Food barcodes may look like simple black lines, but to a manufacturer, quality manager, or co‑packer, they are the bedrock of modern food traceability. These machine‑readable identifiers unlock operational efficiency, help companies meet safety regulations, and build consumer trust. Without them, identifying where a contaminated batch came from or how many pallets were shipped becomes an ordeal.

In the wake of the U.S. Food Safety Modernization Act (FSMA) Section 204, the Food and Drug Administration (FDA) requires food businesses to maintain detailed traceability records and to supply these within 24 hours during an investigation. It means capturing data elements such as lot code, origin, and processing steps for each product. Consumers and retailers are also demanding transparency: shoppers want to scan a label and learn where their meal originated and whether it contains allergens.

Throughout this guide, you’ll learn what a food barcode is and isn’t, why it matters to your business, how to obtain and print barcodes, and how emerging 2‑D codes like QR and digital links can elevate both compliance and customer engagement.

What is a Food Barcode?

A food barcode is a series of bars or squares that encodes information in a format that scanners can read. It isn’t “just another label”; it is a structured data carrier that links a physical product to digital records. A barcode can store a Global Trade Item Number (GTIN), which uniquely identifies each item and packaging level, and can carry additional attribute data such as batch number and expiration date. The “machine‑readable” nature means scanners instantly convert the lines or modules into numbers and letters, eliminating manual keystrokes and errors. Barcodes come in various symbologies: one‑dimensional (1‑D) linear codes like UPC‑A or EAN‑13 and two‑dimensional (2‑D) codes like QR and Data Matrix, each with different data capacities.

Why Barcodes Matter in Food

Barcodes are the unsung backbone of modern food operations, driving accuracy, speed, and safety from receiving to retail. By transforming manual tracking into automated precision, they eliminate costly errors, accelerate traceability, and help you meet strict retailer and GS1 standards.

Operational Efficiency & Data Accuracy

Manual data entry has an error rate of about one mistake per 300 characters. Barcode scanning reduces this error rate dramatically to about one error in 36 trillion characters. For food manufacturers, this means fewer mislabeled pallets, fewer wrong shipments, and more accurate inventory counts.

Efficiency benefits ripple through the plant: scanning incoming ingredients ensures the right lot goes into the right batch, and scanning at packing prevents mis‑picks. Automated data capture also frees operators from time‑consuming paperwork, allowing them to focus on production and quality.

Traceability & Food Safety Compliance

The FDA’s FSMA 204 rule requires firms to assign a traceability lot code (TLC) to foods on the food traceability list and record key data elements from creation to shipping. These records must be retrieved within 24 hours during a recall or outbreak investigation. GS1 identification standards – GTINs, batch/lot numbers, and expiry dates underpin this traceability. Without barcodes linking product units to digital records, complying with FSMA would be nearly impossible.

Barcodes also enable rapid recalls. As per stats, more than half of food recalls cost over US$10 million, and some exceed US$100 million. Robust barcoding shortens the time to identify affected lots, reducing both consumer harm and financial losses.

Retailer & Distributor Mandates

Major retailers require suppliers to use barcodes. Walmart, for example, mandates that suppliers obtain a GS1 company prefix to generate unique GTINs for items sold in its stores. Without UPCs/GTINs, your products simply cannot be listed in large retailer systems. Distributors and third‑party logistics providers (3PLs) also rely on standard barcodes for inbound receiving and cross‑docking. Meeting these mandates isn’t optional; it’s a prerequisite for shelf space and market access.

Barcode Types Used in the Food Industry

Barcodes in the food industry aren’t one-size-fits-all as each format serves a unique purpose, from retail checkout to cold-chain traceability. Understanding the right barcode type helps you optimize compliance, ensure scan accuracy, and build a transparent, connected supply chain.

One‑dimensional (1‑D) Barcodes

- UPC‑A / UPC‑E: The Universal Product Code is the workhorse of North American retail. UPC‑A encodes 12 digits and identifies the manufacturer and products. UPC‑E compresses this information into six digits for small packages like candy or cosmetics.

- EAN‑13 / EAN‑8: International equivalents to the UPC used in Europe and many other regions. EAN‑13 carries 13 digits; EAN‑8 holds eight digits for limited space.

- GS1 DataBar: A family of linear codes that can carry additional data (weight, batch) and are often used for fresh foods like produce.

- GS1‑128 (Code 128): A versatile linear barcode that can encode up to 48 characters of data, including best‑before dates, lot numbers, and quantities. It appears on cases and pallets in distribution.

Two‑dimensional (2‑D) Barcodes

- QR code: Recognisable square modules. When encoded with GS1 Digital Link, a QR code can carry GTINs alongside a web URL, linking to product information and marketing content.

