Food safety managers and processors know that the threat of invisible microbes looms over every batch of food. Every year, contaminated foods sicken an estimated 48 million people, hospitalize 128,000, and kill roughly 3,000 Americans. Outbreaks erode consumer trust and can trigger expensive recalls that reverberate across supply chains; half of all recalls cost more than US$10 million, and nationally distributed products can push losses toward US$100 million.

Rather than wait for a crisis, the Food Safety Modernization Act (FSMA) shifted U.S. policy from reacting to illness toward preventing contamination. For manufacturers, this preventive mindset means adopting robust pathogen testing programs that catch hazards early, validate sanitation, and reassure customers.

This comprehensive guide explains why pathogens matter, how to choose the right detection methods, and how to build an effective, risk‑based testing program. It balances technical detail with plain language so you can engage your team, select appropriate laboratory partners, and protect your brand.

Understanding Pathogens & their Impact

Foodborne pathogens are microorganisms, typically bacteria, viruses, or parasites, that cause disease when ingested. Some produce heat‑stable toxins, while others infect the intestines or blood. According to the U.S. Centers for Disease Control and Prevention (CDC), about 31 known pathogens account for 44 % of foodborne illnesses; the remaining diseases are linked to unidentified agents. It means that detection must be broad enough to catch both common culprits and emerging threats.

Why are Pathogens Dangerous?

Once pathogens enter a food product, they can multiply under favorable conditions or linger for months in dry goods. Ingesting contaminated foods can lead to gastroenteritis, severe infections, or even death, particularly in pregnant women, older adults, and people with compromised immunity. Because clinical laboratories only identify a fraction of all cases and many illnesses are unreported, the actual burden is likely higher. As a result, testing gives producers a chance to prevent foodborne pathogens before they reach consumers.

Major Foodborne Pathogens

Several pathogens dominate foodborne illness statistics:

- Norovirus is the leading cause of illness; it spreads easily via contaminated produce, seafood, and food handlers.

- Salmonella spp. live in the intestines of animals and can contaminate raw meats, eggs, dairy, and produce. They can survive for extended periods in low‑moisture foods such as spices and powders.

- Clostridium perfringens produces heat‑stable toxins that flourish when cooked foods cool slowly.

- Campylobacter is commonly associated with poultry and raw milk.

- Staphylococcus aureus produces enterotoxins that may remain active even after cooking.

- Listeria monocytogenes is unusual because it thrives in moist environments and is tolerant of refrigeration. It mainly threatens ready‑to‑eat foods and vulnerable consumers.

- Shiga toxin‑producing E. coli (such as O157:H7) can cause life‑threatening kidney failure, particularly in children.

In addition, Bacillus cereus (in rice and pasta), Cronobacter sakazakii (in powdered infant formula), and emerging pathogens like Vibrio and Hepatitis A underscore the need for vigilance. No single test covers every organism, so risk assessment guides target selection.

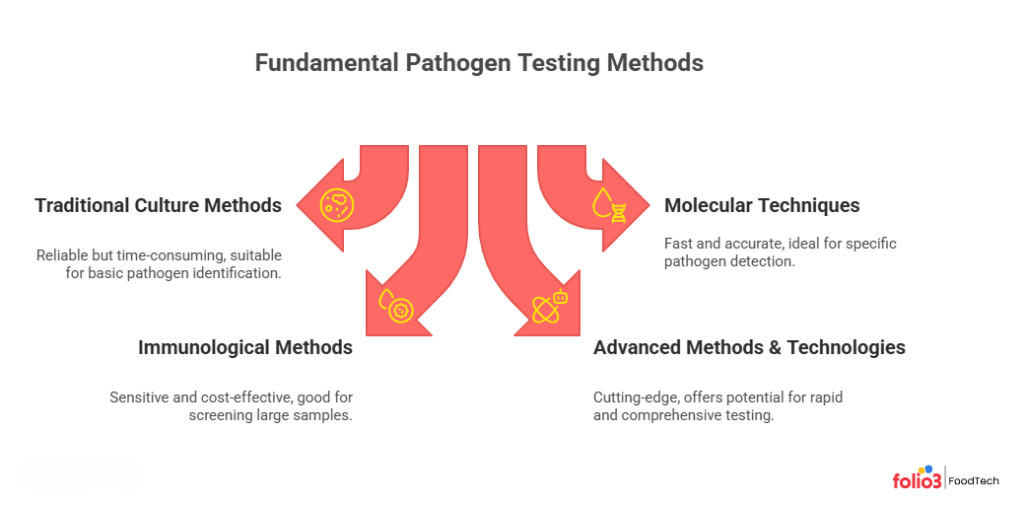

How Pathogen Testing in Food Works: Fundamental Methods

How do you test for pathogens in food? Choosing the right detection technique depends on your product matrix, target organism, desired turnaround, and budget. No single method fits all scenarios, so many companies combine rapid screening with confirmatory culture.

