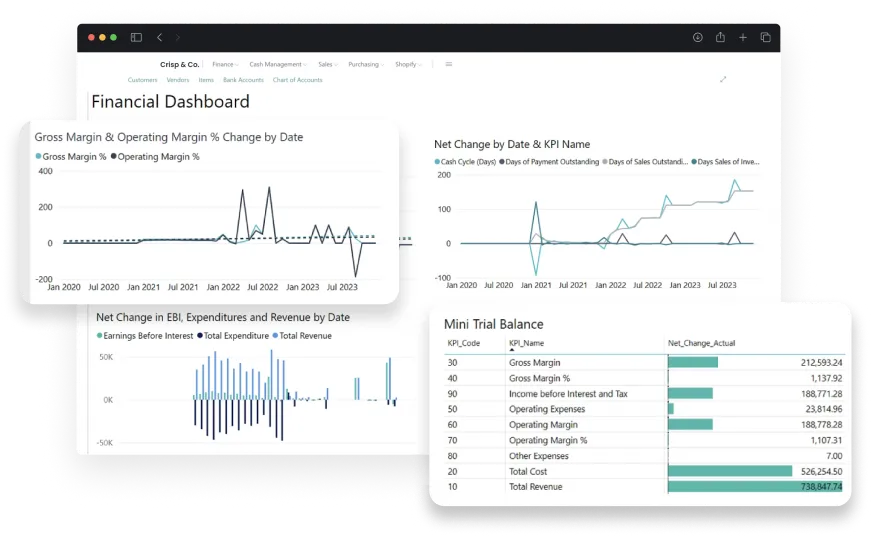

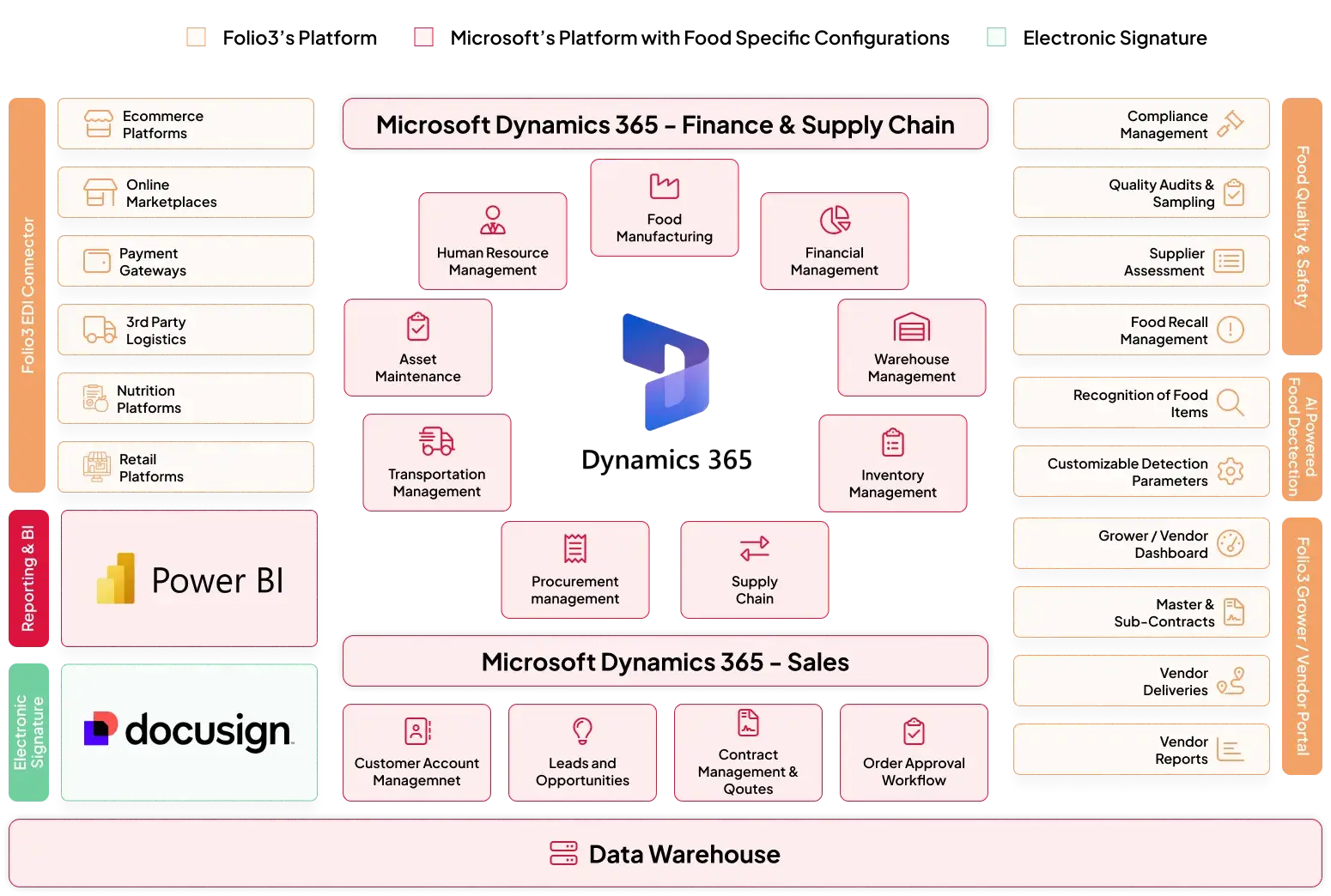

Every snack ERP module you need is built to evolve with your business and keep pace with the latest trends.

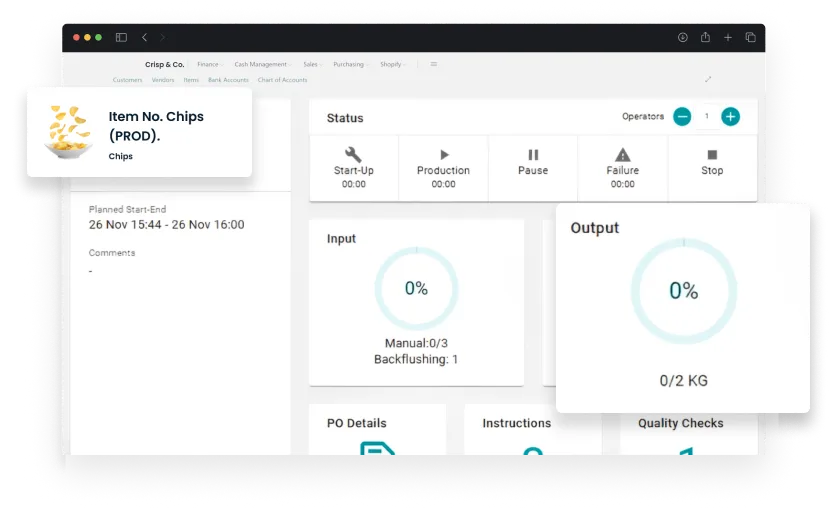

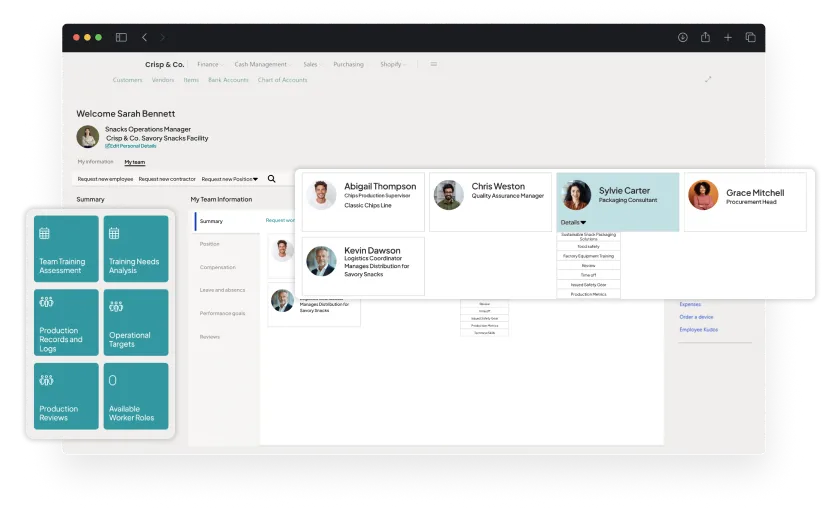

ERP for snack production helps you drive operational efficiency across the entire snack production process, improving collaboration and delivery speed at each stage.

Ensure consistent ingredient quality, manage sourcing costs, and manage inventory to meet production needs with real-time insights.

