Food manufacturers are under increasing pressure to keep pace with rising consumer demand, stricter regulations, and rapidly changing technology, all while maintaining efficient and cost-effective operations. Traditional methods that once fueled growth are quickly becoming outdated, creating inefficiencies that manufacturers can no longer afford to ignore.

With the global population projected to reach nearly 9.1 billion by 2050, the Food and Agriculture Organization emphasizes that food production must rise by 70%, forcing manufacturers to rethink how they produce, package, and deliver products. From labor challenges to sustainability goals, the industry is facing a pivotal moment.

Leading manufacturers are already investing in smart automation, clean-label initiatives, and advanced data tools to stay competitive. Moreover, three forces are driving this shift, including rapid tech adoption, environmentally responsible practices, and evolving consumer preferences.

Together, these food manufacturing trends aren’t just reshaping the industry, but they’re setting the bar for survival and success in 2025 and beyond. So, keep reading to find out what the top food manufacturing trends to watch in 2025 are.

Why Are Food Manufacturing Trends Important for Business Success?

Staying ahead of industry trends is crucial for maintaining competitiveness in the rapidly evolving food manufacturing industry. In markets where margins are tight and customer expectations shift rapidly, early awareness of emerging developments can shape smarter strategic choices.

Food manufacturing trends signal where consumer demand, regulatory frameworks, and technological innovation are heading. Proactively aligning operations with these shifts enables manufacturers to streamline their production, improve quality, and adapt more quickly than their competitors. This agility often translates into increased efficiency, cost savings, and stronger market positioning.

Moreover, the early adoption of relevant technologies and practices provides a first-mover advantage, helping companies lead rather than follow. Rather than reacting to change under pressure, trend-aware manufacturers invest with precision, avoiding wasteful upgrades and capturing growth opportunities at the right time.

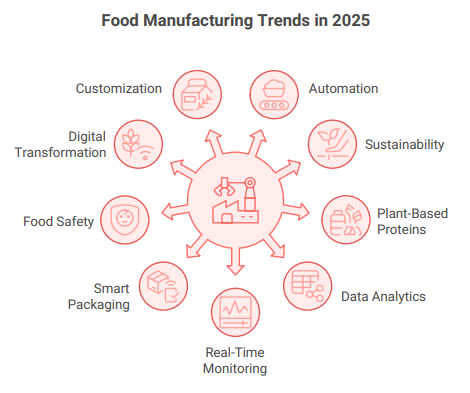

Top 9 Food Manufacturing Trends Set to Shape 2025

The food manufacturing industry is entering a new era shaped by automation, sustainability, and evolving consumer demands. But not every trend is built to last. Let’s break down the top 10 food manufacturing trends making waves in 2025, explaining what’s driving them, how they’re transforming production, and which ones are likely to define the future of food manufacturing for years to come.

1. Surge in Automation and Robotics Production Lines

Automation is one of the most transformative food manufacturing trends today, reshaping operations across businesses of all sizes. As labor challenges intensify and demand for consistent quality rises, food producers are turning to robotics and intelligent systems to remain competitive.

Trend Overview

Modern robotic systems now handle tasks requiring speed, precision, and reliability far beyond human capabilities. From processing delicate baked goods to stacking heavy beverage cases, automation adapts to a wide range of product types. These systems go well beyond simple mechanical arms; they integrate machine learning, computer vision, and real-time data processing to enhance decision-making and performance.

Advanced automation also connects multiple production stages, including mixing, forming, packaging, and palletizing, into a single, organized workflow. This reduces manual handling, minimizes the risk of contamination, and ensures consistent product quality.

Impact on Food Manufacturing

Automated production lines can increase output, while also improving consistency and lowering defect rates. Quality control becomes more reliable, resulting in fewer resources being wasted due to human error or inconsistent handling.

Additionally, automation enables manufacturers to reallocate labor from repetitive tasks to more strategic roles, such as system monitoring, maintenance, and quality assurance. This shift not only improves job safety but also enables faster scaling of operations to meet demand spikes without the delays and costs of hiring and training new staff.