Traditional Culture Methods

Classic microbiological culture remains the gold standard. Samples are enriched and plated on selective agar to isolate colonies, which are then identified and enumerated. Cultures provide hard evidence and allow further strain typing, but take two to five days for results. These delays can hold inventory and complicate just‑in‑time supply chains. For processors of perishable goods, culture is often reserved for confirmatory testing after rapid screening.

Molecular Techniques

Modern food safety relies on precise, science-driven tools that can uncover contamination risks invisible to the eye. See how molecular-level testing has revolutionized accuracy, speed, and confidence in food pathogen detection:

PCR amplifies specific segments of DNA through repeated heating and cooling cycles. When primers match the pathogen’s genes, the assay produces millions of copies that are detected via fluorescence. Commercial PCR systems such as Eurofins’ BACGene/BAX® and the Enteric Pathogen Risk Indicator (EPRI™) can detect Salmonella and Shiga‑toxin‑producing E. coli within hours. The sensitivity of PCR is high, but inhibitors present in complex foods require careful sample preparation and controls.

LAMP uses a set of four to six primers and a strand‑displacing polymerase to amplify target DNA at a constant temperature. It eliminates the need for thermocyclers and enables portable, field‑friendly devices for environmental monitoring or on‑farm testing. Results can be visualized through turbidity or fluorescence. However, designing specific primers and validating results remain crucial to avoid false positives.

ddPCR partitions a sample into thousands of water‑in‑oil microdroplets, each acting as an independent PCR microreactor. After amplification, droplets are counted as positive or negative to provide absolute quantification of target DNA. ddPCR excels at detecting low‑level contamination, distinguishing between closely related strains, and assessing gene co‑localization. Its precision makes it valuable for quantifying pathogen load in finished products or validating sanitation, though the instruments are more expensive than conventional PCR.

Immunological Methods

Antibody‑based assays detect proteins or toxins produced by pathogens. Enzyme‑Linked Immunosorbent Assay (ELISA) coats plates with antibodies that bind specific antigens; a secondary antibody produces a color change. Enzyme‑Linked Fluorescent Assay (ELFA) uses fluorescence instead of color. These methods are relatively inexpensive and simple to perform, making them useful for initial screening or toxin detection. However, cross‑reactivity and lower sensitivity mean that results often require confirmatory PCR or culture.

Advanced Methods & Emerging Technologies

As the food industry embraces smarter, data-powered solutions, innovative testing approaches are setting new benchmarks for safety and efficiency. Here are the robust technologies shaping the next era of pathogen detection:

Next‑Generation Sequencing (NGS) reads entire genomes, enabling investigators to identify the exact strain responsible for an outbreak and track its spread through supply chains. Whole‑genome sequencing is used by public‑health agencies to link cases during outbreaks, but is rarely employed for routine screening due to cost and slower turnaround.

MALDI‑TOF Mass Spectrometry profiles the protein composition of microbes. By comparing the mass spectrum of an isolate to reference libraries, laboratories can identify species within minutes. It is valuable for confirming the identity of isolates obtained from culture, but it does not directly detect pathogens in complex matrices.

Biosensors and Lab‑on‑a‑Chip Systems miniaturize laboratory functions onto microchips. Electrochemical sensors, photonic devices, and microfluidic cartridges can detect pathogens directly in food or environmental samples. Some experimental systems achieve detection limits below a single colony‑forming unit per microlitre, delivering results in minutes. Integration with smartphones could soon enable on‑site testing without a traditional laboratory. However, most systems are still prototypes or limited to specific organisms, and cost remains a barrier.

DNA Microarrays and Aptamers allow parallel detection of multiple pathogens. DNA microarrays immobilize hundreds of probes on a chip; when labeled sample DNA binds to complementary probes, the pattern reveals which organisms are present. Aptamers, short nucleic acid sequences that bind specific targets, can be incorporated into nanosensors for highly specific recognition. These technologies are powerful but require specialized equipment and expertise.

Regulatory Landscape & Compliance Emphasizing Food Pathogen Testing

Food safety rules have tightened over the past decade. In the United States, the FSMA demands that processors identify hazards, implement preventive controls, and verify their effectiveness. This shift from reaction to prevention raises the bar: companies must validate sanitation programs and prove that testing regimes effectively detect pathogens. Overseas, similar frameworks apply.

The European Union’s General Food Law and Commission Regulation (EC) 2073/2005 require microbiological criteria for foodstuffs; Codex Alimentarius offers global guidelines; and ISO 17025 accreditation ensures laboratories meet competence and quality standards.

Aligning testing with Hazard Analysis and Critical Control Points (HACCP) or the Hazard Analysis and Risk‑Based Preventive Controls (HARPC) mandated by FSMA helps document compliance. Meeting these standards not only minimizes regulatory penalties but also protects consumer trust and brand reputation.

