Food waste and spoilage remain two of the most pressing challenges in today’s food industry. According to the Food and Agriculture Organization (FAO), one-third of all food produced for human consumption is lost or wasted globally, creating not only economic losses but also significant environmental consequences. For food processors, exporters, and retailers, this makes product preservation more than just an operational concern; it is a strategic necessity.

One solution that has redefined how food is stored, transported, and consumed is vacuum packaging. By removing air from packaging before sealing, vacuum technology creates an oxygen-free environment that slows bacterial growth, prevents oxidation, and significantly extends product shelf life. This innovation directly supports businesses looking to reduce spoilage across long distribution routes while maintaining quality and safety standards.

For commercial operations in sectors such as meat, seafood, and fresh produce, vacuum sealing ensures that products reach retailers with maximum freshness and consistency. At the same time, home users benefit from the same technology to reduce waste, preserve nutrition, and stretch household food budgets.

In this blog, we will explore what vacuum packaging is, how it works, its benefits, key applications across industries, and best practices to maximize freshness and minimize waste.

What Is Vacuum Packaging?

Vacuum packaging is a method of sealing food by removing air from the package before closing it securely. By eliminating oxygen, which bacteria and mold need to grow, this technique significantly extends the shelf life of both fresh and processed foods.

Unlike regular sealing methods, where air remains trapped inside, vacuum packaging creates a tightly sealed environment around the food. This makes it ideal for products that are sensitive to moisture, temperature, and contamination.

Some of the most common examples of vacuum sealed food include:

- Fresh meat and poultry in retail stores

- Cheese and dairy products

- Coffee beans and ground coffee

- Frozen seafood

- Pre-cooked meals

Vacuum packaging has become standard in the food industry because it not only increases shelf life but also enhances food safety, improves product presentation, and reduces waste.

How Vacuum Sealing Food Works

Vacuum sealing is a simple yet highly effective preservation method that removes air from packaging to extend food freshness and safety. The process of vacuum sealing food involves three basic steps:

Placement in packaging

The food product is placed in a specially designed vacuum bag or pouch that can withstand the sealing process. These materials are engineered to block oxygen, moisture, and contaminants, providing superior protection compared to conventional packaging.

Air Removal

A vacuum sealer extracts the air from the bag, leaving little to no oxygen inside. This step is critical because oxygen accelerates spoilage, supports bacterial growth, and causes freezer burn in frozen goods. By removing oxygen, vacuum sealing creates an environment that slows down these natural processes.

Sealing

Heat sealing secures the package, locking in freshness and preventing air from re-entering. This airtight seal not only extends shelf life but also preserves taste, texture, and nutritional value.

While the process seems simple, its impact is substantial. In commercial environments, industrial-grade vacuum sealers often integrate with automated production lines to ensure consistency, speed, and traceability. For example, meat traceability for processors and seafood exporters rely on high-capacity systems to meet strict safety and export requirements. At the household level, compact countertop sealers give families the ability to preserve leftovers, bulk purchases, or pre-prepared meals with ease.

The result is vacuum-packed food that lasts longer, stays safer, and retains its original quality. Over time, this translates into lower operational losses for businesses, cost savings for households, and stronger food safety standards across the supply chain.

