In food manufacturing, every ounce of efficiency counts, especially when raw material costs can surge without warning. Yield management in food production is about getting the most out of every batch, whether it’s potatoes, poultry, or grain, while keeping waste to a minimum. For plant managers, this is often the difference between staying profitable and slipping into a loss in an industry where margins are razor-thin.

Globally, a major portion of food is lost between harvest and retail, with a significant chunk happening during processing stages like cutting, cooking, or packaging. These losses don’t just hurt the bottom line; they add to the environmental toll, as food loss and waste contribute to 8-10% of global greenhouse gas emissions. For manufacturers, every percentage point of yield improvement can translate to thousands in savings and a smaller ecological footprint.

Achieving yield management in food production means turning every batch into a chance to improve efficiency and keep your operation competitive. It’s about spotting where your line loses product, whether it’s excess trim in meat processing or overcooking in bakery lines, and using innovative tools like food manufacturing systems to stay on top of it. This blog explains the essentials of yield management, the challenges manufacturers face, and practical steps to make operations more efficient.

Understanding Yield Management in Food Production

Yield management in food production centers on turning as much of your raw ingredients into sellable items as possible, without letting waste eat into your profits. Think of it as the straightforward measure of output versus input, calculated by dividing the weight of the finished product by the starting raw material weight, then multiplying by 100 for a percentage.

Yield Percentage = (Weight of Finished Product ÷ Weight of Raw Material) × 100

For example, if you start with 100 kg of raw carrots and end up with 80 kg of peeled, cut carrots, the yield is (80 ÷ 100) × 100 = 80%.

This gives plant managers a clear picture of efficiency right on the factory floor.

How to Measure and Track Yields Effectively

Getting a grip on yield management in food production starts with consistent tracking. Begin by logging yields for each batch or product line over time. This baseline data reveals patterns, like seasonal dips in vegetable quality or machine settings that cause extra trim.

To make it practical, break it down into these steps:

- Inspect Incoming Materials: Grade raw goods for size, freshness, and defects upon arrival.

- Monitor Each Processing Stage: Watch for losses during cutting, cooking, or packaging. Simple logs or digital tools can pinpoint issues, such as evaporation during boiling that shrinks batches by up to one-third.

- Model Improvements: Use basic calculations to test tweaks, like changing blade thickness on slicers to salvage an extra product.

Digital tools and innovative systems can automate this tracking, pulling in data from scales and lines to spot trends without manual hassle.

Factors That Impact Yields in Daily Operations

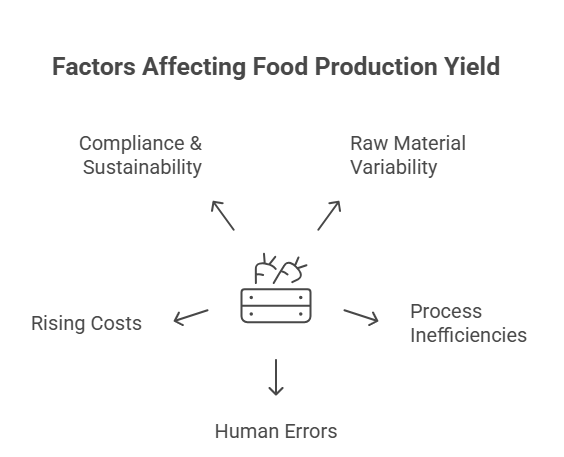

Several everyday elements play into yield management in food production, and knowing them helps avoid costly surprises.

- Raw Material Variability: Ingredients aren’t always uniform, think potatoes with odd shapes or high moisture that lead to inconsistent cuts.

- Process Inefficiencies: Overheating or poor equipment calibration can cause sticking or breakage, turning good product into scrap.

- Human Elements: Operator errors, like imprecise weighing, add up over shifts, but training and checklists keep things tight.

Addressing these with routine checks keeps yields steady and operations smooth.

Challenges of Yield Management in Food Production

Yield management in food manufacturing sounds straightforward: get more product out of every batch, but it comes with real hurdles that can trip up even the most experienced plant managers. From inconsistent raw materials to equipment quirks, these challenges demand attention to keep losses low and profits steady. Below, we break down the key obstacles and why they matter, with examples to show how they hit your operation and ways to tackle them.

