When you’re running a food processing or manufacturing operation, understanding the principles of HACCP becomes crucial than ever. It’s your primary defense against biological, chemical, and physical hazards that could compromise your products from raw materials through distribution. According to USDA data, implementing HACCP systems reduced Salmonella contamination on broiler chicken carcasses by 56 percent between 1995 and 2000, preventing an estimated 190,000 foodborne illness cases annually.

Although HACCP was formalized in the 1990s, it remains the global gold standard because it adapts to evolving processes, equipment, and technologies without losing its core purpose of protecting consumers. The seven HACCP principles food safety professionals rely on today provide a systematic framework that addresses critical stages of food safety.

In this guide, you’ll explore the preliminary steps required before building a HACCP plan, a clear breakdown of the seven principles, practical implementation guidance, and modern digital innovations that make HACCP easier to maintain and verify.

Prerequisite Programs & Preliminary Steps Before the Seven HACCP Principles

Before you begin applying the seven HACCP principles and steps, a strong foundation of prerequisite programs is essential. These programs create the baseline conditions for food safety compliance that allow HACCP to function effectively. Without these fundamentals in place, even the most well-designed HACCP plan may fail to deliver the level of HACCP principles food safety protection your operation needs.

Step 1. Assemble the HACCP Team

A reliable HACCP system begins with a cross-functional team that understands your facility’s processes. This typically includes quality assurance, production supervisors, maintenance or engineering, procurement, and management. Each team member contributes operational insight that ensures the plan is practical and accurate.

Step 2. Describe the Product and Its Distribution

Document the product’s characteristics like ingredients, formulation, processing steps, packaging materials, and storage requirements. Also define how the product is distributed, whether refrigerated, frozen, or ambient.

Step 3. Identify Intended Use and Consumers

Clarify whether the product is ready-to-eat, requires further cooking, or has other specific handling requirements. Identifying the target consumer group is critical, especially when serving infants, the elderly, or immunocompromised individuals who are more vulnerable to foodborne illnesses.

Step 4. Develop and Verify a Process-Flow Diagram

Map each step in your production process, from receiving raw materials to final shipment. Once created, verify the flow diagram on the production floor to ensure every step, bypass, and rework loop is accurately represented.

Step 5. Conduct Preliminary Hazard Analysis

List all potential hazards at each process step and categorize them as biological, chemical, or physical. This stage distinguishes hazard identification from hazard analysis, determining which hazards are significant and must be controlled. A weak or incomplete analysis significantly increases the likelihood of contamination later in production.

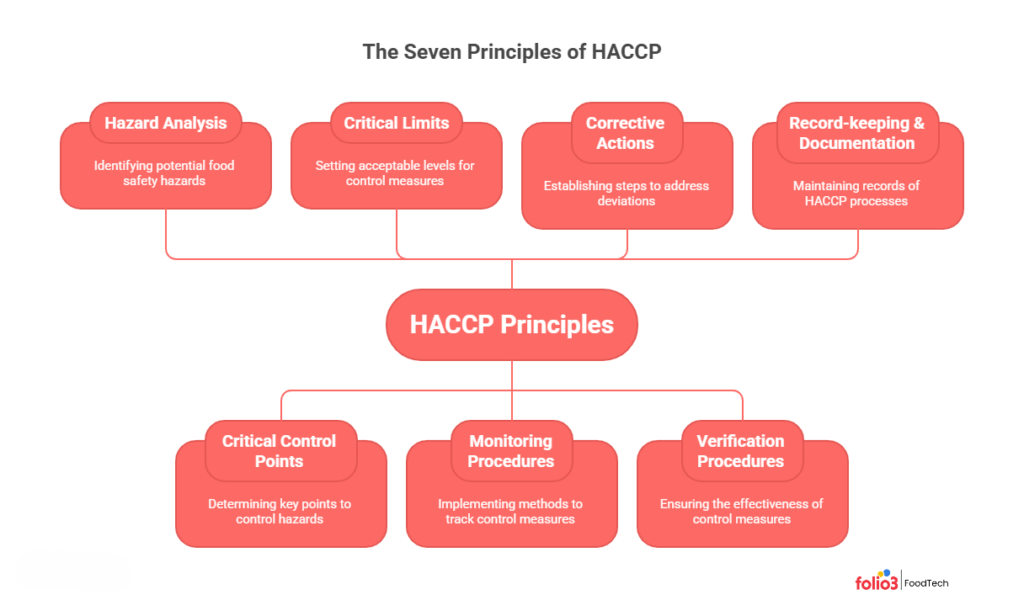

What are the Seven Principles of HACCP?

