The meat processing industry operates in a high-stakes environment, where even minor disruptions can lead to major losses. With global demand for meat products climbing, the global meat products market reached USD 1,730.57 billion in 2024 and is projected to hit USD 2,710.39 billion by 2034, according to research.

Producers handling meat supply chain must understand growing logistical complexity, stricter safety regulations, and a shrinking margin for error. Unlike shelf-stable goods, meat products require near-perfect timing, temperature control, and inventory precision. A single misstep in cold chain logistics or compliance tracking can result in widespread spoilage, costly recalls, or regulatory violations.

These challenges are magnified by volatile demand patterns, limited shelf life, and rising operational costs. To stay competitive, meat processors are turning to digital tools, meat solutions, and strategies that bring visibility, automation, and intelligence to every stage of the supply chain.

From real-time tracking and automated replenishment to predictive demand planning and compliance monitoring, technology enables faster decisions and fewer mistakes. Companies implementing comprehensive strategies report reductions in food waste, improvements in inventory turnover, and significant enhancements in regulatory compliance capabilities.

This guide outlines proven strategies used by forward-thinking meat companies to improve supply chain performance through digital transformation. Let’s get started!

Understanding the Meat Supply Chain and Its Challenges

The meat supply chain is one of the most operationally demanding in the food industry. It requires precise coordination across sourcing, production, meat packaging, and distribution while maintaining strict quality and safety standards. Each phase introduces high-risk variables that can impact product integrity, compliance, and profitability.

The Complexities of the Meat Supply Chain

From livestock sourcing to retail delivery, the meat supply chain includes six key stages: livestock transportation, slaughtering, processing, packaging, cold storage, distribution, and final delivery. Each stage brings its own set of challenges:

- Temperature control is paramount. Meat must be kept within narrow thresholds, typically 28–32°F during processing and 35–40°F during distribution. Even brief fluctuations can result in spoilage or safety risks, mainly when multiple handoffs occur between facilities.

- Food safety compliance adds additional pressure. HACCP mandates continuous documentation, sanitation tracking, and pathogen testing across all operations. Manual or fragmented systems struggle to keep pace with evolving audit and regulatory requirements.

- Perishable shelf lives challenge inventory turnover. Fresh products like ground beef can spoil within 48 hours, requiring fast, accurate demand forecasting and agile logistics to minimize waste.

- Transportation logistics are complex and costly. Refrigerated freight can be 40–60% more expensive than standard trucking, and route planning must account for driver regulations, facility operating windows, and last-mile delivery constraints.

Why the Meat Industry Needs Optimization?

Operational inefficiencies in such a high-stakes environment translate directly into financial loss. With average processor margins between 2% and 4%, even minor disruptions or delays can tip the balance between profit and loss. By optimizing processes with modern technologies like IoT, AI, and cloud-based supply chain platforms, meat processors can meet compliance standards, reduce operational costs, and position themselves for long-term resilience.

- Waste reduction and quality assurance are no longer optional. A single quality issue can impact consumer trust and brand value, especially in an era where social media accelerates reputation damage.

- Compliance pressure is intensifying. New FDA traceability rules under the Food Safety Modernization Act (FSMA) require digitized records and real-time tracking. Paper logs and siloed spreadsheets are no longer viable.

- Demand for digital solutions is growing. The global food traceability market is projected to double, reaching $44.2 billion by 2033. This reflects a clear shift toward integrated systems that improve visibility, reduce labor-intensive processes, and deliver measurable ROI.

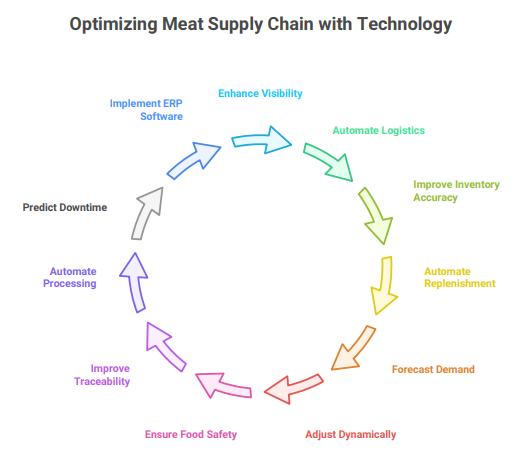

Smart Strategies for Optimizing the Meat Supply Chain with Technology

With rising compliance demands, tight margins, and perishable products, today’s meat supply chains need more than just traditional logistics. They need technology-powered precision, speed, and automation to stay competitive and compliant.