One compelling example is Chef Robotics, a San Francisco-based startup that’s quietly transforming meal assembly lines using AI-powered robotic arms.

These systems are trained through real-world production data and on-the-job learning, allowing them to handle complex, delicate food items with high precision, a challenge traditional automation often faces.

At facilities like Amy’s Kitchen, they’ve improved product consistency, reduced food waste, and increased labor productivity without the need for extensive reprogramming or upfront CapEx.

Future Outlook

The integration of artificial intelligence will make automated systems more adaptive and predictive. Instead of following fixed programming, future robotic systems will learn from production data to continuously optimize their operations. Predictive maintenance capabilities will reduce unexpected downtime while improving overall equipment effectiveness scores.

Collaborative robots, designed to work safely alongside human operators, will become more prevalent, especially in facilities that process diverse product lines and require frequent changeovers. These systems will handle routine tasks, allowing human workers to focus on complex problem-solving and quality judgment decisions.

As demonstrated by Chef Robotics, the future of food manufacturing lies in intelligent automation, where AI-driven machines not only execute tasks but also evolve with the operation, making the entire production process smarter, faster, and more resilient.

2. The Growing Role of Sustainability in Food Manufacturing

Sustainability is no longer a nice-to-have, but it’s a core business priority in food manufacturing. With rising consumer expectations, tightening environmental regulations, and growing investor scrutiny, manufacturers must adopt more sustainable practices to stay viable.

Trend Overview

Sustainability in food manufacturing encompasses every aspect of the production process, from energy and water usage to packaging materials and waste management. Companies are increasingly being held accountable not just for the quality of their products but also for how those products are made.

Consumers now demand transparency and favor brands that demonstrate environmental responsibility. At the same time, regulatory bodies are enforcing stricter standards around emissions, water usage, and packaging waste. This dual pressure is pushing manufacturers to adopt energy-efficient systems, reduce their carbon footprint, and rethink packaging through eco-friendly alternatives.

For instance, many plants are now implementing renewable energy sources (like solar or biogas), optimizing transportation logistics to cut fuel usage, and investing in water recycling systems, especially in drought-prone regions.

Impact on Food Manufacturers

Sustainability isn’t just about compliance, but it can also deliver real cost savings. Upgrading to energy-efficient machinery, reducing material waste, and optimizing water usage can result in operational cost savings of 15–25% within a few years, according to research.

These savings, coupled with reduced environmental impact, create a win-win for businesses and the planet. Moreover, sustainability efforts enhance a brand’s image and foster customer loyalty. Products labeled as “eco-friendly” or “responsibly made” often command premium pricing and outperform competitors in increasingly values-driven markets.

Future Outlook

Regulations around emissions, packaging, and resource consumption will continue to tighten, making sustainability investments essential, not optional. We’ll also see greater adoption of circular economy practices, where waste is minimized and by-products are repurposed or recycled within the production cycle.

Innovations such as biodegradable packaging, closed-loop water systems, and zero-waste manufacturing lines are likely to become industry standards rather than competitive advantages.

In short, sustainability is reshaping food manufacturing, from how facilities are powered to how products are packaged. Companies that lead in this area will be better positioned for long-term success.

3. The Rise of Plant-Based and Alternative Proteins in Food Manufacturing

As demand for alternative proteins continues to grow, food manufacturers are adapting their processes to accommodate new ingredients, formats, and safety requirements. This shift isn’t just about changing recipes; it’s about rethinking entire production systems.

Trend Overview

Producing plant-based and alternative proteins involves fundamentally different processing techniques than those used for traditional animal-based foods. These products require specialized equipment, handling systems, and preservation methods tailored to diverse protein sources like legumes, fungi, algae, and cultured meat.

They also present unique challenges in texture, moisture retention, and shelf life, often requiring novel manufacturing strategies and robust allergen controls when facilities handle both animal and non-animal products.

Across the UK, this transformation is becoming more visible as startups explore innovative raw materials and production methods. According to research, companies like Oceanium are turning seaweed into protein-rich ingredients through cascade biorefining, while Naylor Nutrition is pioneering cabbage-based protein products.

