Food manufacturers face mounting pressure to meet growing consumer demand while managing rising labor costs and maintaining product quality. Traditional palletizing, where workers manually stack goods, often creates production bottlenecks, raises the risk of injury, and adds to operational expenses.

With manufacturing job openings reaching over 620,000 in 2024, according to the Bureau of Labor Statistics, the labor shortage continues to challenge the industry. Automated palletizing has emerged as a practical and scalable solution. Using robotic systems, this technology stacks products onto pallets with speed and precision far beyond manual capabilities.

Food manufacturers adopting automated palletizing report gains in productivity and a significant drop in workplace injuries. It also supports compliance efforts, as consistent product handling aligns with food safety protocols emphasized by regulatory bodies, such as the FDA.

In food production, where items range from fragile baked goods to bulky beverage containers, palletizing is not a one-size-fits-all solution. Automating this process allows businesses to maintain product integrity, reduce damage, and scale efficiently to meet growing market demands.

Understanding Automated Palletizing and How Does it Work in the Food Industry?

Automated palletizing refers to the use of robotic or mechanical systems to systematically arrange products onto pallets for storage, shipping, or further processing. Unlike manual operations where workers lift and position items by hand, these systems use programmable machinery to handle products with consistent placement patterns and timing.

Definition of Automated Palletizing

The technology combines robotics, sensors, and software to create a coordinated system that receives products from production lines and stacks them according to predetermined patterns. These patterns optimize pallet stability while maximizing space utilization, factors that directly impact shipping costs and warehouse efficiency.

Modern automated palletizing systems can handle products weighing anywhere from a few ounces to over 100 pounds. They work continuously without breaks, maintaining consistent speed throughout production shifts. The systems also adapt to different product sizes and packaging types through programmable settings, making them suitable for food manufacturers producing multiple product lines.

How Does Automated Palletizing Work in the Food Industry?

Automated palletizing in the food industry involves a synchronized system of conveyors, robotic arms, and sensors that transfer packaged goods from the production line to pallets in a structured, efficient manner.

These systems are designed to handle various product types and packaging formats, ensuring consistent stacking patterns, minimizing damage, and preparing items for storage or distribution with minimal manual intervention.

Key Components of Automated Palletizing Systems

An automated palletizing system comprises several integrated components that work together to streamline the palletizing process. Each part plays a critical role in ensuring speed, accuracy, and adaptability across different product types and packaging formats. Understanding these components enables food manufacturers to select the most suitable system for their operational requirements.

1. Robotic Arms

Robotic arms serve as the primary handling mechanism in most automated palletizing systems. These articulated machines use multiple joints to pick up products and place them onto pallets with millimeter-level precision. In food applications, robotic arms often feature specialized end-effectors designed for specific product categories.

For example, vacuum-based grippers work well with sealed packages like cereal boxes or frozen food containers, while mechanical claws handle cases of canned goods or bottled beverages. The arms can rotate, extend, and pivot to accommodate different pallet configurations and product orientations. Modern robotic arms also incorporate force sensors that detect when they’re handling fragile items, automatically adjusting grip strength to prevent damage.

2. Conveyor Systems

Conveyor belts transport products from packaging lines to palletizing stations, creating a continuous flow that maintains production speed. These systems often include sorting mechanisms that organize products into specific sequences before they reach the robotic handling equipment.

Smart conveyors use sensors to detect product presence and communicate with the palletizing system about incoming items. This coordination ensures the robotic arms are positioned correctly and ready to receive each product as it arrives. Some installations include multiple conveyor paths that allow different product types to be palletized simultaneously on separate pallets.

3. Vision Systems

Cameras and sensors form the “eyes” of automated palletizing systems, identifying product characteristics and confirming proper placement. Vision systems scan incoming products to determine their size, shape, orientation, and position on the conveyor. This information guides the robotic arms in making precise pickup and placement movements.

