If you’re juggling throughput, quality, and compliance, kitting in manufacturing can change the game. By pre-gathering everything needed for a job into one ready-to-use unit, you reduce picking time, speed changeovers, and lower error risk.

That matters because kitting cuts average parts-fetching time by 43%, with kitted parts retrieved in 1.86 seconds vs 3.29 seconds from racks. Specifically in the food industry, kitting helps manufacturers streamline production by grouping all the necessary parts or ingredients before assembly begins. By preparing kits of components in advance, workers spend far less time hunting down items on the line.

In this guide, we’ll discuss the kitting process in manufacturing in plain language, contrast it with its types, examples, and benefits, and show you how to deploy it without disrupting production.

Whether you’re a food manufacturer, production manager, inventory supervisor, supply-chain executive, or operations director, you’ll leave with a practical blueprint to implement kitting with confidence.

What is Kitting in Manufacturing?

Kitting in manufacturing means assembling multiple separate components or goods into a single package (a “kit”) that is treated as one unit in production or fulfillment. Each kit is assigned its own SKU (stock-keeping unit), distinct from the individual parts’ SKUs. Kits can be preassembled ahead of time or compiled on demand, but either way, the goal is to have all required items gathered and ready together.

For example, a kit might include all ingredients for a particular food product batch, or all parts and tools needed to assemble a machine sub-component. This differs from simply shipping items together. With kitting, the grouped items effectively become a new single product for internal use or sale, often with custom packaging or instructions included.

Kitting vs Bundling vs Assembly

- Kitting: The process of packing separate but related items together and supplying them as one unit with a unique SKU. A kit often contains some items (like a custom box or insert) that are not sold separately but exist only as part of the kit.

- Bundling: Grouping individual products for sale as one combined unit (the bundle also gets its own SKU). However, each item in a bundle is usually a normal standalone product that could be sold individually.

- Assembly: The process of physically combining parts into a finished product or sub-assembly. Kitting happens before or separately from assembly; it’s about collecting everything needed in one package, whereas assembly is about using those parts to build something.

Why Food Manufacturers Use Kitting:

Food manufacturers turn to kitting to simplify ingredient management and ensure readiness. If you’ve ever run short of an ingredient mid-process, you know the downtime and waste it causes. Kitting all required ingredients for a recipe or production run in advance means everything is on hand before production starts, preventing costly line stoppages.

Kitting also allows pre-measuring or pre-weighing ingredients, which improves consistency in flavor and quality. Overall, kitting operations in food manufacturing help coordinate multiple components from spices and flavor packs to packaging materials so that nothing is forgotten or out of sync when you begin production.

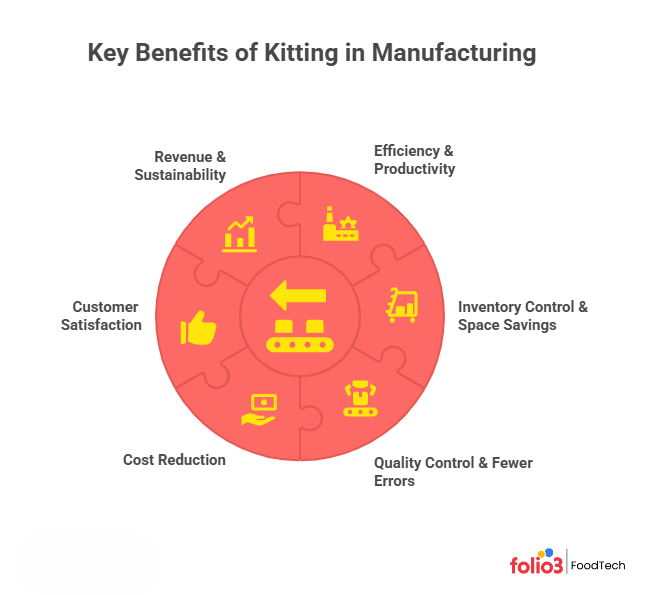

Key Benefits of Kitting in Manufacturing

Implementing kitting in your manufacturing process can yield significant benefits across efficiency, cost, and customer satisfaction. Here are some of the top benefits of kitting in manufacturing:

Efficiency & Productivity

Kitting directly boosts operational efficiency. By having all the required parts together, workers no longer waste time searching multiple bins or shelves for each item. Kitting reduces this burden by cutting down individual picks; workers grab one kit rather than dozens of separate items. In practice, this translates to faster assembly times and less idle machine time.