The HACCP system is built on the seven principles of HACCP, which outline how to identify, control, monitor and document food safety hazards. The first two principles establish the foundation while the remaining five guide control, verification and record keeping. These principles are universally recognized in global food safety standards and form the core of every HACCP plan.

Principle 1. Conduct a Hazard Analysis

The first of the HACCP principles is where your food safety system truly begins. At this stage, your HACCP team lists every step in your production process from receiving raw materials to final shipment and identifies the hazards most likely to occur. This principle requires a two-step process: hazard identification (what could go wrong) and hazard analysis (which hazards are significant enough to require control).

To make this step manageable, your team should build a hazard analysis worksheet. This worksheet typically includes:

- A list of all process steps

- Potential hazards at each step

- Hazard classification (biological, chemical or physical)

- Severity of the hazard

- Likelihood of occurrence

This structured approach ensures you’re assessing hazards consistently and supporting strong HACCP principles food safety outcomes. Hazards can originate from multiple sources like raw materials, ingredients, processing equipment, employee handling practices, storage conditions or distribution environments. Without a thorough analysis, even a well-written HACCP plan can collapse, because control measures may be assigned to the wrong steps or overlooked entirely.

For example, failing to identify the risk of Salmonella survival during cooking may lead to insufficient time–temperature controls. Similarly, not evaluating the risk of glass fragments from broken packaging can allow a serious physical hazard to enter the food supply. These real-world scenarios show why hazard analysis is essential within the 7 principles of HACCP explained.

Principle 2. Determine Critical Control Points (CCPs)

The second step within the HACCP 7 principles is determining your Critical Control Points. A Critical Control Point (CCP) is any step in your process where you can apply preventive measures for food safety control that prevent, eliminate or reduce a food safety hazard to an acceptable level. In practical terms, a CCP is the point where losing control would directly put your customers at risk.

Most facilities use a HACCP decision tree to determine whether a step qualifies as a CCP. The logic is simple: if a loss of control at that step could cause harm and no later step can correct it. This is a core part of the 7 HACCP principles used worldwide.

Common CCPs include:

- Thermal processing such as cooking or pasteurization

- Maintaining cold storage temperatures to prevent bacterial growth

- pH adjustments to inhibit pathogens

- Sanitation steps that prevent cross-contamination

- Physical hazard detection systems like metal or glass detectors

It’s also normal for a single hazard to require multiple CCPs, or for one CCP to control several hazards at once. Because every process is different, CCP identification varies by facility and often relies on a structured HACCP principles decision-tree tool to ensure consistency and accuracy.

Principle 3. Establish Critical Limits

Once you identify a CCP, the next step in the HACCP principles and steps is to define the critical limit for that point. A critical limit is the exact maximum or minimum value a biological, chemical or physical parameter must meet to ensure a hazard is prevented, eliminated or reduced to a safe level. If your process crosses this limit, the CCP is considered “out of control,” and corrective actions must be taken immediately.

Critical limits must always be scientifically validated, not assumed. You can validate them using regulatory standards such as FDA or USDA guidelines, published scientific literature or data from controlled studies. Validation ensures that your chosen limit truly keeps the product safe.

Typical parameters used as critical limits include:

- Time and temperature (for cooking, cooling or pasteurization)

- pH levels (to inhibit pathogen growth)

- Humidity or moisture content

- Salt concentration

- Water activity (aw)

- Viscosity in certain formulations

Make sure every critical limit is clearly documented, visible to your team and supported by equipment that’s properly calibrated. Accurate measurement is essential if your tools are off, your critical limits lose their protective value.