Inconsistent Raw Materials Throw Off Yields

No two batches of raw ingredients are ever quite the same, and that variability can affect yield management in food production. Fruits, vegetables, or even meat cuts vary in size, moisture, or quality depending on the season, supplier, or harvest conditions. For example, a shipment of tomatoes with high water content might lose more weight during cooking than a drier batch, leaving you with less sauce than planned. In meat processing, a single uneven carcass can mean extra trim, cutting usable product. These changes make it tough to predict yields and plan production.

Ways to Counter It:

- Set strict supplier specs for raw material quality.

- Use meat ERP software to track variations and adjust processes on the fly.

Process Losses Drain Efficiency

Every step in food manufacturing, whether it’s chopping, cooking, or freezing, introduces chances for product loss. Evaporation during cooking can shrink a batch of soup, while sticking in mixers or improper cutting in vegetable lines can turn good product into waste. These losses add up fast, especially in high-volume plants, where a single bad run can cost thousands.

Ways to Counter It:

- Regularly calibrate equipment to minimize sticking or overprocessing.

- Test cooking times to reduce moisture loss, keeping more products intact.

Rising Costs Put Pressure on Yields

With ingredient prices climbing, think grain or meat costs jumping 10-20% in a year due to supply chain issues, manufacturers feel the squeeze to maximize every input. In recent years, global agricultural commodity prices have stayed volatile, pushing plants to stretch resources without sacrificing quality, but rushing to cut corners can backfire, leading to higher waste if processes aren’t perfected.

Ways to Counter It:

- Use food ERP systems to balance cost data with yield tracking.

- Forecast demand to avoid overbuying perishable inputs.

Labor Shortages and Errors Add Up

Skilled workers are hard to come by, and with fewer hands on deck, mistakes become inevitable. Inconsistent weighing, miscuts, or skipped checks lower yields per shift. For instance, in a poultry plant, an untrained operator might trim too much fat, dropping usable meat yield. Without enough staff to monitor lines closely, these small errors can lead to big losses over time.

Ways to Counter It:

- Train teams on precise yield tracking and standard procedures.

- Automate checks with tools like food checkweighing systems to catch mistakes early.

Regulatory and Sustainability Demands

Food safety rules and sustainability goals add layers of complexity to yield management in food production. Stricter regulations mean more testing and documentation, which can slow lines if not optimized and connected. Meanwhile, the push to reduce waste puts pressure on plants to rethink processes without clear roadmaps. For example, ensuring traceability in meat processing can divert focus from yield optimization, as teams juggle compliance with output goals.

Ways to Counter It:

- Integrate compliance tracking systems into daily yield management routines.

- Repurpose trim or byproducts into secondary goods, like broths, to improve overall yield.

These challenges aren’t just theoretical; they hit your bottom line and efficiency every day. By understanding them, you can turn obstacles into opportunities to keep your plant running lean and strong.

Best Practices for Smarter Yield Management

For food manufacturers, more innovative yield management in food production is about turning challenges into wins by making every ingredient count. It’s not about flashy overhauls but practical, focused steps that improve efficiency, cut waste, and keep your plant competitive.

Below are outlined key practices to strengthen your yield management, with real-world examples and actionable tips to keep your production line moving.

Build a Baseline to Spot Losses

Knowing where you stand is the first step to improving yield management in food production. Track yields for each product line, whether it’s canned vegetables, frozen fish, or baked goods, to identify where waste creeps in. Regular yield logs, even simple spreadsheets, help you see patterns and set realistic targets.

Best Practices:

- Record yields daily for each batch, noting losses at every stage (e.g., trimming, cooking).

- Compare data across weeks to catch seasonal or supplier-driven dips.

Grade Raw Materials Upfront

Not all ingredients are created equal, and poor-quality inputs can affect your yields. Checking raw materials when they arrive helps you adjust processes before losses pile up. In a potato chip line, sorting tubers by density can improve usable slices by 5-10%, as denser potatoes yield cleaner cuts.

Best Practices:

- Set clear quality standards with suppliers to ensure consistency.

- Use visual inspections or basic scales to grade inputs on delivery.

- Adjust cutting or cooking settings based on material quality, especially for users handling varied carcasses.

Optimize Processes to Minimize Waste

Small changes in processing can make a big difference in yield management in food production. For example, in a poultry plant, adjusting knife angles during deboning can increase usable meat by 3%. These changes don’t require massive investments, just attention to detail.

Best Practices:

- Test small process changes, like shorter cooking cycles or sharper blades.

- Monitor moisture loss in real-time with sensors tied to Microsoft Dynamics for food and beverage.