Inventory Control & Space Savings

By combining items into kits, you can simplify inventory tracking and even save space. A kit with its own SKU consolidates what might have been many separate SKUs, making stock levels easier to monitor. Physically, combining products into kits can reduce the overall packaging and storage space required, as one packaged kit often takes less room than the sum of its parts stored separately.

Quality Control & Fewer Errors

Kitting can act as an extra quality checkpoint. When all kit components are gathered and verified upfront, there’s less chance a part is wrong or missing by the time it reaches assembly. In fact, pre-defining kits greatly lowers the picking and packing mistakes that plague fulfillment. In food manufacturing, kitting ingredients can improve quality consistency and reduce contamination risk by handling ingredients in a controlled kit assembly area.

Cost Reduction

Many of the above efficiencies translate into dollars saved. Labor costs drop when workers spend less time walking and searching and more time assembling. Kitting can also reduce overtime or staffing needs during peak production because the preparatory work is optimized.

Customer Satisfaction

Delivering accurate, complete orders on time makes customers happy. Kitting helps achieve this by ensuring everything that the customer needs comes together correctly. Faster fulfillment is another plus, because kitting streamlines picking and packing, orders go out quicker, resulting in shorter lead times for customers.

Increased Revenue & Sustainability

Smart kitting strategies can open new revenue streams. By creating kits, you can offer curated product packages (e.g., a snack & drink combo, or a meal prep kit) that command a premium or encourage larger purchases. From a sustainability angle, kitting often means less packaging waste, which supports overall food manufacturing waste reduction. One box or container holds what used to require several.

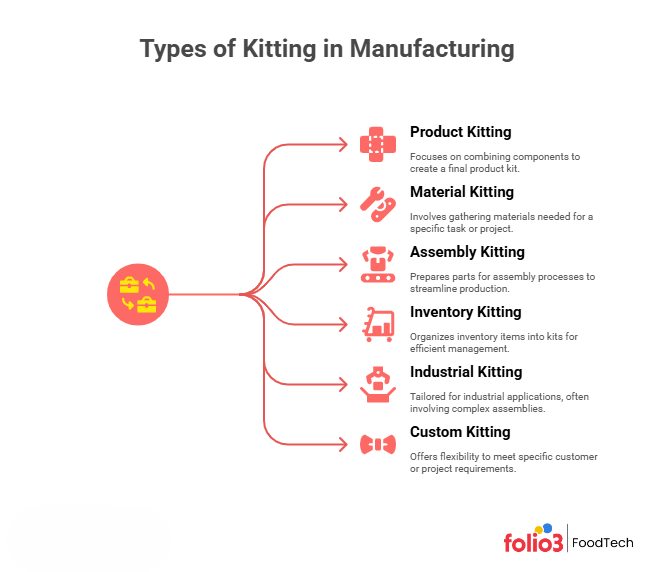

Types of Kitting in Manufacturing

Kitting isn’t one-size-fits-all. Depending on the context, kitting operations take on different forms. Here are the major types of kitting relevant to manufacturing, including specialized custom kitting services in food manufacturing:

Product Kitting

Also called product bundling, this refers to combining finished goods into a kit that’s sold as a new product with its own SKU. In food manufacturing, product kitting might mean creating a multi-pack. The key is that the items are already finished products; kitting simply packages them together in a convenient offer. Product kitting expands your catalogue and can increase sales. It’s usually customer-facing; the kit is sold to an end customer who enjoys the grouped items.

Material Kitting

Sometimes called parts kitting or assembly kitting, this is kitting on the production side. Material kitting involves gathering all the raw materials, ingredients, parts, and sub-components needed for a manufacturing run or assembly station. Material kitting is very common in factories to feed assembly lines; it ensures each workstation or production batch has precisely what it needs. In food plants, material kitting can help with allergen control, too.

Assembly Kitting

This term overlaps with material kitting. It refers specifically to kitting for a particular assembly process or sub-assembly. In food processing, you might kit all components for a flavored beverage mix so that assembling the final product is fast and error-free. The idea is to support assembly operations by pre-organizing the parts. Assembly kitting ensures that the assembly worker or machine has a kit where nothing is missing, drastically cutting down assembly time and mistakes.

