The dairy industry plays a crucial role in the global food supply chain, providing essential products that are staples in households worldwide. However, as we move into 2025, dairy manufacturers and processors face mounting challenges threatening their operational efficiency and profitability.

Understanding these dairy industry issues, from supply chain disruptions and evolving consumer preferences to stricter regulations and sustainability demands, requires a proactive approach. Handling perishable products adds another layer of complexity, as maintaining product quality while minimizing waste remains a top priority.

According to recent reports, global dairy demand is projected to grow by 2.3% annually, putting further pressure on manufacturers to optimize production processes while ensuring compliance with food safety standards. In this blog, we’ll explore the biggest dairy industry issues in 2025.

Let’s explore what lies ahead for the sector and how businesses can stay resilient despite evolving dairy industry issues.

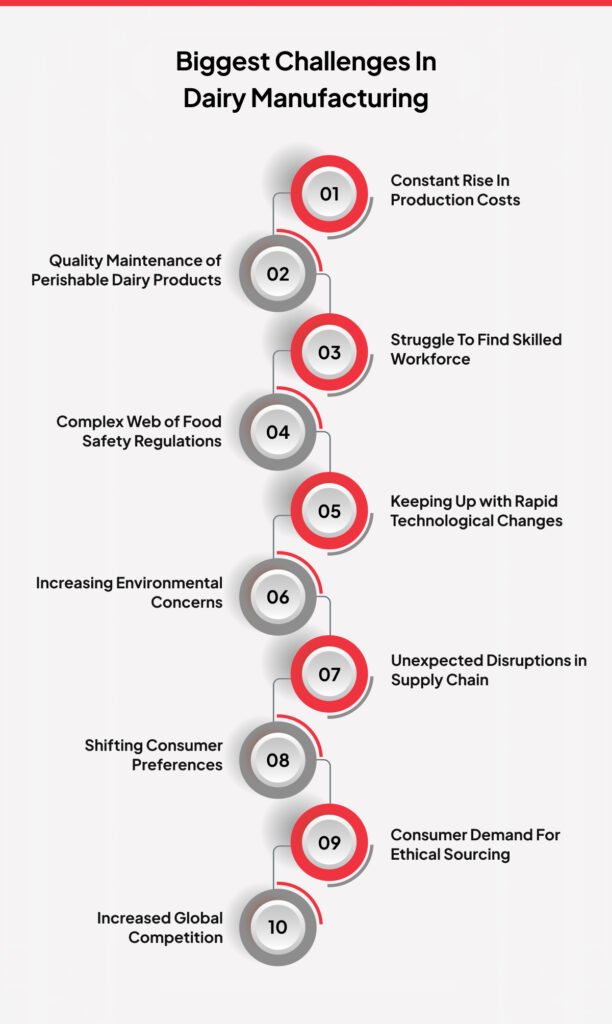

Dairy Industry Issues and Solutions

Dairy manufacturing is a complex process that involves managing delicate, perishable products while ensuring compliance with strict food safety regulations. Manufacturers must also contend with unpredictable market conditions, fluctuating milk prices, and labor shortages. Additionally, achieving sustainability goals and reducing waste are becoming increasingly crucial.

To remain competitive, businesses must adopt innovative technologies and streamline their operations. Addressing these dairy industry issues requires a multifaceted approach, from automated production systems and advanced quality control measures to robust supply chain management solutions.

In the following sections, we’ll explore the most pressing dairy industry issues facing dairy manufacturers and offer actionable solutions to help them thrive in this evolving industry.

Rise in Production Costs and How Dairy Manufacturers Can Manage?

One of the most significant dairy industry issues facing dairy industry manufacturers is the constant rise in production costs. The cost of raw materials, particularly milk, has been volatile due to supply chain disruptions, extreme weather events, and increasing feed prices.

Energy prices have also contributed to the financial burden, with dairy processing facilities requiring substantial electricity for refrigeration, pasteurization, and packaging. Additionally, labor shortages have driven up wages, further impacting production expenses.

Solution

Dairy manufacturers can reduce rising production costs by leveraging the dairy ERP solution, which enhances process automation and optimizes resource allocation. The system integrates real-time production tracking, automated milk reception, and efficient inventory management to reduce wastage and labor costs. Additionally, real-time analytics within the ERP helps monitor energy consumption, allowing businesses to cut costs and improve profitability.

Maintenance of Product Quality and How Dairy Manufacturers Can Prevent Spoilage?

Manufacturers constantly battle to maintain the quality of perishable dairy products. Milk, cheese, yogurt, and other dairy products have a limited shelf life, making temperature control and sanitation essential throughout the supply chain. Even minor temperature fluctuations during transportation or storage can lead to spoilage, resulting in financial losses and potential damage to brand reputation.

Solution

Maintaining temperature-sensitive dairy products throughout the supply chain is critical. Using a dairy ERP can provide real-time tracking of raw materials and finished goods, ensuring cold chain integrity from production to delivery.

It also supports quality control automation, helping manufacturers monitor critical control points (CCPs) and prevent food contamination. Advanced reporting tools streamline compliance documentation, minimizing risks associated with regulatory violations.

