When you work in food manufacturing or processing, the safety of your products isn’t merely a regulatory hurdle; it’s the foundation of your reputation. Foodborne outbreaks can shutter a business and erode consumer trust for years. Modern retailers increasingly insist on proof of robust food‑safety controls before they’ll stock your products.

That’s where the Global Food Safety Initiative (GFSI) has set the benchmark for food manufacturers and processors to comply with the food safety standards. So, certification against a GFSI-recognized scheme (such as BRCGS, SQF, or FSSC 22000) demonstrates that your facility follows globally accepted practices and is audited by an accredited third party.

An extensive survey of 828 GFSI‑certified food processors from 21 countries found that nearly 90 % of companies believe GFSI certification benefits their food‑safety programs and 74 % would go through the process again, even if customers didn’t require it. The program is continually evolving; new Benchmarking Requirements 2024 mandate stronger food‑safety culture practices and require all schemes to conduct unannounced audits at least once every three years.

In this guide, you’ll learn what GFSI certification is, why it matters, which standard to choose, and how to achieve recognition while controlling costs and avoiding pitfalls.

What is GFSI?

The Global Food Safety Initiative was established in 2002 by the Consumer Goods Forum (CGF). This CEO‑led organization brings together senior leaders from more than 400 retailers and manufacturers across 70 countries. The CGF created GFSI to harmonize food‑safety requirements and reduce audit duplication after high‑profile outbreaks undermined consumer confidence. GFSI doesn’t create its own standard; instead, it benchmarks existing food‑safety management schemes to ensure they meet a shared set of requirements.

Food producers achieve GFSI certification by being audited and certified against one of these recognized schemes by an accredited certification body, not by GFSI itself. Understanding what food safety compliance truly means in the context of GFSI helps clarify how certification fits into broader regulatory obligations. Once approved, their certificate is accepted by major retailers worldwide under GFSI’s “once certified, recognized everywhere” principle.

How GFSI Works

GFSI defines its Benchmarking Requirements through expert consensus. Part III of the current requirements sets expectations for Hazard and Risk Management (HACCP), Food‑Safety Management Systems, and Good Industry Practices (GAP/GMP). Certification program owners (CPOs) must embed these elements in their standards, and accredited certification bodies audit companies against them.

Meanwhile, third‑party auditors now work with more than 100,000 food‑manufacturing facilities in 150 countries. Major retailers such as Walmart and Metro require suppliers to be certified against a GFSI-recognized scheme, driving adoption across supply chains.

GFSI’s requirements are periodically updated in response to emerging risks and stakeholder feedback. A public consultation on the Benchmarking Requirements version 2024 generated over 2,500 comments and led to a new focus on food‑safety culture. It also emphasized global harmonization with Codex and ISO standards, streamlined benchmarking, and provisions for multi‑site operations.

Moreover, certification program owners can seek recognition against the new requirements from 6 January 2025, and existing schemes must transition by 5 September 2025. These updates ensure that GFSI continues to reflect best practice and that your investment remains current.

Benefits of GFSI Certification

Achieving certification against a GFSI-recognized standard yields tangible and intangible benefits that extend far beyond a certificate on the wall:

Global Recognition and Market Access

Major retailers and multinationals require suppliers to hold certification against a GFSI-recognized scheme. With BRCGS, SQF, and FSSC 22000 collectively covering tens of thousands of certified sites in more than 130 countries, certification opens doors to export markets and new customers.

Consumer Confidence and Brand Protection

The cost of a food recall can exceed $10 million, not including reputational damage. Understanding how food safety investments impact profitability helps justify certification costs and demonstrate ROI to financial stakeholders. Certification demonstrates that you follow robust prevention and risk‑management practices, helping to avoid recalls and maintain brand trust.

Regulatory Alignment and Risk Reduction

GFSI-recognized schemes integrate HACCP, Food Safety Modernization Act (FSMA) preventive controls, and other regulatory requirements. A strong food‑safety culture reduces errors and encourages staff to identify hazards early.