Here’s how meat businesses can optimize operations from farm to fork using the right strategies:

1. Improve Cold Chain Visibility with Real-Time Tracking

Transporting meat demands strict temperature control to prevent spoilage. Smart tracking systems, powered by GPS and environmental sensors, let you monitor temperature, humidity, and location in real time. These tools send instant alerts for issues like refrigeration failure or route delays, helping you act fast before products are compromised. They also auto-log critical data, reducing manual work and ensuring USDA, FDA, and HACCP compliance.

Best Tip: Use GPS and sensor-based monitoring to maintain cold chain logistics integrity and support USDA/FSIS audit-readiness with accurate, automated records.

Why does it work?

- Sends alerts for refrigeration or routing issues.

- Enables quick corrective action to prevent spoilage.

- Creates automatic compliance logs for inspections and audits.

2. Eliminate Human Error with Logistics Automation

Manual logistics tasks like route planning and delivery scheduling often lead to delays, wasted fuel, and missed delivery windows. Automated logistics platforms use real-time data traffic, shipment urgency, and fleet capacity to optimize every delivery. This not only improves truck utilization but also reduces human error and enables faster, more reliable deliveries. Customers benefit from live updates, and operations stay efficient even during high demand.

Best Tip: Adopt logistics automation tools to reduce operational friction and ensure timely, accurate deliveries every time.

Why does it work?

- Cuts down planning time and delivery errors.

- Improves truck utilization.

- Provides customers with live delivery updates.

3. Improve Inventory Accuracy with Real-Time Tracking

Manual inventory tracking can result in stockouts, overstocking, or wasted products nearing expiration. RFID and barcode systems give real-time updates on product location, age, and quantity. This ensures fresher stock moves first, minimizes manual counting, and allows quick decisions based on accurate data.

Best Tip: Use RFID or barcode-based inventory systems for instant updates on stock levels, product age, and location.

Why does it work?

- Ensures fresher deliveries.

- Helps prioritize products near expiration for quick sale or alternate use.

- Reduces human counting errors.

4. Automate Replenishment to Prevent Over/Understocking

Predictive systems help you restock based on actual demand and trends. They analyze past sales, seasons, and customer habits to trigger restocking automatically, eliminating the need for guesswork. This keeps inventory levels just right, prevents stockouts, and reduces overproduction that leads to spoilage.

Best Tip: Set up automated, data-driven replenishment systems using food inventory management software to match supply with customer demand and avoid inventory issues. Also, use predictive systems that analyze past sales and market trends to trigger restocking automatically.

Why does it work?

- Maintains just the right stock to meet demand

- Adjusts orders based on seasonality and lead times

- Prevents both understocking and overproduction

5. Forecast Demand More Accurately with Data Analytics

Demand for meat fluctuates due to events, seasons, and promotions. AI and machine learning tools analyze historical sales and external factors to forecast demand more accurately. This helps production teams plan, reducing waste from overproduction while ensuring enough stock is available when needed.

Best Tip: Use predictive food data analytics to understand when demand will spike or dip, and adjust production accordingly.

Why does it work?

- Predicts demand spikes (e.g., BBQ season or holidays).

- Improves planning for production and distribution.

- Reduces costly overproduction.

6. Respond Quickly with Dynamic Supply Chain Adjustments

Technology can help you make on-the-fly decisions when sales patterns shift unexpectedly. Smart supply chain platforms adjust inventory, production, and distribution in real-time, keeping operations agile. These tools even simulate “what-if” scenarios to help teams prepare for disruptions.

Best Tip: Implement dynamic planning systems in food supply chain management software to stay ahead of changing market conditions without delays or shortages, and use adaptive systems that adjust operations in real-time based on sales, inventory, and disruptions.

Why does it work?

- Automatically rebalances stock between locations.

- Quickly adapts to promotions or unexpected demand.

- Models “what-if” scenarios for proactive planning.

7. Maintain Food Safety with Real-Time Compliance Monitoring

Safety checks done manually are slow and prone to error. IoT sensors can monitor critical factors like temperature and pH continuously during processing and transport. They send alerts for unsafe conditions, predict equipment issues, and automatically log compliance data.

Best Tip: Use sensor-based monitoring tools to ensure product safety 24/7 and meet USDA, HACCP, and FDA standards with less paperwork.

Why does it work?

- Sends instant alerts when conditions fall out of safe range.

- Predicts equipment issues before they affect safety.

