In the food and beverage industry, delivering consistent quality in every batch is crucial. Rather than taste, Food and beverage quality is directly tied to safety, compliance, and brand trust. A minor lapse can lead to significant consequences as the average food recall costs a manufacturer around $10 million in direct losses, not to mention damaged reputation. In fact, over half of consumers say they would switch brands at least temporarily after a major quality issue like a recall.

To avoid such costly setbacks and consistently deliver quality food and beverage products, companies are turning to intelligent quality management systems (QMS). This advanced approach to food and beverage quality management uses digital tools and automation to ensure every product meets the mark, every time.

The Challenge of Consistent Quality in the Food & Beverage Industry

Maintaining optimal food quality assurance in food and beverage production is challenging due to numerous variables. Common quality issues in F&B range from safety lapses and inconsistent batches to labeling mistakes, ingredient authenticity concerns, and compliance hurdles. Below are some of the top challenges affecting consistent product quality:

Safety and hygiene concerns

Any lapse in sanitation or temperature control can introduce pathogens, putting consumers at risk. Each year, millions of people worldwide get sick from contaminated food, leading to hundreds of thousands of deaths, underscoring why strict safety protocols must never slip. Even a single contamination incident can trigger mass illness or a costly recall.

Inconsistent product quality

Variations in taste, texture, or other attributes from batch to batch hurt customer satisfaction. Inconsistent product quality can slip through internal checks, as only about 1 in 5 recalls is caught by the manufacturer’s own inspections, meaning many issues are first noticed by consumers or regulators.

Supply chain disruptions and labeling errors

Complex supply chains and human error can lead to wrong ingredients or mislabeling. A simple label mistake, like an undeclared allergen, can force a major recall. Undeclared allergens were responsible for nearly 40% of U.S. food recalls recently, illustrating how a minor labeling error can compromise safety. Such errors break consumer trust and require costly fixes.

Ingredient authenticity and shelf‑life

Food fraud and shelf-life variability pose hidden quality risks. Economically motivated adulteration, selling cheaper substitutes as authentic ingredients, costs the global food industry an estimated $30–40 billion per year. Meanwhile, inconsistent storage conditions or formulation can shorten a product’s shelf life, leading to premature spoilage and increased waste.

Regulatory compliance

Regulatory compliance is an ongoing challenge for food and beverage companies, which must meet standards from agencies like the FDA, USDA, and international bodies. Requirements keep evolving, like new labeling laws, FSMA rules, and falling short can result in fines or even forced shutdowns. Staying audit-ready demands extensive documentation and vigilance at all times.

What “QMS” Means for Food & Beverage

A quality management system (QMS) is a framework of processes and procedures designed to ensure consistent product quality and regulatory compliance in food and beverage operations. It covers everything from raw ingredient inspections and production protocols to final product testing and maintaining thorough documentation. In essence, a QMS formalizes how you maintain quality and safety across the company, aligning with standards like HACCP plans.

An intelligent QMS takes those principles further by leveraging digital technology. Instead of relying on paper logs and siloed spreadsheets, an intelligent QMS digitizes all your food and beverage quality control records, automates quality workflows like approvals and Corrective and Preventive Actions (CAPA), and employs AI-driven analytics. This modern approach to food and beverage quality management can highlight trends, predict issues, and enforce consistency across the board.

Core Benefits

- Improved quality and compliance: Ensures every product meets food safety standards and regulatory requirements consistently.

- Streamlined manufacturing processes: Automates quality checks and approvals, eliminating bottlenecks and reducing human error.

- Support for continuous improvement: Provides data insights that help you refine processes and prevent recurring issues over time.

- Cost reduction and stronger brand reputation: Cuts waste, rework, and recall costs while boosting consumer trust with reliable quality.

How Intelligent QMS Ensures Consistency in Food & Beverage Quality?

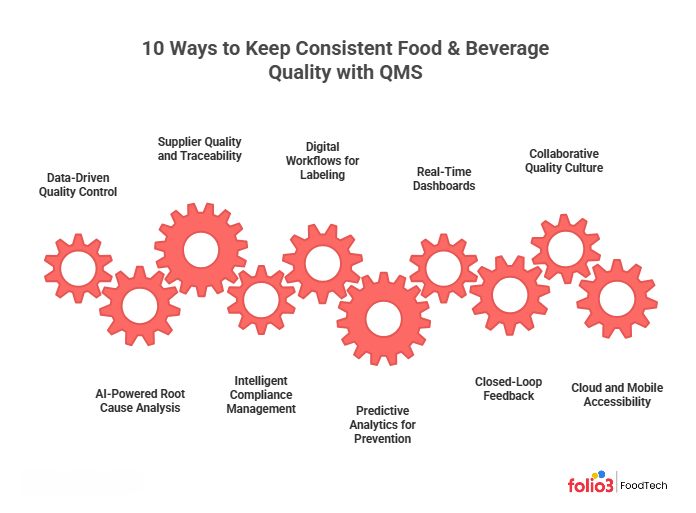

Managing quality in food and beverage operations is a complex task, and traditional manual methods often leave gaps. A QMS closes these gaps by enforcing consistent food and beverage quality control through real-time monitoring, automation, and data-driven insights at every stage of production. Here are 10 ways a QMS maintains quality from raw materials to finished product:

1. Data-Driven Quality Control Across the Production Line

Intelligent QMS platforms use IoT sensors on equipment and production lines to continuously monitor critical parameters like temperature, pH, and humidity in real time. Automated quality checkpoints can be set at each production stage, where the system verifies that each batch meets specifications before moving forward.