- Data Matrix: A compact 2‑D code that holds up to 2,335 alphanumeric characters and includes error correction. It can embed a GS1 Digital Link for food items requiring more data.

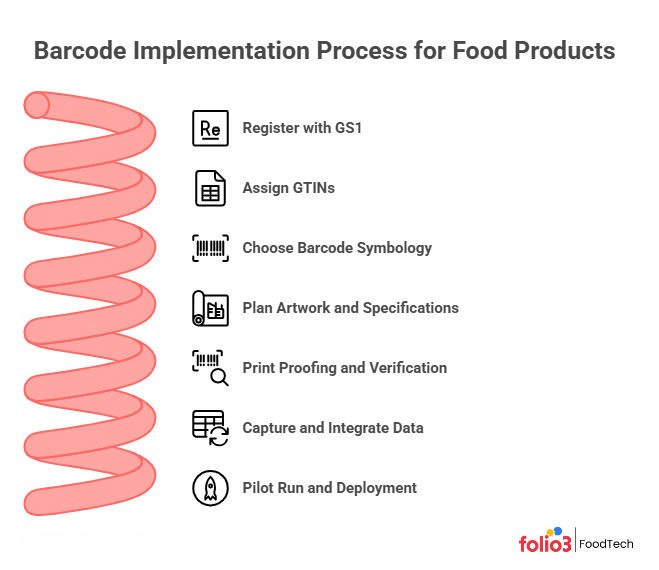

How to Get Barcodes for Your Food Products (Step‑by‑Step)

How do you make barcodes for food products? Implementing barcodes begins long before the first label rolls off your printer. Here’s a structured roadmap for food manufacturers and co‑packers.

Step 1: Register with GS1 and define your GTIN strategy

Obtain a GS1 company prefix from your local GS1 Member Organisation. Above a million companies use these prefixes to create unique identification keys. The prefix length determines how many GTINs you can assign, so plan for future products, packaging levels, and cases.

Step 2: Assign GTINs to all SKUs and packaging levels

With a prefix in hand, assign unique GTINs to each stock‑keeping unit and packaging level. Your local GS1 organisation can advise how many numbers you can allocate based on prefix length. Each variant (flavour, size, case pack) needs its own GTIN; never reuse numbers once retired.

Step 3: Choose the Right Barcode Symbology

Decide whether to use a UPC/EAN for retail units, GS1‑128 for cases, and a QR or Data Matrix for 2‑D purposes. Consider the primary scanning environment and whether you’ll encode static data (such as GTIN) or dynamic data (like lot number). GS1’s guidelines advise selecting a printing process – flexography or offset for packaging with static data; thermal transfer or direct marking for variable data.

Step 4: Plan Barcode Artwork and Print Specifications

Work with packaging engineers to design labels that incorporate proper size, quiet zones, and orientation. EAN/UPC symbols should not be truncated because truncated symbols reduce scan rates. Human‑readable text (HRI) should appear below the symbol; it must show the full number (12 digits for UPC‑A, 13 for EAN‑13, etc.).

Step 5: Print Proofing and Verification

Choose dark colours (black or dark blue) for the bars and a light background for the spaces; avoid red bars since most scanners use red lights. To maintain readability, the quiet zone – the blank area around the barcode – must remain free of graphics or text. Before mass printing, verify the barcode using an ISO/IEC 15416 (1‑D) or 15415 (2‑D) verifier; GS1 recommends achieving at least ISO grade 1.5 (ANSI C) for retail scanning.

Step 6: Capture Master Data and Integrate into Your Systems

Build a master data file linking each GTIN to product descriptions, ingredients, allergen declarations, lot numbers, and shelf‑life data. Integrate this data into your ERP and WMS so that scanning a barcode automatically populates transaction records.

Step 7: Pilot Run, Partner Onboarding, and Full Deployment

Conduct a pilot on a limited set of SKUs to test label placement and scanning across your line, warehouse, and distribution partners. Share sample labels with retailers to ensure they scan correctly. After successful trials, deploy across all products and train staff. Remember that major retailers like won’t accept items without a valid GTIN. Ongoing maintenance includes updating your master data when formulas or packaging change.

Packaging & Printing Considerations for Food Barcodes

Clear, scannable barcodes start with smart packaging design. From label placement to print materials and quality checks, getting these details right ensures every barcode on your food products stays readable across the supply chain.

Placement & Size Guidelines:

- The quiet zone – blank space around the barcode is integral; avoid placing graphics, perforations, or folds within it.

- For retail items, the preferred placement is in the lower-right quadrant of the package back, at least 8 mm (0.3 inches) from any edge and no more than 102 mm (4 inches) from the edge.

