Food and beverage companies are under constant pressure to adjust products faster than before. A single regulatory change, such as new allergen labeling rules in the EU, can trigger immediate recipe or packaging updates. Add in volatile ingredient markets, and reformulations that once took months now have to be delivered in weeks. The risk of error is high, and recalls linked to mislabeling or allergens remain the leading cause of product withdrawals.

What makes it harder is how product information is usually managed: scattered spreadsheets, email threads, and local files that slow everything down. PLM for food and beverage helps by giving everyone access to the same structured record, from recipes and specs to compliance details. In this blog, we’ll explore how PLM fits into the food and beverage landscape. The problems it actually solves, how it integrates with existing systems, and what outcomes matter most for decision-makers.

What PLM Really Means for Food & Beverage Companies

When people hear “PLM,” they often think of generic product data management. In food and beverage, it means something much more specific and far more complex. Unlike discrete manufacturing, where a design drawing can stay unchanged for years, every recipe or formulation in food is subject to constant adjustment. A small tweak in an ingredient, a new allergen rule, or even a packaging material change can cascade through labels, nutrition panels, supplier approvals, and compliance documentation.

That’s why PLM for food and beverage isn’t just an R&D tool. It’s the structured backbone for recipes, packaging, compliance rules, and supplier data that every other system, from ERP to supply chain, depends on. Without it, companies risk slower reformulations, mislabeling errors, and unnecessary recalls. With it, they create a consistent “product truth” that can be trusted across teams, markets, and facilities.

Importantly, PLM also accelerates product launches. For example, if a beverage brand decides to release a low-sugar variant, PLM can instantly calculate the new nutrition panel, flag any allergen risks, update packaging artwork, and push approved specs into ERP for production scheduling. What once took months of back-and-forth can be reduced to weeks, giving companies the agility to respond quickly to consumer trends or regulatory changes.

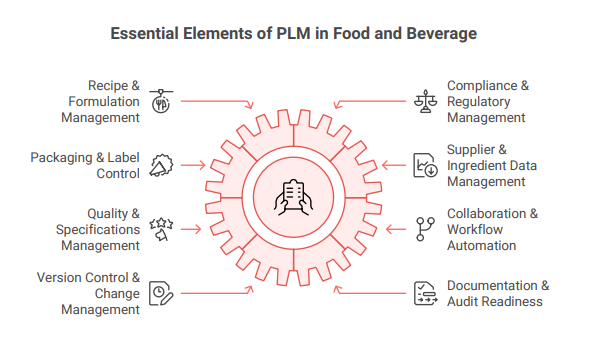

Key Components of PLM For Food and Beverage

In practice, PLM for food and beverage is only as strong as the functions it delivers. The following components define how product data is structured, governed, and applied across recipes, packaging, compliance, and supplier workflows.

1. Recipe & Formulation Management

PLM for food and beverage provides a controlled environment where every recipe variation is versioned, auditable, and linked to compliance data. Instead of static spreadsheets, formulators work with dynamic tools that:

- Auto-calculate nutrition panels through integrated nutrient databases.

- Flag allergen exposure via embedded allergen matrices.

- Model ingredient substitutions with real-time cost impact.

- Validate formulations against region-specific regulatory rules.

This ensures rapid, error-free reformulations while keeping specifications, supplier data, and downstream packaging fully synchronized.

2. Compliance & Regulatory Management

Compliance in food is a moving target. PLM for food and beverage embeds regulatory logic directly into product development, reducing recall risk and audit failures. For example, EU Regulation 1169/2011 requires clear food allergen management, while the FDA mandates “Added Sugars” disclosure and nutrient updates. PLM for food producers automates these checks by:

- Flagging non-compliant formulations at the development stage.

- Linking supplier certifications (Halal, Kosher, Organic) to approved ingredients.

- Maintaining audit-ready documentation for FDA, USDA, or EFSA inspections.

This proactive compliance layer accelerates approvals while safeguarding market access.

3. Packaging & Label Control

Packaging carries both brand identity and mandatory product information. PLM in food and beverage ensures that every packaging asset, artwork, claims, barcodes, and nutrition facts stay synchronized with the latest formulation. Misalignment is one of the top causes of costly food recalls. Food and beverage PLM reduces this risk by:

- Connecting recipes to packaging specifications and digital label templates.