Operational Efficiency and Continuous Improvement

The certification process requires documentation, training, and internal audits, which drive better process control and resource management. Many processors in the global survey reported reduced audit duplication and better data for decision-making.

Competitive Advantage

Almost one out of four food companies requires their suppliers to have SQF certification. Therefore, certification becomes a competitive differentiator. Additionally, GFSI schemes are recognized by regulatory agencies, providing smoother inspections and improved relationships with regulators and customers.

Who Needs GFSI Certification?

If you manufacture, process, pack, store, or distribute food or feed products and plan to supply large retailers or export internationally, you will likely need GFSI certification. Major retailers such as Walmart, Tesco, and Carrefour require suppliers to be certified to a recognized scheme. Certification is especially valuable for:

- Food manufacturers and processors seeking to sell branded or private‑label products across multiple countries.

- Storage, distribution, and logistics companies handling perishable goods for retail customers.

- Agricultural producers and co‑packers supplying raw ingredients to certified facilities.

- Packaging manufacturers and ingredient suppliers whose customers demand an audited supply chain.

However, smaller businesses that lack a formal food‑safety system can enter through GFSI’s Global Markets Program. This voluntary program uses a four‑phase model, from self‑assessment to intermediate checklists to gradually build food‑safety capability before pursuing full certification. It’s explicitly designed to help small and medium enterprises align with their customers’ requirements and gain market access without the immediate burden of a full certification audit.

GFSI-Recognized Certification Schemes

GFSI recognizes several food‑safety management standards, each owned by an independent Certification Program Owner. As of 2025, key schemes include:

- BRCGS Global Standard for Food Safety: Prescriptive, product‑focused standard widely accepted in the UK and Europe; emphasizes process and product controls.

- Safe Quality Food (SQF): Popular in North America; built on HACCP and FSMA principles. Administered by the SQF Institute, it requires a designated SQF practitioner and annual audits. For comprehensive implementation guidance, see our complete SQF food safety guide for manufacturers.

- FSSC 22000: ISO‑based scheme that combines ISO 22000, sector‑specific prerequisite programs (PRPs), and FSSC requirements.

- International Featured Standards (IFS): Emphasizes food safety, quality, and legal compliance; widely used by European retailers and processors.

- PrimusGFS: Focuses on fresh produce, with specific modules for field operations, facility audits, and packing houses.

- Global Good Agricultural Practice (G.A.P.): GlobalG.A.P. ensures safe, sustainable farming by certifying agricultural practices to help producers meet international food safety, environmental, and worker welfare standards.

- CanadaGAP: CanadaGAP certifies Canadian fruit and vegetable operations, guaranteeing safe, traceable, and hygienic handling practices that meet both national and GFSI-recognized food safety standards.

- Global Seafood Alliance (GSA) Standard: This certification promotes responsible seafood processing by ensuring strict controls on food safety, environmental sustainability, and worker welfare across aquaculture supply chains.

- Global Red Meat Standard (GRMS): The Global Red Meat Standard certifies red meat processors for hygiene, traceability, and animal welfare, building consumer trust through globally benchmarked food safety systems.

- JFSM Standard: JFSM offers Japan’s recognized food safety certification, aligning local practices with GFSI standards, enhancing export credibility, and ensuring consistent quality across the Japanese food industry.

- ASIAGAP: ASIAGAP certifies agricultural producers across Asia to meet rigorous food safety, sustainability, and worker welfare standards aligned with GFSI’s global benchmarks.

