Food operators face a constant push‑pull between innovating to attract customers and adhering to rigorous safety standards. The FDA Food Code offers a science‑based, risk‑focused playbook that helps operators, quality assurance (QA) teams, and inspectors pull in the same direction. Understanding the Code means fewer violations, easier audits, and stronger consumer confidence.

This guide is written for owners and operators of restaurants, delis, retail food stores, commissaries, and ghost kitchens, as well as QA managers, health inspectors, and food safety consultants. It explains what the Food Code is, who creates it, and why it matters. You’ll learn how to navigate its eight chapters, prepare for inspections, and avoid common violations with a step‑by‑step roadmap for operationalizing the Code.

What is the FDA Food Code?

The FDA Food Code is a model set of regulations developed by the U.S. Food and Drug Administration (FDA) to safeguard public health and ensure that food sold at retail and served in food‑service establishments is unadulterated and honestly presented. Unlike federal statutes, it is not law; instead, it offers the FDA’s best advice for a uniform system of provisions that state, local, tribal, and territorial jurisdictions may adopt. The Code covers operations as diverse as restaurants, retail food stores, delicatessens, mobile food units, commissaries, ghost kitchens, and institutional feeding operations.

Why does such a model exist? Foodborne diseases exact a substantial toll in illness and economic costs. The Code compiles science‑based best practices and risk controls to reduce these hazards and provides a common language for regulators and industry. Nearly 90 % of the U.S. population lives in a state that has adopted some version of the Code, a milestone credited with reducing norovirus outbreaks and other illnesses.

Though model status allows flexibility, the Code offers tangible benefits when adopted. FDA notes that broad adoption reduces illness risk, creates uniform standards (avoiding conflicting local requirements), eliminates redundant processes, and standardizes inspections. It also recognizes equivalent public‑health alternatives so jurisdictions can tailor requirements without compromising safety.

Who Produces the Food Code & How It’s Developed

The FDA authors and publishes the Food Code, but its development is a collaborative process driven by diverse stakeholders.

Conference for Food Protection (CFP)

The Conference for Food Protection (CFP), a public–private partnership of regulators, industry, academia, and consumers, plays a central role. At its biennial meetings, CFP members debate issues and submit recommendations. After internal review, FDA incorporates approved recommendations into either an interim Supplement or a new full edition of the Code.

Participation of Federal Agencies

The Centers for Disease Control and Prevention (CDC) and the U.S. Department of Agriculture’s Food Safety and Inspection Service (USDA/FSIS) provide epidemiological data and technical expertise; they concur on changes to ensure harmonization of retail and meat/poultry safety rules.

Contributions from Specialized Conferences

The National Conference on Interstate Milk Shipments and the Interstate Shellfish Sanitation Conference also contribute through formal issue-submission processes.

The FDA acknowledges these organizations and the many individuals, regulators, industry leaders, educators, and consumer advocates whose contributions ensure that the Code remains scientifically sound.

How often is the FDA food code updated? Notably, the Code’s release cycle changed. Between 1993 and 2001, the FDA issued new editions every two years, but with CFP support, it moved to a four‑year interval with interim supplements. The 2022 edition is the 10th edition, and the 2024 Supplement reflects recommendations from the 2023 CFP meeting, showing how stakeholder input drives continuous improvement.

Update Cadence & Version History of FDA Code

The FDA’s update cadence aims to balance scientific responsiveness with regulatory stability. After the 1993 inaugural Code, editions appeared in 1995, 1997, 1999, and 2001. Starting in 2005, editions moved to a four‑year cycle with interim Supplements. A major cycle adjustment occurred during the pandemic: the planned 2021 edition shifted to 2022 to align with the CFP’s change to an odd‑year meeting schedule.