- The symbol should be oriented “picket fence” (bars vertical) for optimal scanning; ladder orientation is used only on curved surfaces.

- Avoid placing barcodes on seams, folds, or flaps that can distort them.

Label Material & Print Quality

Select materials compatible with your printing process. Thermal transfer and inkjet printing provide high contrast on paper or synthetic labels, while direct printing on corrugated cases may require GS1‑128 with high contrast. Avoid using reflective or glossy finishes that could cause scanner glare. GS1 colour guidelines recommend dark bars on a light background and discourage printing bars with multi‑coloured processes.

Quality Verification

Barcode verification measures attributes like reflectance, symbol contrast, and defects. ISO 15416 (1‑D) and 15415 (2‑D) standards require averaging multiple scans to assign grades. Printers should aim for grade C (ISO 1.5) or higher. For 2‑D codes, the quiet zone must be at least one module wide on all four sides. Regular verification prevents scanning failures at retail or during audits.

Common Barcode Pitfalls and How to Avoid Them

Even the best labeling strategy can fail if barcodes aren’t managed carefully. From unreadable prints to mismatched data, small mistakes can create costly bottlenecks in your food supply chain. Below are the most common barcode pitfalls and how to prevent them before they disrupt traceability or compliance:

- Data accuracy: Manual entry errors can lead to the wrong GTIN or lot being encoded. Use automated data feeds from your ERP to populate label templates and validate numbers. The error rate for human data entry is roughly 1 error per 300 characters, while properly printed barcodes can reduce it to 1 in 36 trillion.

- Environmental damage: Moisture, abrasion, or extreme temperatures can degrade labels. Choose materials and inks resistant to cold, heat, and humidity, and protect labels on cases with shrink wrap or protective sleeves.

- Supply chain complexity: When products move through multiple processors or distributors, data hand‑offs can break. Ensure each change of custody is recorded and assign a traceability lot code that follows the product.

- Small‑business barriers: Up‑front investment and ongoing maintenance deter some small producers. Early barcode scanners raised productivity by 4.5%, but short‑run gains were small relative to fixed costs, showing why profitability concerns may delay adoption. To mitigate costs, explore GS1‑enabled software services that bundle GTIN licences with label management, and seek support from regional Food Business Centers.

QR Code Traceability & GS1 Digital Link: Engage Consumers and Satisfy Auditors

Two‑dimensional codes like QR and Data Matrix are poised to transform food labelling. QR codes can embed a GS1 Digital Link, a web‑friendly URL format that incorporates a GTIN and other attributes. When scanned, the link resolves to different resources depending on context: a consumer may see an ingredient list and allergen information, while a retailer may access batch-level traceability and recall instructions. Because QR codes hold more data and incorporate error correction, they remain readable even when part of the symbol is damaged.

GS1 US is spearheading Sunrise 2027, an industry transition toward scanning 2‑D barcodes at the point of sale. During this period, packages may carry both a traditional UPC and a 2‑D code. The benefits include more data in less space, fewer labels, improved inventory management, enhanced recall readiness, and the ability to communicate sustainability information to consumers.

Exporters to the European Union should be aware of the emerging Digital Product Passport (DPP). Starting in 2024, the EU will require most products sold in the bloc to include a DPP containing a unique product identifier, compliance documentation, materials composition, environmental impact, and disposal recommendations. Data will be accessible via a digital means, often a 2‑D barcode, enabling cradle‑to‑grave transparency. Linking QR codes to digital passports can boost consumer trust, support circular‑economy goals, and open new export markets.

Real‑World Use Cases of Food Barcodes Across the Supply Chain

From production lines to retail shelves, food barcodes connect every stage of your supply chain with precision and accountability.

Manufacturing & QA

On production lines, scanning ingredient barcodes confirms that the right raw materials are used and records lot numbers. Barcode scanning in quality assurance ensures samples are correctly associated with test results. In sectors such as healthcare, barcoding of medicines reduces errors in drug administration and specimen transport, illustrating how automated scanning improves safety.

Warehouse & Distribution

In warehouses, barcodes on pallets and cases enable real‑time location tracking. Each scan updates the WMS and ERP, reducing picking errors and improving inventory accuracy. In supply chains, combining RFID and barcode technology provides real‑time visibility; automated data capture minimizes manual intervention, reduces errors, and allows seamless integration with ERP systems. This integration synchronizes inventory data with sales, procurement, and production planning.

Retail & Consumer‑level Tracking

At retail, barcodes ensure fast checkout and accurate pricing. 2‑D codes can link consumers to digital content such as farm origin, nutritional information, recipes, or promotional offers, enhancing engagement. Retailers can also track loyalty or expiry data from scanned codes.