Advanced vision systems can read barcodes or QR codes on packages, enabling lot traceability and inventory management integration. They also perform quality checks, identifying damaged packages that should be removed from the palletizing process. Some systems use 3D imaging to assess pallet stability as products are stacked, making real-time adjustments to placement patterns when necessary.

4. Software Integration

The software layer coordinates all system components while connecting to broader manufacturing execution systems (MES) and food ERP platform. This integration allows automated palletizing to respond to production schedule changes, inventory requirements, and shipping priorities in real time.

Modern palletizing software includes machine learning capabilities that optimize placement patterns based on historical performance data. The systems track metrics like pallet stability during transport, space utilization efficiency, and cycle times to continuously improve operations. Integration with warehouse management systems ensures pallets are labeled correctly and routed to appropriate storage or shipping areas.

The Palletization Process in Food Manufacturing

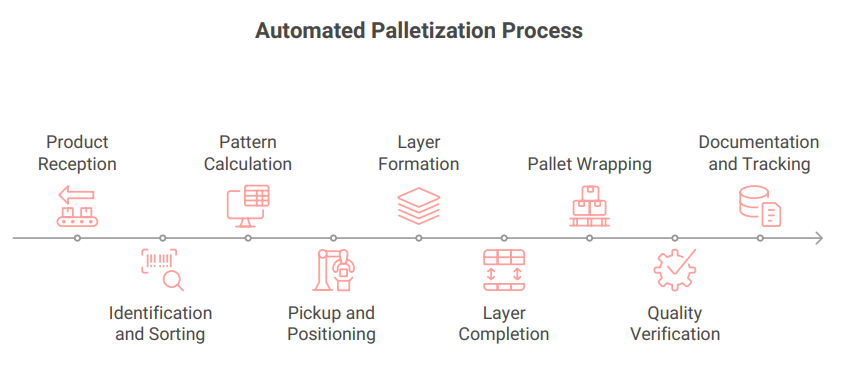

The automated palletization process follows a systematic sequence that transforms individual products or cases into organized, stable pallets ready for distribution:

- Product Reception: Items arrive at the palletizing station via conveyor systems, typically coming directly from packaging or case-forming equipment.

- Identification and Sorting: Vision systems scan each product to confirm specifications, check for damage, and determine the appropriate handling method.

- Pattern Calculation: Software determines the optimal stacking pattern based on product dimensions, weight distribution requirements, and pallet size constraints.

- Pickup and Positioning: Robotic arms utilize suitable end-effectors to lift products and position them in designated locations on the pallet.

- Layer Formation: Products are arranged in organized layers, with the system ensuring proper alignment and spacing for stability.

- Layer Completion: Once a layer is complete, the system may place slip sheets or cardboard separators before beginning the next layer.

- Pallet Wrapping: Completed pallets are moved to wrapping stations, where stretch film or shrink wrap secures the load for transport.

- Quality Verification: Final inspection systems check pallet stability, height limits, and load security before releasing pallets to warehouse areas.

- Documentation and Tracking: The system generates shipping labels, inventory records, and traceability data for each completed pallet, ensuring accurate tracking and record-keeping.

Moreover, the automated palletizing for food and beverage must be able to accommodate a wide range of product characteristics. Fragile items, such as potato chips, require gentle handling and specific stacking limits, while dense products, like canned goods, need careful weight distribution to prevent pallet instability.

The systems adapt to these requirements through programmable parameters that optimize handling for each product type. Temperature considerations also play a role in food palletizing automation.

Frozen and refrigerated products require faster processing to minimize temperature exposure. Some automated palletizing for food and beverage systems include climate-controlled palletizing areas to maintain product quality during the stacking process.

