Drawing on two decades of experience, we develop custom meat software that applies AI and modern technologies to digitize processing, compliance, and optimize meat operations end-to-end.

Grow your operations with our meat solutions powered by industry expertise and AI, built to manage every process smarter.

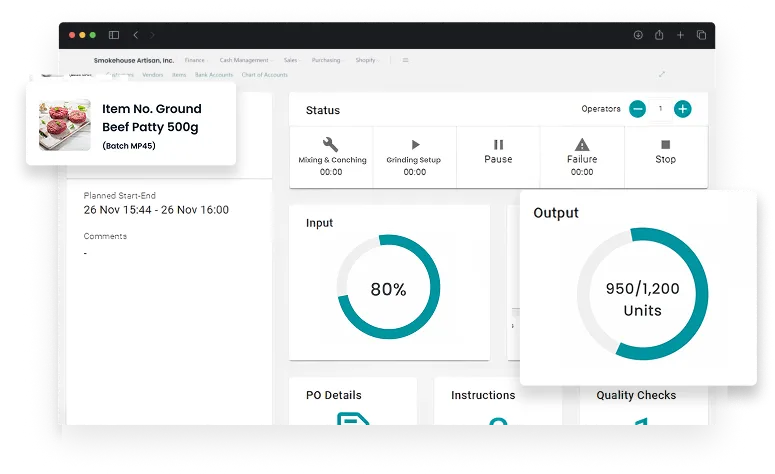

Get custom meat processing software that works the way your facility does. Digitally connect plant-floor operations, quality checks, and compliance processes, giving managers clear visibility and control at every step.

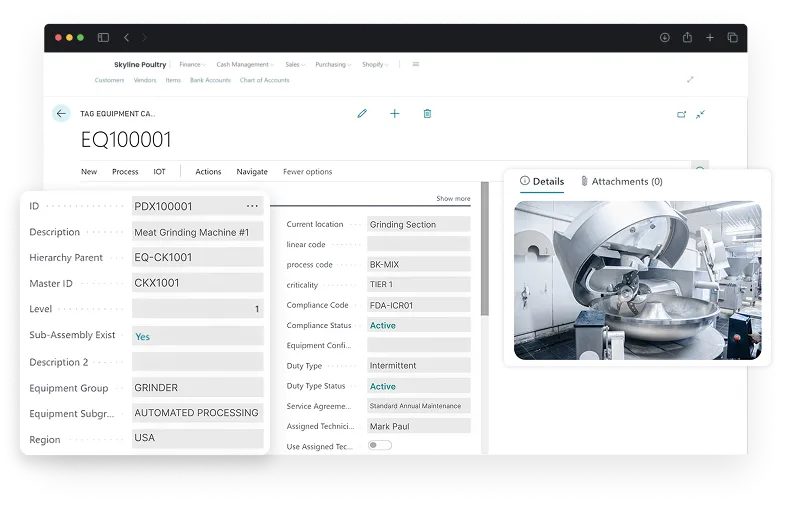

Implement meat processing ERP on NetSuite or Dynamics 365 to integrate plant-floor, supply chain, and management processes with actionable control and full traceability.

