In the food industry, where precision can make or break an operation, understanding gross weight vs net weight is far from technical; it’s fundamental to compliance, efficiency, and profitability. For manufacturers and processors, these terms govern everything from product labeling and pricing to shipping logistics. The distinction between gross and net weight isn’t just about numbers on a scale; it’s about ensuring that what customers pay for reflects the product they’re receiving. For food producers operating at scale—whether dairy processors, meat packers, or basmati rice brands managing bulk exports—the accuracy of weight measurement directly impacts labeling compliance, shipping costs, and long-term brand trust.

For instance, in 2020, a major food company faced a recall when mislabeled packages of deli meat led to confusion over net weight, prompting regulatory action from the USDA’s Food Safety compliance and Inspection Service (FSIS). This highlights how overlooking the distinction can result in labeling errors, inflated shipping costs, and regulatory penalties. As regulations tighten and consumer expectations rise, the conversation around gross weight vs. net weight is becoming increasingly critical.

This blog breaks down the core differences between the two, explains their relevance in food manufacturing management, and provides actionable guidance on calculating and applying weight measurements effectively.

What is Net Weight?

In the food industry, net weight refers to the weight of the actual product itself, excluding any packaging, protective materials, or containers. It’s a foundational measurement that underpins accurate pricing, compliance with labeling regulations, and trust in the supply chain. Unlike gross weight, which is a factor in tare (the weight of packaging and materials), net weight focuses solely on the consumable product.

In practical terms, net weight is critical in inventory control and yield calculations within food processing plants. For example, in the meat packaging industry, the net weight of a beef cut after trimming, deboning, and removal of non-edible parts dictates both cost calculations and customer pricing models. Similarly, for packaged produce, like boxed berries, the net weight ensures that contractual delivery quantities are met without dispute, especially in export operations where every gram can impact tariff calculations and compliance.

Applications in Food Operations

Net weight plays an integral role across various food industry operations, influencing everything from raw ingredient tracking and quality control to regulatory compliance and pricing accuracy. Whether it’s ensuring that bulk shipments of grains meet precise weight requirements or that seafood packaging aligns with export regulations, net weight safeguards both business profitability and consumer trust.

Production Planning

Accurate net weight data plays an integral role in food processing. Imagine a bakery perfecting the ingredient allocation for a batch of baked goods, getting the flour quantity just right is essential not just for flavor, but also for cost efficiency and minimizing waste. Knowing the precise net weight of each component ensures the operation runs smoothly and economically.

Labeling Accuracy

Under the FDA’s CFR Title 21, displaying net weight in both metric and imperial units isn’t just a box to check; it’s about earning consumer trust and staying compliant. When shoppers pick up a package of frozen vegetables or snacks, they want to know exactly what they’re paying for, and proper labeling makes that transparency possible.

Cost Optimization

If not controlled, the food industry’s ingredient costs affect profitability and operations. In the dairy world, net weight is the driver behind pricing models for products like cheese and yogurt. A manufacturer who accurately calculates the net weight can price their products competitively while keeping an eye on margins. It’s a delicate balancing act between production costs and market demand.

Quality Control Checks:

Net weight measurements verify portion consistency in ready-to-eat meals or frozen foods, reducing customer complaints and ensuring product uniformity, which is ensured by adequate quality management software.

How It’s Ensured

To make all this precision possible, food manufacturers use calibrated, precision-grade scales, often in the form of in-line weighing systems that keep up with production speeds. On top of that, Net Content Control Systems (NCCS) automate the weight checks, catching any errors before products make their way into packaging, ensuring that every unit meets standards and consumer expectations.

What is Gross Weight?

In food manufacturing and logistics, gross weight represents the total weight of a product, including its packaging, containers, and any additional materials used for transport. This measurement isn’t just a formality, it directly affects how products are stored, shipped, and processed through customs. Unlike net weight, which focuses on the consumable product, gross weight accounts for everything that physically accompanies the item.

In practical terms, gross weight determines freight charges, load capacities, and warehouse planning. For example, a pallet of frozen goods has a gross weight that includes the product, cartons, pallets, and any wrapping materials. This full measure ensures safe transport and compliance with legal weight limits.

Applications in Food Operations

Whether it’s determining the legal load for transport or calculating accurate tariffs for export, gross weight measurements keep products moving efficiently. Here’s how gross weight holds significant importance to different food operations:

Logistics & Freight:

Carriers calculate transport costs based on gross weight, helping to prevent overloaded trucks that could face delays, fines, or even safety risks. For instance, a logistics team verifies that a shipment of packaged foods stays within weight limits, ensuring both timely delivery and product integrity. Accurate gross weight data keeps everything on track.

