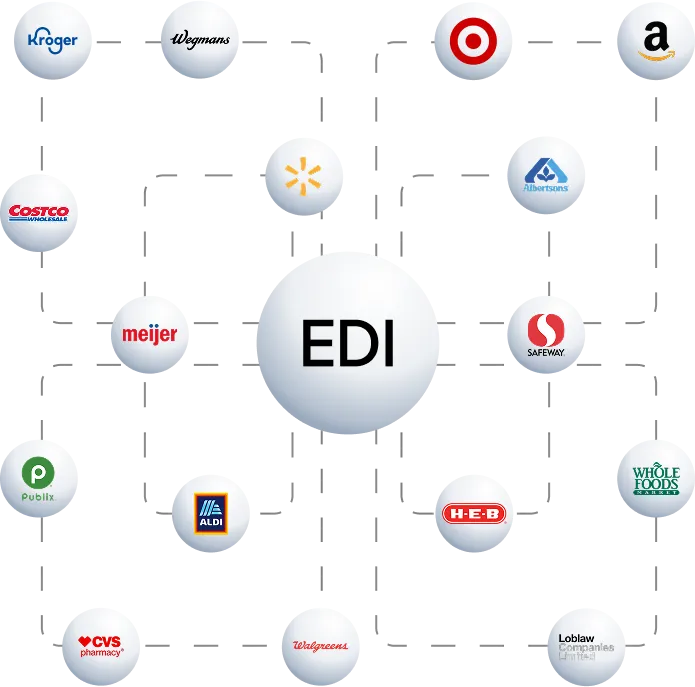

Prevent grocery EDI chargebacks by syncing retailer orders, ASNs, and invoices directly into ERP. EDI for grocery integration delivers real-time validation, GS1-compliant labeling, and FDA-compliant traceability to meet retailer standards.

Maintain accuracy and compliance by driving smooth grocery data exchange between ERP workflows and retailer systems.

Connect grocery EDI with ERP for compliant, automated flows from order through payment.

Integrate EDI for grocery with ERP to centralize all orders, invoices, and shipments in one reliable system.

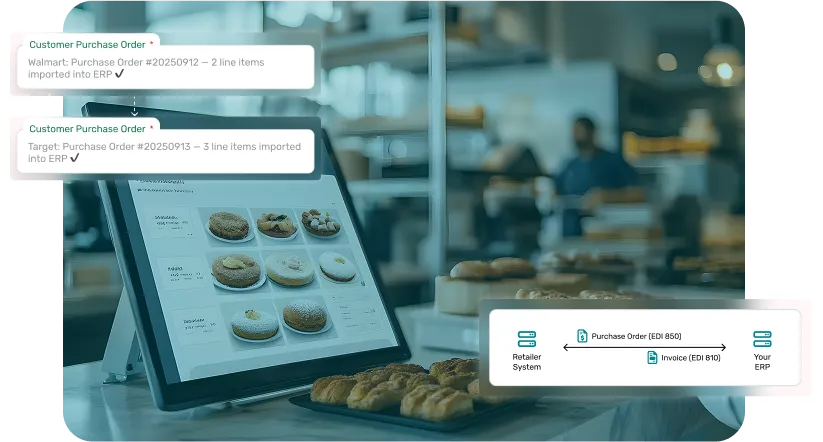

Automate grocery POs, ASNs, and invoices through ERP integration to speed fulfillment and accelerate retailer payments.

Reduce manual data entry, reconciliation tasks, and processing delays by automating grocery transactions within ERP workflows.

Minimize chargebacks and disputes by validating grocery transactions automatically against ERP master data and compliance rules.

Ensure retailer requirements are consistently met by generating shipping and billing documents directly from ERP.

Adapt quickly to higher transaction volumes and expanding retail partnerships by integrating the EDI grocery connector.