Automate Checks for Precision

Manual errors, like inconsistent weighing or missed defects, can chip away at yields. Automated tools catch these issues early, saving product and time. In a bakery, automated checkweighers ensure dough portions hit exact targets, avoiding underfilled trays that cut output by 5%. Using food checkweighing systems can streamline this, keeping your line accurate without slowing down.

Best Practices:

- Install automated scales to verify weights at key stages.

- Train staff to use digital dashboards for real-time yield data.

- Integrate automation with existing systems to track performance.

Align Inventory with Demand

Overstocking ingredients leads to spoilage, while understocking disrupts production; both hurt yields. In dairy processing, mismatching milk supply to cheese demand can lead to excess whey waste. Smart inventory management ensures you process only what’s needed, cutting losses and improving efficiency.

Best Practices:

- Use sales data to predict batch sizes and avoid overproduction.

- Rotate stock to prioritize fresh ingredients, reducing spoilage.

- Sync inventory with yield tracking to balance costs and output, as detailed in how to manage rising food costs with ERP.

Implement Data-Driven Production Planning

Planning production without guesswork is a game-changer for yield management in food production. By using data from past yields, sales trends, and raw material quality, you can schedule runs that match demand and minimize waste. Data-driven planning with the help of industry-specific system providers like Folio3 AgTech also helps adjust for seasonal ingredient variations, ensuring consistent yields year-round.

Best Practices:

- Pull yield and sales data to schedule production runs that align with demand.

- Use forecasting tools to adjust for raw material quality shifts, like moisture in grains.

- Integrate planning with food manufacturing management software for real-time insights and smoother operations.

Repurpose Byproducts for Extra Value

Repurposing byproducts, like vegetable peels for stock or meat trim for pet food, can turn losses into revenue. A fruit juice plant might use pulp for jams, adding to the overall yield value. This approach not only improves efficiency but also aligns with sustainability goals, making your operation leaner and greener.

Best Practices:

- Identify byproducts with market potential, like bones for broth.

- Partner with secondary processors to sell off-cuts.

- Track byproduct yields alongside primary products for a full picture.

By putting these practices into play, food manufacturers can tighten up yield management in food production, saving money and staying ahead in a tough market. Start small, measure often, and use the right tools to make every batch count.

Conclusion

For food manufacturers, yield management in food production is the quiet force that can transform your plant from just getting by to truly excelling. It’s about making smart, deliberate choices, tracking every ounce, refining processes, and turning waste into opportunity. These aren’t just tactics; they’re the foundation for running a plant that’s lean, resilient, and ready for whatever the market throws your way. By committing to these steps, you’re not only boosting profits but also setting your operation apart in an industry where efficiency is everything.T

he path to better yields starts with action, not overthinking. Pick one area, whether it’s tightening inventory or repurposing byproducts, and test it. Measure the results, refine your approach, and build momentum. Yield management in food production gives you the power to control costs, outpace competitors, and meet growing demands for sustainability.

What Is Yield Management in Food Production?

Yield management in food production is the process of maximizing the amount of usable product from raw ingredients while minimizing waste. It involves tracking how much finished product you get from inputs, typically measured as a percentage (finished weight divided by raw weight).

How Does Technology Improve Yield Management?

Technology improves yield management by catching issues early and optimizing processes. Tools like automated scales ensure precise portioning, while sensors monitor cooking losses in real-time, reducing waste from overprocessing. Software systems also track data across batches, helping managers adjust for ingredient variations and improve consistency, all while keeping the line running smoothly.

What Are the Key Metrics for Measuring Yield in Food Production?

Key metrics include the yield percentage (finished product weight divided by raw material weight), waste percentage (unusable material like trim or spoilage), and process loss (weight lost during cooking or cutting).

How Can I Reduce Waste in Food Production?

Reducing waste starts with grading raw materials to catch quality issues early, like sorting potatoes for uniform size to minimize cutting losses. Improve processes, such as adjusting cooking times to limit evaporation, and use automation to avoid human errors. Repurposing byproducts, like turning vegetable peels into stock, also cuts waste. Regular checks and data tracking ensure you catch small issues before they become costly.

What Are the Benefits of Using an ERP System for Yield Management?

An ERP system enhances yield management in food production by centralizing data on yields, inventory, and costs, giving manufacturers real-time insights. It helps track losses across production stages, forecast demand to avoid overstocking, and streamline compliance with safety rules.