Customs & Tariffs

For exports, gross weight is a critical figure in customs paperwork and tariff calculations. Imagine a shipment of frozen seafood being prepared for export; customs officials depend on accurate gross weight data to determine the correct tariffs and confirm compliance with international regulations. A mistake here could lead to shipment delays or additional fees, impacting profitability and reputation.

Storage & Handling

Warehouse managers rely on gross weight data to efficiently plan storage layouts and verify that forklifts, pallet jacks, and shelving systems can safely handle the load. As a busy warehouse receiving bulk grain shipments, precise gross weight measurements are key to avoiding mishaps and ensuring smooth operations.

How It’s Ensured

Maintaining accurate gross weight measurements involves a blend of reliable equipment and well-integrated systems. It’s not just about having a scale on hand; it’s about ensuring that every measurement is precise and consistently documented, supporting smooth operations and compliance.

Understanding gross weight vs net weight is essential for food industry professionals. This distinction affects everything from transport costs and compliance to operational efficiency. Getting the balance right can mean the difference between smooth operations and costly setbacks.

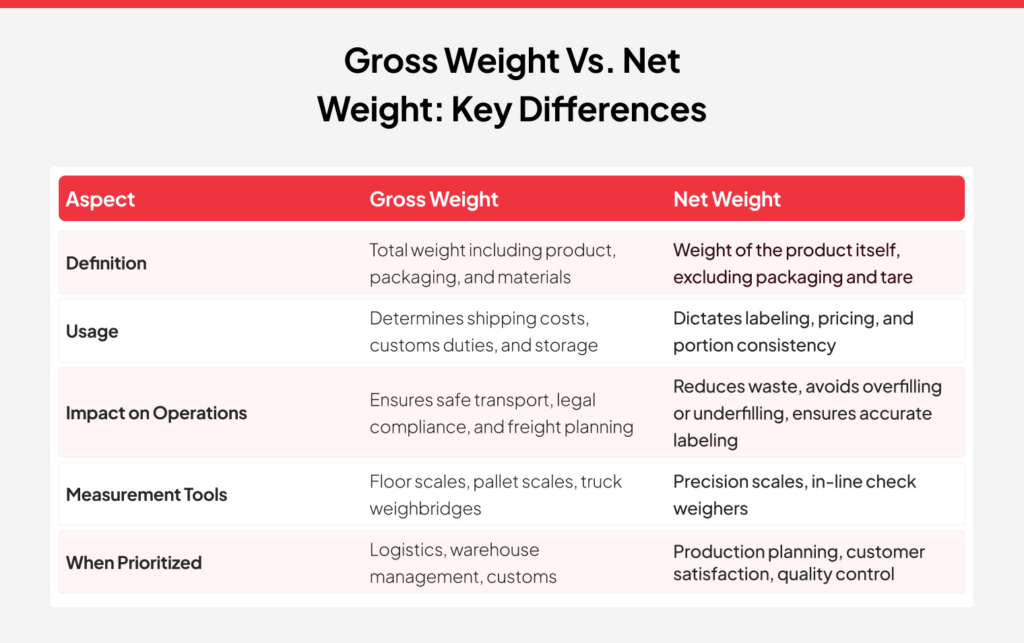

Gross Weight vs. Net Weight: Key Differences

Understanding the practical differences between gross weight vs net weight is essential for maintaining accuracy, efficiency, and compliance in food manufacturing and logistics. Here’s a clear comparison to help professionals apply these concepts effectively:

How to Calculate Gross and Net Weight

In the food industry, precision matters, and that includes knowing how to calculate both gross weight and net weight. These calculations are fundamental, influencing everything from product labeling to shipping logistics.

Net weight is found by subtracting the weight of the packaging from the total weight. This tells you exactly how much product is inside. For example, in a cheese processing facility, a packaged block of cheese might weigh 15 kilograms. If the packaging, plastic wrap, and box weighs 1.5 kilograms, the calculation is simple:

- Net weight = 15 kg (gross) – 1.5 kg (tare) = 13.5 kg

This figure, the net weight, appears on product labels and guides pricing decisions. It’s also crucial for effective compliance management, as underfilled packages can result in penalties or recalls.

On the other hand, if you know the net weight and the tare weight, calculating the gross weight becomes straightforward:

- Gross weight = Net weight + Tare weight

Gross Weight = 13.5 kg + 1.5 kg

Gross Weight = 15 kg

This total figure is essential for managing shipping costs and ensuring trucks and storage facilities can safely handle the load.

For effective food manufacturing and inventory management, these calculations are more than just numbers, they protect both your bottom line and your reputation. Correctly balancing gross weight vs net weight means avoiding extra costs, complying with regulations, and keeping customers satisfied.

Food Industry Regulations And Best Practices

In the highly regulated U.S. food industry, maintaining accuracy in weight measurements is a business necessity. Understanding the balance of gross weight vs net weight ensures proper labeling, fair pricing, and smooth logistics. Here to explore the core regulations and industry best practices that safeguard food businesses and consumers alike.