Inventory Kitting

It refers to how inventory is organized in your system or warehouse. Inventory kitting means arranging your stock into kit SKUs and possibly storing those kits as units. These kits have their own location and SKU in the inventory system, making picking and tracking easier. Inventory kitting can simplify stock counts (it’s easier to count 100 kits than 100 each of 10 items). In a food industry context, you might maintain inventory kits for seasonal promotions, ready to ship out as one unit.

Industrial Kitting

Industrial kitting generally refers to kitting in heavy-duty or complex manufacturing environments. It deals with large bills of materials and often requires special handling. Industrial kitting might also include MRO (maintenance, repair, operations) kits, where spare parts and tools for servicing equipment are kitted for technicians. This type of kitting must account for safety and regulatory compliance, too.

Custom Kitting

Custom kitting is when kits are tailored to specific requirements or made on demand, often by a third-party service. In many cases, companies outsource this to custom kitting services, especially in food manufacturing and CPG. Custom kitting enables businesses to offer a lot of product variety or personalization without overloading their own production lines. These services handle the labor-intensive kit assembly, including sourcing minor kit components and doing specialized packing. For food companies, outsourcing kitting can ensure compliance and can help when you lack space or manpower for assembling kits in-house.

Kitting in the Supply Chain – From Warehouse to Production

Kitting plays a pivotal supply-chain role, bridging the gap between warehousing and production. In a warehouse context, kitting can streamline order fulfillment as items that are frequently needed together are pre-packed, reducing picking time and shipping delays. For manufacturing supply chains, kitting ensures that downstream processes (like assembly lines or co-packers) receive complete sets of components just-in-time. This not only speeds up production but also improves coordination with suppliers and logistics partners.

Coordination with Suppliers & 3PLs:

Many manufacturers work with suppliers or third-party logistics (3PL) providers to implement kitting upstream. Such collaboration can cut down on your internal prep work. Recipients of kits have fewer SKUs to handle and spend less time sorting parts, which can ease supplier relationships and reduce labor costs in distribution.

3PLs often offer kitting services where they will assemble kits per your specs and even handle the warehousing of those kits until you need them. It is especially useful in food manufacturing when dealing with promotions or seasonal kits that you might not have the capacity to assemble on your main line.

Impact on Food Safety & Compliance:

In the food supply chain, kitting must be done with strict adherence to food safety regulations. All components of a food kit need to be traceable and properly handled. By pre-packaging ingredients in a controlled environment, you reduce the amount of open handling on the main production floor, thereby lowering cross-contamination risks.

Additionally, your kit labels should clearly list all ingredients and allergens as required by law. Good coordination with 3PLs or suppliers is key here; you need to communicate requirements and ensure they follow GMP (Good Manufacturing Practices). When every link follows through, kitting in the supply chain leads to faster, safer, and more reliable movement of goods from warehouse to production to customer.

Kitting Process in Manufacturing – Step-by-Step Guide

If you’re ready to implement kitting in your operation, it helps to break down the kitting process in manufacturing step by step. Below is a guide to setting up a kitting process, from planning to continuous improvement:

1. Identify SKUs and Goals

Decide what to kit and why. Analyze orders/production to find items used together. For food makers, map ingredients or packaging sets. Define goals (speed assembly, create a bundled product, reduce errors). List all SKUs and quantities. Involve production, inventory, and quality to prevent omissions; one missing packet or fastener can derail kitting.

2. Assign a New Kit SKU

Create a unique kit SKU in your ERP/WMS and define the kit BOM with components and quantities. Set up kit/assembly items so components auto-deduct when built or sold. Track kits like products, simplify counts, and include custom packaging (boxes, inserts, labels) in the BOM for accurate planning and costing.

3. Pick & Assemble

Use BOM-driven pick lists or digital instructions to gather components. Assemble by placing items into the kit container; light sub-assembly if required. Verify with checklists, barcode scans, or computer vision to catch omissions in real time. For example, place ingredient packets, spice mix, and recipe card into a meal-kit box, then mark the kit built.