Struggle to Find Skilled Workers and Facing Labor Shortages

Labor shortages continue to strain dairy manufacturers, causing production slowdowns and inefficiencies. The dairy industry relies heavily on skilled workers for milking, processing, packaging, and equipment maintenance. However, companies face increasing difficulties maintaining smooth operations with an aging workforce and fewer young professionals entering the sector.

According to the International Dairy Foods Association (IDFA), the dairy sector in the U.S. alone supports nearly 3.3 million jobs, but the labor gap has grown by over 20% in recent years.

Solution

Labor shortages remain a major challenge, but food ERP software, specifically the one that is designed for the dairy industry, enables dairy manufacturers to automate key processes such as milk processing, packaging, and warehouse management. By integrating workflow automation, businesses can reduce reliance on manual labor while ensuring seamless operations. The system also optimizes workforce management by streamlining task assignments and monitoring productivity.

Regulatory Pressures Impacting Dairy Operations

Navigating the complex web of food safety regulations and quality standards constantly challenges dairy manufacturers. With highly perishable milk and dairy products, ensuring compliance at every stage of production is non-negotiable. From sanitation protocols to temperature controls and product labeling, manufacturers must meet strict food safety guidelines set by agencies like the Food and Drug Administration (FDA) and the U.S. Department of Agriculture (USDA).

Non-compliance isn’t just a risk to consumer health—it also threatens your brand’s reputation and financial stability. In 2023 alone, dairy product recalls surged by 18%, reflecting the heightened scrutiny of food safety. Additionally, evolving international standards pose further dairy industry issues for exporters, adding complexity to quality assurance processes.

Solution

Staying compliant with strict food safety regulations is simplified by using a food safety and compliance management solution. The system automates compliance checks, maintains digital records for audits, and provides real-time alerts for non-conformance issues. By integrating traceability management features, manufacturers can track products from farm to shelf, ensuring full transparency and reducing the risk of recalls.

Struggling to Keep Up with Rapid Technological Changes

Adopting the latest technologies can be a double-edged sword for dairy manufacturers. While innovations like automated milking systems, predictive maintenance tools, and AI-powered quality control promise efficiency gains, integrating these solutions into existing operations isn’t always seamless. Many manufacturers grapple with outdated infrastructure, limited budgets, and a lack of technical expertise, making it difficult to unlock the full potential of advanced technologies.

The dairy industry’s growing reliance on data also presents dairy industry issues. From monitoring milk quality to managing supply chains, the influx of real-time information requires robust data management systems. Unfortunately, over 60% of dairy companies report difficulties consolidating and analyzing their data effectively, leading to delayed decision-making and missed opportunities.

Solution

Dairy manufacturers can overcome these dairy industry issues by implementing scalable digital platforms designed specifically for the food processing sector. Integrated solutions like Enterprise Resource Planning (ERP) systems or manufacturing management modules offer a unified view of operations, streamlining everything from inventory management to quality assurance.

Sustainability: Putting Pressure on Your Dairy Operations

Environmental concerns are intensifying, with the dairy industry facing increasing scrutiny over its carbon footprint, water consumption, and waste generation. Producing one liter of milk requires approximately 1,020 liters of water and generates significant methane emissions, contributing to climate change. Additionally, regulatory bodies are introducing stricter sustainability targets, forcing manufacturers to adopt greener practices.

Solution

Dairy manufacturers can strengthen their sustainability efforts with a food ERP solution that helps track energy consumption, optimize resource usage, and reduce waste. The system offers real-time monitoring of sustainability metrics, enabling businesses to improve their carbon footprint while ensuring compliance with environmental regulations. By integrating waste reduction strategies, dairy processors can lower operational costs while contributing to a greener supply chain.

Unexpected Disruptions in Supply Chain

Supply chain disruptions remain one of the most pressing dairy industry issues, with unpredictable events like extreme weather, geopolitical conflicts, and transportation bottlenecks impacting the steady flow of raw materials. Over 70% of dairy manufacturers have reported delays in milk collection and ingredient shortages, leading to production slowdowns and increased costs. Additionally, managing perishable products adds urgency to every supply chain decision.

Solution

Implementing advanced supplier management software enables real-time visibility and predictive insights, allowing manufacturers to address disruptions proactively. Diversifying suppliers, investing in cold chain logistics, and using blockchain for traceability can further ensure operational resilience.

Shifting Consumer Preferences Leaving Your Dairy Business Behind

Evolving consumer preferences are reshaping the dairy industry, with a growing demand for plant-based alternatives, lactose-free options, and sustainably sourced products. In 2024, the global plant-based dairy market is projected to reach $55 billion, reflecting changing dietary habits. Additionally, transparency in labeling and ethical sourcing now influence purchasing decisions. Dairy manufacturers must adapt quickly to evolving dairy industry trends to stay competitive.

Solution

Conduct regular market research to track consumer trends. Diversify product offerings, explore dairy-free innovations, and ensure transparent supply chain practices. Leveraging data analytics can further refine product development and tailor marketing strategies to meet evolving demands. Partnering with a performance marketing agency in New York and other states can also help translate these insights into high-impact campaigns that drive measurable growth and brand loyalty.