Key U.S. Regulatory Requirements

FDA Labeling Standards

The Food and Drug Administration (FDA) mandates that packaged food products display an accurate net quantity of contents in both U.S. customary and metric units. The FDA labeling requirement applies to the principal display panel, ensuring consumers receive correct product information. Failure to comply can result in warning letters, product recalls, and reputational damage.

USDA Guidelines for Meat and Poultry

For meat and poultry, the U.S. Department of Agriculture (USDA) requires net weight declarations that reflect the actual product content. The USDA recognizes that minor variations may occur but sets clear standards to prevent misleading practices.

NIST Handbook 133 for Verification

The National Institute of Standards and Technology (NIST) provides official test methods to verify net contents. These standards help federal and state inspectors determine whether packaged foods meet legal requirements.

Best Practices for Accurate Weight Measurement

Regular Calibration and Maintenance

Routine calibration of weighing equipment helps ensure consistent measurements. U.S. food businesses, especially those using food ERP systems, integrate automated checks to minimize errors and enhance compliance efforts.

Integration with Food Supply Chain Management Software

Many producers and distributors now leverage food supply chain management software to track weights at every stage, from production to packaging to shipping. This integration simplifies reporting, reduces manual errors, and supports full product traceability.

Using Check weighers for Real-Time Control

Installing check weighers on production lines ensures each package meets declared weight standards. These systems allow real-time monitoring and automatic rejection of out-of-spec products, safeguarding compliance and quality.

Detailed Documentation and Record-Keeping

Maintaining records of calibration, weight checks, and corrective actions demonstrates due diligence and supports inspections by FDA or USDA officials. Digital records, often integrated within food systems and apps, provide an accessible, audit-ready trail.

Essential Software Features for Handling Weight in Food Supply Chains

After understanding the intricacies of gross weight vs net weight, it’s clear that manual tracking alone isn’t enough for modern food businesses. Custom software solutions, such as Folio3 FoodTech’s Food ERP systems, offer tools that make managing weights easier, more accurate, and fully integrated into operations.

Weigh Scale Integration

By connecting weigh scales directly to ERP systems, weight data is captured automatically, reducing errors and saving time. This is especially crucial in facilities handling large volumes of variable-weight products.

Labeling and Printing

Accurate weight labels are a regulatory necessity. The right ERP allows smooth configuration and printing of labels, even from mobile devices, ensuring compliance across the food supply chain.

Catch Weight Functionality

Products like meat, seafood, and dairy often have variable weights. Meat ERP and Dairy ERP systems with catch weight functionality ensure accurate net weight measurements for these items, simplifying operations and reducing manual corrections.

Bill of Lading (BOL) Tools

Accurate gross weight data is mandatory for BOLs. An ERP that integrates this functionality pulls weight data directly from the system, ensuring accurate shipping documentation and reducing delays.

Real-Time Inventory Reconciliation

By integrating weight data with live inventory management systems, ERPs can automatically reconcile inventory levels based on product weights received, produced, or shipped. This reduces manual stock adjustments and improves accuracy.

Conclusion

Accurate weight measurements are a great success in the food industry. The relationship between gross weight vs net weight affects everything from cost control and compliance to customer satisfaction and operational efficiency. Getting these measurements right, every time, is not just good practice, it’s essential for staying competitive.

In a sector where precision can make or break a business, understanding and applying the principles of gross weight vs net weight ensures products are priced fairly, labeled correctly, and delivered without logistical issues. Companies that invest in smart systems and best practices to manage gross weight vs net weight position themselves to thrive in an increasingly complex marketplace. For food businesses aiming to strengthen their supply chains and ensure smooth operations, mastering gross weight vs net weight isn’t optional, it’s a strategic priority that safeguards both reputation and revenue.

FAQs

Why is it important to distinguish between net weight and gross weight for shipping purposes?

Distinguishing between net weight and gross weight is vital for shipping because it affects freight charges, customs declarations, and compliance with transportation regulations. Gross weight vs net weight discrepancies can lead to miscalculations in shipping costs and potential legal issues, making accurate measurements essential for efficient logistics.

What role does net vs gross weight play in inventory management?

In inventory management, net vs gross weight plays a significant role in tracking the actual quantity of product available for sale (net weight) versus the total weight for storage and shipping considerations (gross weight). Accurate differentiation between these weights aids in efficient stock control and cost management.

Are there regulations that mandate the display of gross weight vs net weight on food labels?

Yes, regulatory bodies like the FDA require that food products display the net weight on labels to inform consumers of the actual product quantity. While gross weight is not typically displayed, understanding gross weight vs net weight is essential for manufacturers to comply with packaging and shipping regulations.