4. Package & Label

Protect contents and label clearly with the kit SKU, contents, and, for food, required regulatory info (ingredients, allergens, expiry dates). Internal kits may use barcode labels only; shipped kits need sealed packaging, padding/dividers, and easy handling for the following user with clear identifiers (e.g., “Kit Product X – Batch 123”) to aid accuracy.

5. Integrate with Inventory & ERP

Ensure that building a kit auto-deducts components and adds finished kits to stock. Connect ERP/MRP, MES, and WMS for real-time tracking, scanning, and allocation to work/sales orders. Maintain a lot and expiry with traceability management, especially for food. Accurate integration provides a single source of truth for kit status, usage, and availability.

6. Store & Ship

Stage internal kits near the line, or store in dedicated kitting zones under correct conditions (cold chain, ESD, etc.). Ship kits as single SKUs—one scan reduces misses. Use FIFO/FEFO and carry forward the earliest component expiry. For outsourced kitting, monitor 3PL inventory and service levels closely.

7. Monitoring & Continuous Improvement

Track kit build time, accuracy, line impact, and inventory turns. Use dashboards to spot bottlenecks; redesign layouts or add automation where justified. Gather operator feedback, audit kits, and run root cause analysis on discrepancies. Tune forecasts, switch slow movers to on-demand kitting, and iterate, aiming for sustained time, cost, and quality gains.

Real-World Kitting Examples for Food Manufacturers

Kitting is not just a theory; it’s used in many real-world scenarios in the food industry. Let’s look at a few examples to illustrate how kitting in manufacturing and fulfillment makes a difference:

Meal Kit Production & Subscription Boxes

Meal kit services operate like manufacturers: each week, teams kit fresh ingredients and recipe cards into a single box shipped to subscribers. Every meal kit is a precisely measured set of proteins, produce, spices, and sauces treated as one SKU.

Therefore, operations must maintain a cold chain, apply accurate nutrition/allergen labels, and protect quality in transit. For you, kitting delivers convenience, a ready-to-cook package that removes shopping, measuring, and guesswork while standardizing results at home.

Snack & Beverage Pairings

Brands kit snacks and beverages into attractive combos, say, a sports drink, energy bar, and shaker sold as a single SKU for events or online specials. Breweries and wineries bundle drinks with snacks or glassware for gift sets.

Operationally, teams assemble items and package them in a special box. Kitting lifts perceived value, simplifies picking, and encourages trial, boosting sales of lesser-known products by pairing them with favorites, especially around holidays and promotions.

Ingredient Kitting for Batch Cooking

Plants use ingredient kitting to prep batch mixes: pre-weighed packets of each spice or ingredient are sealed together, so operators open one kit and pour, ensuring correct proportions. Consistency improves batch to batch.

In commercial kitchens, “recipe kits” gather every item for a dish, speeding peak service. Separating perishables from dry items preserves freshness. The same industrial kitting principle applies: gather everything once to make the next step faster and foolproof.

Challenges for Kitting in Manufacturing & How to Overcome Them

While kitting offers many advantages, it also comes with challenges that manufacturers need to manage:

Storage & Space Constraints: Pre-assembling kits means you need space to store those kits (if they’re not used immediately). For manufacturers tight on warehouse space, having hundreds of kits sitting on shelves can be an issue. Kits can be bulky, especially if they include packaging materials.

Overcome it: Optimize your kitting strategy for better inventory management by using a mix of pre-kitting and on-demand kitting. High-volume or predictable items can be pre-kitted, while low-volume or custom orders are kitted only when needed to avoid clogging up space.

Demand Forecasting & Inventory Management: Kitting introduces another layer to forecast; you must predict demand not just for products, but for kits and their components. If forecasting is off, you could kit too many units (tying up inventory in unsold kits) or too few (losing efficiency). Additionally, managing inventory for kits can get complex since components are “hidden” inside kits.

Overcome it: Leverage your ERP/MRP system to plan for kits. Most systems allow creating “phantom” BOMs or kit assemblies that can be exploded for planning. This way, if you forecast 100 kits, the system will plan the parts accordingly.

Complexity & Process Management: Introducing kitting is like adding a new mini-production line. Without good processes, it can create complexity. There’s potential for errors like putting the wrong item in a kit, and the assembly line or customer down the chain will have an issue. Managing hundreds of small parts in kits can be error-prone if not organized properly.