All this data is captured and analyzed instantly. If any reading drifts out of the acceptable range, the QMS flags it or even pauses production to prevent defects. Predictive analytics further helps by identifying patterns that signal a potential deviation early on, so you can address the root cause before it becomes a bigger problem.

2. AI-Powered Root Cause Analysis and CAPA Automation

An intelligent QMS often includes machine learning algorithms that sift through collected quality data to spot recurring issues or subtle deviations. For example, the system might learn that a particular machine tends to produce more defects when using a specific ingredient lot. Once a deviation is detected, the QMS can automatically trigger a CAPA (Corrective and Preventive Action) workflow, assigning tasks to the responsible staff to investigate and resolve the issue.

This closed-loop process links each quality incident to broader operational data, making it easier to pinpoint the actual root cause. Instead of spending days manually crunching data, you get AI-powered analysis and an automated action plan to prevent the problem from happening again.

3. Supplier Quality and Raw Material Traceability

Consistent product quality starts with high-quality ingredients and reliable suppliers. An intelligent QMS helps by digitizing supplier quality management. You can maintain a record of each supplier’s certifications, ingredients, and past performance in one central system. The QMS can even score suppliers on metrics like on-time deliveries, ingredient test results, and defect rates. Every incoming raw material lot is tracked with details to ensure complete food traceability.

If an issue arises like a contamination traced back to a specific ingredient lot, you can quickly identify which finished product batches used that lot and initiate targeted recalls or holds. Integrated supplier monitoring and traceability mean you catch problems early and ensure every ingredient is authentic and meets your quality standards.

4. Intelligent Compliance Management and Audit Readiness

Compliance with food safety regulations like GFSI standards, FDA rules, ISO 22000, HACCP plans, etc., becomes much easier with an intelligent QMS. The system provides real-time visibility into your compliance status. You can see at a glance if all required safety checks, sanitation logs, and other records are up to date. The QMS automatically generates and stores documentation like inspection records, cleaning logs, batch production records, and training certifications, creating a secure digital audit trail without paper clutter.

Meanwhile, digital checklists guide operators through daily GMP (Good Manufacturing Practice) tasks and food safety inspections, ensuring nothing is overlooked. It significantly reduces the manual burden of compliance. When an external audit or inspection occurs, you can quickly pull up all pertinent records to demonstrate compliance.

5. Digital Workflows for Consistent Product Labeling and Packaging Quality

Labeling and packaging errors are a common cause of quality failures, but an intelligent QMS can virtually eliminate them. The system integrates with your labeling processes and uses image recognition or barcode scanners to verify that each package has the correct label, allergen info, date code, and barcode. If a label is missing an allergen warning or has a misprint, the QMS will catch it by comparing against the approved digital template.

Moreover, you can maintain a library of packaging and label specifications, including multilingual labels for different markets within the QMS, ensuring the correct version is used every time. By automating label verification and requiring digital approval for any label changes, you drastically reduce the chance of a mislabeled product ever reaching the consumer.

6. Predictive Analytics to Prevent Quality Deviations

Beyond catching current issues, intelligent QMS tools use predictive analytics to foresee future quality problems. By analyzing historical production and quality data, the system might detect subtle trends like a product’s moisture content tends to drift upward during humid summer months. With this insight, the QMS can provide prescriptive recommendations, such as adjusting oven temperatures or ingredient ratios proactively to counteract the trend.

Over time, the AI becomes better at forecasting where a process might go out of spec. It allows your team to make dynamic adjustments and prevent a deviation before it happens. The result is a continuous improvement loop driven by data: the QMS learns from each batch and helps refine processes to keep quality on target consistently.

7. Real-Time Dashboards for Quality Performance Monitoring

An intelligent QMS typically includes real-time dashboards that let you monitor quality performance at a glance. You can set up custom Key Performance Indicators (KPIs) or scorecards for your quality assurance team, such as first-pass yield, daily defect counts, or supplier incident rate. The dashboard visualizes quality trends in real time and lets you drill down by batch, production line, product category, or supplier.

For instance, you might notice that Line 3 has a higher defect rate this week than other lines, prompting an investigation. The QMS also sends instant alerts via email, SMS, or in-app notification if a quality metric crosses a threshold or a deviation occurs. It means you’re never in the dark: managers and QA staff get immediate visibility and can respond to any quality issue as soon as it arises.