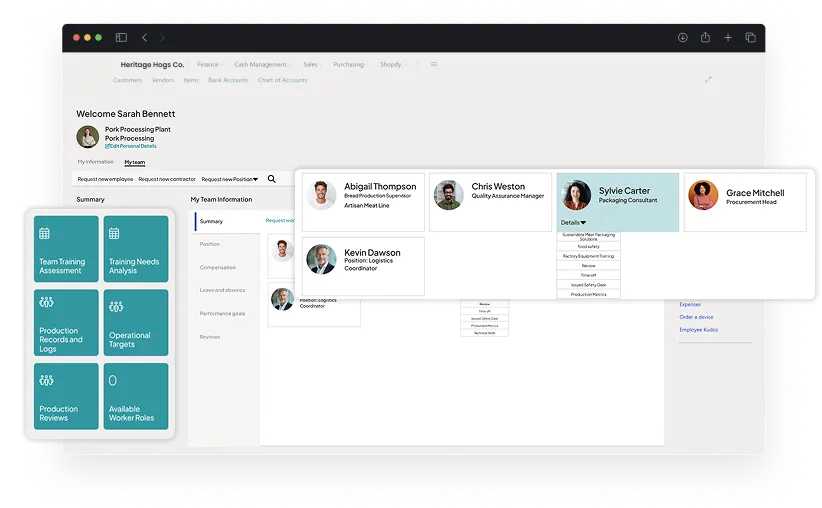

Get custom mobile and web apps for meat processors, connecting plant-floor operations and management seamlessly on Android, iOS, and web.

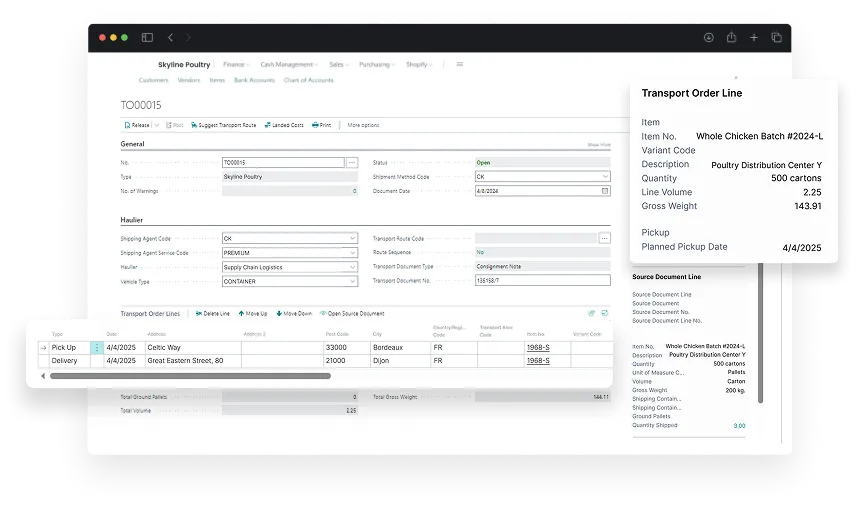

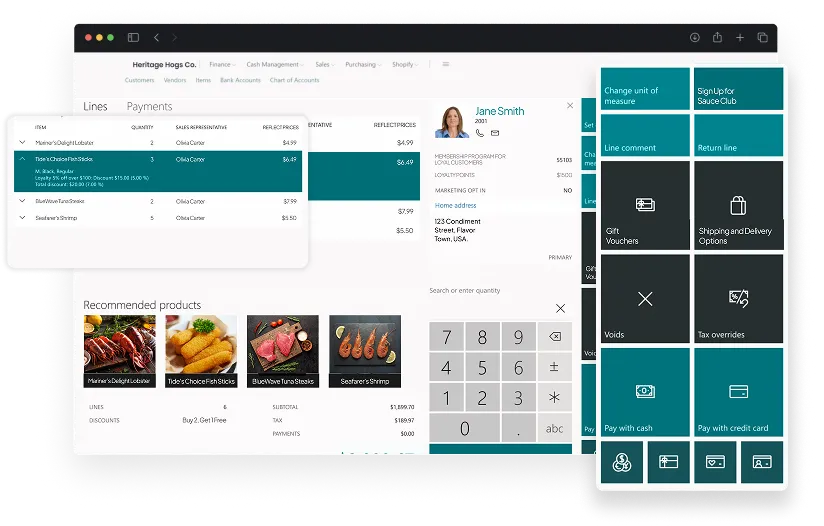

Launch digital meat delivery platform to connect plant-floor operations with customer orders, enabling smooth, traceable deliveries across your distribution network.

Bring intelligence into meat operations with custom solutions that learn from production data, improve decision-making, and strengthen efficiency over time.