Recall Readiness & FSMA 204 recordkeeping

Having barcodes on each package allows companies to trace products back to specific production runs. When the FDA invokes FSMA 204, firms must provide key data elements within 24 hours. Barcode-enabled traceability reduces the scope of recalls and facilitates targeted withdrawal, protecting brand reputation and public health.

Integrating Barcodes with ERP, WMS & Traceability Systems

Data Fields to Capture

A barcode is only as valuable as the data behind it. In your ERP or traceability system, each scan should capture:

- GTIN: Unique identifier for the product.

- Lot or batch number: Links each package to production records and ingredient sources.

- Expiry or best‑before date: Supports first‑expiry‑first‑out (FIFO) inventory management and reduces waste.

- Quantity/weight: Important for variable‑measure products.

- Supplier and production line: Captures where and on which line the product was made.

Sample Workflow

Here’s a standard workflow to ensure the application of food barcodes in your supply chain:

- Production: Ingredients and packaging components are scanned into the ERP, registering lot numbers and expiry dates. When the finished product is packed, a label with both GTIN and lot number is printed.

- Warehouse: Upon receiving a pallet, warehouse staff scan the GS1‑128 or Data Matrix. The WMS records its location and updates inventory. During picking, scanning ensures the right lot is selected.

- Distribution: Logistics partners scan the barcode upon shipment and receipt. Data is fed back to the ERP and to traceability or blockchain platforms.

- Retail: At the point of sale, scanning the barcode at checkout records the sale and triggers inventory replenishment. If a recall occurs, identifying affected batches is quick and precise.

API & Doftware Integration

Modern barcode scanners can connect via Bluetooth, USB, or mobile applications. Middleware or integration platforms link scanner data with ERP and WMS. Moreover, automated data capture and processing enable seamless integration with enterprise resource planning systems, synchronizing inventory data with sales, procurement, and production planning.

Integrating label printers with ERP ensures that GTINs, lot numbers, and dates are pulled directly from master data, reducing manual errors. For advanced traceability, Application Programming Interfaces (APIs) can push scan events into blockchain‑based or cloud‑hosted traceability platforms, generating immutable audit trails.

How Folio3 FoodTech Helps with Barcodes for Food Traceability

At Folio3 FoodTech, we understand that barcodes are not optional; they are the digital backbone of your food supply chain. Our comprehensive food software suites help you implement, integrate, and leverage barcodes so you can comply with FSMA, enhance transparency, and grow consumer trust. Key benefits of partnering with Folio3 include:

- Food Safety: Automates safety checks, traceability, and recall management across production, distribution, and retail, helping you meet FDA, FSMA, and HACCP regulations.

- Food ERP: A unified ERP platform that manages production, inventory, and compliance for producers, processors, co‑packers, and distributors.

- Food Traceability & Recall: Achieve farm‑to‑fork traceability across ingredients, recipes, and finished goods and execute precise recalls.

- Food EDI & Integration Solutions: Seamlessly connect barcode scanners and label printers with your ERP or WMS, eliminate manual data entry, and reduce paperwork.

- Industry‑specific Modules: Whether you manufacture snacks, beverages, dairy, seafood, or meat, our systems support recipe management, batch control, and cold‑chain logistics.

Ready to make your food traceability smarter and compliant? Talk to our FoodTech experts today to see how barcode-driven automation can eliminate manual errors, simplify compliance, and give you total visibility across your supply chain.

FAQs

Do I Legally Need Barcodes for Food Products?

Barcodes aren’t legally required by U.S. government agencies, but they’re essential for doing business with most retailers and distributors. Grocery stores and major outlets rely on them for inventory tracking, pricing, and checkout. So, if you plan to sell your products in retail environments, having a barcode ensures your items can be scanned and sold smoothly through their POS systems.

What Barcodes Do Grocery Stores Use?

Most grocery stores use the UPC-E, a compact, one-dimensional barcode made up of six digits. It’s ideal for smaller product packaging and is widely recognized across global retail systems for quick and efficient scanning.

How Do Food Barcodes Improve Recall Efficiency?

Barcodes make recalls faster and more precise by helping you trace exactly which batches are affected. This minimizes health risks, prevents waste, and reduces costs during a recall. They also play a crucial role in maintaining compliance with food safety regulations.

Can Small Food Businesses Benefit from Barcode Traceability?

Absolutely. Barcode traceability helps small food businesses protect consumer health, meet regulatory standards, and build trust with customers. As supply chains become more complex, traceability gives smaller operations better visibility, improved control, and the ability to respond quickly to potential risks.