- Automatically creates digital compliance records.

8. Improve Traceability from Farm to Retail

In case of a recall or audit, knowing a product’s complete journey is essential. Food traceability software records everything, including processing data, supplier info, quality checks, and meat storage conditions. This helps isolate issues fast and limit the impact.

Best Tip: Use integrated traceability software to quickly access product histories and respond to quality issues with confidence.

Why does it work?

- Provides full product history for recalls or audits.

- Links all records processing, quality tests, and supplier data.

- Speeds up investigation during quality issues.

9. Automate Processing for Consistent Quality and Yield

Labor shortages and inconsistent cuts affect quality and yield. Automation tools like robotic cutters, intelligent RT vision systems, and scheduling software ensure precision and speed. These systems help reduce labor costs, increase output, and maximize the value of every carcass.

Best Tip: Use robotic cutting tools, smart vision systems, and intelligent scheduling software.

Why does it work?

- Cuts labor costs.

- Increases processing speed.

- Maximizes yield from each carcass with precision cutting.

10. Avoid Downtime with Predictive Analytics

Processing slowdowns can ruin schedules and reduce profits. Real-time analytics tools identify bottlenecks, trigger maintenance alerts, and help teams adjust staffing or schedules quickly. This keeps the line moving and minimizes downtime.

Best Tip: Use predictive analytics and real-time dashboards to resolve meat processing issues before they turn into delays.

Why does it work?

- Fixes issues before they cause downtime.

- Optimizes labor and equipment use.

- Improves overall workflow.

11. Use Meat ERP Software for Total Supply Chain Control

Managing production, inventory, compliance, and logistics across multiple systems can cause disconnects and delays. A Meat ERP like Folio3 FoodTech Meat ERP brings everything under one roof, catch weight handling, FEFO inventory picking, traceability, and regulatory compliance. It gives teams full control and visibility across operations, reducing errors and improving decision-making.

Best Tip: Implement a purpose-built Folio3 FoodTech Meat ERP to manage operations, improve meat traceability, and stay audit-ready, without extra manual work.

Why does it work?

- Eliminates manual data entry and silos.

- Streamlines planning, processing, and delivery.

- Enables fast, traceable recalls and smarter decision-making.

Modernize Your Meat Business

with an ERP Built for the Industry

From slaughter to shelf, we design Meat ERP solutions that handle every cut, spec, and compliance need—

helping you track, trace, and scale with confidence.

Talk to a Meat ERP Specialist

Conclusion

Optimizing the meat supply chain isn’t just about cutting costs. But it’s about building resilience, improving quality, and ensuring regulatory compliance. By integrating smart technologies like real-time tracking, automation, analytics, and ERP systems, meat businesses can streamline operations from processing to distribution.

Softwares like the Folio3 FoodTech Meat ERP provide an integrated platform to manage traceability, cold chain visibility, compliance, and inventory, helping you stay audit-ready and efficient. The future of meat supply chains is digital, and using these strategies now sets your business up for sustainable growth and long-term success.

FAQs

What Is Meat Supply Chain Optimization?

Meat supply chain optimization involves using technology and data analytics to improve efficiency, reduce waste, and ensure quality throughout the entire process from livestock sourcing to retail delivery. This includes implementing real-time tracking, automated inventory management, predictive analytics, and comprehensive traceability systems.

How Does Real-Time Tracking Help in Meat Logistics?

Real-time tracking provides continuous monitoring of temperature, location, and other critical parameters during meat transportation. This enables immediate response to temperature deviations, reduces spoilage, ensures regulatory compliance, and improves delivery accuracy.

How Can ERP Software Improve Demand Forecasting for Meat Products?

Advanced ERP systems combine historical sales data, seasonal patterns, weather forecasts, and market trends to predict demand more accurately. Machine learning algorithms identify complex patterns and correlations that traditional forecasting methods miss, typically improving forecast accuracy while reducing inventory waste.

How Does ERP Software Help With Compliance and Traceability?

ERP systems designed for meat processing provide comprehensive traceability that tracks products from farm to table, recording all handling, processing, and distribution activities. These systems enable rapid recall capabilities, provide complete regulatory documentation, and ensure compliance with food safety standards through automated monitoring and reporting.

What Role Does Automation Play in Optimizing Meat Production?

Production automation improves efficiency through robotic processing systems, automated cutting equipment, and intelligent scheduling. These technologies increase throughput, improve product consistency, reduce labor costs, and enhance worker safety while maintaining high-quality standards throughout the production process.