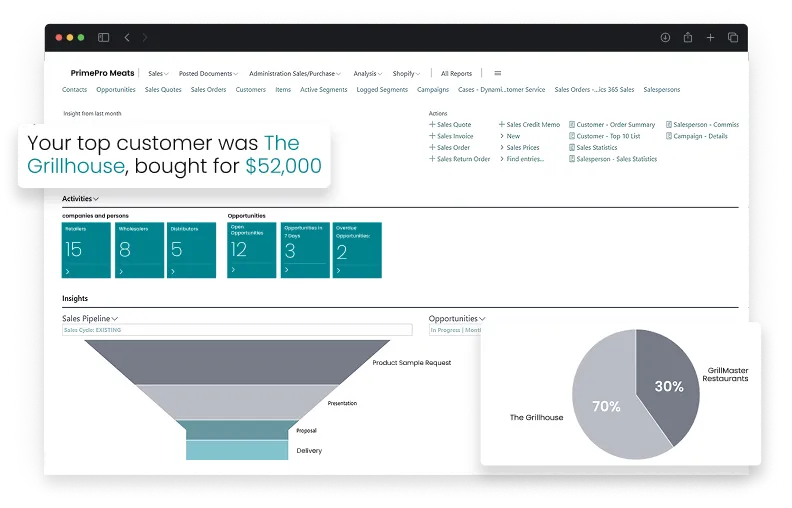

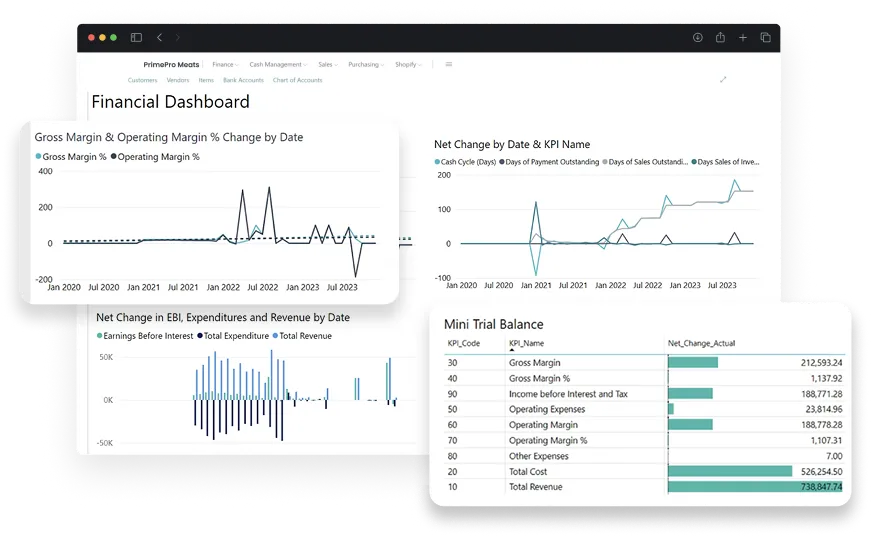

Track yields, throughput, and compliance with analytics built on Microsoft Azure and Power BI, giving processors clear visibility to act decisively.

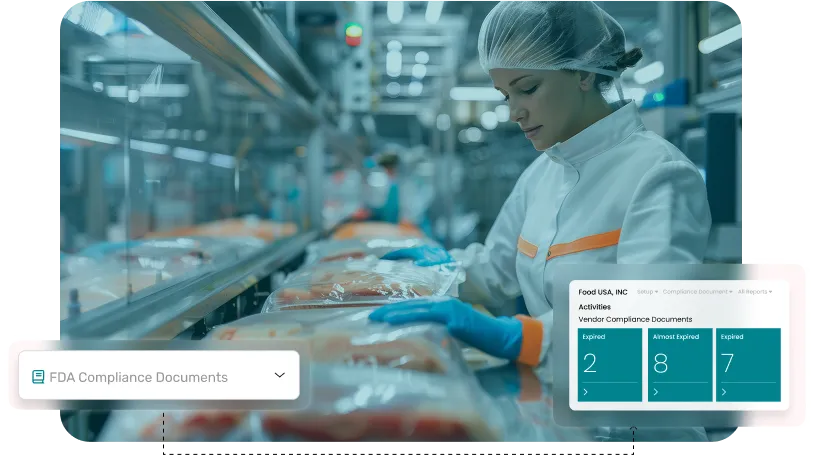

Ensure safety and traceability are built into operations, making compliance continuous, transparent, and reliable across the meat value chain.