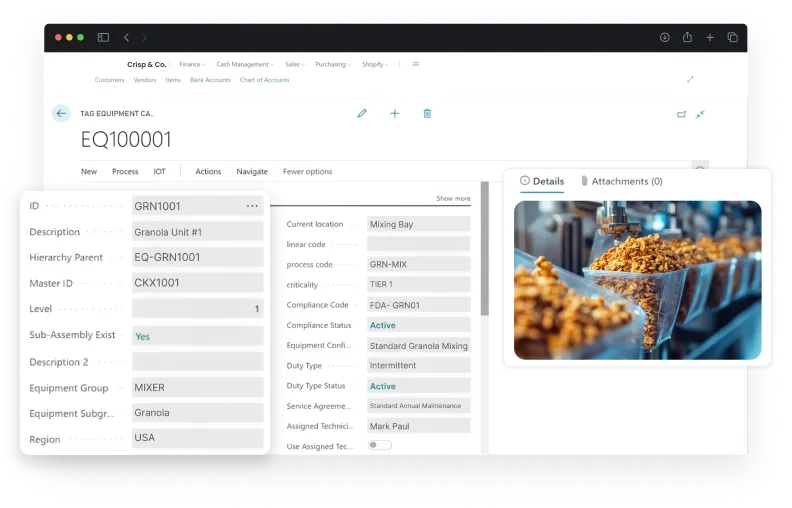

Manage recipes, track allergens, ensure compliance, and simplify production to maintain quality and boost operational efficiency with ERP for snack manufacturers.

Optimize packaging inventory, streamline supply chain coordination, and reduce waste through efficient tracking and timely deliveries with our ERP for snack packaging.

Manage orders, track shipments, and improve delivery efficiency to reduce costs and ensure on-time product availability with the Snack food ERP system.

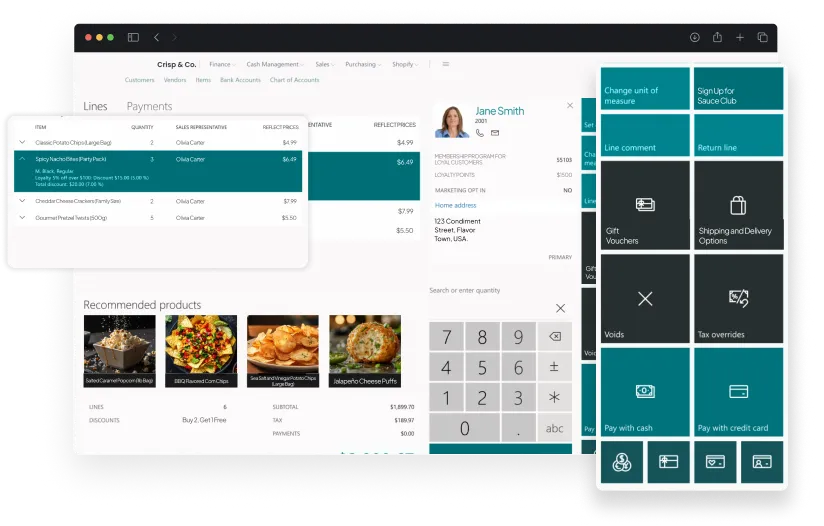

Efficiently manage inventory, track orders, and boost sales across both online and offline channels for optimal retail operations.