8. Closed-Loop Feedback from Customers and Field Data

Quality management doesn’t stop once the product ships; a QMS helps you capture and learn from real-world feedback. It can integrate customer complaints, return claims, or field test data directly into your quality system. For example, if consumers report an off taste or a packaging leak through your customer service channels, those complaints can be logged in the QMS against the specific product lot or batch. The system then aggregates and analyzes this post-market feedback for patterns. These insights drive process improvements; perhaps the need to adjust a recipe, switch a packaging supplier, or reinforce a handling procedure.

By feeding field data and customer feedback back into the production quality loop, you continually improve your processes. This closed-loop approach not only helps prevent future issues but also boosts brand trust. So, you can demonstrate to customers that you’re responsive and committed to quality improvement based on their experiences.

9. Collaborative Quality Culture Through Role-Based Access

An intelligent QMS fosters a company-wide quality culture by engaging everyone in the process. The software provides role-based access, so each team member, including QA managers, line operators, maintenance technicians, and even approved suppliers, can interact with the system in ways relevant to their role. A line operator on the factory floor might use a tablet to complete quality checklists and instantly flag any deviation, which then notifies the QA manager for review.

Furthermore, the QMS tracks training and competencies, ensuring each employee is qualified for the tasks they perform and alerting managers when re-training or certification is needed. All quality actions are logged with the user and timestamp, creating a transparent performance record. This level of accountability and communication encourages a collaborative quality culture where everyone knows their responsibilities and has the tools to uphold standards.

10. Cloud and Mobile Accessibility for On-the-Go Quality Oversight

In a modern food company, quality managers and auditors can’t be everywhere at once. That’s why cloud and mobile access are key features of an intelligent QMS. A cloud-based QMS centralizes all quality data and processes, allowing multiple facilities to work on one platform with the same consistent information. It ensures that whether you have one plant or ten, each site follows the same quality procedures and all data rolls up for a unified view.

Meanwhile, mobile accessibility lets your team conduct inspections and enter data using tablets or smartphones on the factory floor (or even remotely). A supervisor can approve a batch deviation or review a CAPA report right from their phone. This cloud and mobile capability means you have on-the-go oversight of quality anytime, anywhere, problems can be addressed in real time, and best practices are enforced uniformly across all locations.

How to Choose the Right QMS to Manage Quality in Food and Beverage Operations

Ensuring quality food and beverage products requires choosing a QMS solution built for the industry’s specific challenges. Here are key factors to consider when selecting a food and beverage quality control system that will effectively support your quality management needs:

Industry‑specific functionality

Does the QMS support food industry needs like lot traceability, recipe management, allergen controls, and HACCP workflows? An industry-specific solution will have modules for common food and beverage quality scenarios rather than a generic one-size-fits-all design.

AI and analytics capabilities

Look for AI-driven features like predictive analytics, automated anomaly detection, and smart dashboards. The right QMS should not just record data but also analyze it, identifying quality trends or root causes and giving your team actionable insights for continuous improvement.

Integration with existing systems

The QMS should integrate with your existing Food ERP systems for a unified data flow. When quality management connects to production and supply chain data, you eliminate silos – ensuring that specifications, test results, and inventory data all align automatically.

Configurability and scalability

Every company’s processes are a little different, so your QMS should be highly configurable. Look for the ability to customize forms, checklists, and workflows without code. Also, ensure the system can scale with your business from a single facility to global operations.

Cloud and mobile access

In today’s connected world, cloud access and mobile apps are must-haves. A cloud-based QMS lets multiple facilities share one platform with consistent data and updates, while mobile access enables quality teams to conduct inspections, approvals, and data entry from anywhere.

Vendor expertise and support

Consider the vendor’s track record and support. A provider with deep food and beverage expertise will understand compliance requirements and industry best practices. Evaluate their customer success stories, training, and onboarding process, and ongoing support to ensure you’ll have help when you need it.

Maintain Premium Quality Food & Beverage with Folio3’s Next-Gen QMS Solution

For over 20 years, Folio3 has helped food and beverage companies elevate their quality processes with cutting-edge digital solutions. Our next-gen QMS combines AI, IoT integrations, and deep industry expertise to ensure premium product quality and compliance. Ready to transform your quality management? Contact us to book a demo or request a consultation today.

FAQs

What is Quality in Food and Beverages?

Quality in food and beverages means delivering products that are safe, consistent, compliant, and meet customer expectations in taste, texture, appearance, and shelf life. It also includes factors like proper labeling and ingredient authenticity.

Why is Consistent Quality Important in Food and Beverage Manufacturing?

Consistent quality builds consumer trust, ensures regulatory compliance, reduces rework and waste, and helps maintain a strong brand reputation. It also minimizes the risk of recalls and customer complaints.

How Does an Intelligent QMS Improve Food and Beverage Quality Control?

An intelligent QMS automates inspections, monitors production in real time, and uses data analytics to detect issues early. It ensures quality checks aren’t missed and that corrective actions are fast and effective.

How Does AI Improve Quality Management in Food Production?

AI helps predict quality deviations, identifies root causes of recurring problems, and provides actionable insights to prevent failures. It transforms quality control from reactive to proactive, saving time and reducing risk.