The Benefits of Vacuum Sealing Food

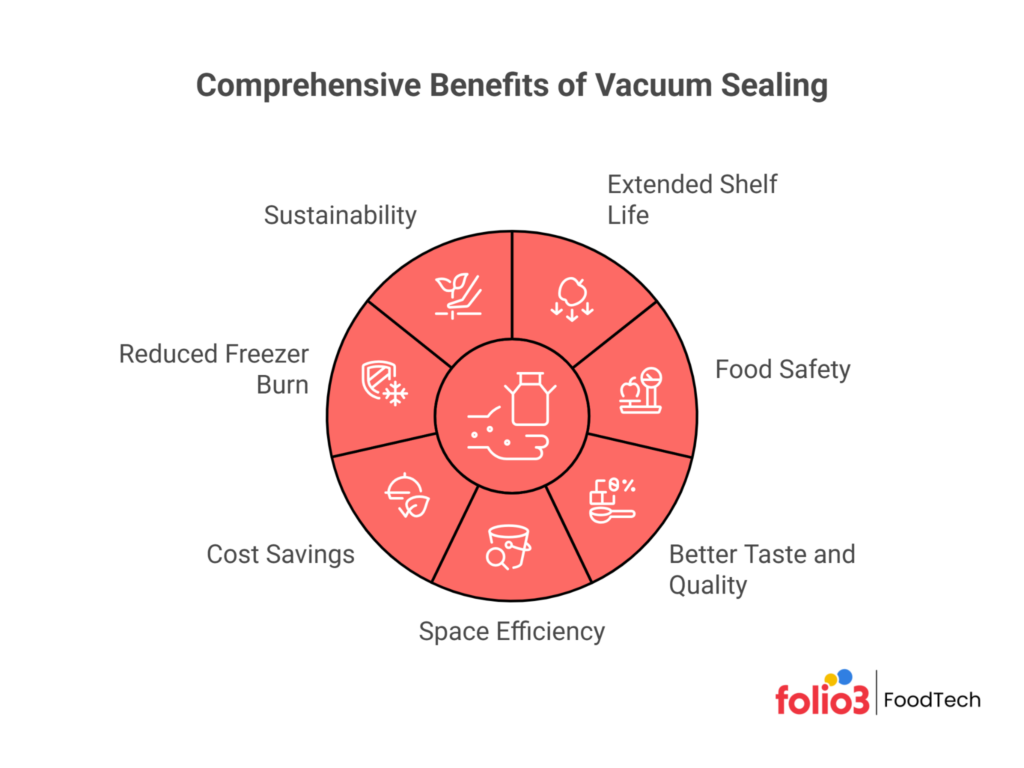

Adopting vacuum packaging brings a wide range of advantages, both for businesses in the food industry and individual households. Below are the most significant benefits of vacuum sealing food:

1. Extended Shelf Life

The most recognized benefit is longer shelf life. Vacuum sealed food stays fresh up to three to five times longer than traditional packaging because oxygen, bacteria, and mold are minimized. This makes it an essential practice for products with short natural lifespans, such as fresh meat, seafood, or dairy. It also helps retailers and distributors manage inventory with less risk of spoilage.

2. Food Safety

Removing oxygen also reduces the risk of Listeria and other harmful bacterial growth. For businesses, this means better compliance with food safety standards. For households, it ensures healthier meals with less risk of spoilage. When combined with proper refrigeration or freezing, vacuum packaging significantly lowers contamination risks during storage and transport.

3. Better Taste and Quality

Vacuum packaging preserves flavor, texture, and nutritional value. Foods like coffee, cheese, or meat retain their original qualities for much longer. By limiting exposure to air and moisture, it prevents flavor loss and helps maintain the “just-prepared” taste that consumers value.

4. Space Efficiency

Vacuum packed food bags take up less room in refrigerators, freezers, or storage areas, making them ideal for both commercial warehouses and small kitchens. Because the packaging is compressed tightly around the food, it eliminates unnecessary bulk, making organization easier and storage more efficient.

5. Cost Savings

Bulk buying becomes easier when food can be vacuum sealed for later use. For companies, it reduces waste and improves profitability. For households, it helps families save money by cutting down on spoiled food. Over time, the savings often outweigh the initial investment in a vacuum sealer.

6. Reduced Freezer Burn

Freezer burn happens when air interacts with frozen food. Vacuum packaging prevents this by creating an airtight environment, keeping frozen items fresh for months. This ensures that meats, vegetables, and prepared meals retain both flavor and texture even after long storage periods.

7. Sustainability

By minimizing food waste, vacuum sealing food preservation contributes to global sustainability efforts. Less food spoilage means fewer resources wasted in production and distribution. It also helps reduce plastic and packaging waste, since vacuum-sealed bags typically require less material than bulkier packaging alternatives.

Common Uses for Vacuum Sealer Machines

A vacuum sealer has countless applications across industries and households. Below are some of the most essential uses for vacuum sealer machines:

- Meat and Poultry Packaging: Keeps meat fresh, prevents freezer burn, maintains quality during transport, making vacuum sealed packaging one of the most common meat preservation methods.

- Cheese and Dairy Products: Stops mold growth and keeps texture intact.

- Seafood Preservation: Maintains flavor and prevents spoilage during freezing or long-distance shipping.