Below is a summary of major editions and supplements and selected highlights:

| Year | Edition/Supplement | Selected changes & highlights |

| 1993 | 1st edition | Inaugural model code providing unified retail food safety standards |

| 1995–2001 | 2nd–5th editions (1995, 1997, 1999, 2001) | Biennial updates; incremental improvements, improved clarity, risk‑based inspection criteria |

| 2003 | Supplement to 2001 | Implemented recommendations from CFP 2002; transitional measures |

| 2005 | 6th edition | First on four‑year schedule; integrated 2003 supplement |

| 2007 | Supplement to 2005 | Added clarifications on employee health and bare‑hand contact; risk factor emphasis |

| 2009 | 7th edition | Updated definitions, cooking temperatures, and cleaning methods; added Annex materials |

| 2011 | Supplement to 2009 | Emphasized certified food protection managers; updated highly susceptible population provisions |

| 2013 | 8th edition | Streamlined structure; clarified hot/cold holding temperatures and allergen labeling |

| 2015 | Supplement to 2013 | Provided updates on handwashing, sink water temperature, and ready‑to‑eat food handling |

| 2017 | 9th edition | Introduced updates on norovirus risk reduction, time/temperature control for safety foods, and certified food protection manager requirements |

| 2019 | Supplement to 2017 | Clarified cleaning/sanitation distinctions and food employee health reinstatement criteria |

| 2022 | 10th edition | Added sesame as the 9th major allergen; clarified food donation allowances; allowed pet dogs in outdoor dining areas; revised definitions for “intact meat |

| 2024 | Supplement to 2022 | Clarified disinfection of food‑contact and nonfood‑contact surfaces, allowed appropriate reuse of consumer containers, and added culture‑independent diagnostic tests |

While the next full revision is planned for 2026, the FDA may issue additional supplements if emergent issues require prompt attention.

What Changed in the 2022 Food Code & the 2024 Supplement

The 2022 Food Code introduced several pivotal changes that operators must incorporate into training and policies.

- Sesame declared the ninth major allergen: To align with the FASTER Act, the Code adds sesame to the list of major allergens. Facilities must update ingredient listings and prevent cross‑contact. FDA encourages retailers to provide written allergen notifications for unpackaged and bulk foods.

- Food donations encouraged: A new Subpart 3‑204 “Food Donation” clarifies that food prepared and stored according to Code provisions may be donated safely. This supports waste reduction strategies and food banks but requires clear labeling and temperature controls.

- Pets in outdoor dining areas: The Code allows pet dogs to accompany patrons in outdoor seating, provided conditions (e.g., separate entrances, no dog contact with food‑service areas, proper waste disposal) are met.

- Updated definitions and temperature requirements: Definitions for “intact meat,” “mechanically tenderized,” and “time/temperature control for safety foods” were revised for clarity. The required hand‑sink water temperature was lowered to 85 °F (29.4 °C) to conserve energy while maintaining hygienic efficacy. Operators should recalibrate water heaters and train staff accordingly.

- Risk designation updates: Many risk designations (Priority [P], Priority Foundation [Pf], and Core [C]) changed, affecting documentation and inspection emphasis. For example, refilling multi‑use beverage containers is now allowed under specific sanitary conditions.

The 2024 Supplement builds on the following changes with practical clarifications:

- Disinfection guidance: It distinguishes disinfectants from sanitizers and specifies when to disinfect food‑contact, non‑food‑contact, and equipment surfaces. Operators should review chemical labels and update cleaning schedules.

- Refillable containers: New language clarifies which containers can be refilled or reused. For instance, customer‑provided beverage containers may be refilled if they are contamination‑free and single‑use containers are not reused.

- Employee reinstatement using CIDT: Employees recovering from Shiga toxin–producing E. coli, Shigella or nontyphoidal Salmonella infections may return to work after negative Culture‑independent Diagnostic Test CIDT results. Operators should liaise with public health authorities to ensure proper documentation.