Comparison of Major Schemes

Each scheme can be applied to multiple sectors. GFSI recognizes 15 supply‑chain scopes covering farming, processing, manufacturing, distribution, retail, catering, and feed production. Understanding your sector and customer requirements will guide your selection.

| Scheme | Recognition/Region | Focus & Specificity | Audit Emphasis | Typical Sectors |

| BRCGS | Strong acceptance in the UK/EU and widely recognized by international retailers | Prescriptive, product‑focused standard requiring detailed process controls | Process & product safety controls | Global brands and exporters need traceability |

| SQF | Widely adopted in North America; many major retailers require it | Program‑based; HACCP foundation; integrates FSMA preventive controls | Documentation and HACCP demonstration | U.S. manufacturers, processors, distributors, packaging, and suppliers |

| FSSC 22000 | Global uptake with 37,000+ certified organizations in 150+ countries | ISO‑based management system | Integration of management systems, PRPs, and continuous improvement | Multinationals, large food manufacturers, beverage and dairy sectors |

| PrimusGFS | Predominantly used in the North & Latin American fresh produce sectors | Emphasizes field practices and facility audits | Hazard controls specific to the production | Farms, packing houses, distribution centers |

| IFS | Popular among European retailers | Focuses on both food safety and quality | Traceability, supplier management, and risk control | European retailers & processors |

GFSI Scopes Explained

Before choosing a scheme, identify which GFSI scope applies to your operations. GFSI categorizes the food supply chain into twenty scopes labeled AI to K in its Benchmarking Requirements. These scopes ensure that certification programs address the unique hazards and practices of different sectors. They include:

- Primary production (Scopes AI–CI): Farming of animals, fish, and plants, including aquaculture and horticulture.

- Processing of perishable products (Scopes CII–FII): Meat, fish, dairy, fruit, vegetables, and ready‑to‑eat foods.

- Product manufacturing (Scopes D–FI): Includes products with long shelf life, food ingredients, pet food, animal feed, and bio‑chemicals.

- Catering and retail (Scopes G–H): Restaurants, hotels, and grocery chains.

- Storage and distribution (Scope I): Warehousing, transport, and cold chain operations.

- Packaging (Scope J): Manufacture of food‑contact packaging materials.

- Broker/agents (Scope K): Traders and brokers without physical possession of goods.

GFSI Certification Requirements & Documentation

Regardless of which scheme you choose, all GFSI-recognized programs share core requirements drawn from the Benchmarking Requirements:

Hazard and Risk Management Systems (HACCP)

Companies must conduct a thorough hazard analysis, identify critical control points, implement control measures, and maintain verifiable documentation. It aligns with FSMA preventive controls and international standards. So, practice compliance strategies that comply with FSMA certification to complement GFSI requirements. Regular validation and verification ensure that controls remain effective.

Food‑Safety Management System (FSMS)

A documented system must define the organization’s policies, objectives, and responsibilities for food safety. It includes management commitment, internal audits, corrective actions, incident management, and continual improvement. Our guide to food quality assurance provides frameworks for integrating quality systems with GFSI food safety requirements. Some schemes, such as FSSC 22000, integrate ISO 22000 and emphasize risk‑based thinking across processes.

Good Industry Practices (GAP/GMP)

These cover facility design, equipment maintenance, sanitation, pest control, personal hygiene, allergen management, training, and waste management. Avoiding common food sanitation and safety mistakes during implementation ensures your practices meet auditor expectations. Good practices are tailored by sector but always focus on preventing contamination and ensuring traceability.

Documentation Checklist

For U.S. operations, ensure your system meets FSMA 204 traceability requirements, as auditors increasingly verify alignment with these enhanced record-keeping mandates. Meanwhile, certification bodies will expect comprehensive records, including:

- HACCP or Preventive Control plan with flow diagrams, hazard analyses, and critical limits.

- Standard operating procedures (SOPs) for sanitation, production, equipment maintenance, and allergen control.

- Prerequisite programs (PRPs) such as pest control, supplier approval, and chemical storage.

- Recall and traceability procedures.

- Training records and competency matrices.

- Internal audit schedules, reports, and corrective action logs.

- Records of product testing, calibration, and maintenance.