- Enforcing region-specific standards (e.g., Canada’s bilingual labeling, EU allergen emphasis, U.S. FDA Nutrition Facts format).

- Automating version control so outdated labels cannot enter production.

| Challenge | How PLM For Food Producers Resolves It |

| Mislabeling from recipe changes | Auto-updates nutrition/allergen data in labels |

| Regional regulation differences | Region-specific compliance templates |

| Multiple artwork versions | Centralized asset library with version history |

4. Supplier & Ingredient Data Management

Ingredient volatility and food safety certification demands make supplier oversight a critical PLM function. Instead of chasing scattered certificates, PLM for food and beverage consolidates all supplier and raw material data into a single structured record. Unique strengths include:

- Integrated COAs (Certificates of Analysis): Auto-linked to ingredient lots for quality verification.

- Dynamic supplier scorecards: Tracking cost, lead times, and compliance history.

- Automated alerts: For expiring certifications (e.g., Organic, Halal, Kosher, Non-GMO).

- Alternate ingredient modeling: Enables quick reformulation when markets shift.

By tying approved suppliers directly to recipes, PLM reduces sourcing risks, accelerates substitutions, and ensures that only compliant, certified materials enter production.

5. Quality & Specifications Management

Every product spec in food carries real consequences. A 0.5% swing in moisture can shorten shelf life. A misreported protein level can break retailer contracts. PLM for food and beverage centralizes these specifications so they’re not buried in lab reports or email chains.

With PLM, QA teams can:

- Record and enforce microbiological, chemical, and sensory specs in one system.

- Auto-match supplier COAs with incoming lots to catch issues early.

- Trigger alerts when parameters drift outside approved ranges.

This means when a bakery’s flour shows abnormal gluten strength, the system flags it before dough mixing starts, protecting consistency, compliance, and margins.

6. Collaboration & Workflow Automation

In food companies, the biggest delays rarely come from the factory floor, they come from waiting on approvals. A new recipe, allergen update, or packaging change often passes through R&D, QA, regulatory, and marketing before it’s released. When these handoffs live in email chains or spreadsheets, weeks are lost and mistakes slip through.

PLM for food and beverage removes this friction by automating collaboration:

- Structured workflows: Every change request follows a defined approval path, reducing back-and-forth confusion.

- Parallel reviews: Packaging artwork, nutrition panels, and ingredient specs can be approved at the same time, not one after another.

- Full traceability: The system records who approved what, creating an audit trail ready for FDA, USDA, or retailer inspections.

7. Version Control & Change Management

In food manufacturing, a mislabeled allergen or outdated recipe version isn’t just a clerical error; it can trigger recalls, fines, and lost retailer trust. The problem usually isn’t bad data, but uncontrolled data. PLM in food and beverage solves this by enforcing version discipline across every product record.

Here’s what strong change management inside food and beverage PLM should guarantee:

✅ The system blocks outdated recipes, specs, and labels from being used in production.

✅ Every formulation tweak is time-stamped, user-tagged, and tied to a change rationale.

✅ Packaging or recipe updates automatically trigger downstream checks for nutrition and compliance impacts.

✅ Regional variants (e.g., sugar limits in the UK vs. U.S.) are tracked as linked, not isolated, versions.

✅ Obsolete versions are archived for audit reference, but never accessible for live use.

When allergen recalls remain the #1 cause of food withdrawals worldwide, this kind of version discipline prevents the classic “wrong file sent to the printer” error that costs millions.

8. Documentation & Audit Readiness

Audit season is stressful when documents live in email chains or paper binders. Retailers, FDA, or EFSA inspectors don’t wait while your team scrambles to prove allergen checks or supplier certifications. PLM in food and beverage eliminates the panic by keeping all compliance evidence structured, current, and instantly retrievable.