Principle 4. Establish Monitoring Procedures

Monitoring is the part of the HACCP principles and steps that tells you whether your Critical Control Points (CCPs) are staying within their critical limits. It’s your early-warning system. When monitoring is done correctly, you can spot loss of control before unsafe food leaves your facility. When it’s done poorly, hazards can go undetected until it’s too late.

An effective monitoring plan clearly defines:

- What to monitor such as internal cooking temperature, freezer temperature, pH level or metal detector function

- How to monitor the type of instrument used (thermometer, pH meter, data logger)

- Frequency like continuous monitoring when possible, or batch checks at defined intervals

- Who is responsible as the trained employee accountable for verifying the CCP

Modern facilities often rely on electronic monitoring tools like IoT sensors or automated data loggers. These technologies improve accuracy, reduce manual errors and provide real-time alerts when a CCP is trending out of control.

Employee training is crucial. Your team should understand why monitoring matters, not just how to record numbers. The FDA also requires that monitoring procedures, methods and frequencies be fully documented in your HACCP plan.

Principle 5. Establish Corrective Actions

Corrective actions are a critical safeguard within the seven HACCP principles. They outline the exact steps your team must take when monitoring shows that a Critical Control Point (CCP) has gone outside its critical limit. In other words, corrective actions prevent food safety failures by ensuring that an unsafe product never moves further in your process..

Corrective actions fall into two categories:

1. Reactive corrective actions: These address the immediate problem. Examples include discarding food that did not reach the required cooking temperature, recalibrating a thermometer that gave inaccurate readings or sending a sick employee home to prevent contamination.

2. Proactive corrective actions: These prevent the issue from recurring. They may involve repairing malfunctioning equipment, adjusting a process step, strengthening sanitation routines or retraining employees who are responsible for the CCP.

Moreover, documentation is non-negotiable. Your HACCP plan should record what went wrong, the action taken, the final disposition of the product and the preventive steps implemented. Proper documentation also supports audits and demonstrates that your facility follows the HACCP principles consistently and responsibly.

Principle 6. Establish Verification Procedures

Verification is the part of the HACCP seven principles that confirms your system is not only being followed but is actually working as intended. Unlike monitoring, which happens at each CCP, verification looks at the overall effectiveness of your HACCP plan. It ensures your controls are scientifically valid, properly implemented and consistently producing safe food.

Verification has two major components:

- Evaluate the HACCP system: It includes reviewing CCP monitoring records, confirming that corrective actions were taken correctly, checking that critical limits are appropriate and making sure procedures match what’s written in the plan.

- Validate the scientific basis of the plan: This step ensures your control measures truly reduce hazards to safe levels.

Common HACCP principles examples of verification activities include reviewing scientific literature for process validation, conducting microbial testing on finished products, auditing suppliers, checking sanitation effectiveness and calibrating instruments such as thermometers, pH meters or metal detectors.

Remember that verification isn’t a one-time task. It includes initial validation, routine ongoing reviews and reassessment whenever equipment, ingredients, processes or regulations change. Regulatory agencies may also perform food safety audits to confirm compliance, so conducting regular internal audits helps you stay prepared and maintain a strong food safety culture.

Principle 7. Establish Record-Keeping & Documentation Procedures

Record-keeping is the final step in the HACCP principles and steps, and it’s what proves your food was produced under safe, controlled conditions. Accurate records also provide full traceability during audits or investigations, making them essential for both compliance and consumer protection. Without proper documentation, even a well-designed HACCP plan can be considered non-compliant.

Your records should cover every part of the HACCP system, including:

- Hazard analysis summary

- HACCP team members and their responsibilities

- Product description and intended use

- Process flow diagram

- Identified CCPs and their critical limits

- Monitoring logs for each CCP

- Verification activities (e.g., calibration, microbial testing)

- Corrective actions taken when deviations occur

These records fall into two categories: the HACCP plan itself (the written framework) and day-to-day operational records that show the plan is being followed. Both are equally important when demonstrating how the 7 principles of HACCP explained apply in your facility.

