If you’re running a food and beverage manufacturing business, chances are you’re spending more time and money on inventory than you’d like, yet still facing out-of-stocks, overages, or unexpected spoilage. The issue isn’t effort; it’s visibility. A 2021 study by Opoku et al. found that inventory accounts for over 70% of capital assets in food processing firms, highlighting how critical effective food and beverage inventory management systems are for operational efficiency and profitability.

Picture this: your food production line is set to start a critical production run. But a single ingredient, something as basic as glucose syrup, is missing. It was marked “in stock” last Friday, but no one caught the miscount. Now you’re forced to reshuffle production, pay overtime, or delay shipments.

This isn’t a rare scenario. For many food and beverage manufacturers, it’s very common. In this blog, we will explore modern strategies for food and beverage inventory management, not just to avoid these breakdowns, but to build a more agile, resilient operation.

How Inventory Management Affects Food Manufacturing Businesses?

Food and beverage inventory management is more than just stocking shelves; it directly impacts how well you can meet consumer demand, manage rising food costs, and maintain quality. With high product perishability, variable demand, and tight margins, even minor inefficiencies can result in major losses.

Here’s how inventory management impacts key areas of a food and beverage manufacturing business:

- Production Continuity: Accurate inventory ensures ingredients and packaging materials are available when needed, preventing costly downtime or production delays.

- Vendor Lead Time Visibility: Poor insight into supplier lead times often results in late deliveries, disrupting production schedules, and causing urgent, costly adjustments.

- Cost Control: Proper stock rotation (FIFO/FEFO), order forecasting, and waste reduction lower holding costs and minimize write-offs from spoilage.

- Batch Quality & Expiry Management: Lack of expiry tracking can lead to batch rejections due to expired or substandard raw materials, impacting product quality and regulatory compliance.

- Cash Flow Optimization: Avoiding excess stock frees up working capital that can be reinvested in equipment, staffing, or R&D.

- Supplier Performance Management: Real-time data helps identify supply bottlenecks or quality issues, enabling smarter sourcing decisions over time.

- Food Safety & Compliance: Lot tracking and expiry monitoring help meet regulatory requirements like FSMA compliance and enable fast, targeted recalls when needed.

Businesses are increasingly adopting advanced technologies to enhance food and beverage inventory management and tracking. For instance, in 2022, Chipotle Mexican Grill tested a high-tech inventory tracking system using radio-frequency identification (RFID) at its Chicago distribution center and selected restaurants. This system allows for real-time tracking of ingredients, improving inventory accuracy and reducing manual counting errors.

Inventory Management KPIs Businesses Should Track

Inventory management KPIs are critical for food and beverage businesses that aim to optimize operations, reduce waste, and ensure product availability. Tracking the right metrics helps manufacturers turn raw data into actionable decisions that support profitability and compliance.

Key KPIs to monitor include:

1. Inventory Turnover

Measures how quickly inventory, such as raw ingredients or finished products, moves through the supply chain. High turnover in food and beverage inventory management indicates efficient use of perishable goods, minimizing spoilage risk. Low turnover often points to excess inventory or slow sales.

Formula: Inventory Turnover = COGS / Average Inventory

2. Days of Inventory on Hand (DOH)

Represents the average number of days inventory sits before being used or sold. In food and beverage inventory management, shorter DOH means fresher products and reduced spoilage; longer DOH may indicate over-ordering or slow-moving stock nearing expiration.

Formula: DOH = (Average Inventory / COGS) × Days in Period

3. Stockout Rate

Tracks how often key ingredients or packaging materials are unavailable when needed, leading to halted production runs. In the food and beverage industry, stockouts disrupt manufacturing schedules, cause order delays, and erode customer trust.

Formula: Stockout Rate = (Stockouts / Total Orders) × 100

4. Waste and Shrinkage Rates

Measures inventory lost due to spoilage, expiration, or theft. High rates in food and beverage inventory management reflect inadequate rotation practices (like not using FIFO), poor storage, or ineffective quality checks.

Formula: Waste Rate = (Lost or Wasted Inventory / Total Inventory) × 100

5. Order Accuracy Rate

Evaluates how consistently customer orders are fulfilled, including correct quantities, lot tracking, and documentation. Accuracy is important for inventory management in food and beverage industry due to regulatory requirements and customer quality expectations.

Formula: Order Accuracy Rate = (Accurate Orders / Total Orders) × 100

6. Backorder Rate

Indicates the percentage of orders delayed due to missing inventory, whether it’s a key ingredient like glucose syrup or a packaging component. High backorders in F&B can trigger costly production delays and damage buyer relationships.

Formula: Backorder Rate = (Backordered Items / Total Ordered Items) × 100

7. Forecast Accuracy

Assesses how well demand forecasts match actual product movement. Poor forecasting can lead to spoilage (from excess perishable stock) and missed sales (from understocking) in the tracking of food and beverage inventory systems.