Quorn, a long-time market leader, continues to dominate with its fermented fungi-based offerings. Meanwhile, Myconeos is leveraging fungal genetics to improve the taste and texture of plant-based cheeses, and Nova Farina is developing pea and fava bean proteins grown in East Anglia.

Emerging players like CellRev are advancing fermentation technology to create scalable cultured proteins using continuous cell harvesting. These businesses are helping to reshape ingredient sourcing and processing expectations, pushing manufacturers to invest in more adaptable, biotech-integrated production capabilities.

Impact on Food Manufacturers

Flexibility is key. To serve both traditional and alternative protein markets, manufacturers are building adaptable production lines or dedicating separate facilities to meet these needs. This ensures product integrity, avoids allergen risks, and supports compliance with food safety standards.

Ingredient sourcing also becomes more complex. Manufacturers must vet new suppliers, develop quality benchmarks for novel ingredients, and adapt to different storage and processing needs. At the same time, diversifying inputs away from animal agriculture creates more resilient supply chains and opens access to fast-growing consumer segments.

Future Outlook

Looking ahead, hybrid protein products and advancements in cellular agriculture will further blur the line between food and biotech. Manufacturers that embrace this complexity, investing in flexible infrastructure, smart processing, and cross-functional R&,D will be best positioned to lead in this evolving protein economy.

4. The Growing Importance of Data Analytics in Food Manufacturing

In a fast-paced food production environment, data is becoming just as valuable as the ingredients themselves. With increasing complexity across operations, food manufacturers are turning to data analytics to enhance efficiency, minimize waste, and respond more quickly to market shifts.

Trend Overview

Modern manufacturing systems generate massive volumes of data from production line sensors to inventory and quality control systems. Advanced analytics tools transform this raw information into actionable insights, enabling manufacturers to identify bottlenecks, optimize processes, and detect issues before they escalate.

Real-time data analysis enables teams to respond promptly to production slowdowns, quality inconsistencies, or equipment malfunctions. Predictive analytics helps forecast maintenance needs, align production with demand, and manage inventory more effectively, which is crucial in an industry dealing with short shelf lives and fluctuating supply chains.

Impact on Food Manufacturers

Manufacturers that utilize data analytics typically experience efficiency gains of 10–20%, reduced downtime, and improved product consistency. With real-time monitoring and process adjustments, quality issues can be addressed before they impact output.

Inventory data tied to demand forecasting reduces spoilage and cuts storage costs making operations leaner and more responsive to consumer trends. For food producers managing perishable goods, this kind of optimization can be a game-changer.

Future Outlook

Machine learning will uncover patterns and opportunities that surpass human detection, enabling fine-tuning of production with minimal intervention. The integration of internal manufacturing data with external sources, such as weather patterns, consumer trends, and supply chain metrics, will support more intelligent and more adaptive decision-making across the board.

5. Real-Time Monitoring and Remote Management Are Reshaping Food Production

As food manufacturing becomes increasingly distributed and demand becomes more volatile, real-time visibility into operations is no longer optional, but it’s essential. Remote management technologies are enabling manufacturers to maintain control and consistency, even across multiple locations or during workforce disruptions. In these setups, secure connectivity tools such as a VPN with port forwarding, as those reviewed by VPNOverview, can help authorized teams access monitoring systems and equipment dashboards remotely, without exposing critical infrastructure to unnecessary risks.

Trend Overview

IoT-enabled sensors now track key variables, such as temperature, humidity, and pressure, throughout the production process. Cloud-based platforms centralize this data, allowing managers and specialists to oversee operations in real-time from anywhere.

These systems proved their value during recent food supply chain and labor disruptions, enabling production to continue even with limited on-site staff. They also allow consistent oversight across facilities, making multi-site management far more efficient.

Impact on Food Manufacturers

Remote access to live production data dramatically improves response times. Instead of waiting for manual reports or audits, teams can act immediately when a deviation occurs, preventing defects and ensuring regulatory compliance.

For smaller manufacturers, remote access to expert support levels the playing field, allowing them to compete more effectively. Specialists can troubleshoot issues remotely, reducing downtime and eliminating the need for constant on-site support.