Benefits of Automating the Palletizing Process

Food manufacturers implementing automated palletizing systems typically experience significant operational improvements across multiple performance metrics. Below are some of the benefits of automating the palletizing process:

Improved Efficiency

Automated systems operate at consistent speeds that often exceed manual palletizing rates by 200-300%. While human workers stack 200-400 cases per hour, robotic systems handle 600-1,200 cases per hour with consistent performance throughout shifts. This speed advantage compounds during peak production periods when manual operations slow due to worker fatigue, creating predictable output for accurate planning.

Reduced Labor Costs

Automated palletizing reduces direct labor requirements, redirecting workers to higher-value tasks that require human judgment. The financial impact extends beyond wage savings, as it also reduces workers’ compensation claims related to repetitive strain injuries and back problems. Food manufacturers also eliminate dependency on seasonal, temporary labor, avoiding overtime costs and production delays during peak periods.

Consistency and Accuracy

Automated systems execute identical stacking patterns repeatedly, creating uniform pallets that maximize stability and space efficiency. Robotic arms position products within millimeters of target locations, creating arrangements that resist shifting during transport. Vision systems automatically detect and reject damaged products, preventing defective items from reaching customers while maintaining high-quality standards.

Enhanced Food Safety Compliance

Automated systems reduce human contact with food products, minimizing contamination risks and supporting HACCP protocols. The technology maintains detailed logs of handling processes, temperatures, and timestamps that auditors require for compliance verification. Consistent handling procedures eliminate variability in food safety practices, helping manufacturers meet FDA requirements and pass third-party certifications more reliably.

Improved Workplace Safety

Manual palletizing is associated with a significant number of workplace injuries, particularly in lifting-related incidents among manufacturing workers. Automated systems eliminate repetitive lifting motions that lead to musculoskeletal disorders, reducing injury rate. This creates safer work environments while lowering insurance premiums and workers’ compensation costs for food manufacturers.

Better Space Utilization

Automated palletizing optimizes product placement to maximize pallet density and warehouse space efficiency. Systems calculate optimal stacking patterns that increase cases per pallet as compared to manual operations. This improvement reduces transportation costs, warehouse storage requirements, and overall logistics expenses while maintaining load stability during shipping.

24/7 Operational Capability

Automated systems operate continuously without breaks, shift changes, or performance degradation, supporting round-the-clock production schedules. This capability becomes critical during seasonal peaks or when urgent orders arise, as manual operations often face limitations. Continuous operation maximizes equipment utilization and meets demanding delivery schedules that manual palletizing cannot consistently accommodate.

Conclusion

Automated palletizing has evolved from a luxury technology to an operational necessity for competitive food manufacturers. The combination of labor shortages, increased safety requirements, and pressure for operational efficiency makes automation an attractive investment for companies seeking sustainable growth.

As food companies continue scaling operations to meet consumer demand, automated palletizing provides the reliability and flexibility needed to support growth without proportional increases in labor costs or operational complexity. The technology represents a foundation for future automation initiatives that can further optimize food manufacturing operations.

FAQs

What is Automated Palletizing?

Automated palletizing is the use of robotic or mechanical systems to stack products onto pallets for storage or shipping. In the food industry, these systems use robotic arms, conveyor systems, and vision technology to handle products with consistent speed and precision, replacing manual stacking operations that are slower and more prone to injury.

How Does Automated Palletizing Benefit Food Manufacturers?

Food manufacturers gain multiple benefits from automated palletizing, including increased throughput (often 200-300% faster than manual operations), reduced labor costs, improved workplace safety, and consistent product handling. The technology also supports better inventory tracking and quality control.

How Can Automated Palletizing Improve Food Manufacturing Efficiency?

Automated palletizing improves efficiency by eliminating bottlenecks in production lines, maintaining consistent operating speeds throughout shifts, and reducing product damage that leads to waste. The systems also optimize pallet configurations for better space utilization in shipping and storage, reducing transportation costs and warehouse requirements.

How Does Automation Improve Product Traceability?

Automated palletizing systems integrate with inventory management software to track each product as it’s placed on pallets. This creates detailed records of pallet contents, including lot numbers, production dates, and product codes.