- Enhanced food defense & FSMS: The Supplement expands food defense measures, requiring the Person‑in‑Charge (PIC) to monitor for suspicious activities and secure ingredients and finished products. It also clarifies when an FSMS is required, emphasising that robust systems reduce out‑of‑compliance risk factors.

- Thawing oversight: The PIC must ensure that time/temperature control for safety foods is maintained during thawing and be able to articulate intentional adulteration prevention strategies to inspectors.

These updates demand immediate action: update allergen controls, revise donation policies, train staff on disinfection vs sanitation, review container reuse protocols, incorporate food defense procedures, and verify FSMS robustness.

What the Food Code Covers (8 Chapters)

If you’ve ever wondered what the FDA Food Code actually contains, think of it as your operational playbook for food safety. It translates public health science into daily food handling and facility management practices that keep customers safe and regulators satisfied. The Food Safety Code is organized into eight chapters, each addressing a critical aspect of your food business.

Chapter 1: Purpose and Definitions

This chapter lays the foundation. It defines terms and explains the Code’s purpose—to protect public health by reducing the risk of foodborne illness. Understanding these definitions helps you interpret the rules consistently across your team.

Chapter 2: Management and Personnel

Food safety starts with people. This chapter defines the responsibilities of the Person in Charge (PIC), employee health policies, and hygienic practices. It covers illness reporting, handwashing, and personal cleanliness, key points inspectors review closely during audits.

Chapter 3: Food

This is the heart of the food code. It details safe food sourcing, receiving, storage, preparation, cooking, cooling, and serving. You’ll find time and temperature control requirements (TCS foods), cross-contamination prevention, and allergen management, all essential to keeping food safe from farm to fork.

Chapter 4: Equipment, Utensils, and Linens

This chapter sets the standards for equipment design, installation, cleaning, and maintenance. It ensures everything that touches food from cutting boards to thermometers, is durable, easily cleanable, and used correctly.

Chapter 5: Water, Plumbing, and Waste

Here, the FDA Food Code establishes requirements for potable water supply, backflow prevention, handwashing stations, and waste disposal. A well-maintained plumbing system ensures safe water for food preparation and cleaning.

Chapter 6: Physical Facilities

Covers your building itself, floors, walls, ceilings, lighting, ventilation, and pest control. Maintaining clean, well-lit, and well-ventilated facilities directly supports overall food safety compliance.

Chapter 7: Poisonous or Toxic Materials

This chapter guides the storage and use of chemicals like sanitizers, detergents, and pesticides. The goal is clear: prevent contamination of food and food-contact surfaces.

Chapter 8: Compliance and Enforcement

Finally, this chapter explains how the Code is enforced, from inspections to corrective actions. It outlines permit requirements, violations, and enforcement procedures that help regulators ensure uniform application of the food safety code nationwide.

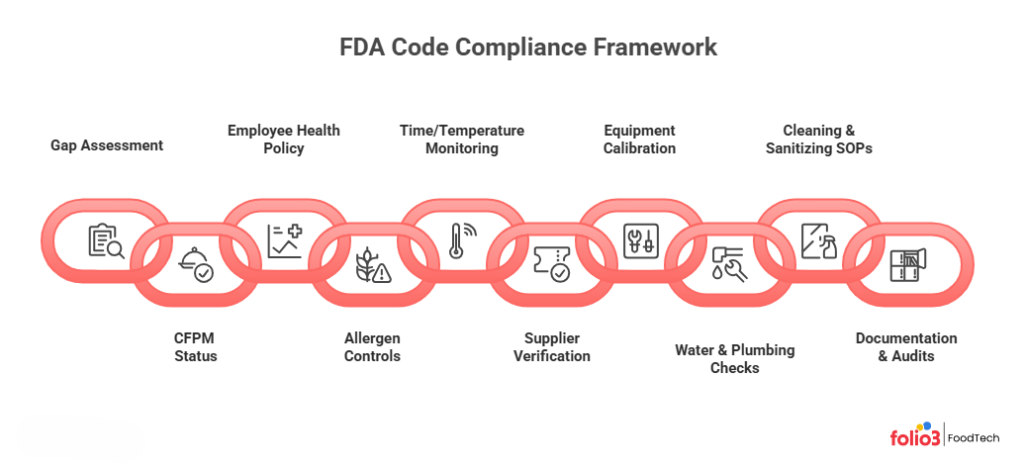

Compliance Roadmap for Operators to Comply with the FDA Code (Step‑by‑Step)