Future Outlook

Emerging tools, such as augmented reality, will enhance remote support, enabling experts to guide on-site staff through repairs and processes via live visual overlays. In parallel, automated systems will increasingly handle routine tasks, alerting human operators only when complex issues arise.

Over time, these technologies will evolve from passive monitoring to intelligent systems that learn, adapt, and optimize production autonomously.

6. The Integration of Smart Packaging

As packaging evolves from a passive container to an active part of the product experience, food manufacturers must rethink how they design, produce, and monitor packaged goods. Smart packaging is introducing both challenges in food industry and opportunities across the production floor.

Trend Overview

Smart packaging technologies, such as freshness sensors, QR codes, NFC tags, and temperature indicators, enable real-time communication about a product’s condition, origin, and authenticity. Active packaging materials can also interact with the food itself to extend shelf life or absorb moisture and oxygen.

To implement these technologies effectively, manufacturers must upgrade packaging lines, ensure system compatibility, and introduce new quality control checkpoints to verify sensor accuracy and data integrity. Integration with production data systems is critical to ensure consistency and traceability.

Impact on Food Manufacturers

Though initial investment in smart packaging can be high, the long-term benefits are substantial. Enhanced traceability improves food safety compliance and recall responsiveness. Real-time freshness data reduces waste and allows proactive food inventory management. Products using smart packaging often earn consumer trust and shelf space by offering transparency, interactive features, and sustainability credentials.

For instance, companies like FreshPoint use TTIs to reduce waste, while others, like Coca-Cola and Nestlé, have incorporated QR codes and augmented reality to enhance consumer engagement. As a result, food packaging becomes not just protective, but communicative and interactive.

Future Outlook

The future of smart packaging lies in the convergence of technology and sustainability. Expect to see biodegradable sensors, plant-based smart films, and compostable IoT components become more common. Blockchain may also play a key role in tamper-proof traceability from farm to fork.

As consumer demand shifts toward transparency, safety, and sustainability, smart packaging is quickly becoming a manufacturing standard rather than a premium feature.

7. Evolving Food Safety and Compliance Standards in Manufacturing

As public health concerns rise and supply chains become increasingly complex, food safety regulations are becoming stricter, and manufacturers must adapt to them. Ensuring product integrity is no longer just about meeting minimum requirements, but it’s also about building trust, protecting brand reputation, and staying competitive in a global market.

Trend Overview

Food safety standards are expanding in scope and enforcement. Regulators now expect full product traceability, real-time monitoring, and thorough documentation across all stages of the production process.

To meet these demands, manufacturers are adopting technologies like rapid pathogen detection systems, automated temperature and humidity monitoring, and blockchain-based traceability platforms. These tools reduce the risk of contamination, enable faster responses to potential issues, and support seamless audits.

Impact on Food Manufacturers

Compliance efforts require new investments in equipment, training, and digital systems; however, the cost of inaction is significantly higher. Contamination incidents can lead to product recalls, legal consequences, and lasting damage to a brand’s reputation. Manufacturers with robust food safety programs often benefit from lower insurance premiums and fewer disruptions to their operations.

In a market where consumers are highly aware of safety issues, having a clean record is a brand advantage. Companies known for safety and transparency gain customer loyalty and partner trust that competitors can’t easily replicate.

Future Outlook

Looking forward, AI-powered safety systems will predict contamination risks before they occur, analyzing environmental data, equipment behavior, and historical food manufacturing trends to identify potential issues early. Meanwhile, international regulatory bodies are working toward harmonization, making it easier for manufacturers to comply across markets through standardized protocols and shared certifications.

Food safety will continue to be a defining factor in how food manufacturers operate and succeed in an increasingly transparent and regulated industry.

8. Digital Transformation Is Redefining Food Manufacturing Operations

As the food manufacturing landscape becomes increasingly complex, digital transformation in manufacturing is shifting from an option to a necessity. From production planning to final delivery, technology is reshaping how manufacturers operate, collaborate, and compete.

Trend Overview

Modern food manufacturers are adopting cloud-based systems and industry-specific ERP platforms to manage everything from inventory and lot tracking to shelf-life monitoring and regulatory compliance. These systems centralize critical information, improve traceability, and reduce manual errors across operations.