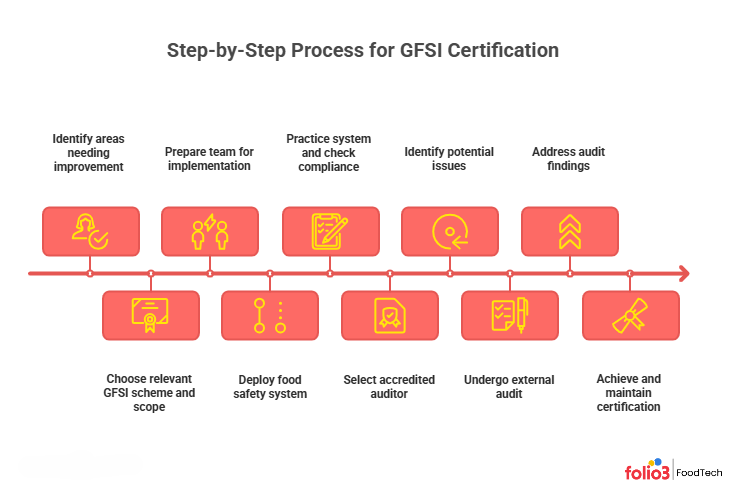

How to Get GFSI Certification – Step‑by‑Step Process

Obtaining certification is a structured journey that requires planning, commitment, and resources. Below is a typical roadmap with approximate timelines. Keep in mind that actual duration varies depending on the maturity of your existing food‑safety system, company size, and complexity.

1. Perform a Gap Analysis

Start by evaluating your current food‑safety management system against the chosen scheme’s requirements. Identify gaps in HACCP plans, documentation, training, and facility practices. Large companies may hire consultants to perform an independent gap assessment; smaller firms can use internal teams or tools from the GFSI Global Markets Program.

2. Select the Appropriate Scheme and Scope

Consider customer requirements, product category, geographic markets, existing certifications, and company culture when choosing a scheme. Retailers in North America often specify SQF, while UK/EU customers prefer BRCGS. Multinationals with ISO‑based systems may find FSSC 22000 integrates more easily. Identify your GFSI scope (manufacturing, distribution, or primary production) to ensure the scheme covers your activities.

3. Train Staff and Assign Responsibilities

Develop awareness of food‑safety culture and specific scheme requirements across the organization. It includes training on HACCP, allergen control, sanitation procedures, and record‑keeping. Appoint a food‑safety team leader; SQF requires a certified practitioner. Training should involve both management and front‑line employees to build ownership.

4. Develop or Update Your Food‑Safety Management System

Based on the gap analysis, update or create HACCP/Preventive Control plans, SOPs, prerequisite programs, food traceability systems, and recall procedures. Document everything clearly and design a records system that is accessible and organized. Use digital tools where possible to streamline documentation and analytics. Integrate FSMA requirements for U.S. operations, including risk‑based preventive controls and environmental monitoring.

5. Implement the System and Conduct Internal Audits

Implement the updated FSMS across all departments. Conduct internal audits to verify compliance management and effectiveness, and address non‑conformities promptly. Many certification bodies expect at least one full cycle of internal audits before scheduling the certification audit. Allocate time for corrective actions and continuous improvement.

6. Choose an Accredited Certification Body

Select a certification body that is accredited to ISO/IEC 17065 or 17021 and recognized by the scheme owner. Using local auditors can reduce travel costs and scheduling delays. Ask about their experience in your sector and request a proposal detailing audit days, fees, and travel expenses. For multi‑site operations, ensure the body understands sampling rules under the new GFSI Benchmarking Requirements.

7. Optional Pre‑Assessment

Some organizations schedule a pre‑assessment or mock audit to identify final gaps. It can be conducted by the certification body (unaccredited) or an external consultant. While optional, it often reduces the risk of major non‑conformities during the actual audit.