- Snack Foods and Grains: Keeps dry items crunchy and free from moisture.

- Prepared Meals: Perfect for restaurants, catering, or busy households practicing meal prep.

- Export and Retail: Vacuum packed food ensures safety and quality during long distribution chains.

At the consumer level, vacuum seals extend beyond food. Non-food items such as documents, silverware, and camping gear can also be vacuum sealed for protection against moisture or dust.

Vacuum Packaging in the Food Industry

In the commercial food sector, vacuum packaging is not just about extending shelf life. It has become a cornerstone of modern food operations, supporting efficiency, safety, and brand value across the supply chain. By eliminating oxygen and locking in freshness, vacuum sealed food allows producers and retailers to maintain quality while meeting the rising expectations of consumers. Here are the key ways it plays a role:

Supply Chain Management

Vacuum sealing food ensures that products arrive at retailers fresh, safe, and consistent in quality. From large-scale processors in the meat packaging industry to seafood exporters, vacuum packaging reduces the risk of spoilage during transport. It helps products survive longer distribution routes without compromising safety.

Food Traceability

A Food ERP software now integrates QR or barcode tracking with vacuum sealed packages for better traceability. This provides buyers and regulators with clear information on origin, batch details, and shelf life. In the event of recalls, these systems allow companies to act quickly, reducing both risk and financial loss.

Regulatory Compliance

Vacuum packaging is central to meeting strict food safety compliance in food handling, processing, and storage. It reduces microbial growth, supports HACCP compliance, and aligns with international export regulations. For businesses aiming to expand into new markets, this level of compliance is often a non-negotiable requirement.

Brand Presentation

Clear, tight vacuum packed food improves product appearance on supermarket shelves. Shoppers are more likely to trust and purchase items that look fresh and well-preserved. Attractive, consistent packaging also reinforces brand credibility, especially for premium products like artisanal meats or specialty cheeses.

For businesses, the benefits of vacuum sealing food directly connect to higher customer satisfaction, reduced returns, and more substantial profit margins. When combined with digital tools for traceability and compliance, it becomes a competitive advantage rather than just a preservation method.

Preservation Tips for Vacuum Sealed Food

While vacuum packaging greatly improves food preservation, it is most effective when combined with best practices. Applying the proper techniques helps maximize freshness and avoid common mistakes:

Pre-chill Foods

Always cool hot food before vacuum sealing to prevent condensation inside the bag. Moisture buildup can weaken the seal and create an environment for bacteria to grow. Pre-chilling also ensures that the food’s texture and flavor are preserved more effectively.

Use Quality Bags

Cheap bags may puncture or fail under freezing conditions. Using professional-grade vacuum packaging bags guarantees durability and prevents leaks. Higher-quality materials are also better at blocking oxygen and moisture, keeping food safe for long-term storage.

Seal Liquids Carefully

For soups or sauces, freeze them partially before sealing to avoid spills. Liquids can get sucked into the vacuum sealer and damage the machine if not handled correctly. Pre-freezing also makes it easier to portion liquid foods into single-use servings.

Label Everything

Always note the date and contents on each vacuum sealed food bag using custom packaging labels. Proper labeling helps track shelf life and reduces the chances of forgotten or wasted items in the freezer. For businesses, this also supports food traceability and regulatory compliance.

Freeze When Needed

While vacuum sealing food preservation slows spoilage, freezing provides longer-term protection. Combining both methods ensures items like meats, fish, and seasonal produce can be safely stored for months without compromising taste or quality.

Avoid Overfilling

Leave enough space at the top of bags to ensure proper sealing. Overfilling can cause wrinkles in the seal, allowing air to leak back in. A clean, flat seal line is essential for maintaining freshness and preventing freezer burn.

By following these steps, vacuum sealed food stays fresher for longer and delivers maximum quality, whether at home or in large-scale commercial operations.

Challenges and Limitations of Vacuum Packaging

While the benefits of vacuum sealing food are clear, it is important to recognize some limitations that come with the process:

Initial Equipment Cost

Commercial-grade vacuum sealers can be expensive, with additional costs for maintenance, replacement parts, and the specialized vacuum bags required. For small farms, startups, or households, this upfront investment can be a barrier. Over time, costs may balance out through reduced spoilage and waste, but the initial expense is often a challenge.