Digital record-keeping tools such as cloud-based logs, automated data capture systems and mobile inspection apps can greatly improve accuracy, searchability and security. They also make meeting regulatory requirements easier by reducing missing or incomplete entries.

To stay audit-ready, consider building a standardized documentation checklist or summary table that captures all HACCP activities in one place. This helps your team stay organized and ensures nothing is overlooked during audits or internal reviews.

Digitizing HACCP & Leveraging Emerging Technologies

Many food businesses are moving away from paper-based forms and manual logs toward digital HACCP systems, and the shift is transforming how you apply everyday HACCP principles food safety activities. Digital platforms automate record keeping, streamline monitoring and issue real-time alerts when a critical limit is breached. Instead of chasing paperwork or deciphering handwritten logs, your team gets clear, actionable insights the moment something goes wrong.

How Digital Tools Strengthen HACCP

Technologies like IoT sensors, wireless temperature loggers and cloud-based dashboards provide continuous data collection and instant visibility across your operation. These tools offer practical HACCP principles examples, such as automatically triggering a corrective action when a cooler rises above its critical limit or when a metal detector fails a sensitivity check. They also simplify compliance reporting, making internal and third-party audits far less stressful.

The Role of AI and Predictive Analytics

Emerging technologies like AI, machine learning and predictive analytics can identify hazard trends before they escalate. By analyzing temperature fluctuations, equipment performance or recurring deviations, these tools can suggest preventive controls that strengthen your HACCP plan.

Why Digitization Matters for Modern Operations

Digital HACCP systems are especially valuable for multi-site companies and remote audits, where consistency and transparency are critical.

When evaluating digital HACCP platforms, look for scalability, compatibility with your existing equipment, strong user training support and compliance with local regulatory requirements. The right solution will enhance efficiency while reinforcing the core principles of food safety.

Common Challenges & Tips for Implementation

Implementing the principles for HACCP can be challenging, especially if your team is new to structured food safety systems. Common hurdles include incomplete hazard identification, difficulty determining CCPs, unclear or unvalidated critical limits and other food sanitation and safety mistakes like inconsistent monitoring, under-trained staff and poor documentation practices. These issues weaken your overall system and make it harder to meet the required HACCP principles and steps.

Practical Tips to Strengthen Your HACCP System

To overcome these challenges, focus on practical, actionable improvements:

- Use cross-functional expertise during hazard analysis to capture real operational risks.

- Apply decision trees and regulatory guidance when determining CCPs.

- Validate critical limits using scientific and regulatory sources.

- Calibrate instruments regularly to ensure accurate measurements.

- Train employees on why monitoring matters, not just how to do it.

- Document everything consistently, including corrective actions and preventive steps.

Conclusion

Building a strong HACCP system means applying every stage of the HACCP principles with intention from prerequisite programs and detailed hazard analysis to well-defined control points and thorough documentation. When you follow the seven HACCP principles consistently, you strengthen food safety, support regulatory compliance, protect your brand and improve operational efficiency.

Start by assembling a skilled HACCP team and conducting a comprehensive hazard analysis using trusted templates and guidance. If you’re ready to streamline monitoring, automate alerts and eliminate paperwork, get in touch with our Foodtech experts or book a demo to see how a digital solution can help you take over the HACCP principles effortlessly.

FAQs

Why are HACCP Principles Important for Food Manufacturers?

The HACCP principles provide a structured system to identify and control hazards before they affect product safety. This approach helps you prevent foodborne illnesses, stay compliant with regulations and improve operational consistency.

How Often Should a HACCP Plan Be Reviewed or Updated?

You should review your HACCP plan at least annually, or sooner if your ingredients, equipment, processes or regulations change. Regular verification helps you keep the system effective and audit-ready.

Can Digital Tools Improve Implementation of the HACCP Principles?

Yes. Digital HACCP platforms automate monitoring, record keeping and alerts, reducing errors and improving traceability. They’re especially useful for multi-site operations and remote audits.

What Records Are Required for HACCP Compliance?

You must maintain documentation for hazard analysis, product descriptions, CCPs, critical limits, monitoring logs, corrective actions and verification activities. Accurate records demonstrate consistent compliance and support traceability during audits.