Food manufacturers lose approximately $1.4 trillion annually to inventory shrinkage, with the food industry experiencing some of the highest shrink rates across all sectors. According to the National Retail Federation’s Security Survey, food businesses face shrinkage rates averaging 1.6% of total sales, nearly double the retail average.

This challenge extends far beyond simple accounting discrepancies. For food manufacturers, processors, and distributors, inventory shrinkage represents a complex operational issue that directly impacts profitability, regulatory compliance, and market competitiveness.

Unlike other industries, where shrinkage primarily stems from theft, food businesses must contend with unique factors, including spoilage, contamination risks, and stringent safety requirements, that compound traditional loss factors. The Food and Agriculture Organisation reports that post-harvest losses in food supply chains can reach 30% in developing markets, while even advanced economies see 10-15% losses from farm to consumer.

Understanding and controlling these losses isn’t just about protecting margins, but it’s also about building sustainable, efficient operations that can adapt to market pressures while maintaining food safety standards.

What is Inventory Shrinkage in the Food Industry?

Inventory shrinkage refers to any unaccounted-for reduction in stock that cannot be attributed to documented sales, transfers, or approved waste disposal. In food businesses, this encompasses a wide range of losses, some of which are preventable, such as theft, administrative errors, and mishandling. In contrast, others are considered inevitable, like spoilage within accepted thresholds.

Unlike industries where product degradation is minimal, food businesses must carefully distinguish between acceptable spoilage and excessive losses. For example, a 2–5% spoilage rate may be normal for many perishable items, but higher rates can signal underlying operational inefficiencies.

Shrinkage challenges in the food sector are uniquely complex. Temperature fluctuations can spoil entire shipments, pest infestations can contaminate stock, and even if goods appear intact, they must be discarded if they have expired. These factors require dedicated processes for monitoring, identifying, and managing inventory loss.

How to Calculate Inventory Shrinkage

Inventory shrinkage is calculated by comparing recorded (book) inventory with actual physical stock. The basic formula is:

Shrinkage Rate = (Book Inventory – Physical Inventory) / Book Inventory × 100

For instance, if your system records $100,000 in inventory, but the physical count reveals only $96,000, the shrinkage rate would be 4%.

While this basic formula provides a general overview, food businesses often require more detailed calculations that break shrinkage down by product type, storage environment, period, and root cause. A dairy processor, for instance, may track separate shrinkage rates for refrigerated goods versus dry storage items, since spoilage and handling risks vary significantly.

To stay proactive, many companies conduct shrinkage analysis on a monthly or even weekly basis, especially in fast-moving categories like fresh produce, where short shelf lives leave little room for delay. Delayed identification of issues in these segments can lead to rapid inventory losses.

Modern inventory management systems can help automate this process by synchronising real-time inventory data with physical counts, identifying anomalies, and generating shrinkage reports across various locations, SKUs, or timeframes. These tools reduce manual errors and offer the visibility needed to identify loss patterns before they escalate.

What Are the Common Causes of Food Inventory Shrinkage?

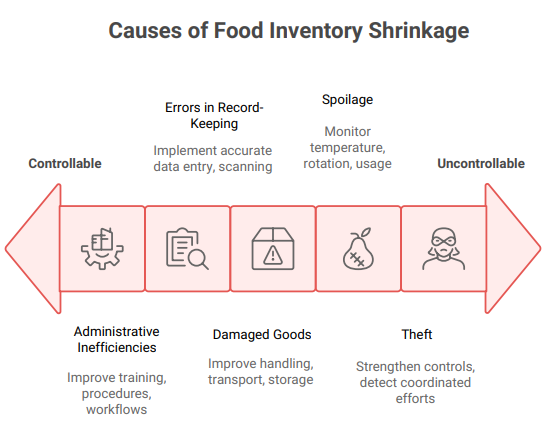

Food inventory shrinkage stems from five primary sources, each requiring different food inventory management strategies and management approaches:

- Theft: Internal and external theft are major contributors to shrinkage. Employees may manipulate inventory records or divert shipments, while external actors target easily resold food items. These actions often involve coordinated efforts and are challenging to detect without strong controls.

- Spoilage: Improper temperature control, inadequate inventory rotation, and delays in usage lead to spoilage. Failures in cold storage systems and inadequate stock management lead to products expiring or degrading before they can be used.

- Errors in Record-Keeping: Inventory discrepancies often result from administrative mistakes such as incorrect receiving, missed shipments, or inaccurate data entry. Scanning errors and mislabeling also contribute to inventory mismatches.