However, digital transformation extends beyond simply installing new software. It requires rethinking processes, upskilling teams, and creating a connected, data-driven culture across departments from production to quality assurance to logistics.

Impact on Food Manufacturers

With real-time visibility into inventory, production status, and quality metrics, teams can respond more quickly to issues, optimize output, and minimize waste.

Departmental silos begin to break down as integrated systems enable sales, planning, and quality teams to work from a shared data environment, improving coordination and customer responsiveness. Digital tools also enhance compliance readiness, making audits and reporting more efficient and less prone to errors.

Future Outlook

Artificial intelligence will soon play a larger role in food manufacturing, automating routine decisions such as reorder points, schedule adjustments, and equipment tuning. Over time, these systems will learn from historical outcomes to offer smarter, more accurate recommendations.

Looking externally, digital integration with suppliers and distributors for food distribution management will enable end-to-end visibility across the supply chain, helping manufacturers transition from reactive to predictive operations.

9. The Rise of Customization and Personalization in Food Production

Today’s consumers want more than just food. They want products that reflect their personal preferences, lifestyles, and values. In response, food manufacturers are shifting from mass production to flexible, consumer-centric models that prioritize customization and direct engagement.

Trend Overview

Customization in food manufacturing goes beyond flavors and packaging. It includes dietary preferences, portion sizes, nutritional profiles, and even ingredient sourcing. To meet these expectations, manufacturers must adopt agile production systems that can handle small-batch runs, rapid changeovers, and dynamic order inputs without sacrificing quality or efficiency.

E-commerce and direct-to-consumer (DTC) channels are driving much of this shift. Online platforms enable consumers to specify their preferences, which are then translated into real-time production specifications, automating what was once a costly and manual process.

Impact on Food Manufacturers

Meeting customization demands adds complexity to production planning. Shorter runs and frequent adjustments can raise setup costs and operational strain. However, the payoff comes through premium pricing opportunities, stronger brand loyalty, and deeper customer relationships, advantages that mass-produced products often lack.

Customization also offers a competitive edge. Manufacturers that can reliably deliver personalized products gain trust and differentiation in crowded markets, particularly as consumers increasingly seek transparency and control over their food choices.

Future Outlook

Modular production systems designed for fast reconfiguration will become more common, enabling manufacturers to switch between product variations efficiently.

These systems will rely on standardized components to reduce downtime and increase throughput. As technology evolves, manufacturers will be better equipped to deliver highly personalized food experiences on a large scale.

Conclusion

The food manufacturing industry is undergoing rapid transformation, driven by evolving consumer expectations, regulatory pressures, and breakthrough technologies. Manufacturers that invest in digital infrastructure, prioritize food safety, and embrace agile production models will not only meet market demands but also unlock new revenue streams and operational efficiencies.

As the industry continues to modernize, staying ahead means rethinking traditional processes and adopting the future of food production management now.

FAQs

What Are The Key Trends In Food Manufacturing For 2025?

The key food industry trends include the implementation of automation and robotics, sustainability initiatives, plant-based product development, the adoption of data analytics for food safety, real-time monitoring systems, smart packaging integration, enhanced food safety measures, digital transformation, and mass customization capabilities.

How Does Folio3’s Food ERP Support Food Manufacturers?

Food-specific ERP systems address the unique industry requirements of lot tracking, shelf-life management, regulatory compliance, and traceability. These systems integrate production planning, inventory management, quality control, and regulatory reporting in unified platforms that provide real-time visibility across all operations.

How Does Automation Affect Food Manufacturing?

Automation increases production speed by 200-400%, reduces defect rates by 60-80%, and creates more consistent quality outcomes. It shifts labor from repetitive tasks to higher-skilled monitoring and maintenance roles while providing operational flexibility to scale production based on demand without complex hiring and training processes.

What Role Does Sustainability Play In Food Manufacturing?

Sustainability has become essential for regulatory compliance, consumer acceptance, and reducing operational costs. Manufacturers implementing comprehensive sustainability programs report operational cost reductions of 15-25% while gaining brand differentiation advantages.