Implementing the Food Code can seem daunting. Breaking it into steps helps integrate requirements into daily operations. Use the following roadmap to build a robust food safety management system:

- Gap Assessment: Compare your current practices to the applicable Food Code version and identify gaps. Tools like the FDA’s Retail Program Standards and compliance management software help automate gap analyses.

- Person‑in‑Charge/(CFPM) Status: Ensure a qualified person is always on duty. Studies show that delis with Certified Food Protection Manager (CFPM) present have fewer out‑of‑compliance risk factors.

- Employee Health Policy: Develop written policies requiring staff to report symptoms of vomiting, diarrhea, jaundice, sore throat with fever, or diagnosed infections. Provide paid leave to encourage honest reporting.

- Allergen Controls: Update ingredient labels and menu boards to include sesame; train staff on cross‑contact prevention; implement written allergen notifications for unpackaged foods.

- Time/Temperature Monitoring: Use calibrated thermometers and digital sensors to log cooking, cooling, hot holding, and cold holding temperatures. The risk factor study shows that robust FSMS significantly reduces time/temperature violations.

- Supplier Verification: Source food only from approved suppliers; maintain records of certifications, audits, and recall history. Use supplier management compliance verification to flag non‑compliant vendors.

- Equipment Calibration & Maintenance: Schedule routine calibration of thermometers, pH meters, and dishwashers; maintain a master sanitation schedule for equipment cleaning. Document calibration to show inspectors.

- Water & Plumbing Checks: Inspect backflow prevention devices, test potable water quality, and service grease traps. Keep plumbing schematics and inspection reports available.

- Cleaning & Sanitizing SOPs: Develop standard operating procedures for cleaning food contact surfaces, disinfection (as clarified in the 2024 Supplement), warewashing, and sanitizing. Use digital checklists to track tasks and record sanitizer concentrations.

- Documentation & Internal Audits: Maintain organized records of training, temperature logs, corrective actions, and supplier certifications. Conduct internal audits using your jurisdiction’s inspection forms, keeping your establishment inspection‑ready.

By following these steps and regularly reviewing the latest Food Code updates, operators can build a proactive food safety culture that reduces risk and eases regulatory interactions.

Inspection Readiness Checklist

Health inspections are snapshots of your program’s effectiveness. Prepare by ensuring the following documents and practices are in order:

- Employee Health Verifications: Signed health policies and logs of illness exclusions. Inspectors may ask employees to describe symptoms that require restriction or exclusion.

- Temperature Logs: Records for receiving, cooking, cooling, hot holding and cold holding. Logs demonstrate compliance with Chapter 3 requirements and help identify trends.

- Sanitizer Test Records: Logs showing that chemical sanitizers and dish machines are tested and within required concentrations.

- Allergen Labeling Accuracy: Ingredient lists highlighting major allergens, including sesame; training records on cross‑contact prevention.

- Warewashing Parameters: Calibration certificates for dishwashers and glass washers; documentation that water is at correct temperatures and detergent/sanitizer concentrations.

- Corrective Actions: Records of corrective actions for previous violations, such as equipment repair logs or retraining documentation.

- Previous Inspection CAPA: Copies of previous inspection reports and Corrective and Preventive Action (CAPA) plans with evidence of completion. Inspectors may refer to these to verify ongoing compliance.

Common Violations & How to Fix Them

The FDA and CDC identify five risk factors contributing most to foodborne illness. Recognizing common violations and implementing targeted fixes enhances compliance.