- Damaged Goods: Products can become unsellable due to physical damage during handling, transport, or storage. Packaging failures, mishandling, and rough transportation conditions are common causes of such losses.

- Administrative and Operational Inefficiencies: Lack of proper training, unclear procedures, and inefficient workflows increase the risk of shrinkage. These gaps in operations often lead to mistakes or create opportunities for inventory loss.

How Does Inventory Shrinkage Impact Food Businesses?

Food shrinkage has a significant impact on food businesses across financial, operational, and regulatory dimensions. While the immediate loss of products is apparent, the broader consequences can undermine profitability, disrupt operations, and jeopardise compliance.

Financial Losses

The most direct impact of shrinkage is financial. When inventory disappears due to theft, spoilage, damage, or errors, businesses lose not just the cost of the goods but also the potential revenue. Since many food businesses operate on narrow profit margins, even small percentages of shrinkage can erode a significant portion of net profits.

Additionally, the need to replace lost inventory often results in increased procurement costs, mainly when products must be sourced urgently. Administrative overhead also rises as companies invest more time and resources in documenting, auditing, and managing inventory discrepancies.

Operational Inefficiencies

Shrinkage distorts inventory records, making it difficult to plan production and manage supply chains effectively. When actual stock levels do not align with system data, businesses may encounter stockouts or overstocking.

Stockouts can lead to emergency purchasing, expedited shipping, and disrupted customer fulfilment, while excess inventory increases storage costs and poses a risk of spoilage. Furthermore, warehouse staff and managers spend additional time reconciling data, conducting audits, and investigating shrinkage-related issues, which reduces overall labour efficiency.

Pricing Pressure and Margin Compression

Persistent shrinkage puts pressure on pricing strategies. To maintain profitability, businesses may need to raise prices, which can reduce competitiveness in price-sensitive markets. Alternatively, they may absorb the losses, leading to margin compression. Both options can weaken market positioning and limit growth opportunities.

Customer Satisfaction and Trust

Inaccurate inventory records resulting from shrinkage can lead to fulfilment errors and missed deliveries, damaging customer trust. Repeated service failures can harm long-term relationships and lead to lost business, especially in industries where reliability and consistency are critical.

Regulatory and Compliance Challenges

Food shrinkage complicates compliance management with food safety regulations and traceability standards. Missing or undocumented inventory can hinder the ability to track product movement, which is essential for recalls and audits.

Regulatory bodies may view significant discrepancies as red flags, which could trigger investigations. High or unexplained shrinkage rates can also raise tax-related concerns if they fall outside accepted norms for business losses.

How Can Food Businesses Overcome Inventory Shrinkage?

Successfully reducing food shrinkage requires a systematic approach that addresses each major cause while building operational excellence throughout the organisation.

Implementing Accurate Inventory Tracking Systems

Modern inventory tracking systems help reduce shrinkage by providing real-time visibility into stock levels, movements, and storage conditions. Technologies such as barcoding or RFID eliminate many manual errors by automating data capture during receiving, storage, picking, and shipping.

When integrated with operational workflows, these systems ensure records are updated instantly, reducing lag time and minimising the risk of phantom inventory or unrecorded losses.

Regular Audits and Stocktaking

Frequent inventory audits help detect discrepancies before they escalate. Rather than relying solely on annual physical counts, many businesses adopt cycle counting, where a portion of inventory is checked on a rotating basis. This ensures ongoing accuracy without disrupting operations.

Using blind counts, where employees verify stock without viewing expected quantities, further improves count reliability. Statistical sampling can also be used to target high-risk categories, making audits more efficient and focused.

Improved Warehouse and Storage Management

Proper storage practices are essential to preventing shrinkage due to spoilage and physical damage. Temperature-controlled environments should be continuously monitored with alert systems to detect any deviations from the set temperature.

To minimise losses from expired goods, businesses should employ inventory rotation techniques, such as the First In, First Out (FIFO) method, which ensures that older stock is sold before newer stock. Investing in the proper handling equipment and maintaining orderly storage also reduces product damage and improves overall efficiency.

Employee Training and Security Measures

Educating employees on best practices for managing inventory, minimising waste, and understanding their role in preventing shrinkage is crucial. Well-trained staff are less likely to make procedural mistakes and more likely to identify and report potential issues.

Security measures such as CCTV monitoring, provided by a reliable CCTV installation company, restricted access areas, and clear accountability protocols help deter theft and provide oversight of inventory handling. Additionally, anonymous reporting channels can encourage employees to report suspicious behavior without fear of retaliation.