Overcome it: Develop clear Standard Operating Procedures (SOPs) for kitting. It includes how to pick parts for a kit, checklists for assembly, and labeling standards. Incorporate quality checks by using visual aids in the kitting area: diagrams or photos of a correctly assembled kit can guide workers.

Maintaining Freshness & Food Safety: For food manufacturers, kitting has an extra challenge: preserving product quality. If you kit ingredients too early, some components might expire or lose freshness. There’s also risk of cross-contamination if, say, allergens are kitted near non-allergens without proper controls.

Overcome it: Timing and storage conditions are everything. Use First-Expire-First-Out (FEFO) inventory logic when creating kits, ensuring the component with the nearest expiration drives the kit’s shelf life, and mark that date on the kit clearly. Don’t pre-kit perishable items too far in advance; often, food kits are assembled just hours or days before shipment, not weeks.

Tech Innovations to Improve the Kitting Process in Manufacturing

Technology is rapidly transforming how kitting is done, making it faster, smarter, and more reliable. Here are some key tech innovations enhancing the kitting process in modern manufacturing:

- Kitting Software & ERP Integration: Dedicated kitting software or advanced manufacturing management ERP can automate and optimize kit creation. Integration with your ERP/MES means that as soon as a work order for a kit is released, tasks are sent to workers or robots to assemble the kit, and inventory updates occur instantly.

- AI & Machine Learning: AI algorithms can analyze historical data to predict what kits will be needed when improving planning utilizing AI in food industry. Machine learning can also optimize how kits are put together, adapting to the best layout of parts in a kit for quick retrieval.

- Automation & Robotics: Many warehouses and factories are deploying automation to handle kitting tasks. Robotic arms with vision systems can pick items from bins and place them into kits at high speed. Automated storage and retrieval systems (AS/RS) can bring all needed components to a kitting workstation.

- MES & Real‑Time Data Integration: Integrating kitting with a Manufacturing Execution System (MES) and other real-time data sources allows for on-the-fly adjustments and transparency. Moreover, real-time dashboards can show how many kits are completed, in progress, or pending, giving supervisors instant visibility.

Conclusion – Pulling It All Together

Kitting in manufacturing, when done thoughtfully, is a game-changer for operational efficiency. By pulling together all necessary parts or ingredients into ready-to-go kits, you can cut down production time, reduce errors, and lower costs – all while improving the consistency and quality of your output. This is especially powerful in food manufacturing, where ensuring every component is present and safely handled can make the difference between a smooth operation and a recall. As a food production manager or supply chain executive, you should evaluate your processes for kitting opportunities. Start with your most significant pain points, maybe it’s frequent missing ingredients or slow changeovers, and consider a kitting solution to address them. Engage your team and perhaps run a pilot with our FoodTech experts; you might be surprised how quickly kitting pays off in productivity.

FAQs

Is Kitting Considered Manufacturing?

Yes. Kitting is a manufacturing activity because it organizes parts and materials into kits for a specific product or assembly, reducing errors, accelerating lines, and streamlining overall production.

How Does Kitting in Manufacturing Apply to Food Processors?

It bundles pre-portioned ingredients and components into a single “kit,” enabling faster, error-resistant production and simpler inventory. Prepped in advance, kits smooth line flow before final processing or packaging.

How Does Kitting Improve Supply Chain Efficiency in the Food Industry?

Pre-assembled kits speed fulfillment, cut labor, reduce SKUs to track, lower shipping costs via optimized packaging, and improve accuracy by limiting picking errors and returns. Standardized kits also enhance food safety and traceability.

How Can ERP Software Automate and Optimize the Kitting Process?

ERP centralizes data and provides real-time visibility, creating a single source of truth. It reduces manual errors and coordinates planning, allocation, assembly, and tracking to accelerate end-to-end kitting.

Which Type of Kitting Is Most Relevant for Food Manufacturing?

Primarily material kitting (internal, for production) and product kitting (finished-goods bundles). The right choice depends on when kitting occurs in the process and who receives the kit.

How Does Kitting Reduce Waste and Improve Compliance in Food Processing?

Pre-portioned, standardized kits limit over-portioning and spoilage while minimizing handling errors. Consistent labeling and traceability support regulatory compliance and faster issue resolution.