Formula: Forecast Accuracy = [(Forecast – Actual) / Forecast] × 100

Best Practices for Food and Beverage Inventory Management

Whether you’re running a sauce line or looking for a system to manage your bakery inventory, smart inventory management is what keeps production moving and margins protected. These seven best practices will help you take food and beverage inventory control and make it work smarter for your business.

1. Use the First-In, First-Out Approach

The First-In, First-Out (FIFO) method means using older raw materials before newer ones, a simple rule that can save much money in the food and beverage industry. When you’re working with perishable ingredients, letting even a few pallets sit too long can quietly eat into your margins.

Take dairy processing, for example. If milk powder or cream stabilizers aren’t used in the correct order, you risk quality issues or wasted product. A dairy ERP system can help enforce FIFO by tracking expiration dates and flagging older stock first. Combined with clear labeling and smart storage practices, it keeps inventory moving efficiently.

2. Set Reorder Points and Safety Stock Levels

Running out of a key ingredient mid-production isn’t just frustrating, it’s expensive. Setting smart reorder points and safety stock levels helps ensure that it doesn’t happen. Reorder points act as early warning signals, telling your team when to restock before inventory runs too low. Safety stock, on the other hand, is your buffer, extra inventory that protects you from delays in supply or unexpected demand.

Pro Tip: Use a food and beverage inventory management ERP system to automatically adjust reorder points and safety stock for precise, data-driven restocking.

3. Categorize Inventory Using ABC Analysis

Not all inventory holds the same value or impact on production. ABC analysis helps you prioritize by categorizing raw materials based on their consumption value and criticality.

For example, in a snack manufacturing facility, high-value ingredients like specialty nuts or imported spices fall into the “A” category and require tight control and frequent review. “B” items might include bulk staples like flour or sugar, while “C” could be low-cost seasonings or packaging materials. This approach ensures you allocate resources efficiently, paying more attention to items that drive cost and quality risks while simplifying food and beverage management.

4. Use Tools To Forecast Demand

Using demand forecasting tools helps food manufacturers avoid guesswork when ordering raw materials. For example, a confectionery company can use confectionery ERP to analyze past sales trends to predict how much cocoa or sugar it’ll need during holidays or special promotions. This prevents ordering too much, which risks spoilage, or too little, which can halt production.

These tools factor in seasonality, customer buying patterns, and market changes to give a realistic picture of future needs. When connected to your inventory system, forecasting helps plan purchases smartly and keep production running smoothly, even when demand shifts unexpectedly.

5. Conduct Regular Inventory Audits

Food and beverage inventory tracking audits aren’t just about counting stock; they’re critical for catching discrepancies, reducing waste, and keeping operations running smoothly. Regular food and beverage inventory management checks help identify missing or damaged inventory, record errors, or stock nearing expiry that might otherwise slip through. This proactive approach ensures accurate stock levels and helps avoid costly last-minute surprises during food manufacturing.

Pro Tip: Don’t wait for quarterly audits. Consider spot checks on high-turnover items or critical ingredients. Managing issues early is easier than fixing them later, when the stakes are higher.

6. Track Inventory Batches for Recall Preparedness

No food manufacturer wants to face a product recall or food safety failure, but being unprepared can amplify the damage. Effective batch tracking ensures that if a recall becomes necessary, you can swiftly identify and isolate the affected products, minimizing both financial loss and reputational harm.

Consider the recent case of Hormel Foods, which recalled over 256,000 pounds of its Dinty Moore Beef Stew due to potential contamination with wood fragments. The recall was limited to cans with a specific lot code and establishment number, highlighting the importance of precise batch tracking. Without such detailed records, the management of food recalls could have been broader, more costly, and more damaging to consumer trust.

7. Set Up Inventory Alerts

Unexpected stock shortages or expired products can throw production off track and result in missed deliveries. Inventory alerts help teams act quickly by flagging low stock levels, approaching expiry dates, or delaying supplier shipments. Food and beverage inventory management alerts ensure that critical items, whether raw ingredients or packaging, are always available to keep food processing moving smoothly.

Pro Tip: Use a food ERP system to get real-time alerts for critical inventory events, so your team is notified when something needs attention.

Why Choose Folio3 FoodTech Inventory Management Software For Your F&B Business

Food and beverage inventory management isn’t just about numbers on a screen; it’s about using them to operate the business more efficiently and without any errors. Folio3 FoodTech’s inventory management software is built specifically for the challenges of the food industry, where perishable goods, fluctuating demand, and strict compliance standards complicate things.