Training Needs

Vacuum packaging requires correct handling to ensure food safety. In commercial facilities, staff must be trained to clean equipment properly, operate machines without damaging seals, and follow hygiene protocols to avoid cross-contamination. Inconsistent training or errors in sealing can lead to product recalls or safety risks.

Not Suitable for All Foods

Delicate foods such as berries, leafy greens, mushrooms, or baked goods can be crushed under vacuum pressure, reducing quality and presentation. To manage this, producers may use gentler sealing methods, partial vacuuming, or switch to alternatives like modified atmosphere packaging (MAP). Understanding which products are suitable for vacuum packaging is critical for maintaining product integrity.

Storage Conditions Still Matter

Vacuum packaging extends shelf life by slowing bacterial growth, but it does not stop it entirely. Perishable foods must still be refrigerated or frozen to remain safe. For example, vacuum-sealed meat stored at room temperature is still at risk of rapid spoilage. This makes temperature control an essential part of the process, alongside packaging.

Environmental Considerations

Vacuum packaging relies heavily on single-use plastic bags and films, many of which are not recyclable. For businesses focused on sustainability, this presents a challenge. Some suppliers now offer biodegradable or recyclable vacuum pouches, but adoption is limited due to cost and availability.

How Folio3 FoodTech Enhances Vacuum Packaging Efficiency

Vacuum packaging is only as effective as the systems that manage it. For food businesses handling large-scale operations, packaging is not just about sealing products but also about ensuring traceability, compliance, and efficiency across the entire supply chain. This is where Folio3 FoodTech’s Food ERP plays a transformative role by integrating vacuum packaging processes with end-to-end business operations.

Key Features of Folio3 Food ERP for Vacuum Packaging

- Automated Batch Tracking – Ensures every vacuum-sealed product can be traced back to its source, improving food safety and recall management.

- Quality Control Management – Monitors sealing integrity, temperature logs, and packaging standards to ensure compliance with global food safety regulations.

- Inventory and Shelf-Life Management – Tracks stock levels of both packaged products and packaging materials, while monitoring expiry dates to minimize waste.

- Integration with Packaging Equipment – Streamlines workflows by connecting directly with vacuum sealers and packaging machines for real-time data capture.

- Regulatory Compliance Tools – Simplifies documentation for audits, certifications, and export requirements, particularly for industries like meat, seafood, and dairy.

- Cost and Waste Reduction Analytics – Provides insights into packaging efficiency, helping businesses optimize resource use and cut unnecessary expenses.

By embedding vacuum packaging into a centralized ERP system, Folio3 FoodTech helps businesses achieve greater transparency, efficiency, and sustainability. From reducing errors to improving compliance with global standards, our solutions enable companies to maximize the benefits of vacuum sealing while aligning with modern food industry demands.

Conclusion

Vacuum packaging has proven to be one of the most effective methods for preserving food quality, ensuring safety, and cutting waste. From extending shelf life to improving supply chain efficiency, the uses for vacuum sealer machines span across households, supermarkets, and global food industries.

For anyone looking to optimize storage, reduce waste, and enhance freshness, vacuum sealing food is a simple yet powerful solution. Whether it’s preventing freezer burn at home or ensuring compliance in large-scale food production, the benefits are undeniable.

As technology advances, the future of vacuum packaging looks even brighter, promising smarter, more sustainable solutions for the way we store and enjoy food.

FAQs

What Is Meant by Vacuum Packaging?

Vacuum packaging is a method of sealing food or other products in airtight packaging by removing the surrounding air. This reduces oxygen exposure, slows spoilage, and extends shelf life.

What Is an Example of Vacuum Packaging Food?

A typical example is vacuum-sealed meat, cheese, or coffee. By removing air, the packaging keeps the product fresh for longer and prevents freezer burn in frozen items.

What Are the Advantages and Disadvantages of Vacuum Packaging?

The advantages include extended shelf life, reduced spoilage, and protection from contaminants. Disadvantages may consist of higher packaging costs, the need for specialized machinery, and potential texture or flavor changes in some foods.

Which Gas Is Used in Vacuum Packaging?

In some cases, vacuum packaging is combined with gas flushing, where nitrogen or carbon dioxide is used to further preserve the product and prevent bacterial growth.