8. Certification Audit

During the audit, an independent auditor reviews your documentation, inspects facilities, and interviews staff. Be prepared to demonstrate your HACCP plan, traceability, training records, and corrective actions. Under the 2024 requirements, auditors must also assess your food‑safety culture and may conduct the audit unannounced.

9. Corrective Actions and Follow‑Up

If non‑conformities are identified, you’ll receive a report outlining corrective actions required. Address them within the prescribed timeframe and provide evidence to the auditor. For significant issues, a follow‑up audit may be scheduled.

10. Certification and Maintenance

Once corrective actions are accepted, the certification body issues your certificate. Certification is typically valid for 12 months, after which an annual surveillance or recertification audit is required. Every third audit must be unannounced. Maintain compliance by conducting regular internal audits, updating your FSMS, and fostering a strong food‑safety culture.

GFSI Audit & Ongoing Maintenance

Certification isn’t a one‑time event but a continuous commitment to food safety. Understanding the audit structure and maintaining readiness will help avoid last‑minute scrambles and costly non‑conformities.

What Happens During an Audit?

Certification and food safety audits follow a similar structure: the auditor reviews your documented FSMS, inspects production and storage areas, observes practices, and interviews personnel. The focus is on verifying that policies are implemented effectively and that records support your claims.

Therefore, auditors look for evidence of hazard analysis, training, sanitation, allergen control, supplier approval, and traceability. Under the 2024 Benchmarking Requirements, certification programs must include food‑safety culture evaluations and unannounced audits every three years. During an unannounced audit, there is no prior notice beyond a general window, so your processes must be audit‑ready at all times.

Staying Compliant After Certification

- Keep records up to date: Regularly review and update documentation, ensuring that HACCP plans, SOPs, PRPs, and training records reflect current practices.

- Conduct internal audits and management reviews: Schedule routine internal audits to identify gaps and verify corrective actions. Review audit results with leadership and allocate resources to address issues.

- Monitor suppliers and maintain traceability: GFSI schemes require robust supplier approval and monitoring programs. Maintain clear records of ingredient origins, supplier certifications, and testing results.

- Invest in your food‑safety culture: Empower employees to report issues, celebrate good practices, and provide ongoing training. Implementing proven strategies to avoid food safety failures ensures your system remains robust between audits. A strong culture ensures readiness for unannounced audits and reduces risks.

- Leverage technology: Use digital tools like food quality management software for record‑keeping, trending analysis, and real‑time alerts. Automation reduces paperwork and improves data integrity.

How to Choose the Right GFSI Scheme for Your Business

Selecting a certification scheme is not “one size fits all.” Consider these factors to choose the program that best suits your business:

- Market requirements: Ask key customers which schemes they accept. North American retailers often prefer SQF, while European customers lean toward BRCGS. Some global brands accept any recognized scheme.

- Existing management systems: If your organization already follows ISO 9001 or ISO 14001, FSSC 22000 may integrate more seamlessly because it’s ISO‑based.

- Product category and risk level: Fresh produce growers may choose PrimusGFS or GlobalG.A.P., while manufacturers of packaged goods may prefer BRCGS or SQF.

- Company size and resources: Small and medium enterprises can start with the Global Markets Program to build capacity before progressing to complete certification. Large multinationals might choose schemes that support multi‑site sampling.

- Geographic recognition: Ensure the scheme is recognized in the markets you serve. BRCGS and FSSC 22000 enjoy strong global recognition, whereas some regional schemes have limited acceptance.

Costs & Time for Major GFSI Audits

Understanding the financial and time commitment required for certification helps set realistic expectations and budgets.

Typical Cost Components

Certification audit fees: Audit fees vary by scheme, facility size, number of products, and auditor travel. These figures are approximate industry ranges and will vary.

- BRCGS audits often range from $5,300–$7,500 for a two‑day on‑site audit.

- SQF certification may cost $7,300–$9,000 for the initial audit, with $4,500–$6,000 for annual recertification.

- FSSC 22000 costs are almost similar to these.