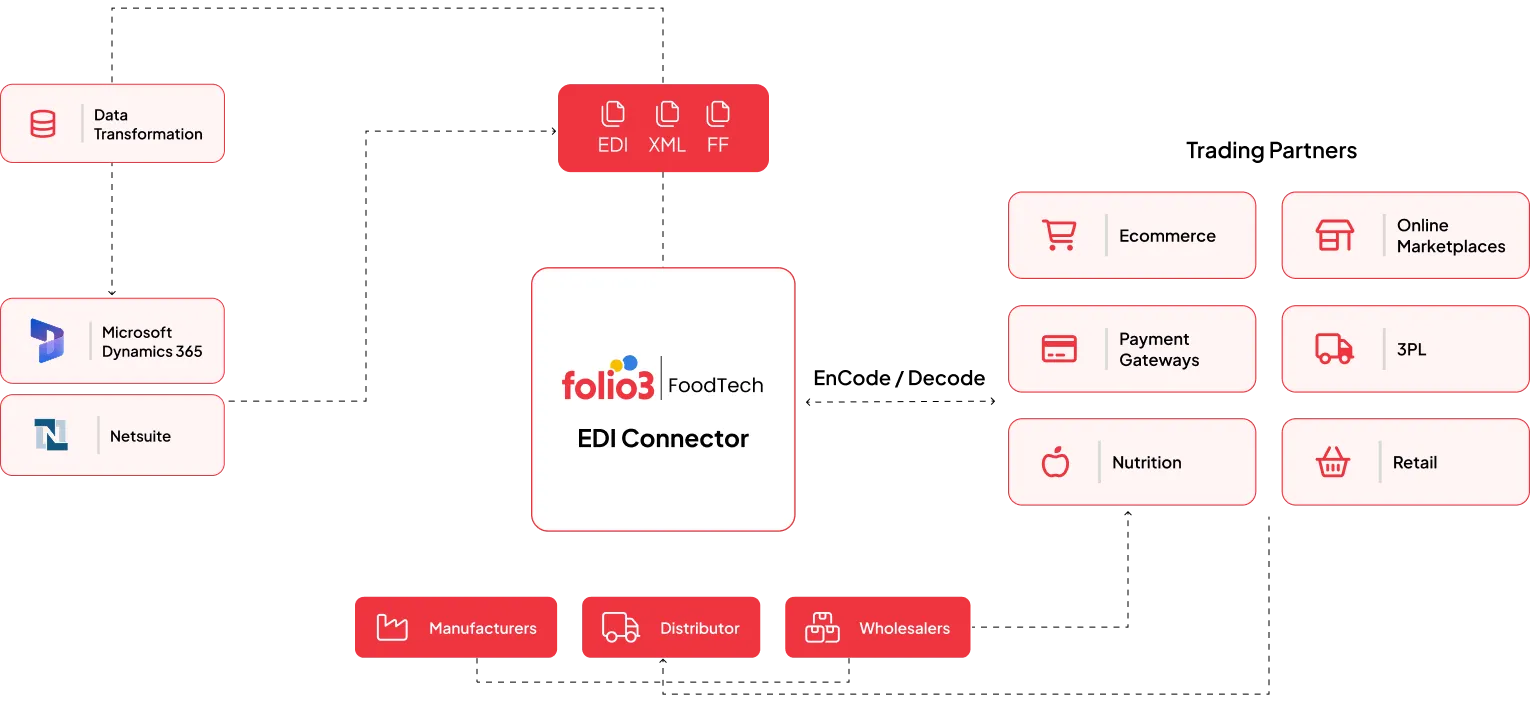

Integrate ERP and essential platforms effortlessly using Folio3 EDI connector.Move orders, inventory, and shipment data automatically, reducing errors and manual work.

Standardize dough hydration and gluten development for uniform crumb structure and minimal waste.

Monitor infusion ratios and carbonation levels to maintain flavor fidelity and batch accuracy.

Precisely control tempering and sugar crystallization for ideal texture, flavor, and stability.

Track somatic cell counts and pasteurization parameters to guarantee hygienic milk processing.

Ensure temp-controlled logistics and blast freezing precision to prevent structural degradation.

Enable full-lot traceability and pathogen control while complying with labeling regulations.

Regulate thermal cooking profiles and viscosity for uniform texture and flavor consistency.

Optimize frying oil temperature and seasoning distribution for consistent crispness and taste.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

Yes. Each grocery retailer enforces unique standards for pack sizes, lot codes, shelf-life data, and delivery appointments. The connector maps these requirements into ERP, ensuring manufacturing orders, shipments, and labels align with routing guides before release.

The connector supports peak loads common in food manufacturing, such as holiday or seasonal production spikes, by processing large batches of retailer POs, ASNs, and invoices in parallel. Queue management and ERP resource throttling prevent slowdowns in production scheduling and warehouse execution.

Folio3 FoodTech’s grocery EDI connector applies transaction control numbers, timestamp checks, and ERP-side validation to prevent duplicate imports of POs or invoices. It also reconciles quantities and item codes against ERP production and inventory records, ensuring grocery orders match manufactured output.

Folio3 FoodTech’s grocery EDI connector applies transaction control numbers, timestamp checks, and ERP-side validation to prevent duplicate imports of POs or invoices. It also reconciles quantities and item codes against ERP production and inventory records, ensuring grocery orders match manufactured output.

ERP data on batch, lot, and packaging runs is linked to EDI outputs, generating GS1-128 labels with pallet SSCCs and carton IDs. This enables case- and pallet-level traceability from production lines to grocery distribution centers, ensuring compliance during audits or recalls.

Integration provides ERP dashboards with real-time updates: order acknowledgements linked to production scheduling, ASN confirmations tied to shipping execution, and remittance advices tied to AR. Food manufacturers gain end-to-end visibility from order intake to payment settlement, reducing blind spots across operations.

Exceptions, such as mismatched quantities, invalid item codes, or failed ASNs, are flagged in ERP with error codes. Manufacturing and supply chain teams receive alerts, enabling corrections before orders, shipments, or invoices are resent to grocery partners.

Integration ties production batch numbers, expiration dates, and lot codes directly to EDI transactions. This ensures every shipment, catalog update, or recall trace is aligned with FDA/USDA standards and grocery retailer traceability requirements.

The EDI connector in Food ERP supports configurable mappings and workflow rules, adapting to custom ERP fields such as formulation codes, QA checks, or multi-site plant hierarchies. This flexibility lets food manufacturers align EDI processes with their own operational logic.