- Improper Holding Temperatures: Cooling and hot/cold holding violations are among the most frequent; ensure TCS foods are cooled rapidly, maintain refrigerators ≤41 °F (5 °C), and hot holding at ≥135 °F (57 °C). Use calibrated thermometers and monitor logs.

- Inadequate Cooking: Undercooked animal foods (e.g., poultry, ground beef) or improper reheating of leftovers. Follow required cooking temperatures and verify with a sanitized thermometer; train staff to use time/temperature charts.

- Contaminated Equipment: Dirty cutting boards, inadequate separation of raw and ready‑to‑eat foods, or inadequate cleaning of food contact surfaces. Implement strict cleaning schedules and provide color‑coded utensils.

- Unsafe Food Sources: Receiving food from unapproved suppliers or using home‑prepared foods. Maintain supplier approval lists and verify certifications. Reject deliveries that do not meet specifications (e.g., damaged packaging, incorrect temperatures).

- Poor Personal Hygiene: Lack of handwashing, employees working while ill, or bare‑hand contact with ready‑to‑eat foods. Provide accessible handwashing stations; enforce glove use and no bare‑hand contact; empower employees to report illness.

Focusing on these risk factors and adopting a robust FSMS reduces the likelihood of violations and protects public health.

How to Stay Compliant with the FDA Code Using a Compliance Management Software

While manual spreadsheets and paper logs can work, they often fall short when regulations change and operations scale. A digital compliance management system centralizes data, automates tasks, and provides real‑time visibility. Our food regulatory compliance software offers features tailored to FDA Code adherence:

- License & Permit Tracker: Track permit expirations, receive alerts, and auto‑generate renewal applications, ensuring nothing lapses.

- Supplier Compliance Verification: Cross‑check supplier certifications and flag non‑compliant vendors, protecting you from unsafe sources.

- Regulatory Audit Preparation: Store audit reports and conduct self‑audits to prepare for inspections.

- Contaminant Risk Alerts: Sync with FDA/USDA databases to receive real‑time contamination alerts using AI risk assessments.

- Cross‑Border Compliance Checker: Validate global export requirements, ensuring adherence to country‑specific standards.

- Cleaning & Sanitation Logs: Digitally track sanitation tasks, send overdue alerts, and integrate IoT sensors for verification.

- Label Compliance Checker & Regulatory Risk Assessment: Verify product labels and identify regulatory gaps before inspections.

- Data Analytics: Gain insights into compliance trends to improve processes and mitigate risks.

Ready to Simplify Compliance for the FDA Code? Consult with our FoodTech experts to see how our solution can fit your specific operations, or book a personalized demo today to experience how digital compliance can transform your food safety management.

FAQs

What is the Purpose of the FDA Food Code?

The purpose of the FDA Food Code is to provide a science-based framework that helps food businesses prevent foodborne illnesses and protect public health.

It serves as a model regulation for state, local, and tribal agencies to standardize food safety practices across restaurants, retail stores, delis, institutions, and mobile food units. By following the Food Code, operators ensure consistent standards for food handling, sanitation, and employee hygiene, reducing health risks and improving consumer confidence.

Is the Food Code a Federal Law?

No, the Food Code is a model regulation, not a federal law. States and local jurisdictions adopt it voluntarily, often with modifications, to ensure consistency in retail food safety standards.

What are the Core Temperature Rules I Should Bookmark?

Maintain 41°F (5°C) or below for cold foods and 135°F (57°C) or above for hot holding. Cook poultry to 165°F (74°C) and ground meats to 155°F (68°C), key benchmarks that prevent bacterial growth and foodborne illness.

Do I Always Need a Certified Food Protection Manager On-Site?

Yes. The FDA Food Code requires at least one Certified Food Protection Manager (CFPM) on duty during operating hours to oversee safe food handling and ensure employee compliance.