What Auditors Ask vs. How PLM Responds

| Auditor Request | Without PLM | With PLM |

| Show all allergen declarations for a product family. | Manual search through spreadsheets and labels. | Instant allergen matrix linked to live recipes. |

| Provide supplier certificates for raw materials. | Certificates are scattered in emails or filing cabinets. | Certificates are stored, time-stamped, and linked to each approved ingredient. |

| Demonstrate change history on a nutrition panel. | No clear audit trail, reliance on staff memory. | Complete version history showing who made the change and when. |

| Generate compliance reports for multiple regions. | Time-consuming manual collation. | Automated reporting aligned with FDA, USDA, and EFSA rules. |

Top 3 Emerging Applications & Trends in PLM For F&B

PLM is shifting from being a back-office compliance tool to a driver of innovation. Food and beverage companies now rely on it not just to manage recipes, but to predict, adapt, and innovate in real time.

1. AI-Driven Formulation & Labeling

AI inside PLM for food producers isn’t about replacing formulators, it’s about giving them speed and foresight. For instance, AI engines can run “what-if” simulations when an ingredient price spikes or a supplier drops out, instantly suggesting compliant alternatives without breaking nutrient or allergen thresholds. Label automation goes further. Systems can now generate multilingual nutrition facts and allergen statements, validated against FDA, EFSA, or CFIA rules in seconds.

2. Sustainability & ESG Tracking

Retailers like Walmart and Tesco now score suppliers on sustainability, while the EU’s upcoming Digital Product Passport (DPP) will demand complete lifecycle data by 2030. PLM for food and beverage is becoming the place where environmental metrics, CO₂ per kilogram of product, water intensity, packaging recyclability, and transport miles, are linked directly to formulations and packaging specs.

When integrated with ERP, this data flows into purchasing, production, and logistics, giving companies a clear view of how sourcing choices, manufacturing runs, or transport routes impact their sustainability targets. Just as importantly, it equips brands to answer growing consumer questions about origin, footprint, and packaging with data-backed confidence. In this model, sustainability isn’t an afterthought report; it’s embedded in daily operational decisions.

3. Digital Twins of Products

Digital twins are moving from aerospace into food, giving manufacturers a virtual way to test recipes and packaging before spending on trials. Within PLM, a digital twin can model how a reformulated beverage holds shelf stability under different temperature profiles, or how packaging performs in long-haul cold chains.

When connected with ERP, these simulations go further, feeding cost, production scheduling, and sourcing data into the model. That means a Dairy ERP solution can be used to test yogurt reformulation virtually for shelf life, carbon impact, and line efficiency before ingredients are even ordered. The result is fewer failed pilot runs, faster compliance sign-offs, and more predictable margins.

Product Lifecycle Management as the Missing Link in the Digital Stack

PLM for food producers alone can manage recipes, specs, and compliance, but its real value appears only when it integrates with the wider digital stack. Without those connections, the “product truth” inside PLM never reaches planning, production, or labeling systems.

That gap creates silos. R&D knows the right recipe, but food ERP still uses the old one, or QA runs checks on outdated specs. Integration ensures food PLM drives every downstream process, so decisions are based on current, approved data.

1. ERP Integration

ERP governs purchasing, costing, and production planning. But in food and beverage, formulations change constantly due to allergens, nutrient targets, or raw material volatility. Without food PLM, ERP may schedule runs or place orders on outdated specs. Integrated PLM pushes validated formulations, approved suppliers, and cost updates directly into ERP. For example, if sunflower oil is swapped for canola, PLM for food and beverage updates the BOM in the oil manufacturing ERP instantly, ensuring procurement doesn’t order the wrong ingredient.

How PLM and ERP Integration Helps:

- Syncs allergen and nutrition-driven formulation changes into BOMs.

- Adjusts ingredient costs in real time for margin visibility.

- Ensures ERP only uses supplier-approved raw materials.

2. MES Integration

MES executes batch instructions on the factory floor. In food and beverage operations, even small deviations, like oven temperature or pasteurization time, can affect shelf life or compliance. With PLM integration, MES receives current process parameters and formulation specs directly. If PLM updates a cooking profile to meet new FDA pathogen-reduction guidelines, MES instructions update automatically, avoiding production runs on outdated settings.

How PLM and MES Integration Helps:

- Pushes validated process specs (temperatures, hold times, fill weights).

- Reduces rework caused by outdated batch instructions.

- Improves batch traceability for recalls or audits.