Unify disconnected meat operations by linking enterprise systems, plant-floor data, and other platforms into one connected, transparent digital ecosystem.

Explore the real-world impact of our custom solutions on meat processing businesses—backed by data, driven by results.

Enterprise-level meat processors often face fragmented systems that drain margins and create audit risks. Get an ERP Suite built on acclaimed platforms like Microsoft Dynamics or NetSuite to unify operations on a single, scalable system.

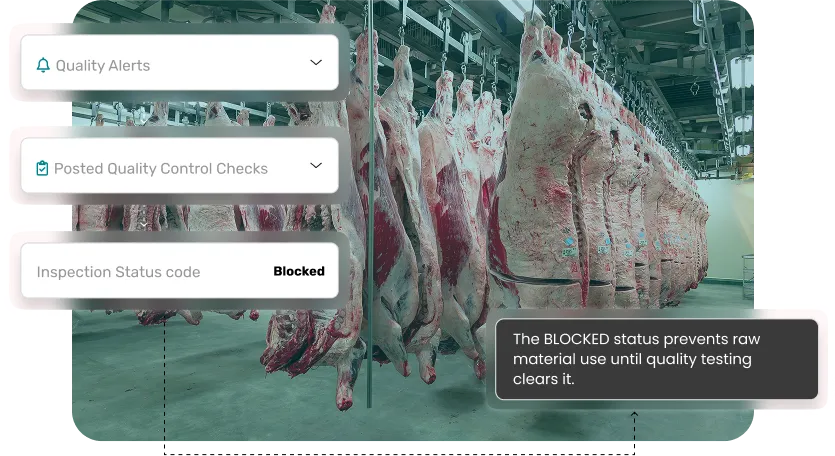

Strengthen meat safety by digitizing plant-floor checks and creating USDA- and FDA-ready traceable records across your operations.

Manage USDA and FSIS compliance digitally, covering HACCP, export certifications, and daily plant checks, to keep meat operations continuously audit-ready.

Standardize carcass grading, packaging oversight, and non-conformance tracking to ensure consistent meat quality and reduce operational losses.

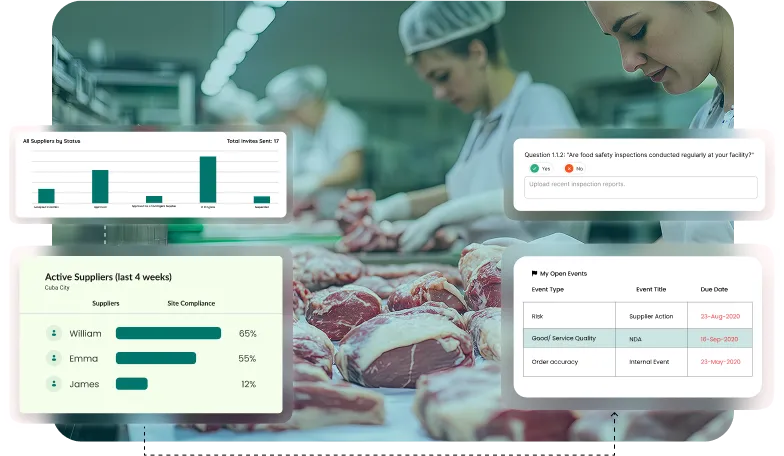

Maintain verified records for livestock and material suppliers, monitor certifications, and enforce approvals to strengthen meat supply chain accountability.

Keep your plant audit-ready every day with real-time meat traceability software that unites safety, efficiency, and accountability. From animal origin to final packaging, gain complete visibility and control across every stage of production.