Designing an Effective Food Pathogen Testing Program

Effective pathogen control begins with a rigorous hazard analysis. Consider the intrinsic properties of your product (pH, water activity, composition) and the processing environment.

Hazard Analysis & Risk Assessment

Start by mapping your process flow to identify where contamination could occur from raw materials and equipment to storage and distribution. Evaluate historical recall data, supplier records, and scientific literature to determine which pathogens are likely. Then, assign risk levels based on product type and consumer vulnerability. This analysis forms the backbone of your HACCP or HARPC plan and guides the choice of sampling sites and methods.

Sampling Strategies & Environmental Monitoring

Sampling must be statistically sound to detect sporadic contamination. Use randomized or stratified sampling to collect representative samples of raw ingredients and finished products. Environmental monitoring should include swabs of food‑contact surfaces, drains, floors, and equipment. Indicator organisms such as Enterobacteriaceae or coliforms can signal poor hygiene, prompting targeted pathogen tests. Increase sampling frequency in high‑risk zones, after equipment maintenance, or if previous results indicate contamination.

Selecting Methods & Validating Results

Select detection methods based on your risk assessment, required turnaround time, and regulatory acceptance. Rapid PCR or immunoassays are helpful in screening large numbers of samples quickly. However, confirmatory culture remains essential to verify positives and provide isolates for further analysis. Validate new methods in your specific matrix to ensure sensitivity and specificity, and periodically verify that instruments and reagents perform as expected. Combining rapid screening with confirmatory culture reduces false results and supports compliance with FSMA and international standards.

Best Practices for Food Safety & Risk Mitigation from Pathogens

Protecting your products from contamination goes beyond lab results; it’s about embedding prevention into every process. A strong food safety pathogen testing program only works when it’s supported by robust preventive practices.

1. HACCP / HARPC Integration

Map out your critical control points and align your testing plan accordingly. Verify that every step from raw material handling to packaging includes clear limits and corrective actions to prevent contamination before it starts.

2. Sanitation & Hygiene

Consistency is everything. Design equipment that minimizes residue build-up, enforce daily cleaning schedules, and make personal hygiene non-negotiable. Even a single neglected surface can harbor pathogens that bypass testing.

3. Training & Culture

Empower your workforce. Regularly train employees to collect samples correctly, interpret test results, and respond swiftly to positives. A culture of accountability and food safety awareness turns compliance into a habit.

4. Trend Analysis & Continuous Improvement

Use real-time data and statistical process control to identify recurring contamination patterns. Continuous review of food contaminant testing results helps you spot root causes early and sustain long-term safety performance.

Future Trends & Innovations for Pathogen Testing in the Food Industry

The next wave of pathogen testing methods is reshaping how plants detect and respond to contamination.

Portable & Labelless Systems: Compact LAMP-based and microfluidic devices are moving testing from central labs to the production floor. Some systems already deliver results within an hour, enabling immediate corrective action.

Artificial Intelligence & IoT: AI algorithms now combine sensor data, weather trends, and environmental readings to forecast contamination risks, a shift from reaction to prediction.

Nanotechnology & Biosensors: Aptamer-coated nanoparticles and biosensors are achieving detection limits once thought impossible. These labless rapid pathogen testing tools allow real-time monitoring with minimal human input.

Regulatory Evolution: The FDA and GFSI standards to include digital traceability and acceptance of rapid molecular methods. Staying ahead of these innovations isn’t just smart, it’s becoming essential for competitive, compliant food operations.

Conclusion

Food pathogen testing is not merely a regulatory checkbox; it protects consumers, secures brands, and keeps supply chains resilient. Understanding the pathogens that threaten your products, choosing appropriate detection methods, and integrating testing into a comprehensive food safety program are essential steps. The economic and human costs of foodborne illness are high, but preventive testing paired with good manufacturing practices dramatically reduces risk. As technology evolves and regulations tighten, proactive investment in rapid, robust testing will set leaders apart and keep food safe.

FAQs

Can Pathogens Be Detected in Food?

Yes, foodborne pathogens can be detected using a range of testing methods. Traditional culture-based tests confirm bacterial presence, while advanced molecular, immunological, and biosensor techniques offer faster and more precise detection.

How To Tell If Food Has Pathogens?

It’s not always easy to spot contaminated food. However, if food smells sour, rancid, or unusually harsh, it may indicate spoilage by bacteria or pathogens. Still, many harmful microbes leave no visible or sensory clues, so testing remains the safest option.

How To Get Food Tested For Contamination?

You can send food samples to an accredited laboratory that conducts food contaminant testing for pathogens and toxins. If illness is suspected, consult a healthcare professional immediately, preserve the food sample if possible, and keep purchase receipts for investigation.

How Can A Food Handler Detect Pathogens?

Food handlers cannot detect pathogens through taste, smell, or appearance alone. The best defense is prevention, maintaining hygiene, temperature control, and proper sanitation. Regular testing and vigilance for spoilage signs like discoloration or mold help identify potential contamination early.