- PrimusGFS audits for fresh produce can range from a few thousand dollars for small farms to tens of thousands for large operations.

Consulting and training: Many companies engage consultants to perform gap analyses, develop HACCP plans, or train staff. Fees can range from $2,500 to $12,000, depending on the scope and complexity.

Internal costs: Staff time devoted to developing documentation, training, conducting internal audits, and implementing corrective actions is often the most considerable cost.

Facility upgrades and equipment: Some facilities may need to invest in sanitation equipment, building repairs, pest control systems, or software to meet standards.

Hidden costs: Travel expenses for auditors, re‑audit fees if major non‑conformities are found, corrective action implementation, and document management systems can add thousands of dollars.

Timeframe

Most companies achieve certification within 6–12 months from the start of the gap analysis to receiving the certificate. The actual time depends on the maturity of your existing food‑safety system, the number of sites, the complexity of operations, and resource availability. SQF certification can take a year or more for organizations building a system from scratch. FSSC 22000 may also require additional time due to its management system focus.

Cost‑Control Tips

- Perform a detailed gap analysis to prioritize improvements and avoid unnecessary spending.

- Engage a local certification body to reduce travel expenses.

- Use the GFSI Global Markets Program as a stepping stone to spread costs over time.

- Invest in training and technology early to prevent costly mistakes during the audit.

Budgeting for certification as a long‑term investment rather than a one‑off cost will help you maintain compliance and reap the full benefits of market access and risk reduction.

Overcoming Challenges & Common Pitfalls of GFSI

GFSI certification can be daunting, especially for companies with limited resources. Common challenges include:

- Documentation overload and training gaps: Developing a comprehensive FSMS with SOPs, hazard analyses, and records can overwhelm teams. Overcome this by using standard templates, scheduling regular training, and breaking implementation into manageable phases.

- Audit anxiety and implementation fatigue: Staff may fear inspections or view food‑safety initiatives as extra work. Build a positive food‑safety culture by celebrating good practices, providing clear expectations, and involving employees in problem‑solving.

- Confusion over which scheme to choose: With several recognized standards, companies may struggle to select the right one. Consult customers, review scheme scopes, and seek advice from industry associations or consultants. Begin with the Global Markets Program if you’re unsure.

- Cost overruns: Unexpected corrective actions, extra audit days, or inadequate preparation can inflate costs. Perform thorough pre‑audit checks, set realistic budgets, and select experienced auditors. Consider phased investments to spread costs over multiple years.

- Regulatory changes: The GFSI 2024 update adds requirements for food‑safety culture and unannounced audits. Staying informed and adapting your FSMS quickly will minimize disruption.

Conclusion

Food safety is non‑negotiable, and GFSI certification provides a globally recognized framework for demonstrating your commitment. Whether you operate a small facility or a multinational enterprise, choosing the right scheme and preparing thoroughly will help you safeguard products, access new markets, and build consumer trust. Start by assessing your current system, consulting with customers and experts, and following the step‑by‑step process outlined here. So, take action by booking a free consultation with our foodtech experts to begin your journey toward certification. A safer, more resilient future for your business and consumers awaits.

FAQs

What is the Difference Between SQF and GFSI Certification?

GFSI sets the global framework for food safety benchmarking, while SQF is one of the GFSI-recognized certification programs. Simply put, GFSI defines the rules, and SQF is one of the verified systems that follow them.

Is it Mandatory to Get GFSI?

No, GFSI certification isn’t mandatory, but many top retailers and global buyers require it. Earning a GFSI-recognized certification boosts your market credibility and food safety reputation.

Is ISO 22000 a GFSI?

ISO 22000 by itself isn’t GFSI-recognized, but it forms the foundation for FSSC 22000, which is officially benchmarked and approved under the GFSI framework.

Is GFSI the Same as HACCP?

No. GFSI is a global initiative that benchmarks food safety standards, while HACCP is a specific hazard-control system required within most GFSI-recognized certification schemes.