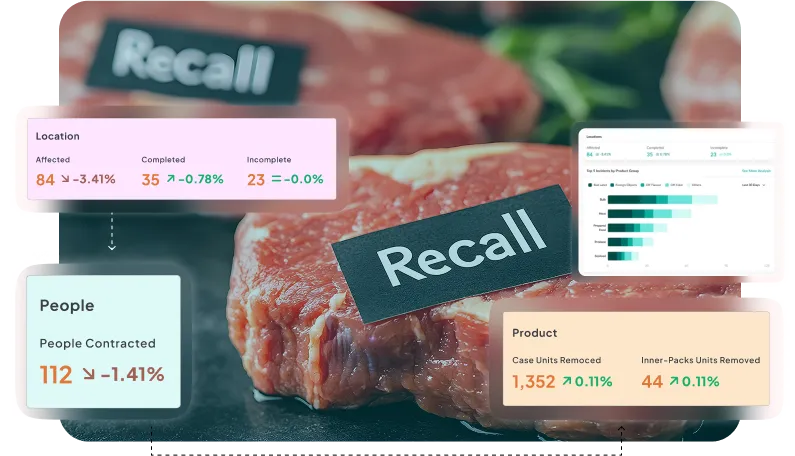

Initiate targeted recalls instantly with precise lot identification and distribution mapping, minimizing disruption while protecting meat safety and brand trust.

Track how staff work on the meat processing line using AI cameras, measure task times, spot delays, and adjust workflows instantly.

Deploy AI-driven cameras on processing lines to automatically detect bones, plastics, or metals, instantly alerting staff to remove contamination.

Apply AI imaging to assess fat distribution and marbling, delivering consistent grading results and eliminating subjectivity in meat quality scoring.

Use AI to confirm workers wear protective gear, follow hygiene standards, and meet USDA safety protocols across plant environments.

Guide cutters with AI-assisted tools that calculate best cut paths, maximize usable meat, and reduce costly yield losses.

Analyze historical sales, seasonal trends, and inventory levels to predict future demand, helping plan production and distribution efficiently.

AI automation is changing the way meat plants operate. From carcass grading to packaging, AI reduces bottlenecks and improves consistency, while computer vision ensures staff compliance with safety and hygiene standards. Integrated with digital traceability, every product movement is captured for accuracy and accountability.

The real question is: will your plant lead the change or follow it?

Digitize your meat business model end-to-end with custom meat solutions that adapt workflows and optimize operations across processing and distribution.

Track animal health, feed, and lineage digitally. Share verified data with processors to guarantee stronger traceability and compliance from farm to slaughterhouse.

Digitize carcass IDs, deboning, yield recovery, and HACCP compliance. Gain real-time plant-floor control that minimizes losses and keeps audits stress-free.

Manage cold chain, variable-weight labeling, and export documentation in one system. Keep shipments accurate, compliant, and moving without delays across the distribution chain.

Access transparent product origins, expiration tracking, and EDI-driven supplier coordination. Build consumer trust with clear labeling, reliable stock, and consistent on-shelf availability.

Manage species-specific workflows from processing through packaging, ensuring each step follows your established operational standards.

As a cutting edge meat company, we build AI-powered, expert-driven digital solutions that help processors meet compliance and manage operations across every stage.

Scale confidently from single facilities to multinational plants. Our platforms adapt to mid-market agility while supporting enterprise-level complexity and compliance needs.

Deploy AI where it matters most, grading, portioning, defect detection, turning plant-floor decisions into measurable gains in yield, safety, and efficiency.

Connect effortlessly with ERP, EDI, and CRM systems. Our integrations unify operations, from plant floor data to retailer orders, ensuring real-time visibility across your supply chain.

Experience working on prototypes within weeks. Align stakeholders early, reduce delivery risks, and validate ROI before committing to large-scale implementation.

Read what our clients say about their experiences and the difference our solutions have made for them.