Ethical Practices are the Missing Ingredient in Your Dairy Business

Consumer demand for ethical sourcing and transparency in animal welfare practices is rising, placing dairy manufacturers under increasing scrutiny. A recent survey found that 70% of consumers prefer dairy products from farms with verified humane practices. Poor treatment of livestock can harm the brand reputation and reduce market competitiveness. Additionally, stricter regulations require clear documentation of animal care standards.

Solution

Implement and monitor animal welfare programs, invest in third-party certifications, and use transparent labeling to build consumer trust. Prioritizing ethical practices mitigates dairy industry issues and strengthens market positioning and brand loyalty.

Staying Competitive in a Rapidly Changing Global Dairy Market

The global dairy market is fiercely competitive, with large-scale producers driving down costs and expanding market reach. Factors like fluctuating trade policies, international tariffs, and currency instability further challenge dairy manufacturers. Additionally, rising consumer demand for alternative dairy options intensifies the pressure. According to industry reports, the global dairy market is projected to grow by 5.5% annually, increasing competition.

Solution

Adopt market intelligence tools, diversify product offerings, and strengthen supply chain resilience. Investing in digital solutions and sustainable practices can help businesses navigate dairy industry issues while maintaining profitability and market relevance.

Fuel Your Dairy Growth with a Scalable ERP Solution

Ready to expand your dairy business? Our purpose-built ERP adapts to your

evolving needs, providing the foundation for sustainable growth.

See How Dairy ERP Scales

Overcoming Dairy Industry Challenges with Folio3 FoodTech Dairy ERP

Navigating dairy industry issues requires a proactive approach, and Folio3 FoodTech Dairy ERP offers an integrated solution to tackle the most pressing dairy industry issues. From regulatory compliance to supply chain visibility, the system is designed to optimize operations, reduce costs, and ensure product quality.

Compliance Management – Ensuring Regulatory Adherence

Maintaining compliance with evolving food safety regulations is critical in the dairy sector. Folio3’s Dairy ERP streamlines documentation and automates compliance checks, reducing the risk of non-compliance penalties. The system tracks real-time production data, ensuring traceability and swift responses during audits.

Data-Driven Decision-Making – Enhancing Operational Efficiency

Access to accurate, real-time data empowers dairy manufacturers to make informed decisions. Folio3 Dairy ERP integrates production, inventory, and sales data to provide actionable insights. Manufacturers can optimize processes, reduce waste, and minimize operational costs by identifying inefficiencies.

Supply Chain Optimization – Improving Visibility and Control

Handling perishable dairy products demands a streamlined supply chain. Folio3 Dairy ERP offers end-to-end visibility, enabling manufacturers to track raw materials, monitor inventory levels, and predict demand fluctuations. Enhanced logistics management minimizes spoilage and ensures timely deliveries.

Sustainability Tracking – Promoting Eco-Friendly Practices

Sustainability is becoming a key focus in the dairy industry. Folio3 Dairy ERP facilitates monitoring resource consumption, waste management, and carbon emissions. By analyzing sustainability metrics, manufacturers can identify areas for improvement and implement eco-friendly practices.

Conclusion

Folio3 FoodTech Dairy ERP is a comprehensive solution to dairy manufacturers’ complex dairy industry issues. From maintaining compliance with regulatory standards to making data-driven decisions, the system streamlines operations and enhances efficiency.

Manufacturers can ensure product quality while meeting consumer demands with improved supply chain visibility, reduced waste, and actionable insights. Additionally, robust sustainability tracking promotes responsible production practices. By partnering with Folio3, dairy businesses can overcome dairy industry issues, stay competitive, and build a resilient global food supply chain in the future.

Take the next step toward operational excellence with Folio3 Dairy ERP!

Fuel Your Dairy Growth with a Scalable ERP Solution

Ready to expand your dairy business? Our purpose-built ERP adapts to your

evolving needs, providing the foundation for sustainable growth.

See How Dairy ERP Scales

FAQs

What Is The Biggest Challenge In The Dairy Industry?

Dairy manufacturers face the biggest dairy industry issues in managing rising operational costs, ensuring regulatory compliance, and maintaining product quality.

What Is The Biggest Threat To The Dairy Industry?

Fluctuating milk prices, supply chain disruptions, and increasing consumer demand for plant-based alternatives pose significant threats to the dairy industry.

What Are The Problems With Milk Production?

Milk production challenges include inconsistent milk yields, animal health management, and ensuring product freshness in the supply chain.

What Are The Sustainability Issues In The Dairy Industry?

High greenhouse gas emissions, water consumption, and waste management are major sustainability concerns in the dairy sector.

What Are The Three Main Challenges Of Sustainability?

Resource management, reducing carbon emissions, and implementing ethical animal welfare practices are the primary sustainability challenges.

How Can Milk Be More Sustainable?

Adopting eco-friendly farming practices, reducing water and energy consumption, and improving supply chain efficiency can enhance milk sustainability.