Using Technology for Better Forecasting and Demand Planning

Accurate demand forecasting helps prevent overstocking, which can lead to spoilage, and understocking, which can cause stockouts. Predictive analytics tools can identify trends and seasonal patterns, enabling more informed purchasing and production decisions. These tools also help flag products at risk of becoming obsolete or expiring, allowing timely interventions such as promotions or redistribution before losses occur.

How Folio3 FoodTech Food Inventory Management Software Helps Combat Shrinkage?

Reducing shrinkage in food businesses often comes down to having better visibility, traceability, and control over inventory. A specialised food inventory management system, like the one developed by Folio3 FoodTech, is designed to address these challenges through integrated tools that support accuracy and operational efficiency. Here’s how Folio3 FoodTech food inventory management software can help:

Real-Time Inventory Tracking

Continuous tracking of raw materials, in-process items, and finished goods ensures stock levels are always up to date. This helps prevent data mismatches and makes it easier to spot irregularities early.

Multi-Location Inventory Management

When inventory is distributed across production sites, warehouses, or cold storage facilities, centralised oversight helps maintain consistency. It reduces miscounts, duplication, and blind spots in the inventory process.

Batch and Lot Tracking

Maintaining batch and lot histories supports better traceability. In the event of a quality issue or audit, businesses can quickly identify where the affected inventory originated and where it’s located, thereby reducing unnecessary waste.

Expiration and Shelf-Life Management

By tracking expiry dates and applying the First Expired, First Out (FEFO) principle, the system helps prioritise stock movement. This reduces the chance of products expiring before they’re used or sold.

Catch Weight Management

In operations involving variable-weight items, such as dairy, meat, or seafood, catch weight-based tracking helps ensure that inventory counts are accurate and consistent with what’s actually handled and sold.

Allergen Information Tracking

As part of allergen management, Tagging and separating allergen-related items minimises cross-contact risk and supports compliance. It also helps prevent unusable inventory shrinkage due to mishandling or misclassification.

Automated Replenishment

When stock levels drop below predefined thresholds, the system can automatically trigger reorders or production tasks. This reduces last-minute procurement and helps maintain optimal stock levels without overbuying.

Demand Forecasting

Analysing historical data and production trends enables more informed planning and decision-making. This helps avoid overstocking—often a significant cause of spoilage and ensures that procurement aligns more closely with actual demand.

Mobile & Barcode Scanning

On-the-go scanning capabilities reduce manual errors during receiving, picking, and stocktaking. Staff can update records in real time, improving accuracy and reducing data entry delays.

Conclusion

Inventory shrinkage remains a critical challenge for food businesses, but with the right systems and processes in place, it can be significantly reduced. A combination of operational discipline, employee training, and real-time inventory visibility is key to addressing both the causes and the costs of shrinkage.

For companies looking to strengthen their inventory control, a purpose-built solution like Folio3 FoodTech Food Inventory Management Software offers the tools needed to improve accuracy, minimise waste, and support long-term efficiency, making it a valuable component of any shrinkage reduction strategy.

FAQs

What Is Food Inventory Shrinkage?

Food inventory shrinkage refers to the discrepancy between recorded inventory levels and the actual physical stock on hand, encompassing losses due to theft, spoilage, damage, and administrative errors. It represents any unexplained reduction in inventory that can’t be attributed to legitimate sales or documented disposal.

How Can Folio3 FoodTech Food Inventory Management Software Help Reduce Inventory Shrinkage?

Folio3 FoodTech’s inventory software reduces shrinkage through real-time tracking, automated FIFO rotation, temperature monitoring, and comprehensive reporting capabilities. The system provides immediate visibility into discrepancies and helps identify root causes of losses, enabling proactive management rather than reactive responses.

What Causes Food Inventory Shrinkage?

The primary causes include spoilage (40-60% of losses), theft (30%), administrative errors, damaged goods, and operational inefficiencies. Food businesses face unique challenges, including temperature sensitivity, short shelf lives, and complex handling requirements, which differ from those in other industries.

How Can I Prevent Food Shrinkage In My Warehouse?

Prevention strategies include implementing automated tracking systems, conducting regular cycle counts, maintaining proper storage conditions, training employees on handling procedures, and using security measures to deter theft. Success requires addressing all significant causes of shrinkage simultaneously.

What Are The Financial Implications Of Food Inventory Shrinkage?

Financial impacts include direct product losses, increased procurement costs, administrative expenses, and margin compression. For food companies operating on 2-5% margins, shrinkage rates of 1-2% can eliminate 20-40% of potential profits, making effective shrinkage management critical for profitability.