We were extraordinarily pleased with the functionality and depth of understanding that Folio3's solution exhibited after a relatively brief but incisive, project kickoff meeting. Folio3 ``gets it`` from the start, relieving us from tedious development discussions drawn out over a long period of time.

Folio3 impressed me by learning a BI tool they did not have prior experience with and in a short amount of time produced analysis reports ready for business consumption. We are excited on the next set of critical reports Folio is working on for us and expect the relationship to continue for the foreseeable future.

"The team has done a tremendous job from testing and deploying our DAX applications to go live. They have also helped develop a reusable pattern for scheduling processes used by multiple workers. We will definitely continue to lean on folio3 for future support of these applications."

Folio3 has been an outstanding NetSuite implementation partner, excelling in complex integrations across our business units. Their expertise, innovative solutions, and responsive, supportive team make them truly impressive.

BioPak adopted NetSuite early in Australia, using its ERP, CRM, and eCommerce. After initial challenges with development partners, we partnered with Folio3 in 2016. Their transparency, work ethic, and seamless collaboration reignited our drive for crucial upgrades and innovations, making them a trusted partner in our growth.

We needed an online presence for our business that catered to both our B2B and B2C clientele and we needed it in record time. Folio3 was able to deliver in our timeline, in budget, and has continued to provide us with excellent on-going support.

We thank Folio3 for their dedication and hard work over the past 12 months. Folio3 team has been a great help to our organization, and I am proud of the relationship we have built between our colleagues and companies. I look forward to continuing to work with the Folio3 team.

Folio3 was extremely qualified within our NetSuite environment & was able to provide advanced proficiency when customizing the integration. I appreciate their ability to navigate the system well & provide the expertise needed to complete the project. We appreciate your hard work & look forward to our continued collaboration.

We are very excited to see the new PigWise app rolling out to production. When we had discussed the initial idea with Folio we had no idea that the final build would look this good. You guys rock!.

"I am happy to recogzine the work that was done by the Folio3 team. Our end users are very satisfied with the user interface and the performance of the app – and are excited to be more mobile. I appreciate the hard work and commiment to deliver a top quality solution. I look forward to continuing our business relationship."

"The Folio3 team has consistently exceeded our expectations. It felt as if we were working with an onshore team. It was their ability to understand our needs and keep us engaged throughout the entire process that has resulted in an exceptional product and a valued partner.."

Custom systems capture carcass weights and specs in real time, applying rules to calculate true yield per cut. Cut plans are generated automatically, and integrated labeling ensures packs match weights, SKUs, and compliance requirements without manual errors.

They address common pain points like limited visibility across plants, manual compliance tracking, and inefficiencies in scheduling. By digitizing these workflows, mid-sized processors gain traceability, predictable margins, and scalable tools that don’t overwhelm lean teams.

A strong cut solution should support variable-weight portioning, enforce customer-specific tolerances, auto-generate case-ready pack labels, and handle multiple order formats like retail, wholesale, or foodservice, without additional rework on the plant floor.

They digitize grading results, link them directly to carcass and primal IDs, and maintain records through cutting and packing. Export documentation is generated automatically from this data, ensuring shipments meet international compliance without manual paperwork.

Compliance becomes part of daily operations when HACCP checks, lot traceability, and audit records are built into the system. Folio3 FoodTech’s integrated platforms generate USDA, FDA, and export-ready reports automatically, ensuring processors meet standards without scrambling during inspections.

The most critical integrations connect ERP for financials, WMS for inventory, labeling for case-ready packs, and shop-floor devices like scales or graders. Together, they remove silos, eliminate manual entry, and create a single source of truth across plants.

ROI shows up in reduced giveaway from more precise cutting, fewer compliance penalties, faster recalls, and better labor productivity. Processors also gain margin visibility in real time, making it easier to identify where profit is slipping or improving.

Folio3 FoodTech reduces risk by starting with pilot deployments, validating cut logic, labeling accuracy, and compliance in one facility before scaling. Our prototype-first delivery approach aligns stakeholders early, while ERP and WMS integrations ensure smooth adoption without disrupting plant operations.