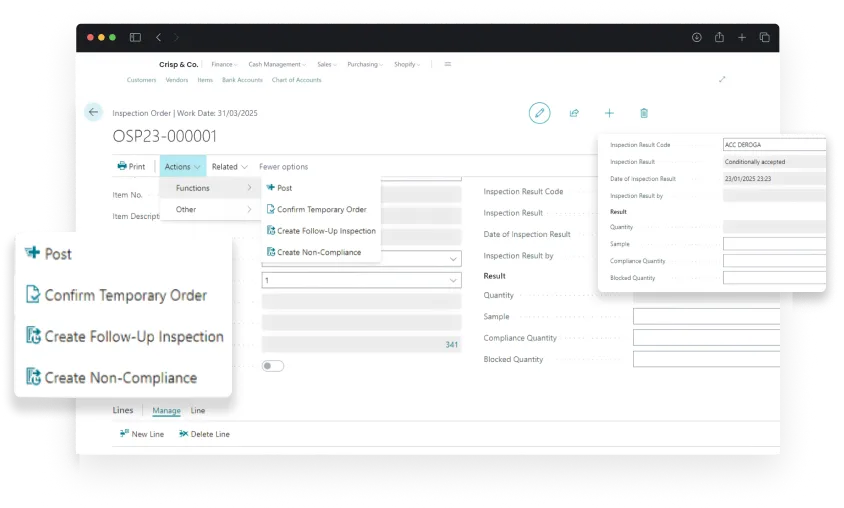

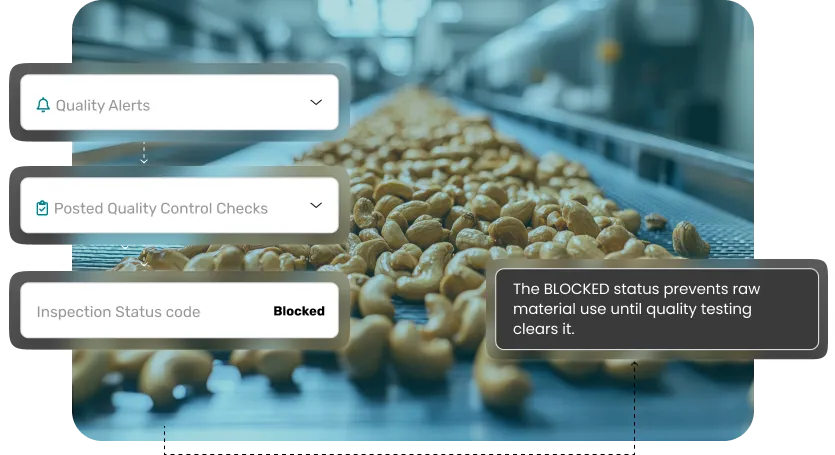

Ensure every snack meets the highest standards of safety and quality, from ingredient sourcing to final delivery, effortlessly.

Ensure every snack meets safety laws, from proper seasoning levels to allergen labeling. Stay ahead of audits with ease.

Perfect crunch, taste, and freshness—track batch consistency, packaging quality, and shelf-life for every snack you make.

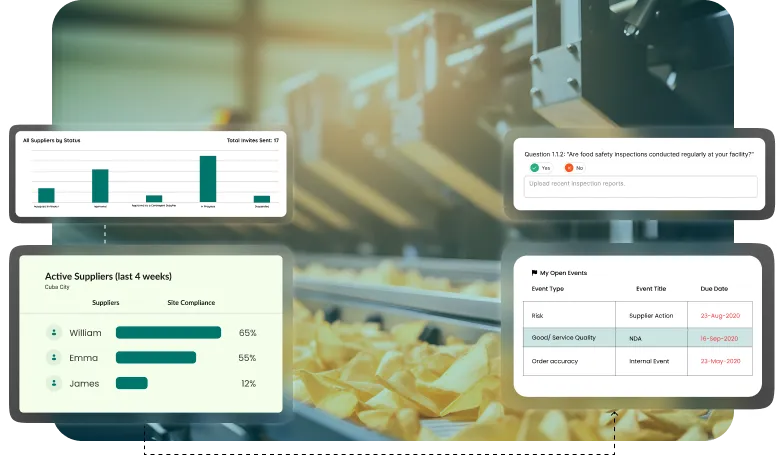

Work only with trusted suppliers who meet your snack standards—track ingredient sourcing and verify certifications for quality and safety.

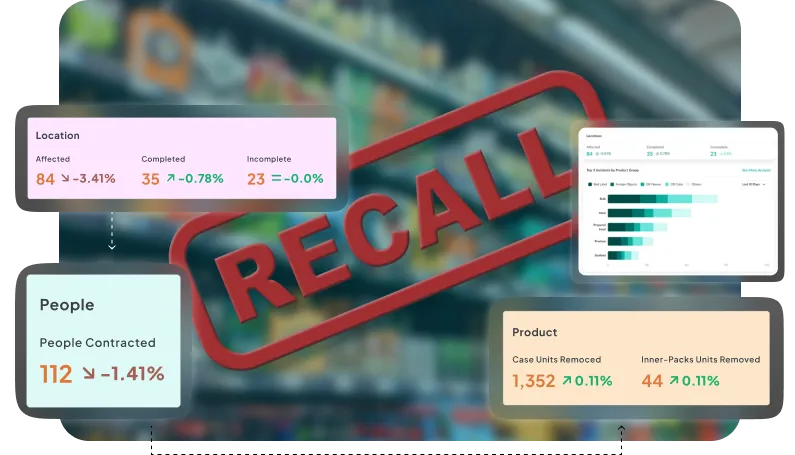

Handle recalls quickly with traceability for snack batches, ensuring every chip or bar reaches your customers safely.