3. QMS Integration

QMS manages audits, CAPAs, and non-conformances. In food manufacturing, this often means checking raw materials and finished goods against exact tolerances (e.g., fat %, moisture, microbiological counts). By integrating PLM, the food quality management system can match incoming COAs and test results against the latest approved product specs. If a supplier’s milk powder arrives outside protein tolerances, QMS flags it automatically before it’s released into production, protecting both compliance and brand reputation.

How PLM and QMS Integration Helps:

- Links COAs and supplier certifications to active product specs.

- Flags non-conformances in real time.

- Provides audit-ready trails aligned with HACCP and ISO 22000.

4. LIMS Integration

LIMS captures detailed lab data, micro tests, pH levels, and allergen traces. But without PLM, these results remain siloed. Integration ensures that lab data feeds directly into product specifications. For instance, if allergen residue is detected in a cleaning validation, PLM locks that recipe or line until QA approves corrective actions. This creates a closed loop between R&D, QA, and regulatory teams.

How PLM and LIMS Integration Helps:

- Embeds lab results directly into live product records.

- Blocks non-compliant lots from moving forward.

- Enables rapid root-cause analysis during recalls.

Implementation & Adoption: What F&B Companies Should Know

Adopting PLM in food and beverage is less about software installation and more about reshaping how product data flows across the business. Companies that succeed treat it as a transformation project, not just an IT upgrade. The critical success factors fall into five areas.

1. Data Readiness

Scattered spreadsheets, inconsistent allergen records, and fragmented supplier certifications are standard in food companies. Cleansing and standardizing this data before migration is essential; otherwise, errors simply get amplified inside PLM.

2. Integration Planning

PLM creates value when connected to ERP, MES, QMS, and LIMS. Integration ensures that approved formulations, process parameters, and quality checks are reflected in downstream systems, preventing costly misalignment between R&D, production, and food safety compliance.

3. Regulatory Configuration

PLM should embed compliance logic from day one: allergen disclosure, FDA nutrition panel updates, food labeling rules, and USDA export standards. Building these into workflows avoids last-minute relabeling or reformulation crises.

4. Phased Rollout

Rather than attempting a company-wide launch, start with high-risk or export-driven categories. Allergen-sensitive products or those subject to stricter international labeling provide a strong proving ground for PLM, with measurable ROI.

5. Change Management

The real measure of adoption is whether R&D, QA, and regulatory teams use PLM as part of their daily workflows. Training should focus on practical tasks such as approving formulation changes, validating COAs, or generating audit-ready reports.

Conclusion

For food and beverage companies, product data has become too complex and too critical to manage in spreadsheets or siloed systems. From allergens and nutrition panels to packaging and supplier compliance, every detail carries regulatory and financial risk. PLM provides the structure to manage this complexity, ensuring accuracy, speed, and transparency across the entire product lifecycle.

When integrated into the digital stack, PLM transforms from an R&D tool into a strategic backbone for innovation and compliance. Companies that approach adoption methodically, with clean data, phased rollouts, and embedded regulatory logic, position themselves to react faster to market shifts and build stronger trust with retailers and consumers alike.

FAQs

What Is PLM in Food Manufacturing?

PLM in manufacturing is a structured platform that manages every product detail, from formulation, nutritional data, and allergen profiles to packaging artwork and supplier certifications. Unlike generic data tools, it accounts for constant recipe changes, regional labeling rules, and compliance demands unique to the food industry.

How Can PLM Benefit Food Producers?

PLM shortens reformulation cycles, prevents mislabeling (the leading cause of recalls), and embeds regulatory checks into workflows. For producers, this means faster market launches, stronger retailer compliance, and the ability to trace every product back to its exact recipe, supplier, and batch history.

What Are the Key Features of PLM for Food Manufacturers?

Important PLM features include version-controlled recipe management, automated nutrition panel calculations, allergen risk matrices, packaging–formulation synchronization, and supplier data governance. Many systems also provide audit trails and integration hooks for ERP, MES, and QMS, ensuring product truth flows consistently across operations.

Can PLM Food and Beverage Be Integrated with ERP Systems?

Yes, integration is a critical part of adoption. PLM pushes approved formulations, bills of materials, and cost updates directly into ERP. This ensures procurement orders the right raw materials, production schedules reflect current recipes, and financial planning aligns with real ingredient costs.