Here is a quick glance at the features offered by Folio3 FoodTech’s food inventory management module:

| Feature | Description |

| Real-Time Inventory Tracking | Live visibility into inventory across all sites to prevent delays and optimize fulfillment. |

| Shelf-Life Management | Track expiry dates to reduce spoilage and maintain product quality. |

| Batch and Lot Traceability | Link ingredients to finished goods for fast, accurate recalls and compliance. |

| Catch Weight Management | Handle variable-weight items like meat and cheese for accurate costing and processing. |

| Automated Reordering | Automatically generate purchase orders based on consumption trends and reorder points. |

| Mobile & Barcode Scanning | Enable quick, accurate inventory updates and tracking from handheld devices. |

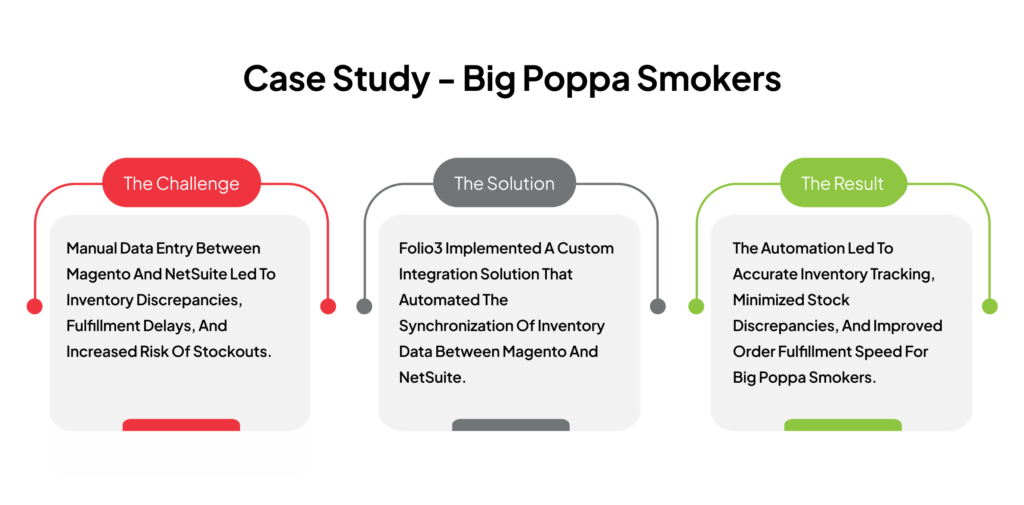

Case Study: How Big Poppa Smokers Optimized Inventory with Folio3

Big Poppa Smokers is a leading online retailer specializing in BBQ products. It is known for its premium offerings and commitment to customer satisfaction. As the business expanded, managing inventory across multiple systems became increasingly complex. We worked closely with Big Poppa Smokers to simplify these operations and support growth.

Optimize Your Food & Beverage Inventory Management

with Purpose-Built ERP Software

We help food and beverage businesses transition from manual inventory tracking to a fully integrated ERP solution, designed to optimize operations, reduce waste, and ensure real-time inventory visibility.

Talk to an ERP Specialist

Conclusion

Inventory management isn’t just about tracking products; it’s about controlling costs, meeting customer expectations, and ensuring consistent product quality. In food and beverage manufacturing, where freshness and precision are non-negotiable, having the right systems and processes in place makes all the difference.

By applying smarter food and beverage inventory management practices, manufacturers can reduce waste, optimize production, and stay prepared for demand shifts or supply challenges. Staying proactive with inventory safeguards operations and creates room for growth and long-term success.

FAQs

What Is Food And Beverage Inventory Management, And Why Is It Critical For Manufacturers?

Food and beverage inventory management tracks raw materials, packaging, and finished goods across your supply chain. For manufacturers, it’s crucial to prevent spoilage, reduce waste, and ensure production continuity.

How Can Food And Beverage Inventory Management Software Help My Business?

The inventory management software for food and beverage businesses automates tracking, forecasting, and stock alerts. It provides real-time visibility, reduces manual errors, and helps ensure compliance with industry regulations, all while freeing up your team to focus on growth and efficiency.

What Role Does Inventory Control Play In Food And Beverage Management?

Inventory control in food and beverage management helps businesses monitor stock levels accurately, optimize order quantities, and reduce overages or shortages. It’s especially important for perishable goods where shelf life directly impacts profitability and food safety.

What Are The Different Types Of Inventory In Food And Beverage Manufacturing?

Common types of inventory in food and beverage include raw materials (like flour or milk), work-in-progress (semi-finished sauces or doughs), and finished goods (packaged products ready to ship). Effective tracking across all stages ensures better cost control and traceability.

How Do I Know If My Food And Beverage Inventory Process Needs Improvement?

If you’re regularly facing stockouts, overstocking, or product spoilage, it’s time to review your food and beverage inventory process. Look for inefficiencies in tracking, reorder timing, and batch traceability, signs that a smarter system might be needed.