Link your candy and snack ERP software with the software you already use to simplify your

workflow, save time, and keep every process connected.

From understanding your snack operations to implementation and beyond, we ensure a smooth ERP journey

explicitly catering to your business needs.

We dive deep into your snack-making process—whether it’s perfecting flavors, managing seasonal ingredients, or ensuring allergen compliance.

Our snack-focused roadmap prioritizes key processes like batch tracking, inventory control, and production flow optimization.

We customize ERP to your snack business, handling everything from sourcing ingredients to ensuring consistent packaging and distribution.

Every feature is tested against snack industry standards, guaranteeing the perfect taste, texture, and shelf-life for your products.

We seamlessly integrate your ERP with existing tools, from production line tech to inventory systems, for a smoother workflow.

We ensure secure migration of critical data like ingredient records, batch histories, and supplier information to keep operations running smoothly.

Our team ensures ERP frictionless launch, minimizing disruptions to production schedules and ensuring orders are fulfilled on time.

With comprehensive training and ongoing support, we empower your team to make the most of your ERP system.

Track milk from farm to shelf, ensuring freshness, quality, and safety while optimizing production and extending shelf life.

Keep your beverage production in check with consistent quality, ingredient tracking, and efficient batch management from start to finish.

Track storage conditions, manage production based on demand, and reduce waste, ensuring your frozen foods stay fresh longer.

Simplify your bakery operations with tools for inventory, recipe management, and quality control to stay ahead of trends.

Manage ingredient inventory, allergen safety, and production cycles to deliver sweet products with consistency and safety.

Handle large-scale snack production with real-time inventory, ingredient sourcing, and quality control.

Track meat quality and processing conditions, meeting safety standards while maintaining efficiency and product consistency.

Maintain batch control, track ingredient sourcing, and ensure consistent flavour profiles for every batch of your sauces.

See how food businesses boost efficiency with solutions that simplify daily tasks!

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

ERP systems simplify production schedules by integrating real-time data on ingredient availability, production capacity, and demand forecasts, ensuring optimal resource utilization, minimizing downtime, and meeting customer delivery deadlines.

An ERP system helps manage allergen segregation by tracking ingredients and their allergen content, ensuring safe handling and storage. It integrates allergen alerts, ensuring your production teams follow strict guidelines for preventing cross-contamination.

ERP software enables detailed tracking of raw materials, production processes, and distribution channels, providing full visibility from ingredient sourcing to final product delivery. This ensures quick access to vital product data for quality control and recalls.

ERP systems provide tools to monitor batch quality, conduct in-line inspections, and track test results. This includes setting quality benchmarks, monitoring ingredient consistency, and ensuring adherence to food safety standards, minimizing defects and waste.

Yes, ERP systems for the snack industry include features to handle packaging variations, including size, labeling, and compliance with industry regulations. It can automatically generate labels with nutritional information, allergen declarations, and expiration dates.

The ERP system allows real-time inventory tracking, including raw materials, in-process items, and finished goods. It optimizes stock levels, ensures proper rotation (FIFO), and alerts manufacturers to re-order critical ingredients, reducing the risk of shortages or overstocking.

ERP software offers formulation management, tracking ingredient quantities and variations in recipes. It provides complete control over ingredient substitutions, ensures compliance with regulatory standards, and allows easy adjustments to recipes for product testing or new flavor development.

Yes, ERP systems support DSD operations by tracking orders directly from manufacturers to retailers. It enables delivery scheduling, real-time updates on stock levels, and invoicing for DSD routes, ensuring efficient distribution and customer satisfaction.

The implementation timeline typically ranges from 8 to 12 weeks, depending on the complexity of the system and the specific requirements of your snack manufacturing operations. This includes system customization, training, and data migration.

ERP systems provide advanced security protocols, including encryption, multi-user authentication, and regular security audits. They protect sensitive data like production formulas, supplier information, and consumer safety details against unauthorized access and breaches.